Bray BBU User manual

1

08/20/22

© 2022 Bray International, Inc.

Bray Commercial Division

13788 West Road, Suite 200A

Houston, Texas 77041

BCDSales@Bray.com

Phone: 1-888-412-2729

www.braycommercialdivision.com

Battery Backup Unit (BBU) for Series 70

IOM Manual

2

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications ..................................................4

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Battery Status Indicator .........................................5

Battery Charging ...............................................5

Quick Start Guide ...............................................6

Activating the BBU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacing Batteries .............................................7

Installation Guide ...............................................8

1.0 Purpose ..................................................8

2.0 Tools and Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.0 Bill Of Materials ...........................................8

4.0 Actuator/BBU Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.0 Initial Assembly and Battery Installation . . . . . . . . . . . . . . 9, 10, 11, 12

6.0 Wiring ..................................................13

7.0 Testing .............................................14, 15, 16

8.0 Final Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18, 19, 20

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – www.braycommercialdivision.com

Table of Contents

Bray Battery Backup Unit - Installation, Operation and Maintenance Manual

3

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Safety Instructions - Definition of Terms

Read, Follow and Save these instructions

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE

Used without the safety alert symbol indicates a potential

situation which, if not avoided, may result in an undesirable

result or state, including property damage.

Hazard Free Use

This device left the factory in proper condition to be

safely installed and operated in a hazard-free man-

ner. The notes and warnings in this document must

be observed by the user if this safe condition is to be

maintained and hazard-free operation of the device

assured.

Take all necessary precautions to prevent damage to

the BBU due to rough handling, impact, or improper

storage. Do not use abrasive compounds to clean the

BBU, or scrape its surfaces with any objects.

Configuration and setup procedures are described

in this document. Proper configuration and setup is

required for the safe operation of the BBU.

The control system in which the BBU is installed must

have proper safeguards to prevent injury to person-

nel, or damage to equipment, should failure of system

components occur.

This document does not cover every detail about

every version of the product described. It cannot take

into account every potential occurrence in installation,

operation, maintenance and use.

If situations transpire that are not documented in

sufficient detail, please request the required infor-

mation from the Bray Distributor or Representative

responsible for your area.

Qualified Personnel

A qualified person in terms of this document is one

who is familiar with the installation, commissioning

and operation of the device and who has appropriate

qualifications,

such as:

• Is trained in the operation and maintenance of

electric equipment and systems in accordance with

established safety practices.

• Is trained or authorized to energize, de-energize,

ground, tag and lock electrical circuits and equipment

in accordance with established safety practices.

• Is trained in the proper use and care of personal

protective equipment (PPE) in accordance with estab-

lished safety practices.

• Is trained in first aid.

• In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the

operation, commissioning, operation and maintenance

of equipment in hazardous locations.

4

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Construction and Performance

Power Requirements 24-27 VAC or 30-38 VDC (the minimum voltage is required to provide proper battery

charging). Use dedicated Class 2 non-bonded transformer rated 100 VA per BBU

Power Output

BBU output with 24 VAC supply is 30-38 VDC

On failure of AC/DC supply, Battery output is 24-25.5 VDC

BBU will provide fail open or fail close operation

Battery Monitoring Local LED indicator and voltage free 2-wire normally open contact for remote monitoring

Battery Conservation Automatically shuts-o batteries after one minute or when actuator stops

Battery Monitoring SLA (Sealed Lead Acid) Power Sonic PS1212 or Equal

Current Draw @ 24 VAC 4 years, depended on ambient temperature

Current Draw of Actuator &

BBU with Full Torque Load

800 inlb = 2.0A

2,000 inlb = 3.1A

3,000 inlb = 3.1A

5,000 inlb = 4.1A

Power Protection Two 5 amp, 250 V fast blow, 5x20mm fuses, one for the external power output circuit and

the other for the battery output circuit

Operating Temperature -4ºF (-20°C) to 122ºF (50°C) LED light may not function below -20°F (-29°C)

Housing Die Cast Aluminium, Polyester finish, Nema 4X (IP 65)

Exposed Fasteners Stainless Steel

Battery Specifications

Battery (2) 12 volt 1.4 ampere-hour (AH) rechargeable sealed lead acid battery wired in series

Features

Valve regulated, spill proof construction allows safe operation in any position

Rugged impact resistant ABS case and cover (UL94-HB)

U.L. Recognized under file number MH 20845

Specifications

Battery Case: ABS plastic

Maximum discharge current (7 minutes): 4.2 amperes

4 years, depended on ambient Temperature

Shelf Life (% of nominal capacity at 68°F (20°C)

1 month = 97%

3 months = 91%

6 months = 83%

Temperature

Charge: -4°F to 122°F (-20°C to 50°C)

Discharge: -20°F to 140°F (-29°C to 60°C)

Storage: -20° to 140°F (-29° to 60°C)

1

The BBU should be powered up for a minimum of 12 hours

Wiring

Conduit Entries (2) - 3/4” NPT Terminal Block - 14 to 24 AWG.

Size wires per NEC guidelines with respect to distance

and current draw.

Max Distance Between Actuator and Supply - ft

Torque (in-lbs) 800 2000/3000 5000

I load (Amps) 1.9 3.0 4.0

8 GA 873 785 524

10 GA 549 494 329

12 GA 345 311 207

14 GA 217 195 130

16 GA 137 123 82

18 GA 86 77 52

1

Leaving the battery in an unpowered state for long periods at ambient temperatures greater than 40°F will result in

excessive battery drain.

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their

application. The right to change or modify product design or product without prior notice is reserved.

5

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Operation

The BBU is operated by a micro controller which per-

forms all of the functions pertaining to power man-

agement, battery monitoring and charging, and con-

trol of the Series 70 Servo NXT or On/Off Controller.

The BBU constantly monitors the incoming power. In

the normal mode of operation with power supplied to

the actuator, the batteries maintain a charge and are

in an offline mode. The power applied to the motor is

from the power supply, not the batteries.

When a power loss occurs, the BBU pauses for 5 seconds

and then reads the “Open/Close” fail position switch

setting. The BBU circuitry applies the stored power in

the batteries to move the valve or damper to the full

open or full closed position as initially designated by

the user. The BBU will allow up to one minute for the

actuator to attain the fail position. If the fail position

is reached before one minute, the BBU will detect the

loss of motor current and turn the power off to the

actuator to conserve battery power. The actuator re-

mains in this position until external power is restored

to the unit. When power is restored to the BBU, the

battery charge cycle commences.

Battery Status Indicator

The BBU has a bi-color red/green indicator on the

side of the battery enclosure to provide information

regarding the operation and battery status of the BBU.

Table 1 is a summary of the different indications.

Battery Charging

A battery charge cycle will commence upon the return

of power to the BBU. Charge cycles will require from a

few minutes to several hours depending upon the dis-

charged state of the battery, condition of the battery,

and ambient temperature. When the charge cycle is

complete, the batteries are held in a fully charged state

by applying a voltage which maintains the “Stand-by

Mode” of the battery.

Every 8 hours, a full charge cycle commences which

tests the condition of the batteries. This cycle will nor-

mally last a few seconds with batteries that are in good

condition. Batteries that require replacement will

require a longer period to complete the charge cycle.

After 12 hours, if the batteries cannot attain full

charge, the alarm relay is engaged to indicate that the

batteries require replacement.

Indication Description

Solid Green The BBU is powered and the

batteries are fully charged.

Flashing Green The BBU is powered and the

batteries are charging.

Fast Flashing Red The BBU is not powered and the

actuator is seeking the fail position.

Slow Flashing Red The BBU is not powered and the

BBU is in low power stand-by.

Table 1 - Indicator Lamp Guide

6

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Remove

Battery Cover

Activate Batteries

Power & Command Signal

See page 14 - Section 7.3

Connect Power and Command Signal

per the respective wiring diagrams

found on pages 17 to 19 of this

document or on the lid of the actuator.

Replace Battery Cover &

tighten down screws

11

2

2

3

3

4

4

Quick Start Guide

The large majority of BBUs will be received pre-assembled and pre-wired. Under these conditions, the Quick

Start Guide is applicable. For situations in which the BBU and/or batteries need to be installed, then skip to

the Installation Guide page 7.

7

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

1.0 Purpose

For assembly of a Bray Battery Backup Unit (BBU) to

a Bray S70 electronic actuator.

2.0 Tools and Equipment Required

• Wire Strippers

• Wrench

• Allen Wrench

• Signal Generator

• Power Supply (100 VA Minimum Isolated Transformer)

• Screw Driver

3.0 Bill of Materials

• Series 70 Actuator

• BBU

• Batteries (2)

• Wiring Diagram with applicable Wire Colors

• Mounting Hardware

• O-Rings

Installation

4.1 Wear safety glasses and all other appropriate safety equipment as directed by your governing body.

before performing any of the listed tasks.

4.2 Retrieve all parts required to construct the S70/BBU assembly as specified on your sales order's.

BOM. Some hardware depicted below [Figure 1].

CAUTION: Risk of Property Damage.

Do not apply power to the system

before checking all wiring connections.

Short circuited or improperly

connected wires may result in

permanent damage to the equipment.

IMPORTANT: Do not exceed the electrical ratings of the S70 Actuator or BBU.

CAUTION: Risk of Electric Shock.

Disconnect the power supply before

making electrical connections to avoid

electric shock.

Figure 1

4.0 Actuator/BBU Preparation

8

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

5.1 Remove lid of the actuator [Figure 2].

5.2 Remove four (4) BBU actuator mounting bolts and two (2) conduit plugs from side of S70 actuator [Figure 3].

Figure 2

Figure 3

5.0 Initial Assembly and Battery Installation

9

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

5.3 Disengage the four (4) BBU lid bolts from BBU [Figure 4].

5.4 Remove two (2) battery cover panel screws from BBU [Figure 5].

Figure 4

Figure 5

10

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

5.5 Connect four (4) battery terminals to two (2) 12VDC batteries as shown in the wire color table below

See [Figure 6] for example.

5.6 Gently insert the batteries into the BBU case with the battery terminals positioned nearest

to the circuit board [Figure 7].

Wire Color Description

Battery 1 - Postive

Battery 1 - Negative

Battery 2 - Postive

Battery 2 - Negative

Red

Blue

Orange

Purple

Figure 6

Figure 7

11

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

5.7 Re-attach BBU card plate using two (2) screws previously removed with silver holding cables

crisscrossed like before [Figure 8].

5.8 Add four (4) O-rings to two (2) Long Cap Screws and two (2) Small Cap-Screws [Figure 9].

Figure 8

Figure 9

Figure 10

5.9 Insert these two (2) Long Cap Screws with O-rings into the bottom two (2) holes of BBU base

and assemble to S70 actuator.

5.10 Install the Medium Cap Screws on the top two (2) holes of BBU base that attach to S70 actuator.

5.11 Install two (2) Small Cap Screws with O-rings on top two (2) holes of BBU base [opposite side of

Medium Cap Screws] and secure using Hex Screw Nuts. See [Figure 10] for final BBU attachment

to S70 actuator.

12

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

BLACK

WHITE/RED

MOTOR BBU POWER

DC PWR (-)

DC PWR (+)

STATUS

PGM

FAULT

PWR

OPEN

CLOSE

OPEN

COMMON

CLOSE

24V COMMAND

INPUT

BBU LIMIT SW

COM

OPEN

LIMIT

CLOSE

LIMIT

DRIVE DIR

DRIVE ENABLE

COMMON

HANDWHEEL

COM

OPEN

CLOSE

TORQUE SW

TORQUE

OPTION

OFF ON

24V ON/OFF CONTROLLER

FUSE

1 2

CTSON

6.0 Control Board Wiring

Figure 11

On/Off

On/Off NXT

Servo NXT

6.1 All wiring from BBU to Actuator shall pass through the conduit ports. Do not allow sharp

conduit threads to damage the wire insulation. Use the appropriate Bray S70 wiring diagram for

terminal locations and wire color selection. See [Figure 11] for applicable electronic modules.

Note: The wire diagram will be supplied with the BBU. Contact your Bray Sales Rep or Bray Tech Support if

you need an extra wiring diagram copy.

13

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

7.1 Fail Position (DIP Switch #1) - The actuator position during a power loss is determined by the Close/Open

DIP switch #1 setting [Figure 12] on the BBU. The switch setting is only recognized at the time of a power

failure.

7.2 Control Type Selection (DIP Switch #2) - The BBU needs to be told the type of S70 actuator controller

connected. Use the BBU's DIP switch #2 to select whether the S70 actuator controller is an On/Off NXT

or not. The wiring diagram at the end of this BBU IOM and a paper copy shipped with the BBU, will

provide additional details. [Figure 12]

Figure 12

7.0 Testing

14

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

7.3 Wire the Power Supply and Command Signal Generator according the wiring diagram specific to

your model. Power Supply and Command Signal Generator shall not be powered on yet.

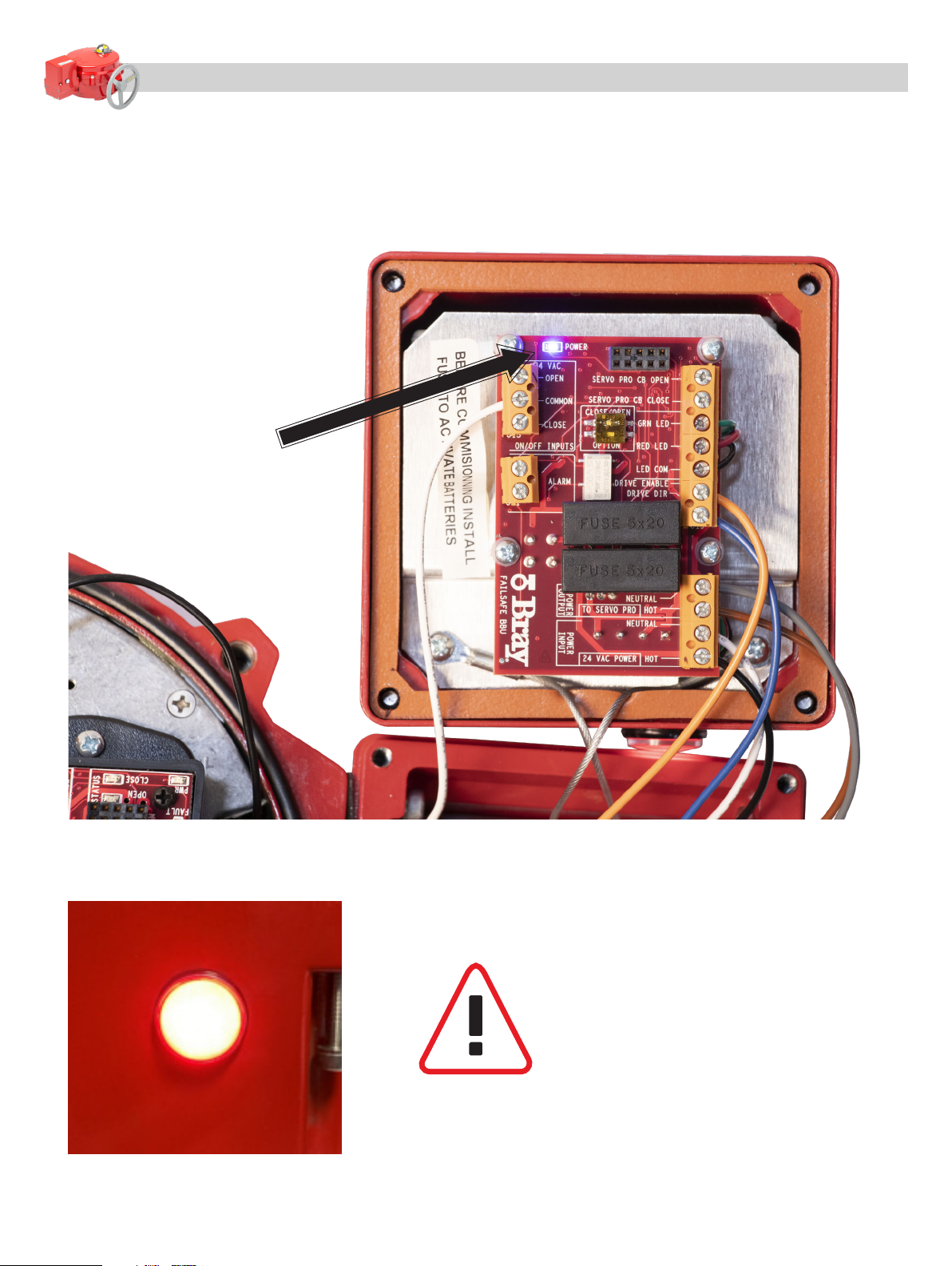

7.4 Insert the fuse supplied under the white label. See [Figure 13] below. Verify LED indicator on the

side of the BBU is flashing RED and the Power LED on the BBU Circuit Board is on.

Figure 13

WARNING – ONCE BATTERY POWER

IS APPLIED TO THE BBU, THE UNIT IS

OPERATIONAL AND MAY CAUSE THE

ACTUATOR TO SEEK THE FAIL POSITION

IF THE MAIN POWER IS NOT CONNECTED

TO THE BBU.

15

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

7.5 Turn on the Power Supply to the BBU. Verify LED indicator on the side of the BBU is flashing or steady

GREEN, see [Figure 14] below. Electrically command the actuator full open and close to verify proper

actuator operation.

7.6 Command the actuator to the position opposite of the Fail Position. Turn off the Power Supply and verify

that the BBU drives the actuator to the full Fail Position and the LED indicator on the side of the BBU

is Rapidly flashing RED. After the actuator has reached full Fail Position, the LED indicator will Slowly

flash RED. See [Figure 15] for details.

Figure 14

Figure 15 Indication Description

Solid Green The BBU is powered and the

batteries are fully charged.

Flashing Green The BBU is powered and the

batteries are charging.

Fast Flashing Red The BBU is not powered and the

actuator is seeking the fail position.

Slow Flashing Red The BBU is not powered and the

BBU is in low power stand-by.

16

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

8.0 Final Assembly

8.1 Reconnect the top and bottom BBU case assemblies. Be careful not to pinch or damage wiring and

ensure the BBU enclosure gasket is in place. [Figure 16]

8.2 If the actuator has already been calibrated then reinstall the actuator lid and the assembly is ready for use.

If the actuator is not calibrated or needs recalibration then procedure with a separate procedure S70 Quick

Start Guide, found on our Bray Commercial Division website and available upon request. [Figure 17]

Figure 16

Figure 17

17

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Battery Backup (BBU) - Wiring

24 VAC On/Off Controller BBU - Size 800-2,000 lb-in - (BCD-WD-A014-3)

18

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Battery Backup (BBU) - Wiring

On/Off NXT BBU - Size 5,000 lb-in - (BCD-WD-A034-3)

19

Battery Backup Unit (BBU) - Installation, Operation & Maintenance Manual Continued

Battery Backup (BBU) - Wiring

24 VAC Modulating NXT BBU - Size 800-5,000 lb-in - (BCD-WD-A035-2)

Other manuals for BBU

1

Table of contents

Popular UPS manuals by other brands

Powerware

Powerware 9335 Installation and operation manual

MGE UPS Systems

MGE UPS Systems PULSAR EVOLUTION 3000 XL Connection instructions

Cyber Power

Cyber Power OL6000ERT3UDM user manual

RS

RS PTM Series Installation instructions and owner's manual

Rockwell Automation

Rockwell Automation Allen-Bradley Bulletin 1609 installation instructions

Borri

Borri UPSaver 400 kVa operating manual