Thermal Care FT Series Instruction Manual

This manual suits for next models

5

Table of contents

Other Thermal Care Chiller manuals

Thermal Care

Thermal Care NQ Series User manual

Thermal Care

Thermal Care TSE Instruction Manual

Thermal Care

Thermal Care Accuchiller KSE Instruction Manual

Thermal Care

Thermal Care Accuchiller EQ Series User manual

Thermal Care

Thermal Care Accuchiller TCF Instruction Manual

Thermal Care

Thermal Care ACCUCHILLER EQ Instruction Manual

Thermal Care

Thermal Care Accuchiller MX Series Instruction Manual

Thermal Care

Thermal Care Accuchiller TCFW375 Instruction Manual

Thermal Care

Thermal Care Accuchiller NQ Series Instruction Manual

Popular Chiller manuals by other brands

Server

Server 01882-REVB-010407 quick start guide

Trane

Trane Water-Cooled CenTraVac S Series installation instructions

Daewoo

Daewoo SDA2252 user manual

Carrier

Carrier 30XW user guide

Buchi

Buchi F-108 Operation manual

Daikin

Daikin Clima-Flex CLIC STAND ALONE Series Installation, operation and maintenance manual

Carrier

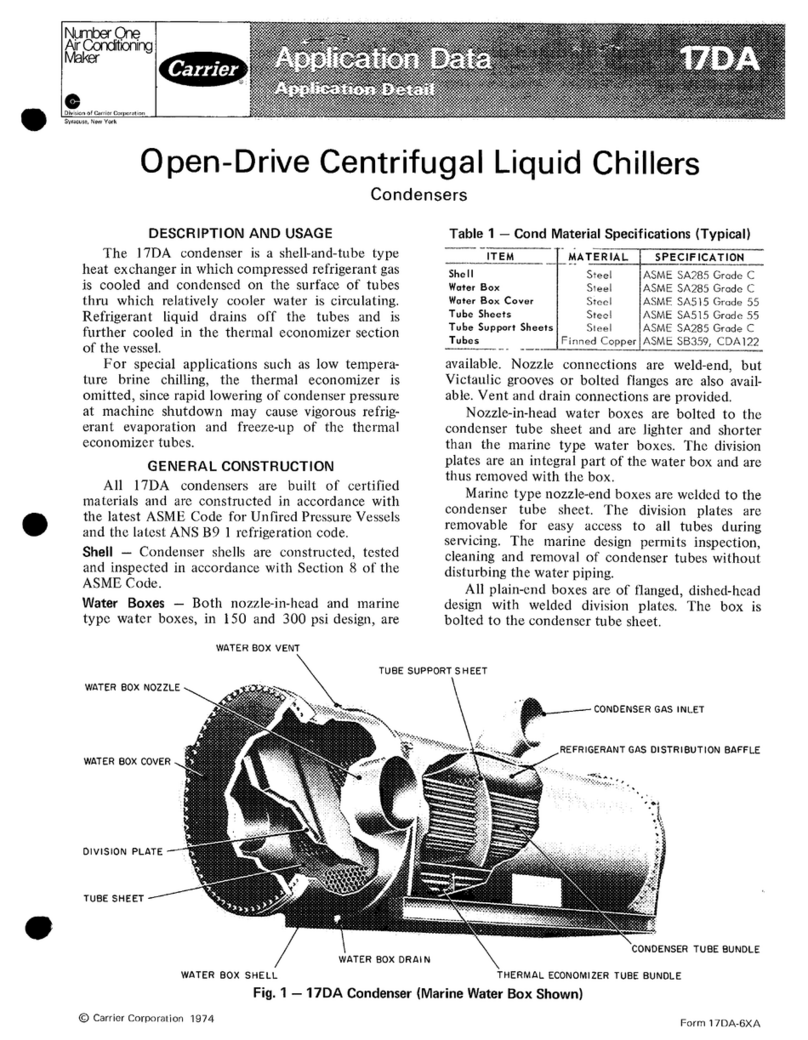

Carrier 17DA Application data

Modine Manufacturing

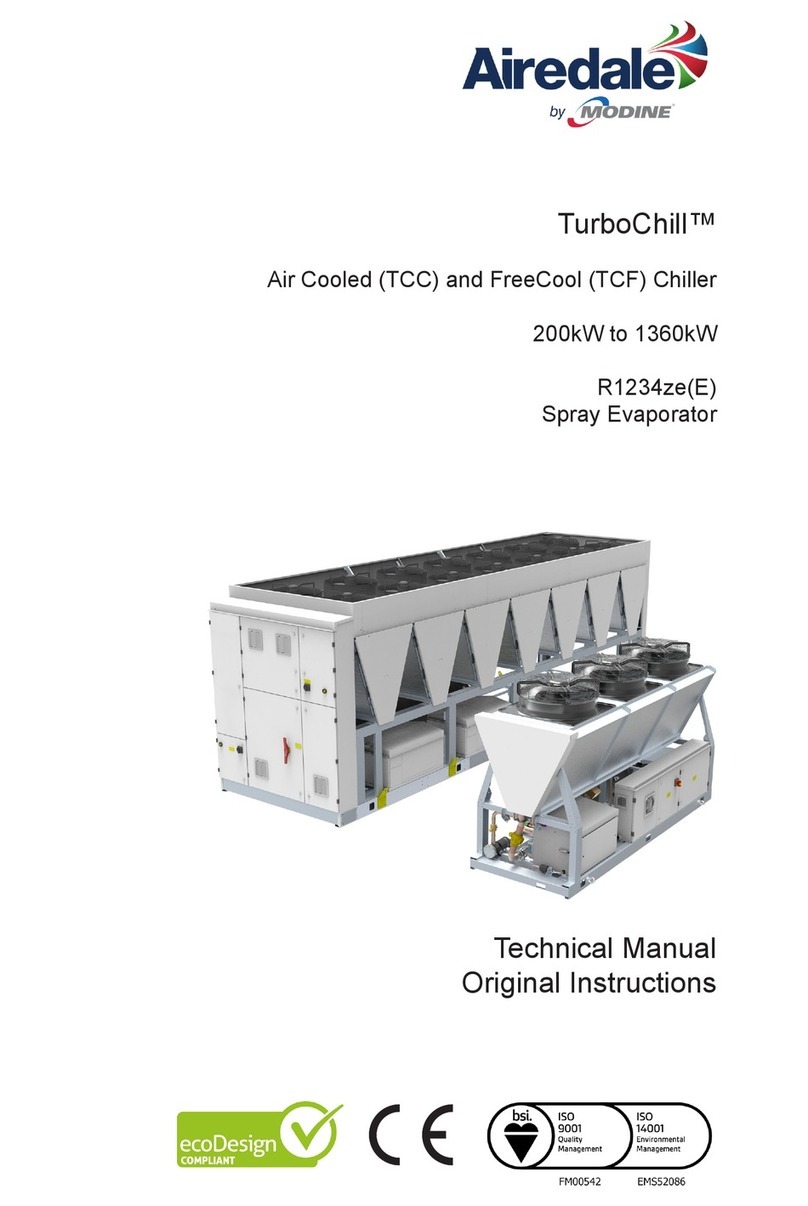

Modine Manufacturing Airedale TurboChill R1234ze manual

Carrier

Carrier 19 user manual

Carrier

Carrier 30HR Series Installation, Start-Up and Service Instructions

Elkay

Elkay ER5 Series Installation, use & care manual

Cleveland

Cleveland TCCT-60-CC supplementary guide

Nordcap

Nordcap SKF 18 GN 1/1 Installation

Carrier

Carrier AquaEdge 19XRV series Start-up and service instructions

Kaysun

Kaysun KEM-HT-65 DRS5 Owners & installation manual

Zip

Zip CH101 Installation and operating instructions

Mueller

Mueller PMC 40/50 Instructions for installation and operation

SMC Networks

SMC Networks HRS012-A*-10-* Operation manual