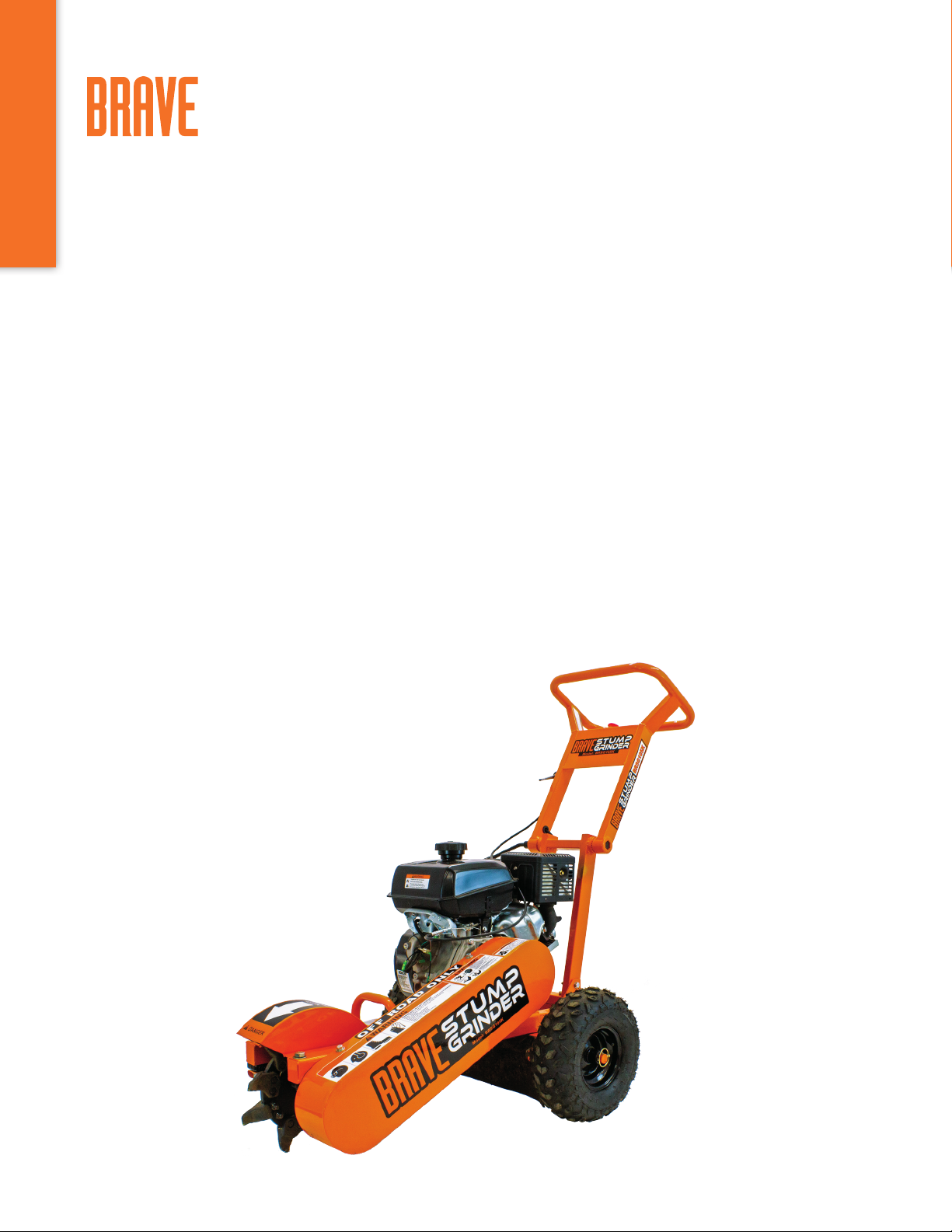

Brave BRSG105K User manual

BRSG105K

STUMP GRINDER OWNER’S MANUAL

1-800-350-8739

WWW.BRAVEPRODUCTS.COM

20195 S. DIAMOND LAKE RD, SUITE 100, ROGERS, MN 55374

MBRSG105K

Place serial tag here

MODEL: BRSG105K

Your Brave grinder is intended for outdoor-use only and can be used to remove many tree stumps and

exposed root systems 9” high or lower to ground level. Approach the stump from the top, cutting straight down.

Raise up out of the cut, move over in the desired direction, plunge again. Repeat these steps across the entire

stump. Make sure you completely read and understand this manual before using the grinder for the first time.

WARNING

READ and UNDERSTAND this manual completely before using the grinder! Failure to properly operate,

and maintain this grinder could result in serious injury or death to the operator or bystanders.

All machines have hazards associated with their operation. This stump grinder has certain special hazards,

which you must be aware of. As an operator or owner you have a duty to be aware of these hazards and know

preventive measures to take to avoid them. When reading this manual pay particular attention to avoiding these

hazards.

In particular, be aware of the following:

• Know location of buried electrical and other utility lines.

• Do not allow children or untrained adults to operate.

• Wear eye protection and other personal protection against flying rocks and debris.

• Check that cutter wheel teeth are secured, sharp and not missing.

• Do not operate if tethered safety switch fails to stop engine when released away/pulled.

• Make sure no children or bystanders are within 75 feet (23 meters) of stump grinding operation.

• Protect cars, windows and other objects within 75 feet (23 meters) from flying debris.

• Be prepared for machine “kickback” when initially contacting the stump.

• Be aware of potential for carbon monoxide (CO) poisoning.

• Prevent fires/explosions from fueling.

• Do not attempt to perform adjustments, declog or clean unit while engine is running.

• Avoid burns from engine or hot exhaust.

• Avoid using in wet or icy conditions where falls may occur.

• Check all hardware is tight before operation.

• Clean area free from all rocks and stones.

Details about these hazards are found throughout the manual and are summarized at the end of the manual under

“Important Safety Information.”

STOP!

ADD ENGINE OIL & FUEL: Your stump grinder requires assembly and that you add

engine oil to crankcase, fuel to tank. Review all assembly instructions prior to assembly.

INSPECT COMPONENTS: Closely inspect to make sure no components are missing or damaged. See the

“Receiving Your Unit” section for instructions on whom to contact to report missing or damaged parts.

2 | BRSG105K REV A

TABLE OF CONTENTS

SECTION I: ASSEMBLY ............................................................3

STEP 1: INSPECT THE PACKAGING......................................................4

STEP 2: WHEELS & AXLE ..............................................................5

STEP 3: HANDLE TOWER ..............................................................6

STEP 4: THROTTLE ...................................................................7

STEP 5: HANDLE & WIRING CONNECTORS ..............................................8

SECTION II: SAFETY & OPERATION .................................................9

YOUR KOHLER ENGINE ..............................................................10

SAFE PRACTICES & GENERAL INFORMATION ...........................................11

QUICK START & TROUBLESHOOTING .................................................12

ADJUSTING THE DRIVE BELTS ........................................................13

TETHERED SAFETY SWITCH .......................................................... 14

SUMMARY OF GENERAL SAFETY INFORMATION .......................................15

SECTION III: PARTS & SCHEMATICS ................................................19

SCHEMATICS .......................................................................20

PARTS LIST .........................................................................21

WARRANTY.........................................................................22

WARRANTY REGISTRATION FORM ....................................................23

ENGLISH

SECTION I

ASSEMBLY

4 | BRSG105K REV A

ASSEMBLY

CHECK THE PACKAGING

STEP 1: INSPECT THE PACKAGING

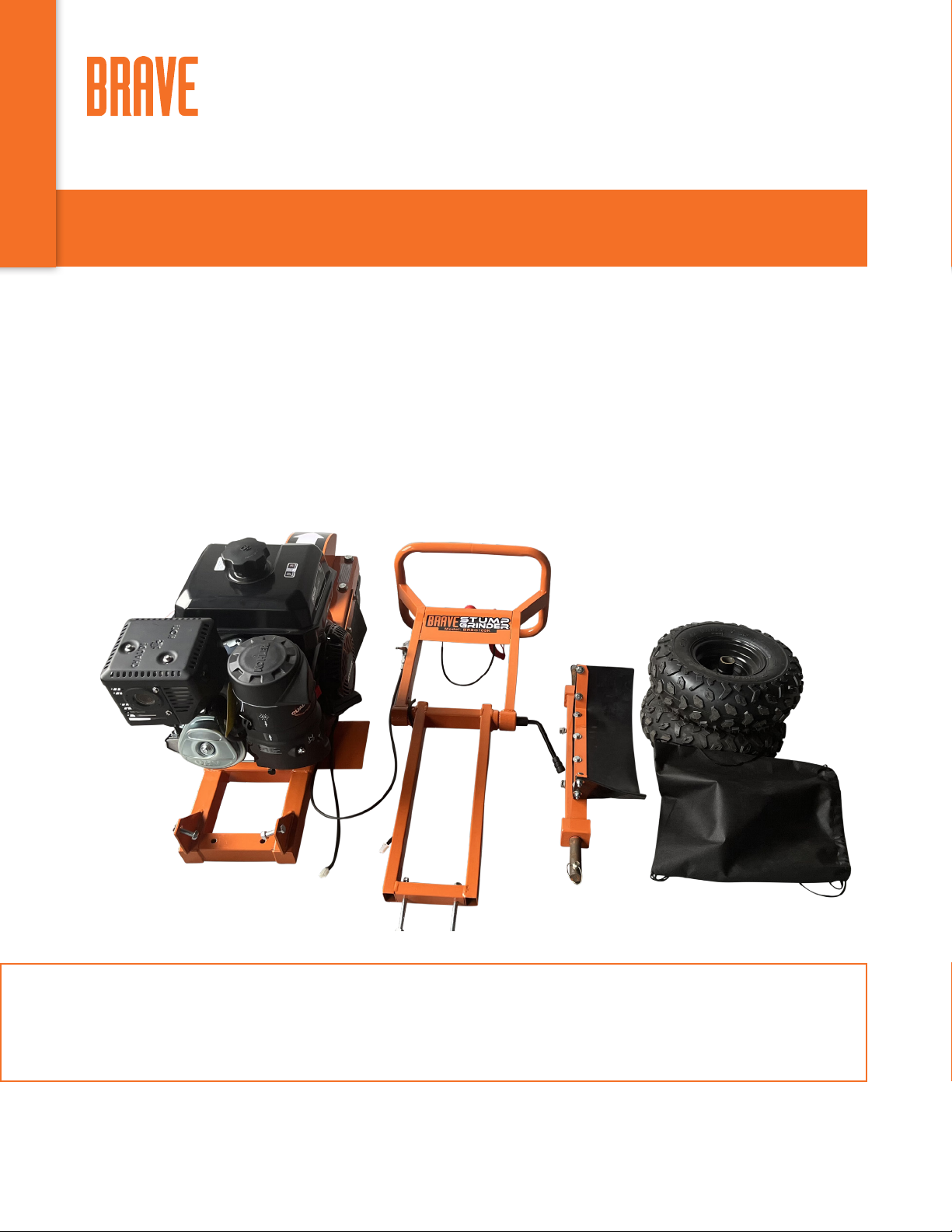

Open and unpack all items. Leave lots of working space. Inspect all parts.

The Stump Grinder is shipped in a crate. Leave the sides folded down and use as your work

space.

NOTE: Upon inspection of parts, if you find any damage or missing parts please call BRAVE

at 1 (800) 350-8739 or contact us via our website at www.braveproducts.com. We will

replace any damaged or missing parts to you for free. Please do not return to the store.

ENGLISH

BRSG105K REV A | 5

ASSEMBLY

STEP BY STEP INSTRUCTIONS

STEP 2: WHEELS & AXLE

1. Slide wheels on to the axle and install the lynch pins.

2. For pivot grinding, insert the pin through the wheel hub and axle to inhibit movement of

desired wheel.

3. Pin only the axle to allow the wheel to spin freely.

4. During transport in trailer or pickup, pin both wheels for dual wheel brakes.

5. Install axle on to frame with two bolts and hardware provided.

PIN FOR FREE ROLLING

BOLT AXLE TO FRAME

PIN HOLE FOR WHEEL BRAKE

ENGLISH

6 | BRSG105K REV A

ASSEMBLY

STEP BY STEP INSTRUCTIONS

STEP 3: HANDLE TOWER

1. Mount the handle tower with the bolts provided.

2. Connect the two wire connectors.

1

2

ENGLISH

BRSG105K REV A | 7

ASSEMBLY

STEP BY STEP INSTRUCTIONS

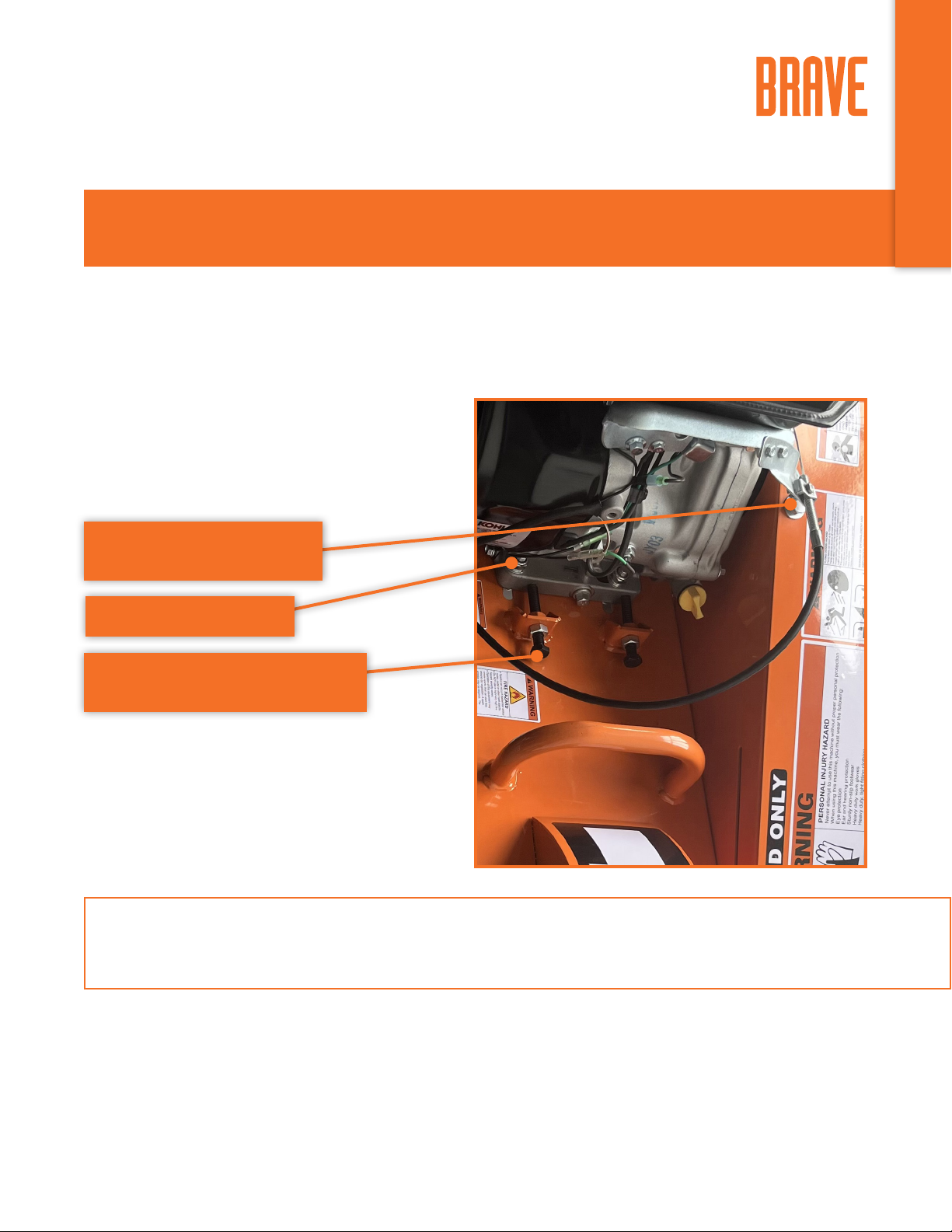

STEP 4: THROTTLE

Note: Throttle tension adjustment nut. Tighten if throttle becomes loose

THROTTLE TENSION

ADJUSTMENT NUT

ENGLISH

8 | BRSG105K REV A

ASSEMBLY

STEP BY STEP INSTRUCTIONS

STEP 5: HANDLE & WIRING CONNECTORS

1. Install the bow handle with the long bolt.

2. Connect the wiring connectors.

1

2

ENGLISH

SECTION II

SAFETY & OPERATION

10 | BRSG105K REV A

SAFETY & OPERATION

YOUR KOHLER ENGINE

Read the Kohler engine manual supplied with your unit for full engine operation, safety, and

maintenance instruction.

1Air Filter - Summer and Winter Positions

2Gas - Use Mid Grade or Higher

3Choke - Left is On / Right is O (Run Position)

4Gas On / O Switch - Left is O / Right is On

5Pull Starter - Pull Tight - Then Pull Start

6Oil - Fill to mark 10W30, will not start if oil is low, has low oil shuto

protection. Two yellow caps are oil fill caps, use either one to fill oil.

2

1

3

4

5

6

ENGLISH

BRSG105K REV A | 11

SAFETY & OPERATION

SAFE PRACTICES & GENERAL INFORMATION

BEFORE PULL STARTING ENGINE

• Clear area of all people and property that could be damaged.

• Flying projectiles from operation can cause injury.

• Wear safety glasses, hearing protection, and gloves.

• Do not wear loose fitting clothes that could get stuck in the moving parts of the machine.

• Children should not run this equipment.

• Stay alert of your surroundings and persons that could appear in the area of operation.

THIS UNIT IS A DIRECT DUAL BELT DRIVE

• No clutch to slip or burn up, but your belts will need to be tightened and checked on a

regular basis to maintain 100% cutting power.

• Tip the stump grinder up with the cutters o the ground when pull starting.

PERFORMANCE OPERATION

Approach the stump from the top, cutting straight down. Raise up out of the cut, move over in

the desired direction, plunge again. Repeat across the entire stump. Move side to side to base

o the stump. Adjust your bow handle for extra comfort during operation.

• For pivot grinding, set one of your wheel brakes on using the pin provided.

• To move the machine forward with the brake on, allow the rotating teeth against the stump

to pull the unit forward.

• Tighten all bolts and teeth before each use. Teeth are not covered under warranty. Clean all

stones and rocks away from the operating area, check for metal stakes and or nails in the

tree stump before cutting.

NOTE: Kohler engines have a low oil shuto to protect the engine, tilting the grinder higher

than 12 inches at an angle can cause the oil to roll back and the low oil sensor will shut the

engine o. Cut your stump 9 to 10 inches o the ground so you don’t trip the sensor on the

engine.

READ AND OBEY ALL WARNING LABELS ON THIS MACHINE

ENGLISH

12 | BRSG105K REV A

SAFETY & OPERATION

QUICK START & TROUBLESHOOTING

QUICK START SETUP

• Add 10W30 oil to the engine

• Add Gas

• If pivot grinding side to side, pin one wheel into pivot brake hole, other wheel free turning

• Insert tether into switch located on handle

• Half throttle (choke optional for cold starts)

• Tip the unit back with the cutters o the ground

• Pull start the engine

STUMP GRINDING

• Engine set on highest speed

• Hold tight on bow handle with both hands

• For plunge cutting, lower cutters into top of stump, grind to the depth of the cutters

• Raise cutters up and move over for next cut, repeat

• Pivot cutters from side to side to face o remainder of the stump

TROUBLESHOOTING

ENGINE WON’T START

• Ensure tether is instered into switch located on handle properly. Check engine oil and

gas level. Ensure red “slap” on/o switch, mounted on handlebar is spring loaded in the

up/run position.

• Unplug wire from On/O switch located at the base of the handle (Step 5 of Assy Instruc-

tions - Pg 8) - if engine starts, replace the On/O switch

• Follow your engine manual for further troubleshooting

UNIT VIBRATES

• Check your cutters for missing or loose teeth

• Check your cutter wheel pillar bearing mounting bolts

• Check all belts and pulleys

ENGLISH

BRSG105K REV A | 13

SAFETY & OPERATION

ADJUSTING THE DRIVE BELTS

POWER LOSS AT CUTTER WHEEL

• Check your belt tension - slipping belts cause power loss

• Worn belts - replace

• Belt tension should be set at .25 inch movement above and below normal belt position

• Check your four engine mounting bolts, loose engine bolts will create loose belt tension

NOTE: Use Brave OEM replacement belts for top performance.

LOOSEN 4 ENGINE BOLTS

ADJUST BOLTS EVENLY TO MOVE

THE ENGINE TO CHANGE BELT

REMOVE FOUR COVER BOLTS

AND REMOVE BELT COVER.

ENGLISH

14 | BRSG105K REV A

THIS STUMP GRINDER COMES EQUIPPED WITH A TETHER SWITCH TO

ENSURE THE OPERATOR CAN TURN OFF THE ENGINE IN CASE OF AN

EMERGENCY SITUATION.

1. Before operation, please ensure that the Safety Rope (67) is tethered to the Safety Switch

and the operator (66).

2. You can locate the tethered safety switch on the left side of the Handle (62).

SAFETY & OPERATION

TETHERED SAFETY SWITCH

2

1

OPERATORS SHOULD BE TETHERED TO

THE SAFETY ROPE AT ALL TIMES. FAILURE

TO FOLLOW THIS INSTRUCTION CAN

RESULT IN SERIOUS INJURY.

WARNING

ENGLISH

BRSG105K REV A | 15

Summary of Important Safety Information

This section provides a summary of the various safety procedures and measures that have been

presented throughout the manual. Keep this summary handy and refer to it to refresh your memory

about how to safely use your grinder.

WARNING

Carefully read and make sure you understand the following safety information before using

the grinder. Improper use or maintenance of the grinder can result in serious injury or

death from fire/explosion, carbon monoxide poisoning, lacerations, entanglement or

burns. Damage can also occur to windows, siding, vehicles, and bystanders from chips

and debris which can become projectiles.

General

• Read manual. Read this Owner’s Manual and the engine Owner’s Manual completely before

attempting to use and service the grinder. Serious injury or death can result if safety instructions are

not followed.

• Instruct operators. The grinder owner or rental company must instruct all operators in safe grinder set-

up and operation. Do not allow anyone to operate the grinder who has not read the Owner’s Manual

and been instructed on its safe use. Make sure Owner’s manual is with the grinder.

• Adults only. Only trained adults should operate and service the grinder. Do not let children operate.

• Under the influence. Never operate, or let anyone else operate, the grinder while under the influence

of alcohol, drugs, or medication.

• Intended use. Carefully read about and understand the intended use of this grinder. Do not use for

other purposes, as unforeseen hazards or equipment damage may result.

• Controls and safety labels. Learn how to use the machine and it’s controls safely. Understand and

follow all safety labels.

• Weather. Never use in foul, bad or questionable weather, which causes a slippery ground condition.

• Prohibition Against Modifications. Never modify or alter the grinder in any way. Modifications can

create serious safety hazards and will also void the warranty.

• Fuel/exhaust system. Never modify the exhaust system, fuel tanks, or fuel lines. Carbon monoxide

poisoning, fire, or explosion could result.

• Guards. Do not operate grinder unless all guards and cover shields, which prevent access to moving

parts and pinch points, are in place. Failure to guard the power transmission mechanisms may result in

serious injury or death.

Safety – Before Use

Know how to operate

• Review safety rules. Before use of this grinder, review the “Safe Operation.” If you have an implanted

medical device, consult a physician before using this device.

• Know how to operate. Be thoroughly familiar with all controls and with the proper use of the

equipment. Know how to stop the grinder quickly if needed.

• Utility marking. Call 811 or your local utility company for utility marking 3 days before stump grinding.

Trees can grow on top of and around underground wiring that was installed many years before a tree

was planted.

Getting Ready

• Flying debris. Clear area of objects such as stones, toys, steel wire, etc. that could become caught in

moving machine parts and ejected as a projectile.

• Operate OUTSIDE only – dangerous carbon monoxide exhaust! Grinders give o carbon monoxide

exhaust, a poisonous gas that can kill. You CANNOT smell it, see it, or taste it. ONLY run grinder

OUTDOORS and at least 20 feet (6 m) from the home, away from windows, vents and air intakes,

to allow proper ventilation. If you start to feel sick, dizzy, or weak while using the grinder, shut o the

engine and get to fresh air RIGHT AWAY. NEVER run grinder engine inside homes, garages, sheds, or

other semi-enclosed spaces. These spaces can trap poisonous gases.

ENGLISH

16 | BRSG105K REV A

• Cooling ventilation. The grinder needs adequate, unobstructed flow of air to allow for proper cooling of

engine and grinder head. Do not allow debris to accumulate and block airflow.

• Transporting. During transporting, take precautions to make sure stump grinder will not tip over and

cause a fuel leak hazard.

• Hot exhaust - fires. Exhaust from engine can be extremely hot and cause fire. Position muer at least

7 feet from combustible objects during operation.

• Fire extinguisher. Keep a fire extinguisher rated “ABC” by the National Fire Protection Association

nearby is always recommended when using gasoline operated machinery. Keep it properly charged

and be familiar with its use.

Personal protective equipment

• Hearing protection. The use of ear plugs or other hearing protection device is recommended for those in

close proximity to the grinder while it is operating.

• Eye protection. Wear ANSI approved (in EU, EN166 1F) eye protection when operating the grinder.

• Face protection. A helmet with a full-face visor or mesh visor with protective glasses is recommended.

• Loose / dangling. Loose or dangling apparel, jewelry or hair can become entangled in moving parts.

Never wear jewelry or loose-fitting clothing when operating the grinder.

• Long pants. Wear long, heavy-duty pants to protect legs from ejected materials.

Gasoline Safety

Gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel.

Use extreme care when handling gasoline:

• Fuel outdoors. Fill fuel tank outdoors – never indoors. Gasoline vapors can ignite if they collect inside an

enclosure. Explosion can result.

• Use approved container. Never pump fuel directly into engine at gas station. Static charge can build and

ignite fuel. Use an UL approved fuel container to transfer gas to the engine.

• Running / hot engine. A running engine is hot enough to ignite fuel. Never add fuel or remove gas cap if

engine is running or still hot. Stop the engine and allow to cool at least two minutes before adding fuel.

• Heat / flames / sparks. Keep sources of heat, flame, or sparks away while adding fuel.

• Don’t fill to the top DO NOT overfill the gas tank. Allow at least 1” (2.5 cm) of empty space below the fill

neck to allow for fuel expansion and operation on slopes.

• Don’t fill to the top. Do not fill the gas tank to the top. Gasoline may spill when operating on a slope.

• Replace cap. Replace gas cap securely before starting engine.

• Spills. Clean up fuel spills immediately. Move grinder away from spilled fuel on the ground. Wipe fuel o

engine and wait 5 minutes for excess fuel to evaporate before starting engine. Gas soaked rags should

be disposed of properly.

• On skin / clothes. If gasoline is spilled on your skin or clothes, change clothes and wash skin immediately.

• Inspect fuel system. Check fuel system on a regular basis. Look for signs of leaks, deterioration, chafed or

spongy fuel hose, loose or missing fuel hose clamps, damaged fuel tank, or a defective fuel shut-o valve.

Do not start grinder until needed repairs have been completed.

• Gasoline storage. Store gasoline in a cool, dry place in an UL-approved, tightly sealed container away

from children.

Safety – During Use

• Safety equipment / controls. Always operate the grinder with all safety covers, guards, and barriers in

place and in good working order, and all controls properly adjusted for safe operation.

• Controls. Stay in the OPERATOR POSITION while actuating controls. Never attempt to ride or stand on

stump grinder.

• Know how to stop. Know how to stop the grinder quickly if needed by releasing the tether switch. If this

does not work, do the following in order until unit is stopped. 1. Use on/o switch on handle

2. Engage full choke by flooding the engine.

• “Kickback”. Machine can experience significant “kickback” when operating or first coming into contact

with the stump.

ENGLISH

BRSG105K REV A | 17

• Slipping/Falling. Operating in wet or icy conditions could lead to losing your footing and slipping or

falling.

• Damaged. Do not operate the grinder with damaged, missing, incorrectly adjusted, or broken parts.

Check for gas leak before starting. After opening gasoline valve, smell for gas before starting engine. If

you smell gas, DO NOT start engine. DO NOT light a match. DO NOT flip on an electrical switch. Exit

area immediately and call fire department.

• Carbon monoxide exhaust. The running engine gives o carbon monoxide, a poisonous gas that can

kill you. You CANNOT smell it, see it, or taste it. If you start to feel sick, dizzy, or weak while using

the grinder, shut o the engine and get to fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

• Other exhaust dangers. This product contains or emits chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm. Avoid inhalation of exhaust.

• Smoking/sparks. Never smoke near the running grinder, and never operate near sources of sparks or

flames.

• Hot muer. Never touch hot muer or hot exhaust manifold. Exhaust and engine parts can be very hot

and will burn you.

• Machine’s moving parts. Keep hands, feet, and apparel away from drive belts, cutter wheel, and other

moving parts. Never remove any drive belt or guard while the unit is operating. Contact with belt or

rotating teeth will cause personal injury.

• Refueling. DO NOT refuel the engine until it has cooled at least two minutes.

• Malfunction during operation. Always shut the machine o if any unusual noise or vibration occurs.

• Vibration. Overexposure to machine vibration on a daily basis may lead to circulatory or nerve

damage.

• Adjusting / repairing. Always turn o grinder and remove spark plug or spark plug wire before working

on the grinder to prevent accidental starting. Disconnect battery (on electric models only).

Safety – After use

• Cool engine before storing. Let engine cool for at least five minutes before storing. A hot engine can

be a fire hazard.

• Shut o fuel supply.

• Storage location. Store the grinder in a dry location away from sources of heat, open flames, sparks or

pilot lights – such as water heaters, space heaters, furnaces, clothes dryers, or other gas appliances –

EVEN IF the grinder’s gas tank is empty. Residual gasoline could ignite.

Safety - Inspection/Maintenance

Inspect and maintain your grinder on a regular basis and repair as needed to keep it in safe working

condition:

• Turn o grinder. Always turn o grinder and remove spark plug or spark plug wire before working on

the engine or grinder to prevent accidental starting. Disconnect battery (on electric models only).

• Replace guards / shields. Make sure all guards and shields are replaced after servicing the grinder.

• Burns. Do not touch hot muer. Muer will be hot even if unit is stopped. Allow unit to cool before

servicing.

• Replacement parts. If a part needs replacement, only use parts that meet the manufacturer’s

specifications. Replacement parts that do not meet specifications may result in a safety hazard or poor

operation of the grinder and will void the warranty.

• Cooling ventilation. The grinder needs adequate, unobstructed flow of air to allow for proper cooling of

engine and grinder head. Do not allow debris to accumulate and block airflow.

• Transporting. During transporting, take precautions to make sure stump grinder will not tip over and

cause a fuel leak hazard.

• Hot exhaust - fires. Exhaust from engine can be extremely hot and cause fire. Position muer at least

7 feet from combustible objects during operation.

• Fire extinguisher. Keep a fire extinguisher rated “ABC” by the National Fire Protection Association

nearby is always recommended when using gasoline operated machinery. Keep it properly charged

and be familiar with its use.

Personal protective equipment

• Hearing protection. The use of ear plugs or other hearing protection device is recommended for those in

close proximity to the grinder while it is operating.

• Eye protection. Wear ANSI approved (in EU, EN166 1F) eye protection when operating the grinder.

• Face protection. A helmet with a full-face visor or mesh visor with protective glasses is recommended.

• Loose / dangling. Loose or dangling apparel, jewelry or hair can become entangled in moving parts.

Never wear jewelry or loose-fitting clothing when operating the grinder.

• Long pants. Wear long, heavy-duty pants to protect legs from ejected materials.

Gasoline Safety

Gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel.

Use extreme care when handling gasoline:

• Fuel outdoors. Fill fuel tank outdoors – never indoors. Gasoline vapors can ignite if they collect inside an

enclosure. Explosion can result.

• Use approved container. Never pump fuel directly into engine at gas station. Static charge can build and

ignite fuel. Use an UL approved fuel container to transfer gas to the engine.

• Running / hot engine. A running engine is hot enough to ignite fuel. Never add fuel or remove gas cap if

engine is running or still hot. Stop the engine and allow to cool at least two minutes before adding fuel.

• Heat / flames / sparks. Keep sources of heat, flame, or sparks away while adding fuel.

• Don’t fill to the top DO NOT overfill the gas tank. Allow at least 1” (2.5 cm) of empty space below the fill

neck to allow for fuel expansion and operation on slopes.

• Don’t fill to the top. Do not fill the gas tank to the top. Gasoline may spill when operating on a slope.

• Replace cap. Replace gas cap securely before starting engine.

• Spills. Clean up fuel spills immediately. Move grinder away from spilled fuel on the ground. Wipe fuel o

engine and wait 5 minutes for excess fuel to evaporate before starting engine. Gas soaked rags should

be disposed of properly.

• On skin / clothes. If gasoline is spilled on your skin or clothes, change clothes and wash skin immediately.

• Inspect fuel system. Check fuel system on a regular basis. Look for signs of leaks, deterioration, chafed or

spongy fuel hose, loose or missing fuel hose clamps, damaged fuel tank, or a defective fuel shut-o valve.

Do not start grinder until needed repairs have been completed.

• Gasoline storage. Store gasoline in a cool, dry place in an UL-approved, tightly sealed container away

from children.

Safety – During Use

• Safety equipment / controls. Always operate the grinder with all safety covers, guards, and barriers in

place and in good working order, and all controls properly adjusted for safe operation.

• Controls. Stay in the OPERATOR POSITION while actuating controls. Never attempt to ride or stand on

stump grinder.

• Know how to stop. Know how to stop the grinder quickly if needed by releasing the tether switch. If this

does not work, do the following in order until unit is stopped. 1. Use on/o switch on handle

2. Engage full choke by flooding the engine.

• “Kickback”. Machine can experience significant “kickback” when operating or first coming into contact

with the stump.

ENGLISH

18 | BRSG105K REV A

Special Safety Information on Static Electricity

Static electricity and filling gasoline:

Static electricity can initiate from ungrounded gasoline tanks or containers, from flowing

gasoline, and from persons carrying a static electric charge

Static electricity on numerous occasions has explosively ignited gasoline vapors that were present during

fueling processes, resulting in serious burns to nearby persons. To avoid static electricity while fueling,

certain steps must be followed before and during the fueling process in order to minimize and safely

dissipate static charge build-up.

Filling Portable Containers at Service Stations:

Use a portable container to fill grinder tank. Never fill the grinder’s gas tank directly from the service station’s

fuel dispenser pump – the grinder’s tank is not grounded and the high velocity flow of gasoline from a fuel

pump can cause static electric build-up. Use an approved portable container to transfer gasoline to the

grinder’s tank.

• Use a portable container made of metal or conductive plastic. It will dissipate charge to ground more

readily.

• Fill container on the ground. Never fill the portable gas container while it is sitting inside a vehicle, trailer,

trunk, or pick-up truck bed. ALWAYS place container on the ground to be filled.

• Touch a grounded metal object before starting. Always dissipate static charge from your body before

beginning the fueling process by touching a grounded metal object at a safe distance away from fuel

sources.

• Keep nozzle in contact with container. Keep fuel dispenser nozzle in contact with the portable container at

all times while filling at a service station. Do not use the nozzle lock-open device on the dispenser hose.

About static electricity and fueling

Many common objects can accumulate and retain a static electric charge. Objects made of nonconductive

materials (e.g. plastics) easily accumulate and retain static electric charge, as can objects

made of conductive material (e.g. metal, water) if they are not electrically grounded. The static electric

charge on an object, such as a human body or plastic fuel tank/container, can reach as high as several

thousand volts!

A static electric spark can be generated if the static electric charge stored on an object “jumps” to

another, less charged object. Such a spark can ignite invisible gasoline vapors that are present during

fueling situations.

Typical sources of static electric hazards during fueling

The following objects can accumulate a static electric charge and cause an ignition spark in typical

fueling situations:

• Ungrounded tanks/containers. Any ungrounded fuel tank or container can accumulate a static electric

charge as a result of contact with other objects or friction during transportation. This static electricity can

discharge as a spark to the grounded gasoline dispenser nozzle, as the nozzle is first brought close to the

tank/container at the beginning of the fueling process.

• Flowing gasoline. Most people are not aware that gasoline accumulates static electric charge while

flowing through a hose or pipe. This charge then transfers to and accumulates in the gas tank or container

that is being filled. The total amount of charge accumulation depends on the amount of gas pumped into

the container, the speed with which it is pumped, and whether or not the tank/container is grounded. If

sucient static electric charge accumulates in the fuel tank or container during the fueling process, the

tank/container may discharge a spark to the grounded gasoline dispenser nozzle.

• Persons. A person dispensing the gasoline can carry a static electric charge on their body, typically

resulting from contact with their car seat or electronics. The static electricity can discharge as a spark

between that person’s hand and either the grounded dispenser nozzle or the fuel tank opening

ENGLISH

SECTION III

PARTS & SCHEMATICS

20 | BRSG105K REV A

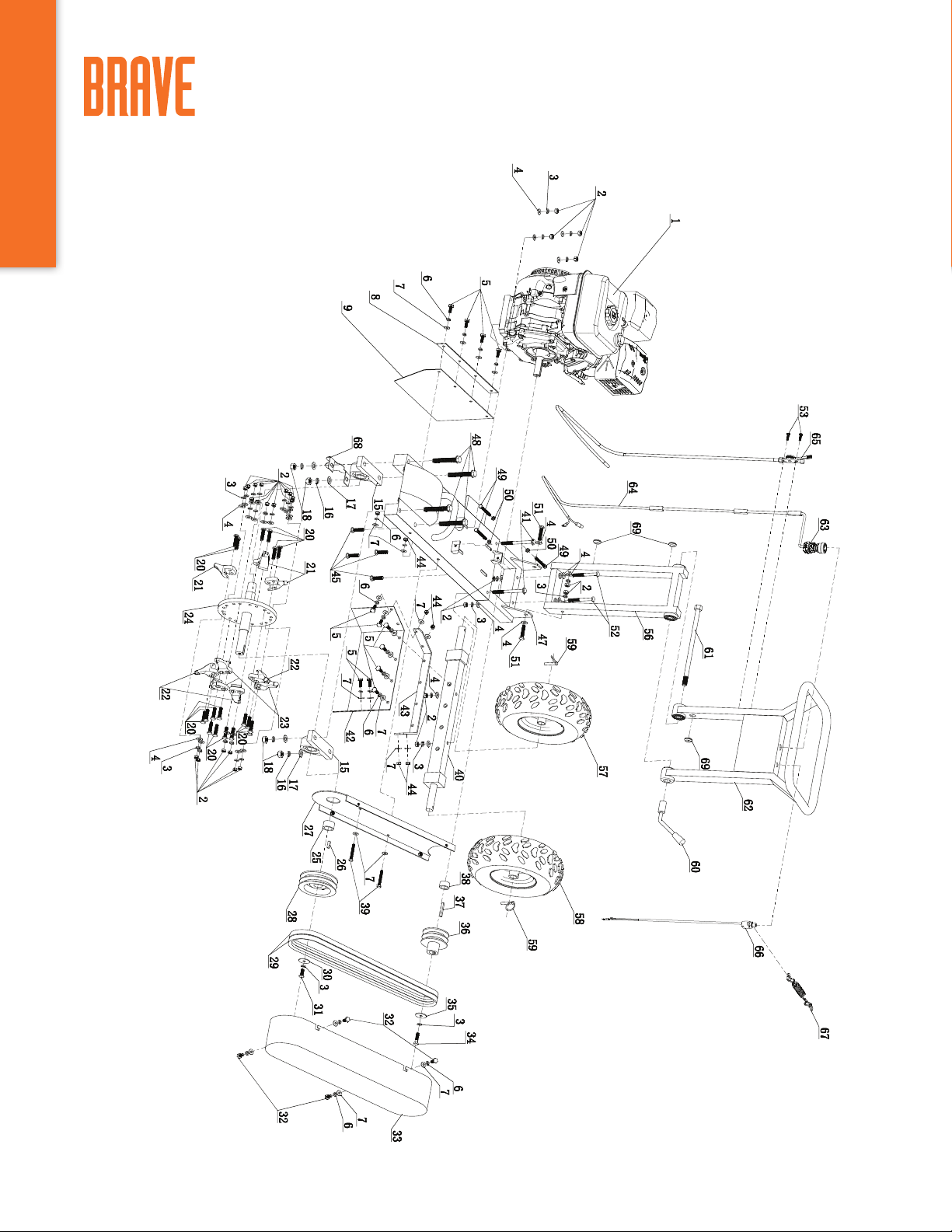

PARTS & SCHEMATICS

SCHEMATICS

ENGLISH

Table of contents