Bradbury Equipment H4441 Instruction Manual

H4441 / H4443 / H4541 / H4543

WHEEL-FREE

T61720

OPERATION AND MAINTENANCE INSTRUCTIONS

Bradbury Equipment

153-165 Bridge Street

GB- Northampton NN1 1QG

England

Tel. +44 (0) 1604 828 648

Date: 180918

Serial No:

Ref.: KM/LJE

Pages: 12

T61720

1

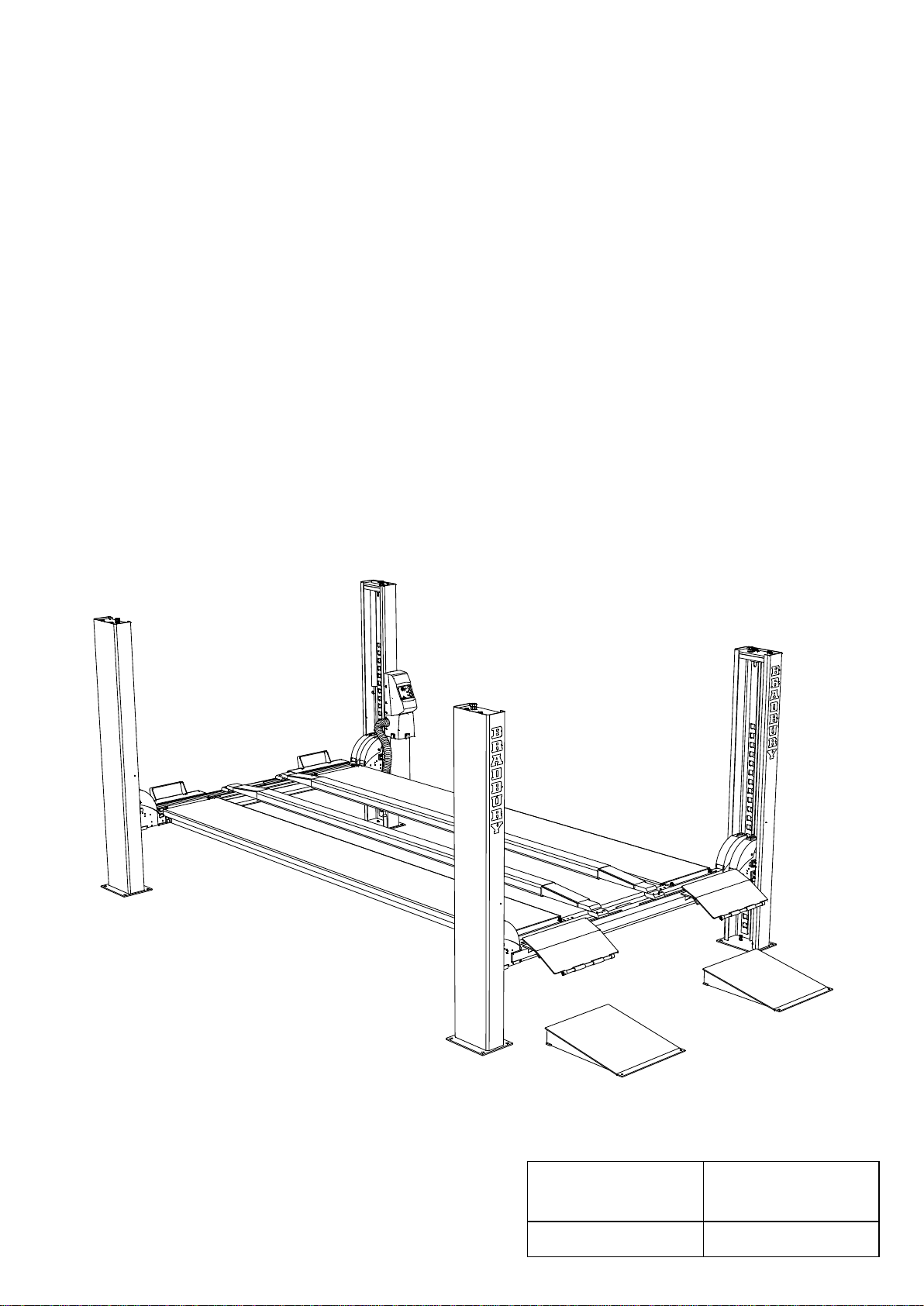

Main lift

Wheel-free

device

OPERATION AND MAINTENANCE INSTRUCTIONS

This lifting device is specially developed to lift motor cars and we strongly recommend not to lift any other

equipment with this automotive car lift.

DESCRIPTION

The lift is an electro-hydraulic 4 post surface-mounted lift with capacity ranging from 3 to 5.2 t.

The lift consists of 2 pairs of posts connected with cross beams. The 2 platforms rest on the cross beams.

Furthermore, the lift is equipped with a wheel-free device; which consists of 2 cross beams placed on the outer

sides of the main cross beams and a pair of rails fitted to the wheel-free cross beams.

Platforms and cross beams for the main lift are raised and lowered bymeans of cables and a hydraulic cylinder

placed under one platform. The cables are attached to a yoke on the piston rod and run via cable pulleys to the four

post tops with an incorporated adjustment device.

The hydraulic pump unit and control box are placed on the front right post.

The lift is operated by means of pushbuttons showing the UP, DOWN and PARKING functions with indicators.

Furthermore, the control unit is fitted with a rotary switch for activation/deactivation of the wheel-free device.

Sound level measured at the control unit at a height of 1.6 m: max. 74 dB(A).

T61720

Revision:

2

INSTALLATION

In order to come up to your expectations now and in the future the lift must be installed in strict accordance with the

installation instructions and maintained according to our recommendations.

Contact your distributor for the name and address of the nearest authorized service shop.

FITTER INSTRUCTIONS

Install the lift in strict accordance with the original installation instructions which are included in each delivery.

The lift must be installed on solid foundation: concrete with minimum load capacity5500 N/m² and surface spot load

under posts 350 kN/m²; torque for expansion bolts attaching the posts: 25 Nּm.

There should be sufficient light for work on and under the lift. For the lift a lighting set is available as an optional

extra comprising four impact-proof, water-tight fluorescent tubes including cable (state model number).

Avoid installing the lift in rooms with danger of explosion.

WARNING: Person transportation is forbidden.

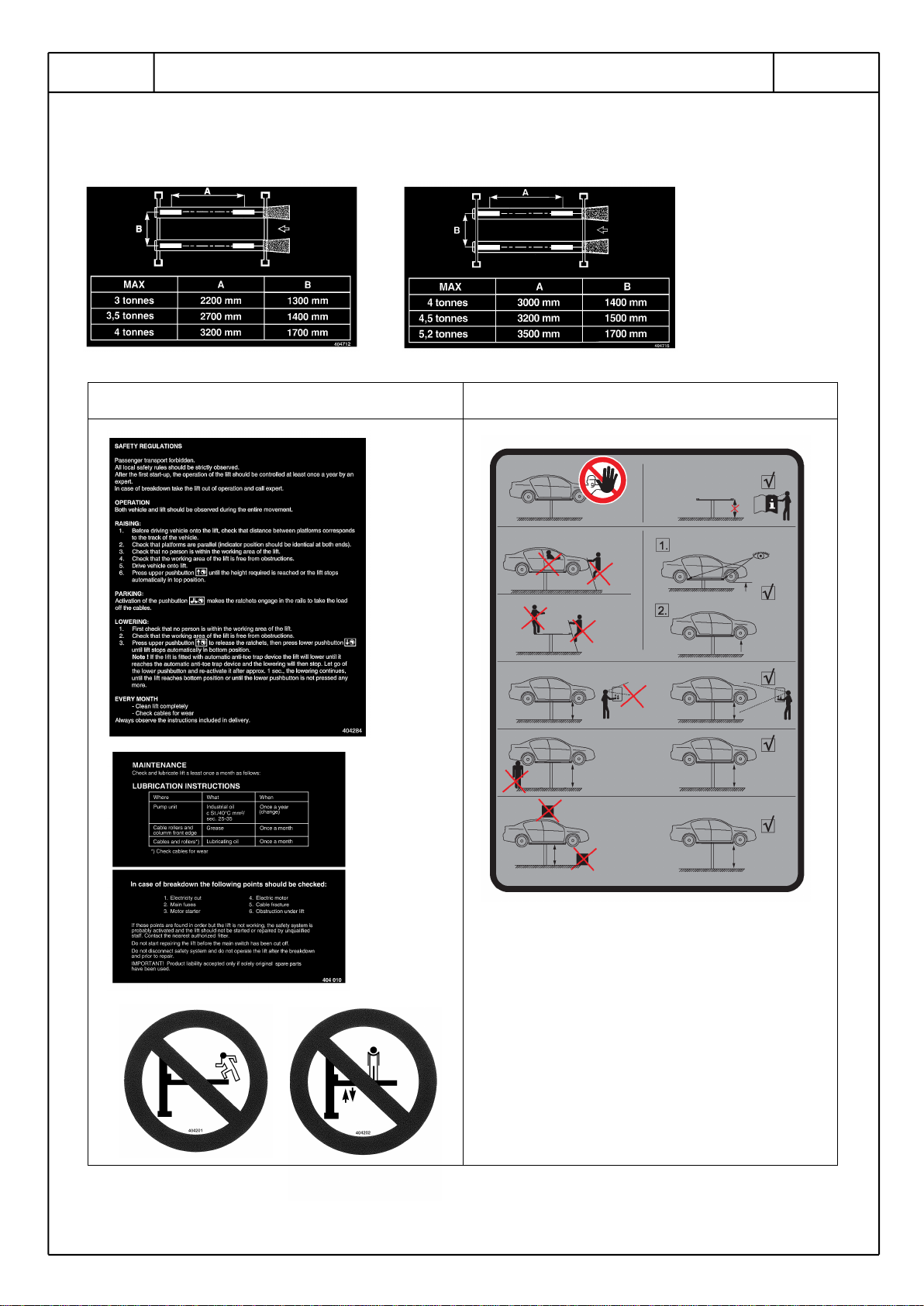

OPERATION

The lift should only be operated bytrained personnel !

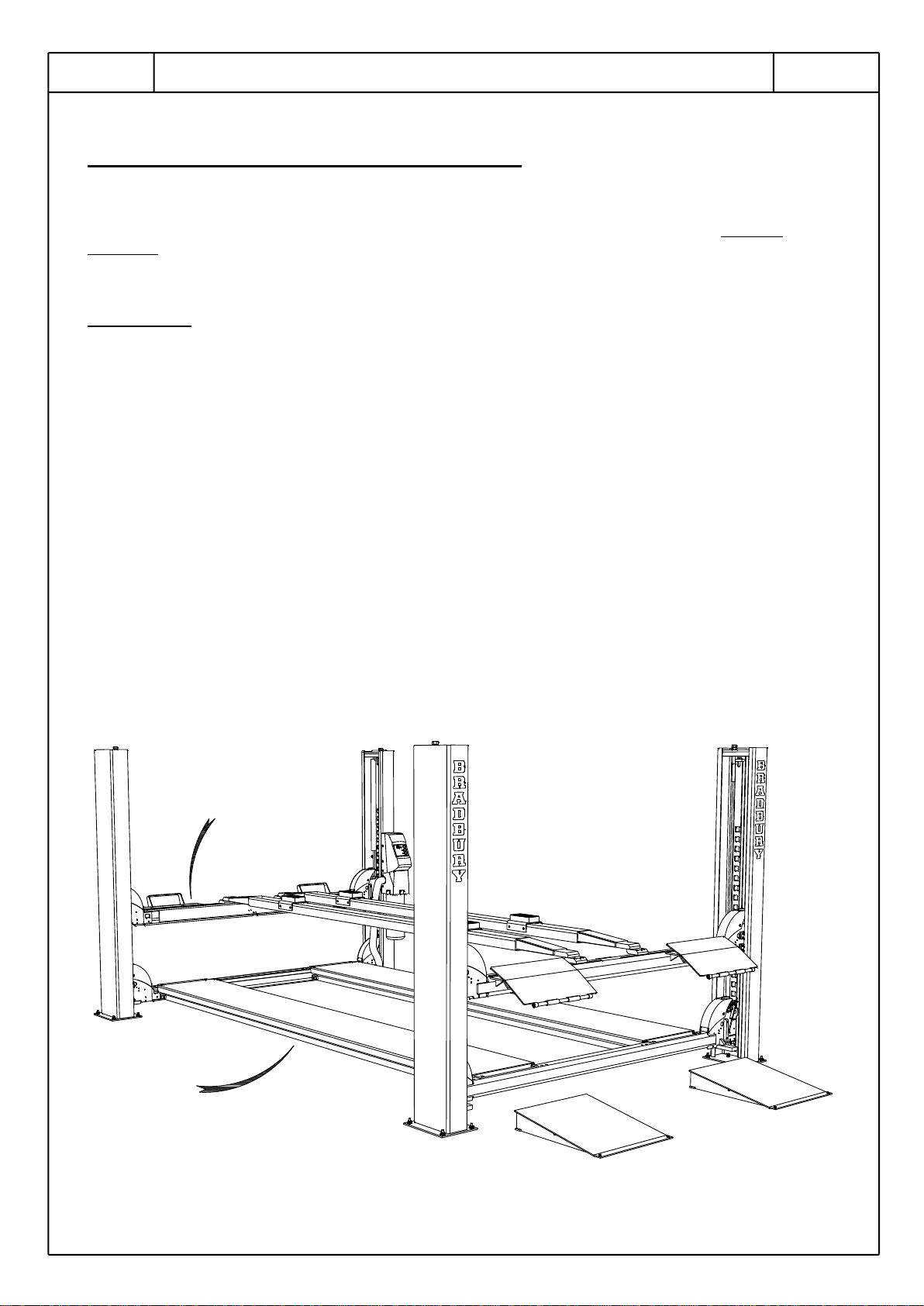

Approch

Before driving the vehicle on to the lift, check that platforms are parallel (the

same indicator position at both ends.

Raising

Push UP-button (motor starts): raise lift to a bit above required working

height.

Parking

Let go of UP-button and push PARK-button ➔ until platforms rest on all 4

ratchets.

Lowering

Check that no person or obstruction is under platforms. Push UP-button

shortly (to release the 4 ratchets) and then press DOWN-button . The lift

then lowers until the lift reaches automatic anti-toe trap device and the

lowering stops. Let go of DOWN-button and re-activate it after approx. 1

sec., the lowering continues until the lift reaches bottom position or until

pushbutton is not pressed any more.

NOTE: Always park lift (press ➔ button) before starting to work under it.

Operation Wheel-free:

When pushing UP-button , both platforms and wheel-free device are raised simultaneously. At the height wanted,

the rotaryswitch is activated and the wheel-free device parked. When pushing DOWN-button the platforms will

be lowered. When the job is finished, the platforms are raised till they reach the wheel-free device and the vehicle is

set off on the platforms. Deactivate the rotaryswitch; check that no persons or obstructions are under the platforms

and push UP-button shortly (to release the 4 ratchets). Push DOWN-button and the lift lowers until it reaches

the automatic anti-toe trap device and then stops. Let go of DOWN button; after app. 1 sec. reactivate it and the

lowering will continue until the lift reaches bottom position.

T61720

3

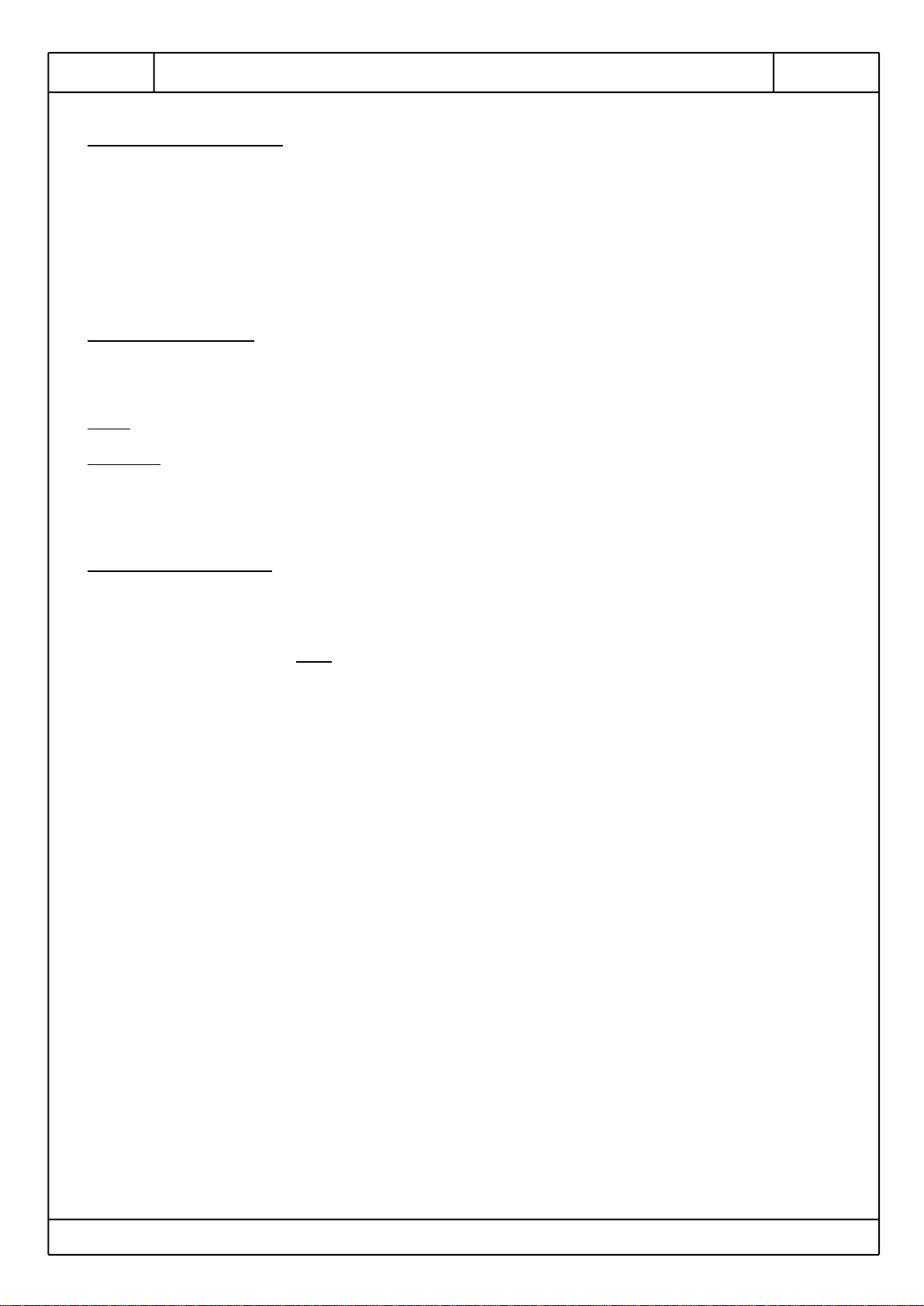

Adjust the platforms to the wheel track of the vehicle.

Place the vehicle centrally on the platforms compared

to the wheel track.

It is not allowed to operate the main lift while the vehicle is raised on one or two scissor jacks and it is not

fastened.

WARRANTY:

This lift is guaranteed for one year, covering faults due to manufacturing or material defects, provided that the

installation, operation and maintenance instructions are observed.

IMPORTANT ! Product liability accepted only if solely original spare parts have been used.

MAINTENANCE

Oil level check Check regularly the oil level in the reservoir under the pump. Fill up as necessary, correct oil

level is in the middle of the oil glass alternatively of dip stick.

Oil change First oil change after one year of operation, thereafter every 6 years.

Oil contents Approx. 8 l (for pump unit with built-on electric motor)

= 6.5 l (for pump unit with plunged electric motor)

Oil type See page 8

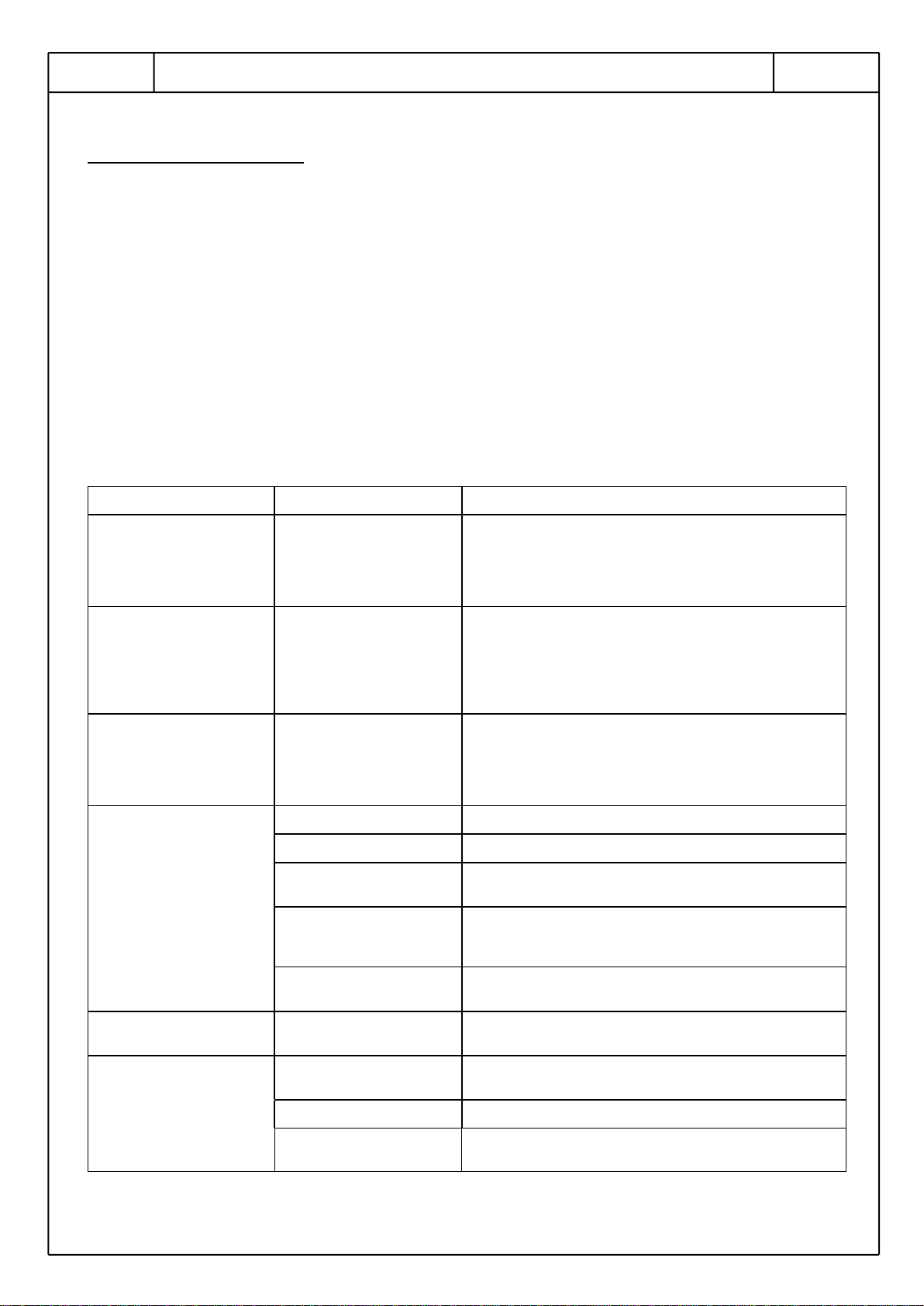

Lubrication and maintenance

Check and lubricate it at least once a month as follows:

Where

What

When

Axles for cable pulleys (with

grease nipples)

Grease

Once a month

Cables and rollers *)

Lubricating oil

Once a month

*) Check cables for wear

CLEANING

Cleaning of 4-post surface mounted lifts to prevent corrosion damages.

Corrosive fluids as brake fluid, oil, fuel or other solvents must be wiped off immediately, otherwise damage will

occur to the coating.

Special attention must be paid to the corrosive effect of salt in fall and winter periods.

The cleansing agents must not have any abrasive effect, nor contain solvents.

The lift must be cleaned at least once a week.

The lift must be cleaned with a non-corrosive cleansing agent.

T61720

Revision:

4

Clean and wipe the lift according to the following scheme:

When:

Where:

How:

Remarks:

Every week

Platforms

Clean and wipe

Wearing surfaces must be

slightly oiled

Drive-on ramps

Post / base plate

Alu rails for jack

Cross beams

Rails

Bradbury Equipment does not accept any claim concerning the paint peeling off or corrosion damages caused by

missing or insufficient cleaning or maintenance.

Repair of damages:

Repair of damages on the coating must be carried out immediately in order to minimize the extent of the repair.

The damages will typically be:

1. Damages which do not affect the metal surface but affects the coating itself

2. Damages going down into the metal surface.

Repairs:

Contact Bradbury Equipment for guidance.

Order number for repair paint is to be seen in the spare parts list and contains basic cleanser, primer and paint

together with instructions for repair of paint damages.

Please state RAL number of paint.

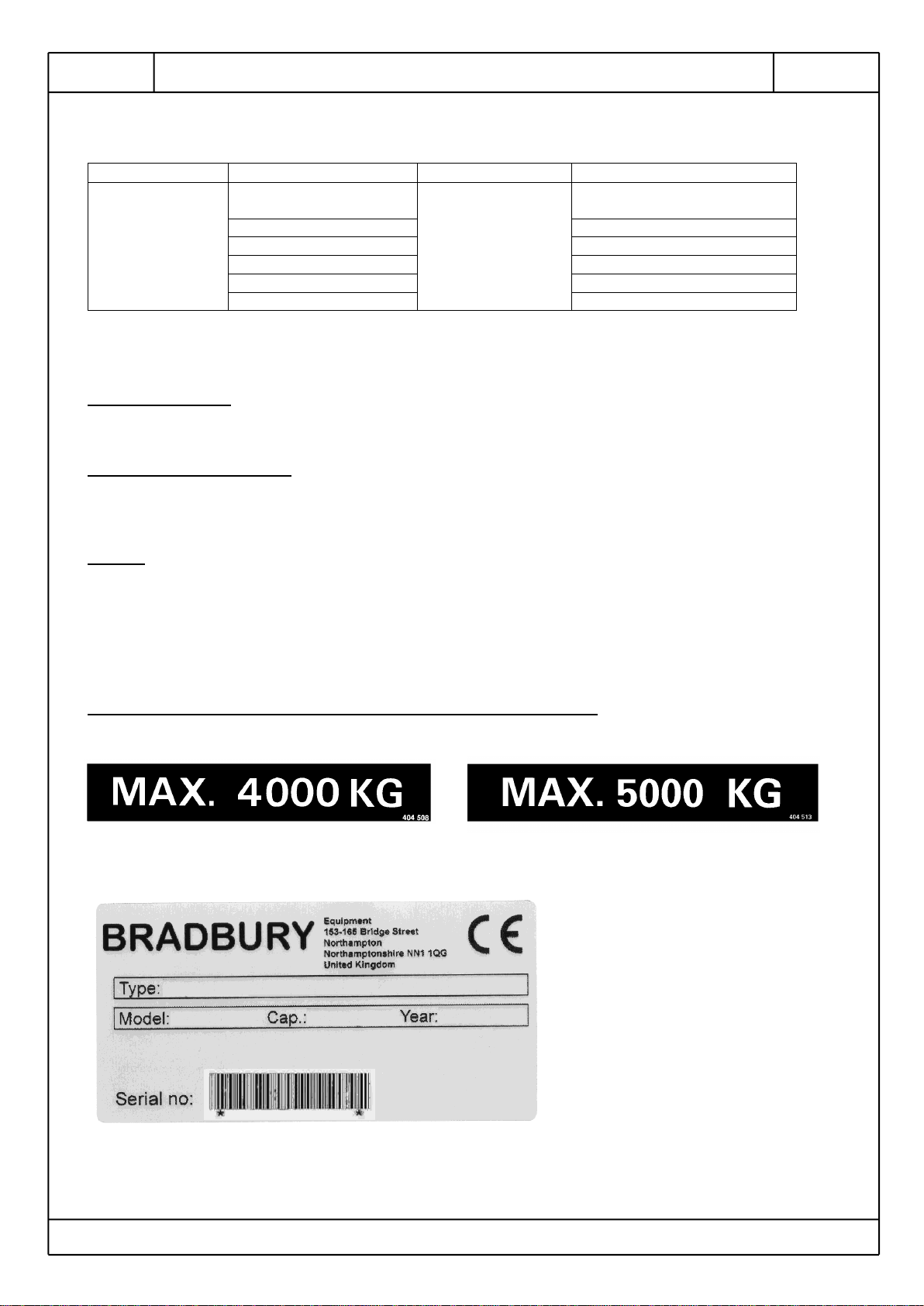

CHECK THAT THE NECESSARY LABELS ARE PLACED ON THE LIFT:

H4443 H4543

Name plate with the following data:

T61720

5

One of following load distribution labels:

H4443 H4543

Operation and maintenance instructions:

Alternative labels:

T61720

Revision:

6

ADJUSTMENT OF CABLES

Steel cables will stretch depending on the operational load and therefore require adjustment as follows:

a. Load the lift with approximately 2500 kg (5500 lbs).

b. Switch off air supply. Adjust wires to make the 4 ratchets engage simultineously when UP-button is activated.

c. Raise lift to top position. Check distance from underside of ratchet to underside of hole in ratchet rail; this

distance must be min. 20 mm.

d. Lower the lift to bottom position and check that the platforms rest against their stops. If not, adjustment of

cables is necessary.

CONTROL OF CABLES

Check cables for wear at the monthlylubrication intervals and replace as necessary (see below paragraph

concerning scrapping).

NOTE: The monthly lubrication with thin penetrating oil reduces cable wear and prolongs cable life appreciably.

GENERAL: At least once a year the cables must be checked-up by an authorized engineer.

Contact your distributor for the name and address of the nearest authorized service shop.

If documentation on cables and/or cable construction is required, please state the stamp on the cable lock. On

this request, copy of original certificate will be forwarded.

SCRAPPING OF CABLES

The steel cable must be discarded when:

•the cable is worn-down on more than10% wear of its nominal diameter

•an individual wire is worn more than 1/3 of the wire diameter

•the number of wire ruptures on a twisting length exceeds 10 on any spot of the cable

•the cable has a kink (pulled-out loop)

•the cable is flattened or cornered, even if there is no wire ruptures

•the wires in a strand are burst

•the cable is damaged by corrosion, even if there is no wire ruptures

•the cable has been damaged through chemical influence.

T61720

7

SERVICE

High pressure cylinder replacement - main lift

To be carried out bytrained personne. Please contract your dealer.

a. Raise the lift to the appropriate working height and allow the safety ratchets to engage.

b. Remove cables from yoke.

c. Remove lock nut and screw off yoke. If the piston rod is seized in the yoke, protect the rod surface with either

rubber or fibre before using a pipe wrench.

d. Remove pipe connection to the cylinder, push the piston rod in until the thread reaches the stuffing box and

remove the clip holding the cylinder to the platform.

e. Fit the new cylinder in the reverse order as above.

f. Raise the lift to the top and lower again to the floor to vent the new cylinder.

g. Test the lift under load and check pipe connections and stuffing box for possible oil leaks.

Replacement of packings in high pressure cylinder

To be carried out bytrained personnel. Please contact your dealer.

Spare parts kit

Spare parts kit for the cylinder contains above mentioned seals:

792425 (AC cylinder with external stuffing box)

792426 Piston seals kit

Spare parts

In order to ensure correct spare parts deliveries please state part number, designation, and quantity (to be seen

from spare parts list included in delivery) as well as lift serial number and year of production (to be seen from serial

number plate).

EMERGENCY LOWERING (In case of power cut-out) (not single phase lifts)

Turn mains on 0-position.

Bymeans of a jack raise one corner of the cross beam 3-4 mm. Pull out the ratchet and block it with a piece of

band. Repeat this in the 3 other corners.

Remove cover of pump unit.

Open carefully emergencylowering valve and lower lift carefully to bottom position. Close emergencylowering valve

again and re-fit cover.

T61720

Revision:

8

OIL SPECIFICATIONS

- Semi-hydraulic lift

(oil in lift cylinder)

- Full-hydraulic lift

- High-pressure No lift

- 4-post lift

- Mistral H

- Pit jack

- All-purpose lift

- Presses

- Scissor lift

- 2-post hydraulic

surface-mounted

- Servicemaster

Lubrication oil for

high-pressure lift

Additives:

Anti-foam, anti-corrosion, anti-oxidation

Other characteristics:

Water-separating

Viscosity:

(cSt=mm²/s)

75-120 cSt (40°C)

215 cSt (0°C)

32 cSt (40°C)

140 cSt (0°C)

22 cSt (40°C)

65 - 110 (40°C)

Viscosity index:

Min. 90

150

90

min. 70

Pour point:

Max. -10°C

Max. -10°C

Max. -10°C

Max. -10°C

ARAL

Aral vitam gf 100

Aral konit 30

AVIA

Abilub hydr.oil rsl 100

Avilub mk 2000

BP

Energol hlp 100

Bratran hv 32/shf 32

Bartran hv 22

Vannellus m 2030

CHEVRON

Hydraulic oil 100

Mechanism lps 32

EP industrial oil 68

GALP

Hidrolep 100

NR 30

ESSO STATOIL

Nuto hp 100

Hydraway hv 32

Hydraway hv 22

Protectway 32

FINA

Hydran tsx 100

Hydran ts 32

Hydran ts 22

Arusan 30

GULF - Q8

Q8 haydn 100

Q8 haydn 32

Q8 haydn 22

Q8 wagner 68

MOBIL

Mobil dte 18

Mobil dte 24

Mobil dte 22

Mobilarma 524

NYNÄS

Td 39 ex

Td 31 ex

OK

Ok hydraulic oil 65

Super hydr. oil 32

Ultima eph 68

SHELL

Tellus oil (S) 100

Tellus oil 32

Tellus oil 22

Remula x 20 w

NOROL

Hydraulikolje hm 100

Lagringsolje sae 20

TEXACO

Rando oil 150

Rando oil hd 32

Rando oil hd 22

Regal oil R&O 100

IGOL

Sonhodro 100/hydro 30

Relax

VALVOLINE

Ultramax hlp 100

Ultramax hvlp 32

Ultramax hvlp 22

Ultramax hlp 68

SUNOCO

Sonvis 8100 wr 100

Sunvis 832 wr-hv

Sunvis 822 we-hv

Sunfill 2630

ELF

Elf olna 100

Olna ds 32

Olna ds 22

Olna ds 100

CASTROL

Hyspin aws/awh 100

Hyspin awh 32

Hyspin aws 22

Rustilo 652

T61720

9

TROUBLE SHOOTING CHART

In case of breakdown check the following points:

1. Electricity cut

2. Main fuses

3. Motor starter

4. Electric motor

5. Cable fracture

6. Obstruction under lift

If these points are found in order but the lift is still not working, the safety system has probablybeen activated, and

the lift must not be started or repaired by unqualified staff. Contact the nearest authorized service shop.

Do not start repairing the lift until the main switch has been cut off.

Do not disconnect the safety system and do not operate the lift after breakdown and prior to repair.

SYMPTOM

CAUSE

REMEDY

A. Platforms no longer

horizontal when

hanging in cables

under load (approx.

1000 kg, 2200 lbs)

One or several cables

stretched

Adjust cables (see page 6)

B. Platforms no longer

horizontal when res-

ting on the ratchets

Incorrect adjustment

Adjust platforms and cross beams until they are horizontal.

Slacken nut under top plate for rail. Raise or lower ratchet

rails as required by means of adjustment bolts in top of

posts. After adjustment tighten lock nut under top plate for

rail. Ratchet rails should preferably be adjusted to lowest

possible position.

C. Activation of control

to lower lift from

topmost position

does not release

ratchets

One or more of the

cables have stretched

Adjust cables (see page 6).

D. Ratchets are not

released regardless

of parking height

Air source failure

Cure fault

Incorrect air pressure

Cure fault (min. 7 bar - max. 10 bar)

Platforms are not lifted

free from ratchet rails

Raise lift a little and lower.

One ratchet binding

Let an assistant operate UP-button so that lift ascends in

small jerks. Meanwhile pull ratchet free manually. Use pliers

or grips.

Defective solenoid

valve

Replace solenoid valve

E. Ratchets fail to

activate

Air system blocked

Strip and clean air system

F. Oil leakage

High pressure hose

defective

Replace hose

Leaks at fittings

Tighten

Cylinder seals

defective

Replace or renovate cylinder

T61720

Revision:

10

TROUBLE SHOOTING CHART (continued)

SYMPTOM

CAUSE

REMEDY

G. Unusually high

noise level

Pump worn

Replace pump

Lift overloaded

Max. load - see decals

Seal in high pressure

cylinder defective

Replace or renovate cylinder

Incorrect post position

Re-position posts according to installation instructions

Oil pressure release valve

out of adjustment

Adjust: 4 t = 230 bar

5.2 t = 320 bar

H. Lift cannot ascend

Overloading

Max. load - see decals

Insufficient pressure from

pump unit

See step M

I. Lift cannot descend

Pump does not start

See step L

One or more of the ratchets

still activated

Lift free from ratchet rails before lowering

Air system blocked

See step E

J. Lift cannot reach

topmost position

Insufficient oil in pump unit

Fill up oil until middle of oil glass/dip stick with

platforms at floor level. Oil type: see oil specifications

on page 8.

Incorrect cable adjustment

(too long)

See page 6

K. Platform descends

when ratchets are

not engaged

Leaks in hydraulic system

See step F

Lowering valve/ non-return

valve leaking (internal in the

pump unit)

Call authorized service engineer

L. Pump unit cannot

start

Electric failure

Check fuses.

Incorrect electric connections

Call authorized electrician

Fault in control box

Faulty electric motor

Defective pushbutton

Replace

M. Pump unit delivers

none or insufficient

pressure

Pump defective

Replace pump

Air in hydraulic system

Lower platforms to bottom position without load and

keep pressing DOWN-button for

approx. 20 sec.

Non-return valve or oil

pressure relief valve defective

(internal in pump unit)

Call authorized service engineer

T61720

11

CONTROL LIST FOR H4443/H4543

CHECK that the technical manuals are delivered with the lift (installation instructions, operation and

maintenance instructions, spare parts list, the EC-certificate of conformity, the electrical diagram in

the control box)

CHECK that all components are enclosed (see installation instructions T70729 and the accessory kit packing

list)

CHECK the lift for anypaint damages occured during transportation, or paint faults from the

production

Follow the installation instructions T70729 delivered with the lift and check the following points:

PLATFORMS AT

FLOOR LEVEL

Cross beams rest against their stops at floor level (all cables loose)

Posts are vertical in both directions

Right-hand platforms can be slid freely along cross beams

The two nuts for cables at top of posts are counter-tightened

Eccentric brake sensoryrollers are free to rotate on axles

Oil level in accordance with "oil level control" (oil level: middle of sight glass)

Important signs/decals:

* Max. capacity

* Maintenance + safety instructions (placed on control post)

* Several warning labels

* Name plate with CE-label

PLATFORMS

HANGING IN

RATCHETS AT

APPROX. 1 M'S

HEIGHT

High pressure hose fittings are tight

Armoured hose hangs freely as a "U" without strain

Air system checked for leaks

Platforms and cross beams are horizontal when lift is parked in ratchets

Cables are correctlyfitted (see installation drawing)

NON LOADED

LIFT

Excess-pressure valve is activated when platforms reach the topmost

position (audible)

LOADED LIFT

(APPROX. 1.5 T)

Platforms can be parked in the topmost ratchet holes (cable adjustment)

Platforms can be released and lowered from topmost ratchet holes

(tolerance approx. 20 mm)

Nylon slide blocks on cross beams must not touch (tolerance 0-0.5 mm)

(post adjustment –cross beam adjustment). Check that ratchet rail does not fret the

cross beam

Platforms horizontal when hanging in cables with load and no air connected.

If the lift is adjusted correctly, ONE click is to be heard from the ratchets when raising

the lift. If not - adjust.

INSTRUCTION

The end user has been thoroughlyinstructed in correct use and maintenance

CONCLUSION

Write any defects/faults on the enclosed note-scheme and return/fax a copy of this control

list (both pages 11 and 12) to:

Bradbury Equipment

153-165 Bridge Street

GB- Northampton NN1 1QG

England

Tel. +44 (0) 1604 828 648

RECEIPT

The above check-up has been made and the lift has been tested with a vehicle

(total weight kg)

Serial No. of lift: Installation date:

Responsible workshop manager: Fitter:

T61720

Revision:

12

NOTES

Other manuals for H4441

1

This manual suits for next models

3

Table of contents