1

CONTENTS

1 GENERAL

1.1 How to use this Manual .......................................................................... 2

1.2 Service and Support ............................................................................... 2

1.3 Used Products and the Environment ...................................................... 3

1.4 Symbols .................................................................................................. 3

1.5 Intended Use and Remarks on Safety .................................................... 3

1.6 Warranty Conditions ............................................................................... 4

2 DESCRIPTION

3 INSTALLATION

3.1 Unpacking and Inspection ...................................................................... 6

3.2 Installation ............................................................................................... 6

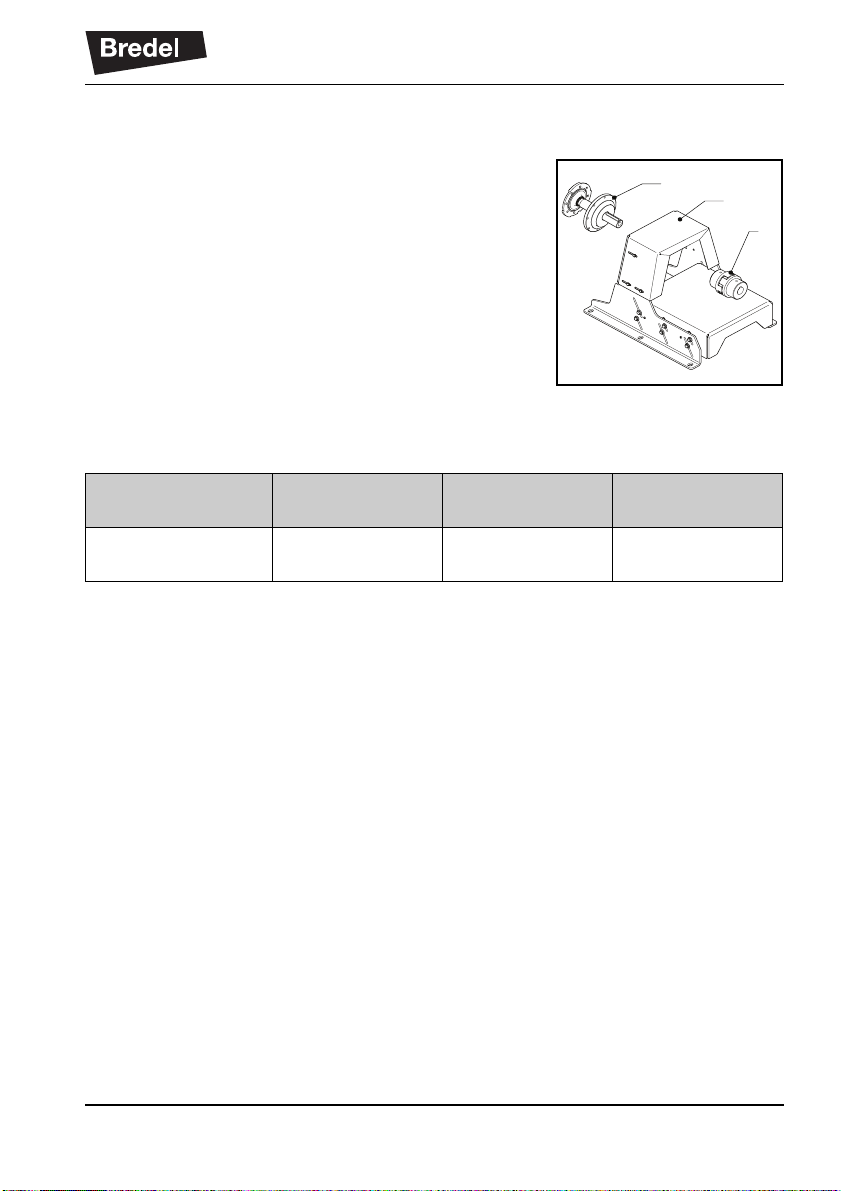

3.2.1 Mounting the support set and the bare shaft kit to

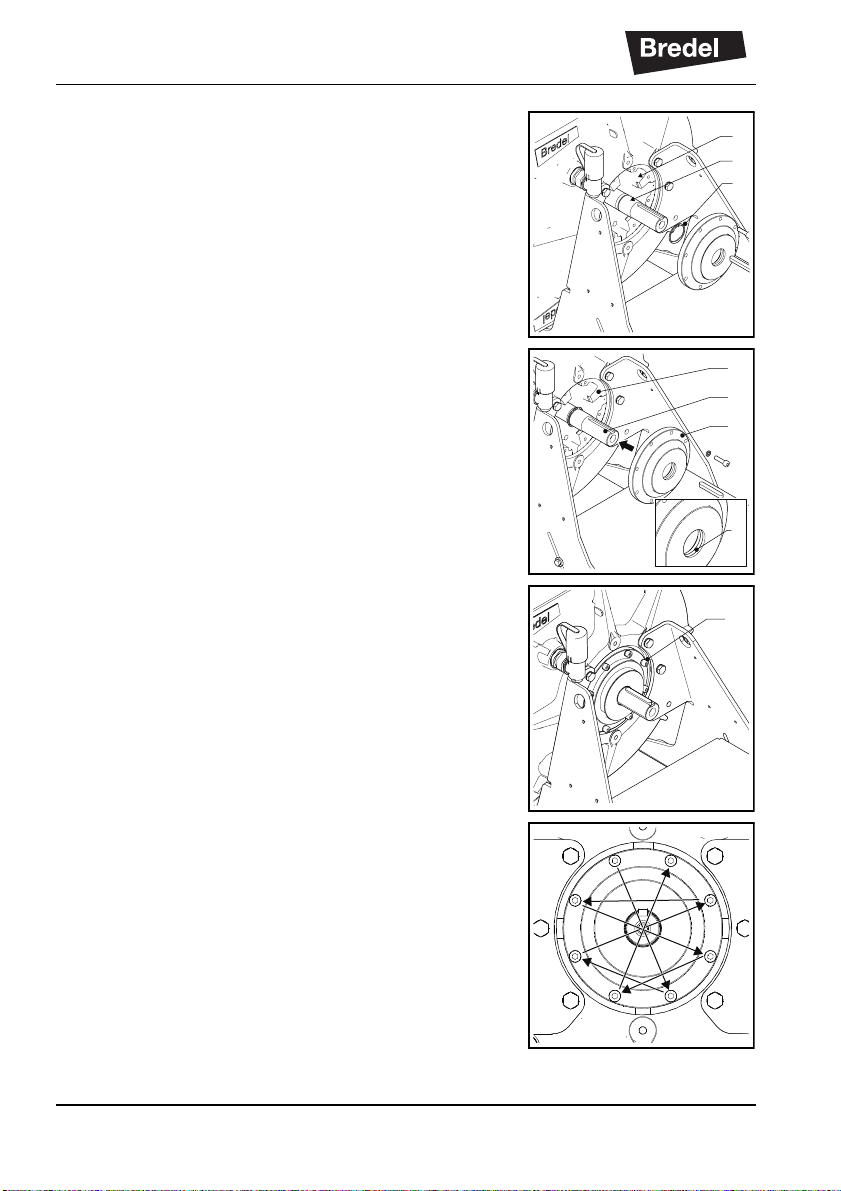

the pumphead ............................................................................. 7

3.2.2 Mounting and aligning the Drive ................................................ 10

4 MAINTENANCE

4.1 Cleaning ................................................................................................ 13

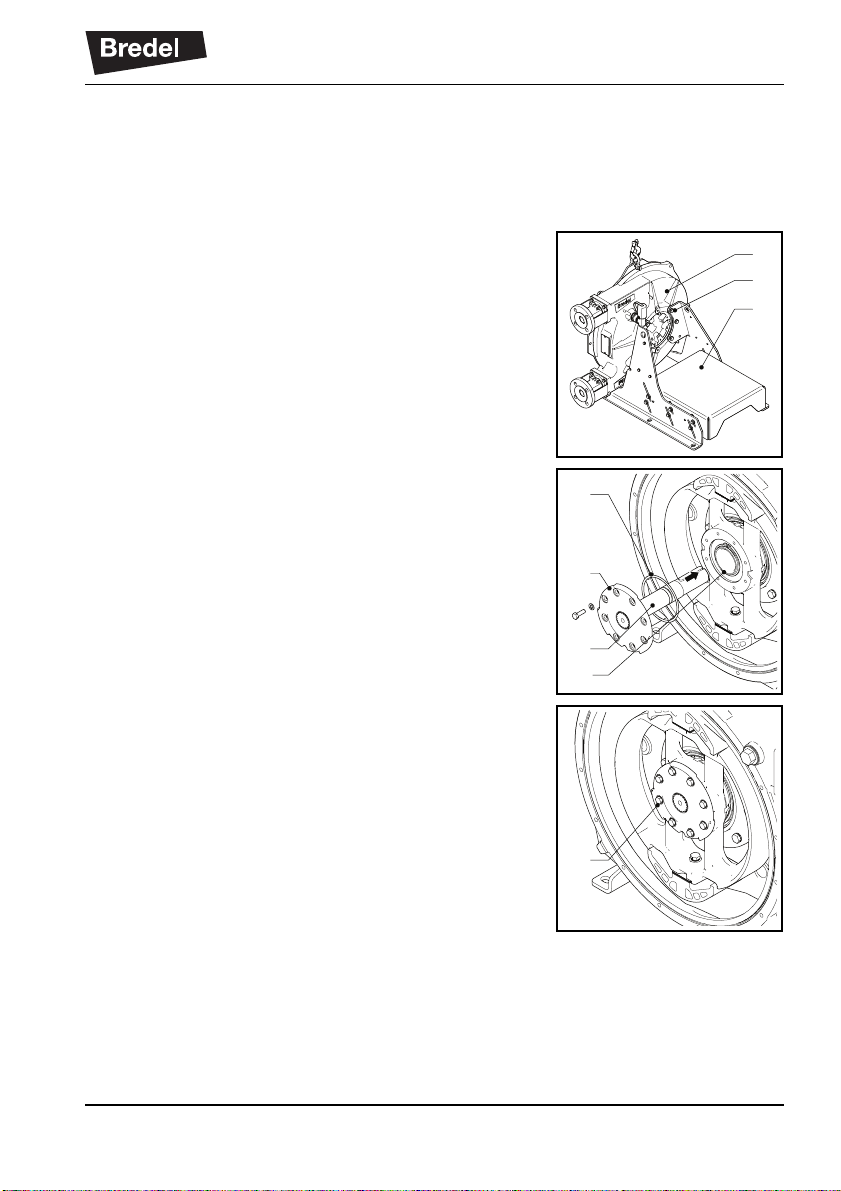

4.2 Demounting the pumphead .................................................................. 13

4.3 Demounting the drive ............................................................................ 14

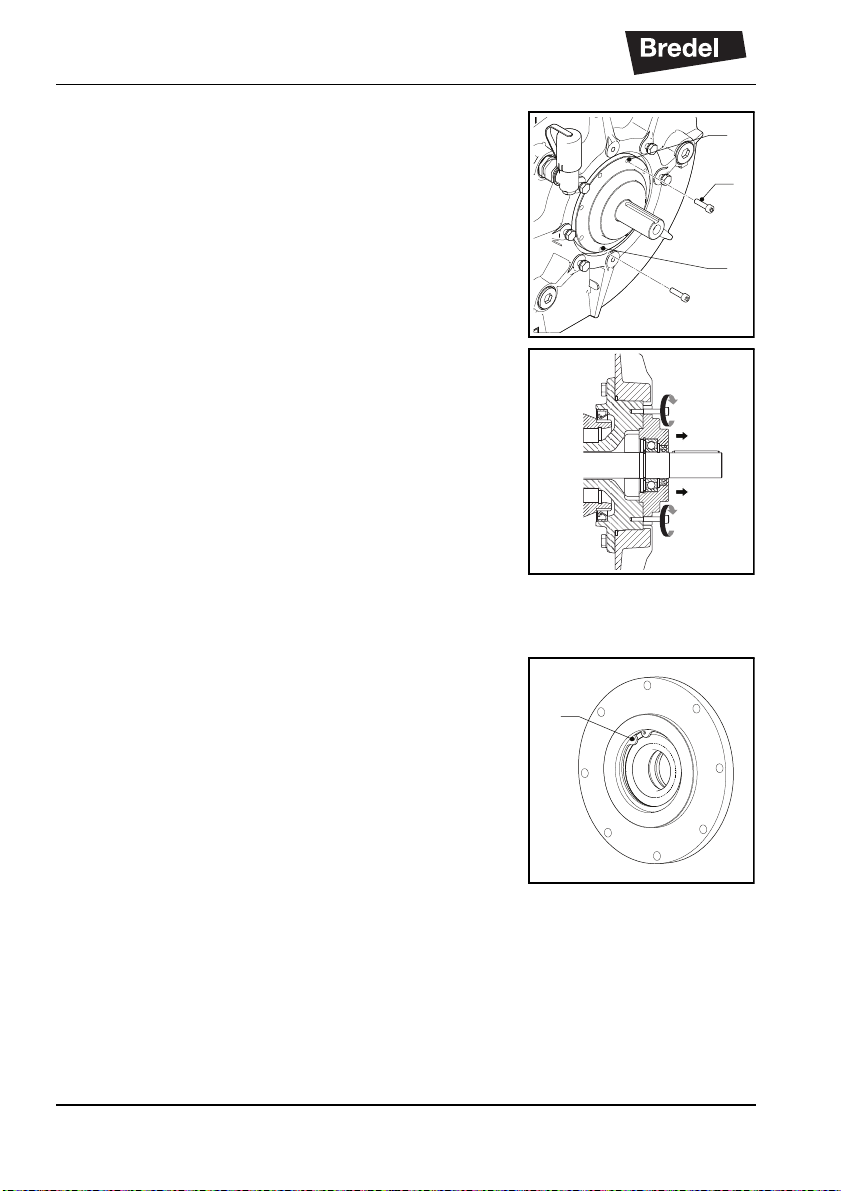

4.4 Demounting the bare shaft hub ............................................................ 15

4.5 Disassembling the bare shaft hub ........................................................ 16

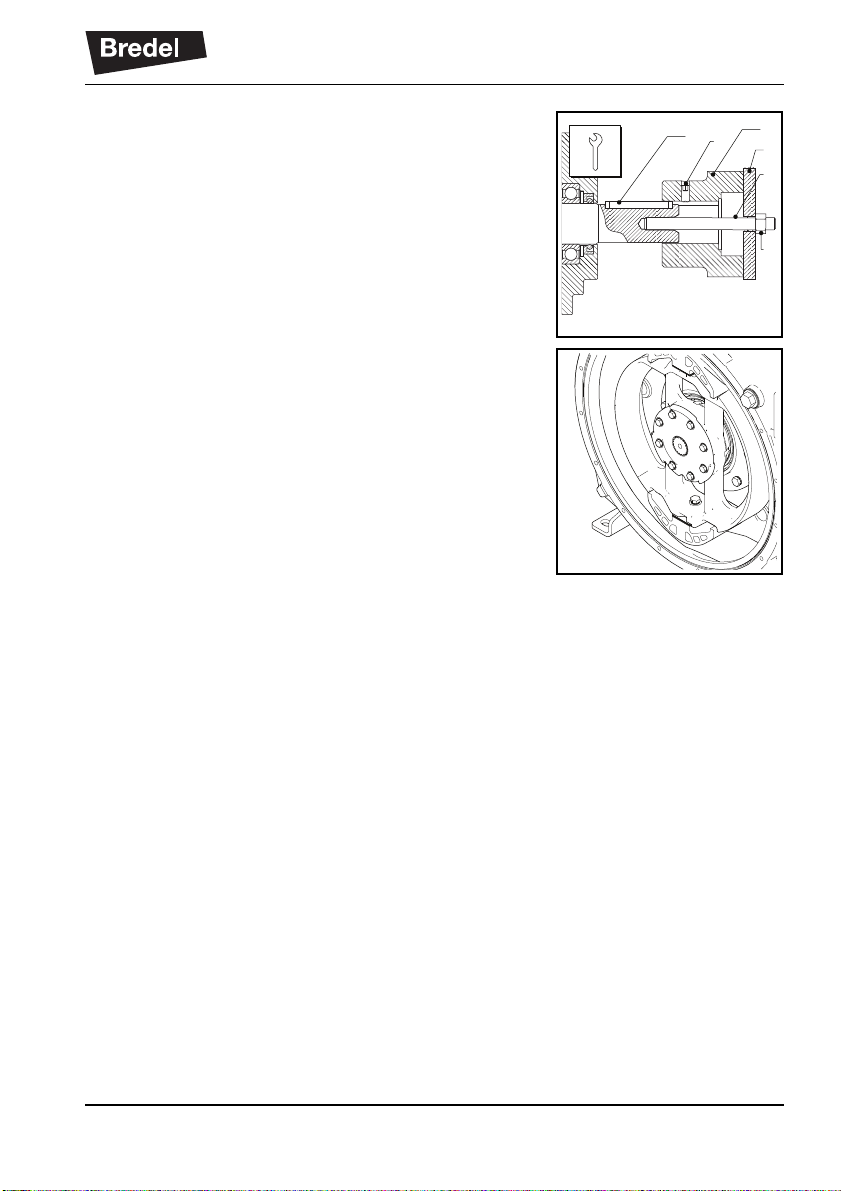

4.6 Assembling the bare shaft hub ............................................................. 17

4.7 Mounting the bare shaft hub onto the pump ......................................... 19

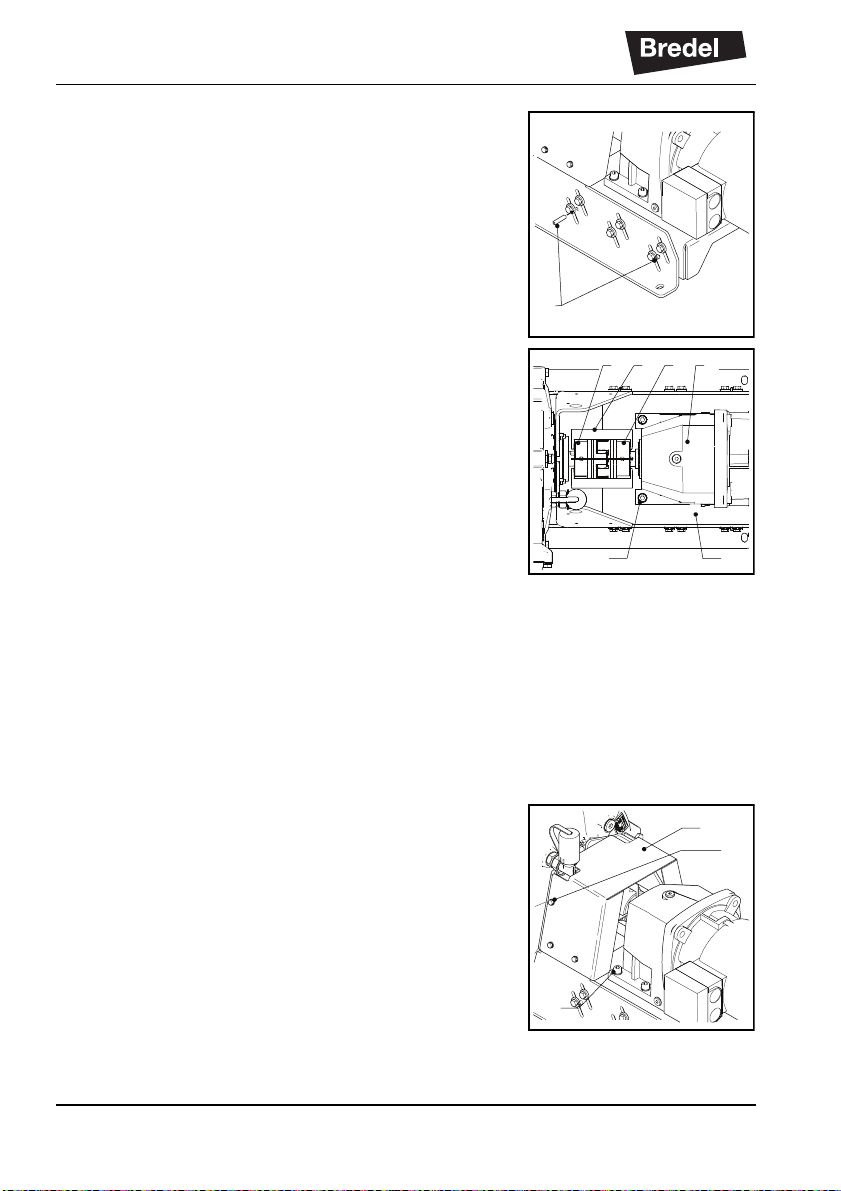

4.8 Mounting the Drive ................................................................................ 20

4.9 Mounting the pumphead ....................................................................... 22

5 TROUBLESHOOTING

6 SPECIFICATIONS

6.1 Bredel 40 bare shaft set ........................................................................ 26

6.1.1 Support set ................................................................................ 26

6.1.2 Bare Shaft Kit ............................................................................ 27

6.2 Weights ................................................................................................. 28

6.3 Torque .................................................................................................. 28

6.4 Coupling ................................................................................................ 28

SAFETY FORM