11.0 Strainer Cleaning

All ASPX modules have a 30-mesh lter strainer in the ChilledWater inlet header. The purpose for the lter strainer is to keep debris from entering the heat

exchanger. An external“Y”or basket type system strainer should also be installed as a pre-lter to the factory supplied strainers.

There is no set time for cleaning the lter strainers. The frequency of this process is dependant on the water quality in the ChilledWater loop. Normally, debris

in a water loop is going to take the path of least resistance and build up on the last modules to receive water.

If circuits are faulting on Low SuctionTemperature, or Low ChilledWater Temperature the ChilledWater inlet lter cartridge should be checked. The strainers

are located in the top header on the Chilled Water side. If the strainers are clean, the fault is most likely being caused by a low ow condition--or set-points

in the master control that are too low. If these possibilities are eliminated, the ChilledWater heat exchangers may need cleaning.

Steps to remove the strainers for cleaning

1. Stop Chilled water pump and shut down chiller.

2. Close inlet and outlet water valves to the chilled water

3. Drain the water/glycol from the top header in the end module so the strainers can be removed.

4. Remove the 4-8”Victaulic end cap on last module.

5. Remove strainers and clean. You may need to make a tool to hook the other strainers for removal.

6. Re-install clean strainers.

7. Open the bottom water isolation valve and ll unit from the bottom up to prevent air from being trapped.

8. Restart Chilled Water pump, bleed any air and start Chiller.

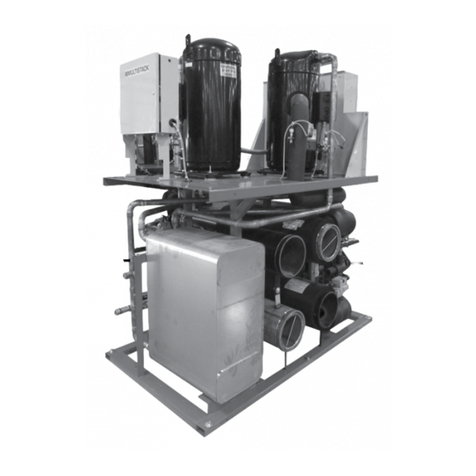

12.0 Compressor Oil Level

Compressors used on ASPX modules are oil charged by the compressor manufacturer. The standard tandem Copeland compressors do have an oil equalizer

line and oil level sight glass indicator. Oil level should be maintained at ⁄ – ¼ full.

To ensure no liquid is present in the oil the crankcase heaters should be on 24 hours before starting of the compressors.

Factory oil charge volume for each compressor can be found in section 13.0.

13.0 Refrigerant Charge/Evacuation

All ASPX modules are factory charged with the recommended refrigerant volume. Prior to charging, each circuit is evacuated to a maximum of 150 microns

and held 15 minutes. The proper refrigerant charge for each module can be found on the module data plate.

On air-cooled packaged machines, the proper charging procedure is calculated by the weigh-in method. Charging to a full sight glass on air-cooled ma-

chines will likely result in over charging because the elbows in the liquid line, as well as the liquid line solenoid valve, still produce some ashing--even with

the correct charge. As fans are cycling, the sight glass will also display some bubbling.

Model # Lbs. R410a Lbs. Low Ambient Total Tandem Compressor Oil Charge

ASP10X 50 90 114 oz.

ASP15X 60 85 220 oz.

ASP20X 100 100 220 oz.

ASP30X 125 125 252 oz.

ASP60X 220 360 426 oz.

14.0 Filter Driers

ASPX Chiller modules have a liquid line lter drier installed. When doing a repair to the refrigerant side because of a compressor motor burn, or moisture

entering the system, a proper replacement drier should be installed.

15.0 Condenser Fan Control

10-, 15- and 20-ton modules can be ordered with standard pressure control cycling of fans or optionalVFD control. ASP30 and ASP60 modules come standard

with VFD control.

16.0 Superheat/Subcooling

ASPX modules use a mechanical expansion valve. By turning the valve adjustment clockwise superheat is increased.

On each module, superheat is set at the factory during the run test. Superheat is set between 10 – 12°F during the test run.

Subcooling is necessary in the system to prevent ash gas when the refrigerant enters the expansion valve. ASPX condensers are sized so that subcooling of

the liquid refrigerant will take place without a separate subcooler. The general range of subcooling seen is 7- 15°F.