Boyd AAVID Kodiak G02 Series User manual

AAVID,THERMALDIVISIONOFBOYDCORPORATION

SERVICEADDRESS:

9AFORBESROAD

WOBURN

,

MA01801

www.boydcorp.com

ServicePhone:+1‐781‐933‐7300

TECHNICAL MANUAL

KODIAKRECIRCULATINGCHILLERS

MODELSRC006,RC011,RC022,RC030ANDRC045

SERIESG02/H02/J02

OneCompany,ManySolutions

Manual# 820-0043 Rev. N, 11/06/2019

©Boyd Corporation 2019

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

1

T

T

Ta

a

ab

b

bl

l

le

e

e

o

o

of

f

f

C

C

Co

o

on

n

nt

t

te

e

en

n

nt

t

ts

s

s

TABLE OF CONTENTS .................................................................................................................................0

INTRODUCTION ..........................................................................................................................................3

RECEIVING YOUR NEW KODIAKCHILLER ................................................................................................................ 3

ABOUT THE WARRANTY .............................................................................................................................................. 3

CUSTOMER SERVICE SUPPORT ..................................................................................................................................... 3

24 HRS./7DAY SERVICE .............................................................................................................................................. 3

SAFETY PRECAUTIONS ...............................................................................................................................4

LABELS AND SILKSCREEN MARKING ..........................................................................................................5

PART NUMBER DESCRIPTION .....................................................................................................................6

SPECIFICATIONS.........................................................................................................................................7

GENERAL INFORMATION............................................................................................................................9

CHILLER SYSTEM DESCRIPTION................................................................................................................................... 9

COOLANT LOOP (FLOW CONTROL)............................................................................................................................... 9

REFRIGERATION SYSTEM AND HOT GAS BYPASS ........................................................................................................ 9

CONTROL PANEL FUNCTIONS ..................................................................................................................11

DESCRIPTION OF INDICATORS:................................................................................................................................... 11

OPTIONAL SYSTEM FEATURES .................................................................................................................13

DEIONIZATION PACKAGE:.......................................................................................................................................... 13

COOLANT WATER FILTER:......................................................................................................................................... 13

HEATER PACKAGE RC011, RC022, RC030, RC045:................................................................................................. 13

HIGH PURITY PLUMBING: .......................................................................................................................................... 13

EXTERNAL MANUALLY ADJUSTABLE FLOW VALVE:................................................................................................. 13

EXTERNAL PRESSURE RELIEF VALVE:....................................................................................................................... 13

AUTO TANK REFILL RC011, RC022, RC030 AND RC045:........................................................................................ 14

WATER COOLED CONDENSER RC022, RC030 AND RC045:...................................................................................... 14

CONTROLLER OPTIONS ............................................................................................................................15

BASIC CONTROLLER (PACKAGE 1; STANDARD WITH ALL UNITS) ............................................................................... 15

PACKAGE 2: (OPTION)................................................................................................................................................ 15

INSTALLATION .........................................................................................................................................16

COOLANT REQUIREMENTS:........................................................................................................................................ 16

ELECTRICAL REQUIREMENTS (FOR UNIT WITHOUT HEATER OPTION).......................................................................... 16

SELECTING CHILLER LOCATION ................................................................................................................................ 16

PLUMBING THE COOLANT LINES................................................................................................................................ 17

INSTALLATION PROCEDURE....................................................................................................................................... 17

FOR WATER COOLED CHILLERS ................................................................................................................................ 18

CONNECTING POWER (FOR UNITS WITHOUT HEATER OPTION).................................................................................... 18

STARTUP PROCEDURE................................................................................................................................................ 19

CHILLER OPERATION ...............................................................................................................................20

CHANGING TEMPERATURE SCALES ............................................................................................................................ 20

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

2

PROGRAMMING CHILLER FUNCTIONS:....................................................................................................................... 20

LT—LOW TEMPERATURE INDICATION (OPTION)....................................................................................................... 22

WEEKLY INSPECTIONS: ............................................................................................................................................. 24

PERIODIC MAINTENANCE .......................................................................................................................................... 25

KODIAK SPARE PARTS............................................................................................................................. 31

DRAWING SPECIFICATIONS RC006 ......................................................................................................... 32

DRAWING SPECIFICATIONS RC011/022 .................................................................................................. 33

DRAWING SPECIFICATIONS RC030/RC045 ............................................................................................. 34

WIRING DIAGRAM RC006G02 ................................................................................................................ 35

WIRING DIAGRAM RC011G02 ................................................................................................................ 36

WIRING DIAGRAM RC011H02/J02 ......................................................................................................... 37

WIRING DIAGRAM RC022H02/J02 ......................................................................................................... 38

WIRING DIAGRAM RC030H02/J02 &RC045H02/J02............................................................................ 39

PLUMBING DIAGRAM............................................................................................................................... 40

REFRIGERATION DIAGRAM...................................................................................................................... 41

BOYD KODIAKTM CHILLER CONTROL.................................................................................................... 42

HOST INTERFACE DATA LINK.................................................................................................................. 42

BOYD RECIRCULATING CHILLER SERVICE POLICY.................................................................................. 46

BOYD WARRANTY................................................................................................................................... 49

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

3

Introduction

Receiving your New KodiakChiller

Inspect your new chiller immediately upon receiving it. If the unit shows shipping damage,

contact the transportation company and file a freight damage claim. Retain all cartons and

packing material until the unit is operated and found to be in good condition. Your chiller has

been fully tested at the Boyd factory with clean water. Although the system has been drained,

some residual fluid may remain. This will not hinder the performance of the chiller.

About the Warranty

All units returned for warranty claims must have an RMA (Returned Material Authorization)

number on the outside of the container. Call Boyd Customer Service at (781) 933-7300 for an

RMA number. Refer to the end of manual for the chiller warranty.

Customer Service Support

Boyd is committed to servicing the customer, both during and after the sale. If you have any

questions concerning the operation of your unit, contact our Application Engineering

Department at (781) 933-7300. To facilitate your call, please have the model number and

serial number of the unit (located on the rear of the chiller) for the Boyd Applications

Engineer.

24 hrs. / 7 day service

Boyd has a 24 hours per day, 7 days per week service hotline to help you with questions on the

startup and operation of your Kodiakrecirculating chiller. (We recommend you review the

troubleshooting guide on page Error! Bookmark not defined. before calling our service

hotline.) Boyd service can be reached by dialing (781) 933-7305. To facilitate your call please

have the model number and serial number (located on rear of the chiller) of the unit for the

Boyd Service Technician.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

4

Safety Precautions

This system is designed to provide fluid cooling only as specified in this manual. If you use this

system in a manner other than as specified, the safety protection of the system may be impaired.

Warnings are posted throughout the manual. Read and follow these important instructions. Failure to

observe these instructions or use other than specified may impair safety protection, void the warranty,

and can result in permanent damage to the unit, significant property damage, personal injury and/or

death.

Make sure you read, understand, and follow all instructions and safety precautions listed in this

manual before operating your unit. If you have any questions concerning the operation of your unit or

the information in this manual, please contact our Applications Engineering Department at (781) 933-

7300.

If the set point is 10oC or below, a freezing point depression additive, such as ethylene

glycol, is required. This unit is equipped with a low flow switch. This feature will shut

the chiller down during a low flow situation to prevent freezing.

DO NOT USE AUTOMOTIVE ANTI-FREEEZE IN THE CHILLER. The rust

inhibitors in the automotive type will cause premature failure of the pump seals. Use of

automotive anti-freeze in a Boyd chiller will void the warranty.

Never place the unit in a location where excessive heat, moisture, or corrosive materials

are present.

The unit must be plugged into a properly grounded power source.

Do not connect the SUPPLY or RETURN fitting to your building water supply or any

pressurized source.

Performance of installation, operation, or maintenance procedures other than those

described in this manual may result in a hazardous situation and may void the Boyd

warranty.

Transport the unit with care. Sudden jolts or drops can damage the unit.

Observe all warning labels. Never remove warning labels.

Do not operate damaged or leaking equipment.

Do not operate the unit without fluid in the reservoir.

Always turn the unit "OFF" and disconnect the power cord from the power source

before performing any service, maintenance procedures, or before moving the unit.

Do not operate equipment with damaged power cords.

A qualified technician should perform Service and repairs.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

5

Labels and Silkscreen marking

(located in the back of unit)

This silkscreen marking identifies the connection where heated

fluid is supplied from the user’s machine.

SUPPLY

This silkscreen marking identifies the connection where chilled

fluid is supplied to the user’s machine.

This symbol certifies that the chiller conforms to the EMC

Directive and all applicable directives at the time of marking.

Product ID Label: Identifies the model number, serial number,

electrical information volts, amps, Hz, phase, pump type,

refrigerant, and charge.

The Protective Earth

(g

round

)

Terminal.

RETURN

The triangle symbol tells maintenance personnel and users

to consult the product technical manual for more

information. In this example, the symbol calls attention to

the High Voltage Warning in the Control Box.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

6

Part Number Description

RC006 G02 BB 1 MXXX

Basic

Model No.

Electrical

Configurations

Pump

Options

Controller

Configuration

Standard

Modifications

RC006 - 600 Watts

RC011 - 1100 Watts

RC022 - 2200 Watts

RC030 - 3000 Watts

RC045 - 4500 Watts

NOTE:

Cooling capacity

and pump flows

are rated at 60Hz.

For 50Hz power,

derate capacity by

17%.

G02 = 115V~/1 Ph/60Hz

H02 = 230V~/1 Ph/50Hz

J02 = 230V~/1 Ph/60Hz

AA* = CP-15

Centrifugal Pump

BB = 1.3 gpm

Positive

Displacement Pump

BC = 1.8 gpm

Positive

Displacement Pump

BG = 4.3 gpm

Positive

Displacement Pump

DA* = CP-25

Centrifugal Pump

EB* = TB-2

Turbine Pump

* Water filter and

DI cartridge not

recommended with

Centrifugal &

Turbine pumps.

1= Temperature control,

calibration offset,

pressure indication, low

flow shut off.

2= Temperature control,

calibration offset,

pressure indication, low

flow shut off.

a. Low level

indication.

b. Low

temperature

indication.

c. High

temperature

indication.

d. Chiller fault shut

down (toggle

“on” and “off”).

e. Relay contacts

for customer

interface.

f. Audible alarm

(toggle “on” and

“off”)

3= Same as "2" above

with the addition of

RS232 communications.

NOTES:

1. Refer to the product ID label on the on the rear of your chiller for the configuration you have

purchased.

2. The above mentioned table refers to Boyd’s standard product offering for the Kodiak

product line.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

7

Specifications

RC006 RC011 RC022 RC030 RC045

Thermal Capacity 2

Watts

Btu/Hr

60 Hz 50 Hz

600 480

2000 1660

60 Hz 50 Hz

1100 913

3700 3070

60 Hz 50 Hz

2200 1826

7500 6225

60 Hz 50 Hz

3000 2500

10,200 8500

60 Hz 50 Hz

4500 3735

15000 12450

115V~ 60Hz 1ph G02 N/A

230V~ 60Hz 1ph N/A J02

230V~ 50Hz 1ph H02

Full Load

Amperage 4

G02

J02

H02

10.0 Amps

N/A

4.4 Amps

15.4 Amps

7.4 Amps

6.9 Amps

N/A

10.0 Amps

9.4 Amps

NA

11.9 Amps

11.0 Amps

N/A

19.6 Amps

16.4 Amps

Compressor

Capacity Hp

1/4 1/2 3/4 1 1 1/2

Refrigerant Type R134A

Temperature

Stability +/- 0.1°C

Operating

Environment

15° to 40° C (59° to 92° F), 80% R.H.

(consult factory for environments below 15°C (59° F)

Coolant

Temperature Range

40°F-95°F

5°C-35°C

Reservoir Capacity,

Gallons Liter 1 (3.8) 2 (7.6) 2 (7.6)

6 (22.6) 6 (22.6)

Dimension, in.

(mm)3

Width, in. (mm)

Depth, in. (mm)

Height, in. (mm)

12.5" (318)

19.0" (483)

22.0" (559)

14.8" (376)

24.5" (622)

26.5" (673)

14.8" (376)

24.5" (622)

26.5" (673)

21.4" (543)

27.8" (705)

31.0" (787)

21.4" (543)

27.8" (705)

31.0" (787)

Connection, FNPT 3/8” 3/8” 3/8” 1/2" 1/2"

Weight, lbs (Kg) 97 (44) 122 (55) 166 (75) 260 (118) 270 (123)

Process Coolant

Delivery Pressure

60 psig maximum (factory preset for PD pumps only)

1Specifications subject to change.

2Capacity for 20°C delivery water at a 20°C ambient.

3Dimensions do not include filters.

4Full load amperage for models with standard pumps without heater.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

8

Performance Curves RC006/011/022/030/045

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

9

General Information

Chiller System Description

Your chiller consists of a refrigeration system, a coolant loop, associated controls and

plumbing. The pump draws coolant from the internal reservoir and pumps it out to cool your

equipment, and then the coolant flows back to the chiller. It flows through the evaporator,

where the heat is removed, and then flows back into to the reservoir.

Coolant Loop (flow control)

Kodiak chillers are designed to operate with continuous coolant flow through a closed loop.

This loop contains the system pump, temperature sensor, reservoir, internal and external

plumbing lines and fittings, and the external heat load. The external plumbing and the heat

loads are provided by the end user and are generally unique to the user’s process and/or

location.

****CAUTION****

Do not put valves in the system that can stop flow while the chiller is operating.

Refrigeration System and Hot Gas Bypass

The chiller uses a standard refrigeration system to keep the coolant at the process temperature

set point. The compressor compresses the refrigerant vapor (gas), which then passes through

the condenser where it is cooled and turns to a liquid. The refrigerant in its liquid state then

passes through the evaporator. The coolant also flows into the evaporator, through passages

separated by thin layers of metal from the refrigerant. The refrigerant evaporates, drawing heat

from the coolant. The refrigerant vapor returns to the compressor and continues the cycle.

Kodiak

Recirculating Chiller

(FRONT VIEW)

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

10

Many refrigeration systems, such as those used in household refrigerators, control the

temperature by turning the compressor on and off. This is a simple, inexpensive method of

controlling the cooling, but its temperature control is not precise and the frequent on-off cycles

cause wear on the compressor motor.

Boyd’s recirculating chillers use a better method for controlling the cooling rate: a hot-gas

bypass system. This employs a liquid line solenoid valve and a hot-gas bypass valve to meter

the refrigerant flow through the evaporator when refrigeration is needed. When the coolant

reaches its set point temperature, the liquid line solenoid valve closes, causing the hot-gas

valve to open. The hot-gas valve lets hot-gas from the compressor discharge into the

evaporator inlet, adjusting the temperature in the evaporator to maintain the correct coolant

temperature. When refrigeration is needed, the liquid line solenoid valve opens, the hot-gas

valve closes and the cycle starts again.

This hot gas bypass control method provides precise temperature control. It also minimizes

wear on the compressor motor, since the compressor runs continuously and does not

experience the stress of repeated cycling.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

11

Control Panel Functions

Key Operation

I Turn on chiller

O Turn off chiller

“UP”+ “DOWN” + Enter menu

(press simultaneously and hold for 3 seconds and

release)

“SET” Push to display or change set point.

“UP” arrow Increase set point temperature

“DOWN” arrow Decrease set point temperature

°F/°C Toggles between °F and °C

Description of Indicators:

Pressure-indicating bar: Displays output pump pressure in psi/bar, 2 psi/segment, 0.14

bar/segment.

Temperature set point: Displays coolant temperature or set point in °C or °F.

Temperature set point °C or °F

Over temperature

(

optional

)

Coolin

g

on/off indication

Low temperature

(

optional

)

International fault s

y

mbols

Tactile feedback buttons

Pressure-indicatin

g

bar

g

raph

Alarm

(

optional

)

Low flow

Low level

Kodiak Control Panel

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

12

Cooling indicator: To maintain set point temperature the chiller must cycle between

cooling and hot gas bypass mode. This indicator illuminates

while in cooling mode.

Low flow indicator: Illuminates to indicate a low flow condition. The chiller will also

shut down during this condition.

Controller package II and III

Alarm indicator: Illuminates to indicate an alarm fault condition.

Low level indicator: Illuminates to indicate a low fluid level condition

Over temperature indicator: Illuminates to indicate an over-temperature condition.

Low temperature indicator: Illuminates to indicate a low-temperature condition.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

13

Optional System Features

Deionization Package:

The Deionization Package consists of a factory-installed deionization cartridge. The

deionization cartridge requires replacement only when the mixed bed is depleted. For

replacement cartridges, Call Boyd’s Customer Service at 781-933-7300. This package is

offered for deionized water applications where the resistance of the water does not exceed 1

megohm-cm, and where the use of brass and copper fittings is acceptable. The deionization

package is not recommended with centrifugal pumps.

Coolant Water Filter:

This factory installed water filter removes particulate from the coolant water. The water filter is

not recommended with centrifugal pumps. For replacement filters, call Boyd’s Customer

Service at 781-933-7300.

Heater Package RC011, RC022, RC030, RC045:

The heater package is for applications requiring coolant temperature well above ambient

temperature. This package is a single set point type. The heater is activated when the water

temperature is 3F below setpoint.

*NOTE: The heater option is not intended to provide tight temperature control, but to bring

coolant temperature up to an application's requirement.

****WARNING****

If your unit was not built with the heater package, do not attempt to retrofit it. If you do,

severe damage will occur to the unit, personal injury may result, and the warranty will be

voided.

High Purity Plumbing:

This option is intended for use with deionized water. Only stainless steel and/or plastic

components and a nickel-brazed heat exchanger come in contact with the coolant. You must

specify this option before you purchase a chiller; it is not field retro-fittable.

External Manually Adjustable Flow Valve:

This option is a valve plumbed between the supply and the return of the chiller. It allows you

to manually adjust the flow rate. To be sure your equipment is receiving

enough flow, install a flow meter at the outlet from your equipment.

External Pressure Relief Valve:

This option is for applications requiring reduced pressure. This kit contains a Pressure Relief

Valve, 2 Tees, Hose Clamps and Plumbing Instructions.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

14

Auto Tank Refill RC011, RC022, RC030 and RC045:

This option automatically maintains the fluid level in the reservoir. This feature requires a city

water connection or equivalent pressurized coolant supply.

Water Cooled Condenser RC022, RC030 and RC045:

This feature replaces the standard condenser and fan with a water cooled condenser. This

requires facility cooling water to be supplied to the chiller at 75F (25C). Minimum flow

rates are as follows:

Model Flow Rate (min)

RC022 1.4 gpm

RC030 1.9 gpm

RC045 3.4 gpm

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

15

Controller Options

Basic Controller (Package 1; standard with all units)

Temperature control, +/-0.1°C.

Temperature display in °C or °F.

Pump output pressure display psi/bar, 2 psi/segment.

Offset temperature calibration -4°C to 4°C , -7°F to 7°F

with 0 the midpoint.

Low flow shut off.

Auto Restart

Package 2: (option)

Has the same function as the basic controller, and includes the following:

Low level indication

Low temperature indication

High temperature indication

Audible alarm (toggle on/off)

Fault chiller shutoff (toggle on/off)

External normally closed contacts. Open under fault. 0.5 amp. Maximum

Package 3: (option)

Has all the same functions as Package 2 above, plus:

RS232 communications

Additional Options:

Remote Start

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

16

Installation

Coolant Requirements:

Boyd recommends using filtered clean water above 10oC as coolant.

If the set point is 10oC or below, a freezing point depressant, such as ethylene glycol, is

required. This unit is equipped with a low flow switch. This feature will shut the chiller down

during a low flow situation to prevent freezing.

Avoid using water with a high mineral content.

Standard RC units may not be compatible with deionized water. Consult Boyd Application

Engineering for deionized water applications.

If the coolant is exposed to sunlight add an algicide to control organic growth in lines.

****CAUTION****

Positive displacement pumps are susceptible to damage from abrasive materials in the coolant.

To reduce risk of damage, a factory-installed water filter is recommended.

Electrical Requirements (for unit without heater option)

Refer to the Specification section and to the product ID label on the rear of the chiller for the

specific electrical requirements of your unit. The chiller power module is configured with a

standard international IEC320/C20 inlet. To safely operate the chiller, use a SJT cord set with

an IEC 320/C19 receptacle and an inlet plug that is compatible to the local power grid and the

power requirements of the chiller. All Kodiak chillers should use CSJT 3 conductor 12 awg

minimum power cord.

****WARNING****

It is the user’s responsibility to provide a proper ground connection.

Selecting Chiller Location

To minimize the heat gain and pressure drop through the connecting hoses, the chiller unit

should be located as close as possible to the heat load (user equipment). This is more important

for units with centrifugal pumps. Coolant lines are best run at or near the same level as the

cooling system. Once the chiller is in position lock the casters.

Air flow is critical to optimize performance of the chiller. The front and one side or the back

of the unit MUST be kept clear and unobstructed. The remaining two sides or back must have

minimum clearance of 18". The top clearance must be at least 6". Ensure that the hot air

exiting the chiller does not recirculate into the inlet openings. The front of the unit must have a

free supply of ambient-temperature air.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

17

NOTE:

The circuit breaker located on the rear of the unit must be kept clear and easily

accessible.

To move the chiller, cap all ports to prevent any coolant leakage. Unlock the casters and move to new

location. Once in the new location lock the casters. To prevent freezing during storage drain water if

the chiller is located in an area below (10C 50F).

Plumbing the Coolant Lines

The coolant ports are located on the rear of the system and are labeled with the Supply

and Return symbols.

To minimize the pressure loss in the coolant lines, use the largest practical diameter tubing. If

substantial lengths of cooling lines are required, they should be pre-filled with coolant before

connecting them to the chiller.

To minimize heat gain, all lines should be as short as possible. Keep them away from heat

sources such as radiators and hot water pipes. Lines that cannot be routed away from heat

sources should be protected with thermal insulation, preferably at least 1/2" (12.7mm).

Flexible tubing, should be of heavy wall or reinforced construction. All tubing should be rated

to withstand 125 psig at 186oF (30o C). Make sure all tubing connections are secured and leak-

tight. Also, whenever possible use opaque lines to prevent algae growth during prolonged non-

operating periods.

****CAUTION****

Do not connect the SUPPLY or RETURN fitting to your building water supply or any

pressurized source.

Installation Procedure

To connect the fluid lines to the chiller and user equipment follow these steps:

1. Remove the plastic caps covering the supply and return ports on the rear panel of the unit.

2. Attach coolant lines to the supply and return ports on the rear panel.

Supply port: chilled coolant goes out to user equipment

Return port: hot coolant returns from user equipment

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

18

3. Refer to the table below for the fitting sizes required for the your unit.

Model# Fitting Size

RC006, RC011, RC022 3/8" FNPT

RC030, RC045 1/2" FNPT

Note: Fittings should either be brass, stainless steel or plastic. Never use steel or cast iron fittings, as

the corrosion will damage the chiller. For chillers with deionization cartridges or high purity

plumbing Boyd recommends the use of either stainless steel or nylon fittings.

4.Remove water filler cover on top of the unit to access the reservoir.

5.Fill the reservoir. Use the reservoir sight tube on the front of the unit to see the coolant level

in the tank as you are filling. Be sure to allow for the volume of coolant needed to fill the

cooling lines between the chiller and the equipment, if they were not filled with coolant before

installation.

6. Centrifugal Pumps must be primed before operation. To prime pumps, disconnect supply line

from rear of chiller, allow air to vent and out of pump head and reconnect line.

For Water Cooled Chillers

7. Connect facility water to connections labeled "City Water In" and "City Water Out".

Minimum flow rate of facility water is shown on page 14. Facility water flow must be started

before chiller is turned on.

****CAUTION****

Standard RC units may not be compatible with deionized water. Consult Boyd Application

Engineering for deionized water applications.

Connecting Power (for units without heater option)

Connect a 3-conductor SJT type power cord with an IEC 320/C19 receptacle to the inlet power to the

module on the rear of the unit and to an appropriate AC power source. All chillers should use a 12

gauge power cord.

****WARNING****

Be sure to provide a proper ground connection.

KodiakRecirculating Chiller Technical Manual

Manual# 820-0043 Rev N, 11/25/2019

19

Startup Procedure

1. Turn "ON" the circuit breaker on the rear of the unit. The controller will go through a diagnostic

test. Turn on the chiller unit using the ( I ) key located on the Keypad Display panel. The

controller displays "OFF" for 8 seconds. The delay prevents rapid cycling of the compressor using

the "ON" and "OFF" switch.

****IMPORTANT****

If you have optional controller package 2 or 3, the fault shutoff may prevent the chiller from operating.

If you turn on the unit and it does not operate, disable the fault shutoff. Then turn on the chiller. After

the chiller is operating and the coolant reaches its setpoint temperature, you can enable the fault

shutoff.

2. Set the temperature setpoint using the controls on the keypad display as follows:

Press the “SET” key once to display the current coolant temperature set point.

Press the “UP” or “DOWN” arrow key until the desired coolant temperature setpoint

appears on the LED display.

Press the “SET” key again to accept the setpoint and return to normal operation.

3. Operate the chiller for a short time and then check the coolant level in the reservoir. If the level

drops, add more coolant.

4. Check all fittings and hoses for fluid leaks. If a leak exists, turn chiller off, disconnect power and

take necessary action to repair the leak.

****IMPORTANT****

Do not operate chiller until leak has been repaired.

This manual suits for next models

7

Table of contents

Popular Chiller manuals by other brands

Carrier

Carrier Ecologic Series 3 Controls, start-up, operation, service, and troubleshooting

Hypertherm

Hypertherm Koolant Koolers N-Series user manual

Skope

Skope SC112N-AC Service manual

SMC Networks

SMC Networks HRLE Series Operation manual

Thermal Care

Thermal Care FT Series Operation, installation, and maintenance manual

Nordcap

Nordcap 433000006 user manual

Multistack

Multistack Airstack ASPX Series Operation and maintenance manual

Oasis

Oasis R3 instruction manual

Trane

Trane Sintesis RTAF-SVX002D-EN Installation, operation and maintenance

Haskris

Haskris R1600 instruction manual

Elkay

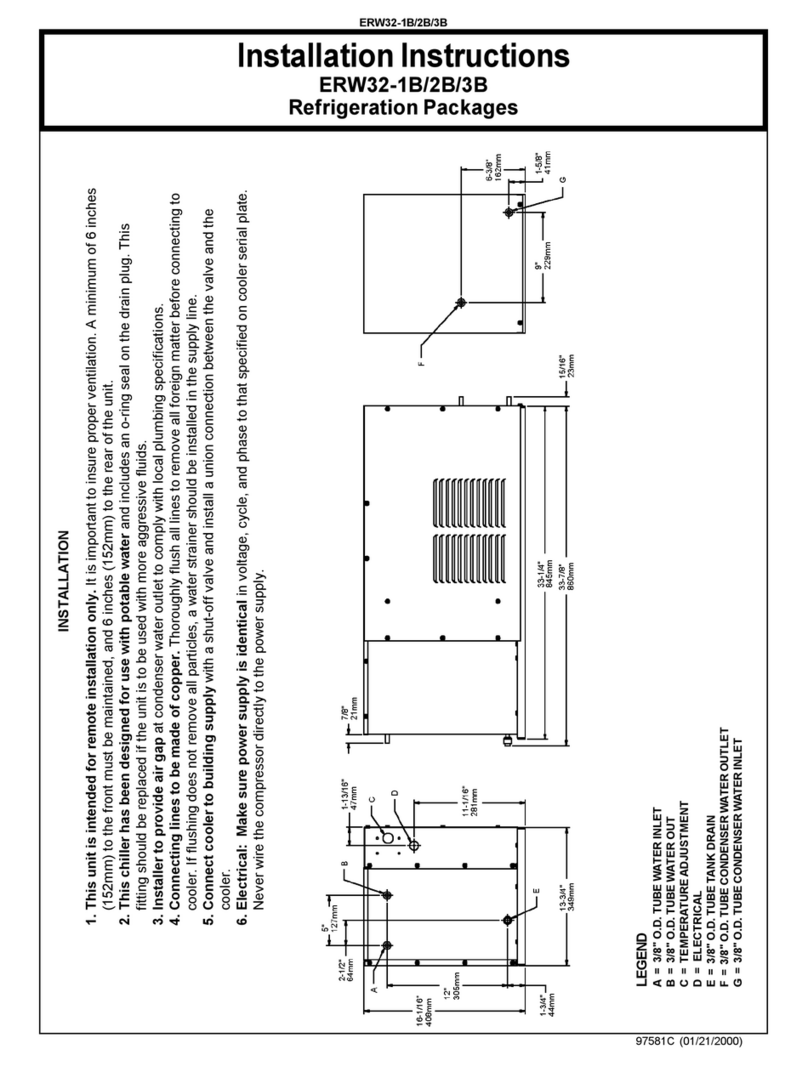

Elkay ERW32-1B installation instructions

Johnson Controls

Johnson Controls YORK YK Series installation guide