Bredel APEX 10 User manual

Copyright © 2016 Watson-Marlow Fluid Technology Group 28-1003208

DuCoNite® and Watson-Marlow Bredel

are registered trademarks.

APEX / BREDEL PUMP

Additional information on APEX and Bredel 10, 15 and 20 pumps with bare shaft

configuration

Additional information on APEX and Bredel

10, 15 and 20 pumps with bare shaft configuration

Original Instructions

© 2017 Watson-Marlow Bredel B.V.

All rights reserved.

The information provided herein may not be reproduced and/or published in any form,

by print, photoprint, microfilm or any other means whatsoever (electronically or

mechanically) without the prior written authorisation of Watson-Marlow Bredel B.V.

The information provided can be changed without prior notification. Watson-Marlow

Bredel B.V. or one of its representatives cannot be held liable for possible damage

resulting from use of this manual. This is an extensive limitation of the liability which

applies to all damage, inclusive of (without limitation) compensating, direct, indirect or

consequential damage, loss of data, income or profit, loss or damage to possessions

and claims of third parties.

Watson-Marlow Bredel B.V. provides the information in this manual "as is" and does not

take any responsibility and does not give any guarantee on this manual or its content.

Watson-Marlow Bredel B.V. rejects all responsibilities and guarantees. Furthermore,

Watson-Marlow Bredel B.V. does not take responsibility for and does not guarantee that

the information in this manual is accurate, complete or up to date.

Names, trade names, brands, etc. used by Watson-Marlow Bredel B.V. may not, as per

the legislation concerning the protection of trade names, be considered as available.

1

CONTENTS

1 GENERAL

1.1 How to use this Manual .......................................................................... 2

1.2 Service and Support ............................................................................... 2

1.3 Used Products and the Environment ...................................................... 3

1.4 Symbols .................................................................................................. 3

1.5 Intended Use and Remarks on Safety .................................................... 3

1.6 Warranty Conditions ............................................................................... 4

2 DESCRIPTION

3 INSTALLATION

3.1 Unpacking and Inspection ...................................................................... 6

3.2 Installation .............................................................................................. 6

3.2.1 Mounting the support set and Bare Shaft Kit ............................... 7

3.2.2 Mounting and aligning the Drive .................................................. 9

4 MAINTENANCE

4.1 Cleaning ................................................................................................ 12

4.2 Demounting the Drive ........................................................................... 12

4.3 Demounting the Bare Shaft Kit ............................................................. 13

4.4 Disassembling the Bare Shaft Kit ......................................................... 14

4.5 Assembling the Bare Shaft Kit .............................................................. 15

4.6 Mounting the Bare Shaft Kit onto the Pump ......................................... 17

4.7 Mounting the Drive ................................................................................ 18

5 TROUBLESHOOTING

6 SPECIFICATIONS

6.1 Parts list ................................................................................................ 22

6.1.1 Support Set 10-20 ..................................................................... 22

6.1.2 Bare Shaft Kit ............................................................................ 23

6.2 Weights ................................................................................................. 23

6.3 Torque .................................................................................................. 24

6.4 Coupling ................................................................................................ 24

SAFETY FORM

GENERAL

2

1 GENERAL

1.1 How to use this Manual

This manual is intended as a reference book for

qualified users, enabling them to install, commission

and maintain the bare shaft set as mentioned on the

front cover. This manual is an addition to the pumphead

manual, drive manual and gearbox manual. This

manual does not replace any of these documents. The

user should carefully read these documents before

using this manual.

Documentation of components such as pumps, motors

and inverters is normally not included in this manual.

However, if additional documentation is supplied, you

must follow the instructions in this additional

documentation.

1.2 Service and Support

For information with respect to specific adjustments,

installation, maintenance or repair jobs which fall

beyond the scope of this manual, contact your Bredel

representative. Make sure you have the following data

at hand:

•

Type and / or serial number of the hose pump.

•

Description of the drive or gearbox.

You will find these data on the identification plates or

stickers of the pumphead and the drive or gearbox.

GENERAL

3

1.3 Used Products and the Environment

Enquire with your local government about the

possibilities for reuse or environment friendly

processing of packaging materials, (contaminated)

lubricant and oil.

1.4 Symbols

In this manual the following symbols are used:

1.5 Intended Use and Remarks on Safety

The bare shaft set is exclusively designed for

supporting a Bredel or an APEX pumphead and a drive.

Every other use is not in conformance with the intended

ENVIRONMENT

Always observe the local rules and

regulations with respect to processing

(nonreusable) parts of the hose pump.

WARNING

Procedures which, if not carried out with

the necessary care, may result in serious

bodily harm.

CAUTION

Procedures which, if not carried out with

the necessary care, may result in serious

damage to the hose pump, the surrounding

area or the environment.

Remarks, suggestions and advice.

GENERAL

4

use. Refer to the manual of the pumphead for more

information on safety and the intended use of the

complete pump.

1.6 Warranty Conditions

Refer to the manual of the pumphead for warranty

conditions. These conditions are applicable to the bare

shaft set as well. Damaged parts of the bare shaft set

that are returned to the manufacturer must be

accompanied by a fully filled in and signed safety form

that can be found in the manual of the pumphead.

DESCRIPTION

5

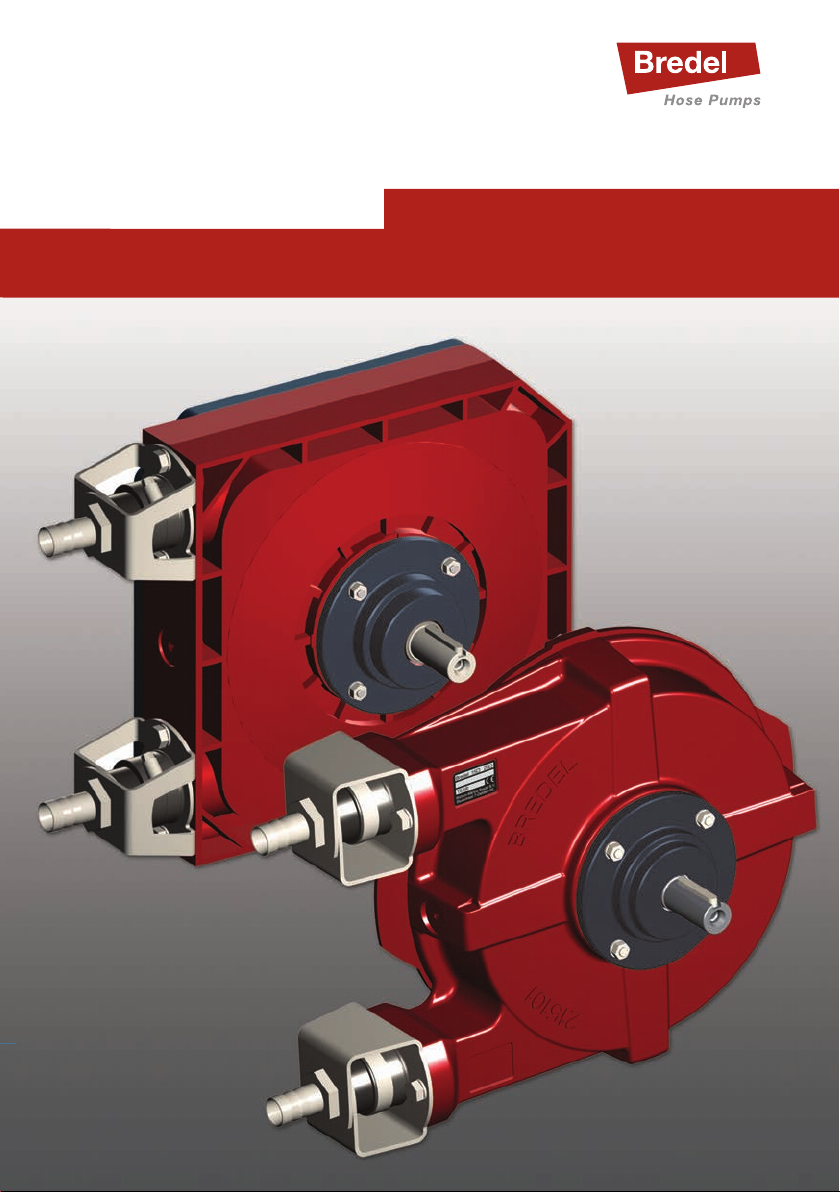

2 DESCRIPTION

The bare shaft set, if delivered separately, consists of a

support set (A) and a bare shaft kit (B). These two

components are packed separately. If the set is

delivered in a complete pump with pumphead and drive

a flexible coupling (C) is included.

The support set consists of a frame, an adjustable drive

support plate and a coupling guard.

The bare shaft kit consists of a shaft, a hub, a bearing

and a seal. No fasteners are provided for mounting the

drive or gearbox.

To align the pump and the drive use alignment jigs. The

jigs are not included in the package.

B

C

A

Although the instructions in this manual are

demonstrated with the Bredel 10-20 pump

series, these are also applicable to the

APEX10-20 series.

INSTALLATION

6

3 INSTALLATION

3.1 Unpacking and Inspection

Follow the unpacking instructions on the packaging.

Check that your delivery is correct and does not have

transport damage. Report any damage immediately to

your Bredel representative.

This chapter describes the installation of the bare shaft

set. Refer to the manual of the pumphead for

installation and setup of the complete pump and the

pipework.

3.2 Installation

CAUTION

The drive or gearbox and the pump must

be aligned within the misalignment limits of

the flexible coupling.

Carry out the alignment of the drive or

gearbox and the pump at the pump’s final

operating position. If the support set has to

be bolted to the floor this must be done

first.

A movement of the complete pump can

disturb the alignment due to elasticity of

the construction.

If the bare shaft set is delivered as part of a

complete pump, including pumphead and

drive, a realignment must be done at the

pump’s final operating position.

INSTALLATION

7

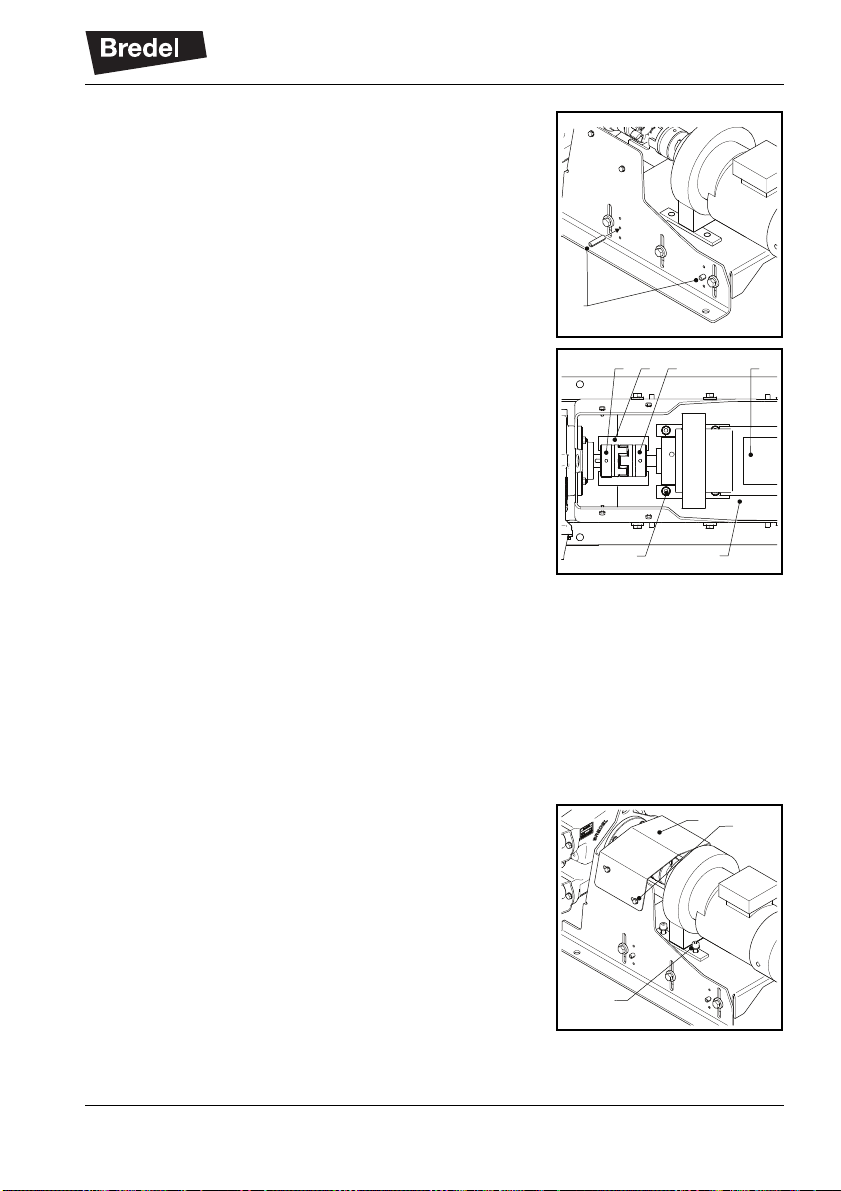

3.2.1 Mounting the support set and Bare Shaft Kit

For mounting the kit to the pumphead, the pump must

not be part of a process line and must be free of

lubricant.

1. Place the bare shaft kit (A) on a flat surface with

the key end upward.

Press coupling half (B) onto the shaft end until

shaft end face (C) and coupling surface (D) are

at equal level.

Slightly fasten screw (E).

Prevent unnecessary axial load on the bearing.

Alternative method of pressing the coupling half

onto the shaft end is using a threaded rod

screwed into the threaded hole in the shaft end,

a disc with hole and a nut. Turning the nut will

drive the coupling half onto the shaft.

This way the coupling half can be mounted after

the placement of the bare shaft kit on the

pumphead.

2. Use a hoist to place the pumphead with the

cover side on blocks.

D

B

C

A

E

INSTALLATION

8

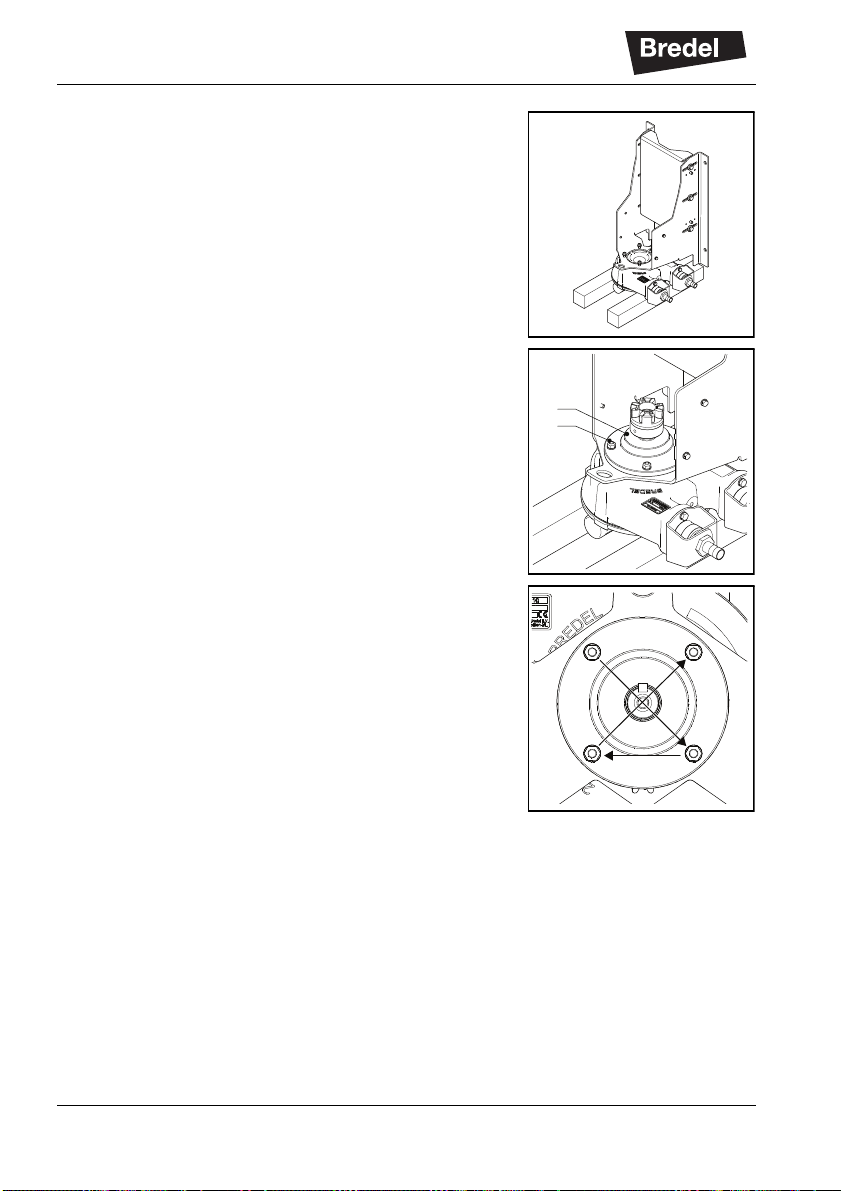

3. Remove the coupling guard from the support

set.

Use a hoist to place the support set on the rear

of the pumphead.

4. Place the bare shaft kit (A) with the 3-teeth

coupling end into the pump.

Make sure the 3 teeth correctly mesh with the

holes in the rotor inside the pump.

5. Place washers and nuts (B).

6. Tighten the nuts in at least two crosswise

cycles. In the last cycle tighten them with the

correct torque. See section 6.3.

7. Use a hoist to turn the pumphead with support

set to the horizontal position.

A

B

11

3

3

4

22

4

INSTALLATION

9

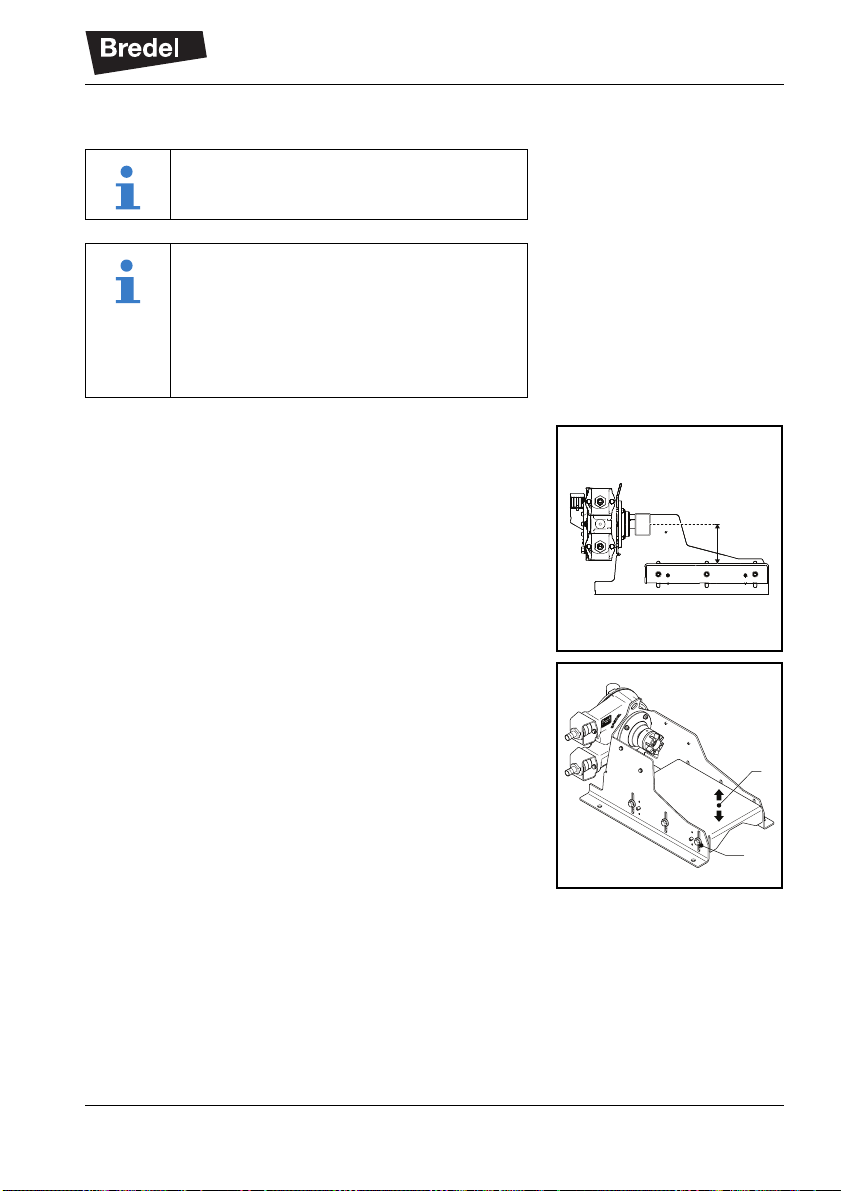

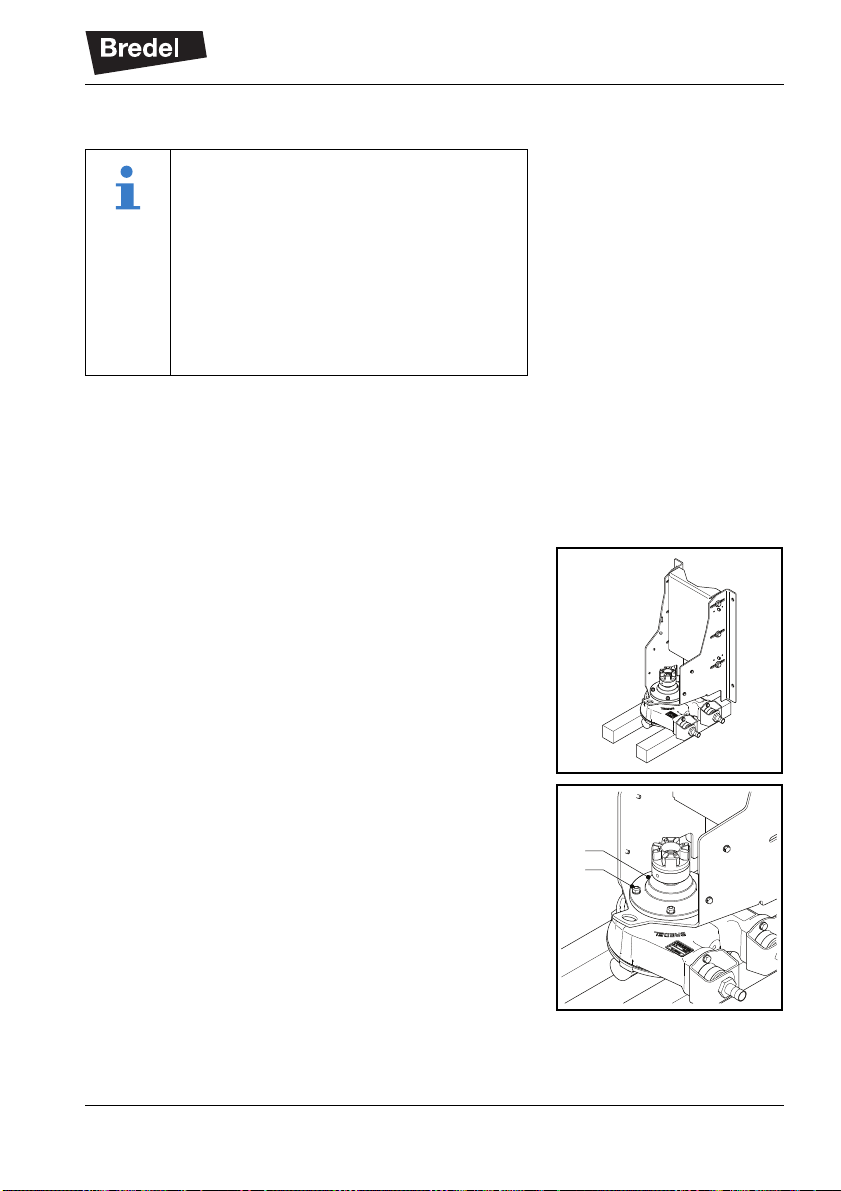

3.2.2 Mounting and aligning the Drive

1. Determine the correct height (H) of the centre of

the bare shaft according to the surface on which

the drive will be mounted. The bare shaft height

must correspond with the height of the output

shaft centre of the drive that will be mounted.

2. To correct the height loosen the six sets of

fasteners (A).

Move the plate (B) up or down to the correct

position and slightly tighten the fasteners (A).

Check the height and repeat this step if

necessary.

If the height is correct, tighten the fasteners (A)

with the correct torque. See section 6.3.

Use a hoist to lift the drive.

Mounting and aligning the drive must be

done on the pump’s final operation

position. Moving the complete pump

assembly after alignment will require re-

alignment at the pump’s final operation

position.

H

A

B

INSTALLATION

10

3. Place coupling half (A) on the output shaft of the

drive and slightly fasten screw (B).

Make sure the shaft end has been shifted far

enough into the coupling half but will not

penetrate into the coupling spider (C).

4. Use a hoist to place the drive on the support

set.

5. Make sure spider is placed in one of the

coupling halves.

6. Slide the drive toward the pumphead.

Make sure that the coupling halves (A) and the

spider mesh correctly.

7. Use two alignment jigs (D) to check the

alignment of the coupling halves in the vertical

plane. Looking from aside both coupling halves

(C) must touch the horizontal edge of the upper

jig.

If necessary loosen the fasteners (A), readjust

the plate (B) and fasten the fasteners (A) to

accomplish this. Use a hoist to lift the drive.

Axial, radial and angular displacement of the

coupling halves must be minimised. See section

6.4.

8. Each side plate of the support set has 2 sets of

3 holes (A). Determine if the upper, the middle

or the lower hole is most suitable to be drilled

through into the side wall of plate (B).

Use a drill of 8mm to drill this hole through both

plates.

AB

C

A

B A

C D C

AB

INSTALLATION

11

9. Drive a pin (A) into each drilled hole to fix the

horizontal plate in the support set side plates.

10. Use two alignment jigs (D) to check the

alignment of the coupling halves in the

horizontal plane. Looking from above both

coupling halves (C) must touch the edge of both

jigs.

If necessary move the drive (E) over the plate

(A) to accomplish this.

Axial, radial and angular displacement of the

coupling halves must be minimised.

11. Mark the holes (B) for fixing the drive on the

plate of the support set using a punch and a

hammer, or a felt-tip pen.

12. Remove the alignment jigs and use a hoist to

remove the drive.

13. Drill holes, with the correct diameter, in the

horizontal plate (A) at the marked places. See

section 6.3.

14. Remount the drive and slide it toward the

pumphead so that the coupling halves mesh.

15. Fix the drive to the horizontal plate with

fasteners (A) (washers, bolts or screws, and

nuts). Do not tighten the fasteners yet.

16. Repeat step 10. (alignment in a horizontal

plane)

Tighten the fasteners (A) and the screws of the

coupling halves with the correct torque. See

section 6.3.

17. Place the coupling guard (B).

Tighten the fasteners (C) with the correct

torque. See section 6.3.

A

C D

BA

C E

C

A

B

MAINTENANCE

12

4 MAINTENANCE

4.1 Cleaning

4.2 Demounting the Drive

1. Isolate the drive from the electrical supply.

2. Loosen the fasteners (C) of the coupling guard

and remove the coupling guard (B).

3. Loosen and remove the fasteners (A).

4. Move the drive (A) backward to separate the

coupling halves (B and C).

Use a hoist to remove and set aside the drive.

WARNING

When cleaning the pump do not use a

high-pressure spraying pistol. This might

damage the seal and the bearing.

Use a hoist to lift the drive.

C

A

B

BCA

MAINTENANCE

13

4.3 Demounting the Bare Shaft Kit

1. Close any shut-off valves in the suction and

discharge lines and disconnect these lines.

Refer to the manual of the pump.

2. Remove the lubricant from the pumphead.

Refer to the manual of the pump.

3. Use a hoist to turn over the pump and put it on

blocks.

4. Demount the bare shaft kit (A) by loosening

fasteners (B).

When the bare shaft kit is demounted the

pumphead will come loose from the

support set. The pumphead must be

supported in some way, or the pumphead

has to be tipped to the front. In the latter

case piping has to be disconnected and

lubricant has to be removed first.

In this manual it is assumed that the

pumphead will be tipped to the front.

A

B

MAINTENANCE

14

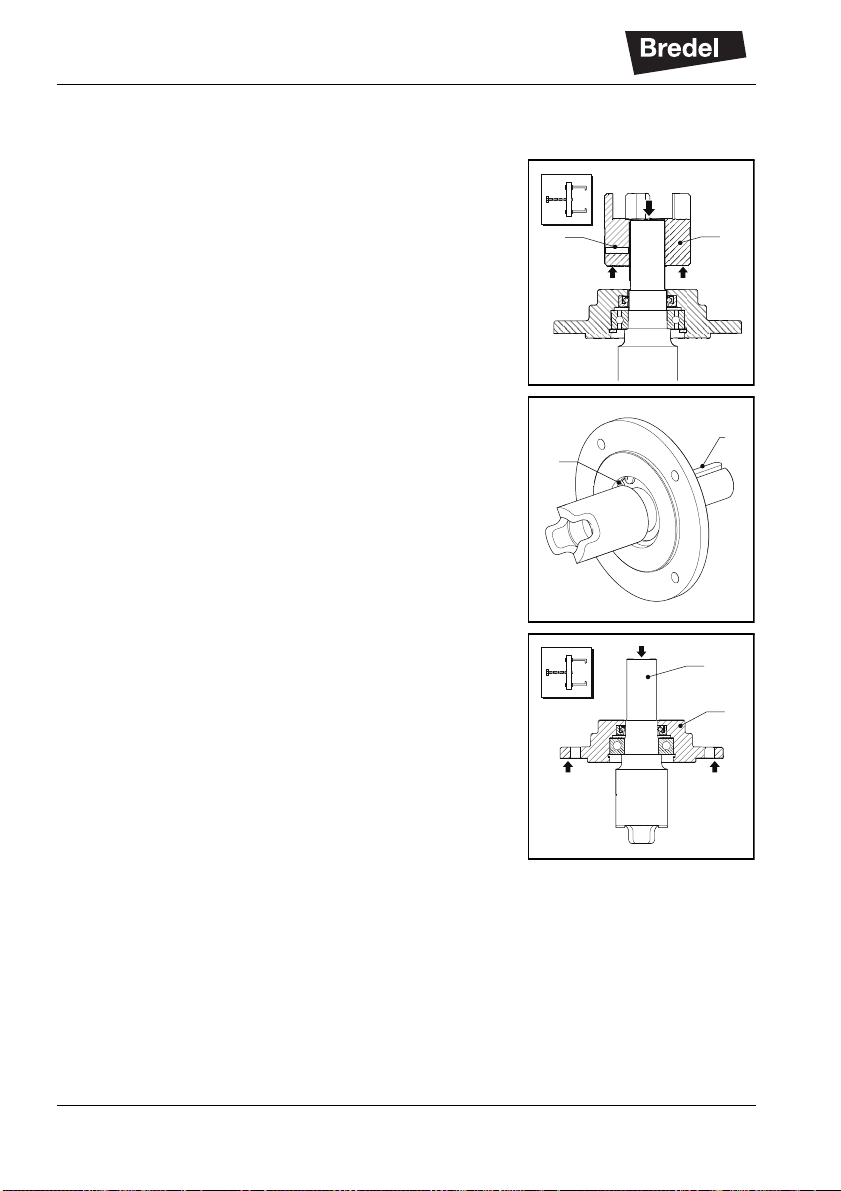

4.4 Disassembling the Bare Shaft Kit

1. Remove coupling half (B) from the shaft by

loosening screw (A). Use a suitable pulling

device.

Do not put axial load on the bearing if it is to be

reused.

2. Remove retaining ring (A).

3. Remove key (B).

4. Push shaft (A) out of hub (B). Use a suitable

pulling device.

B

A

B

A

A

B

MAINTENANCE

15

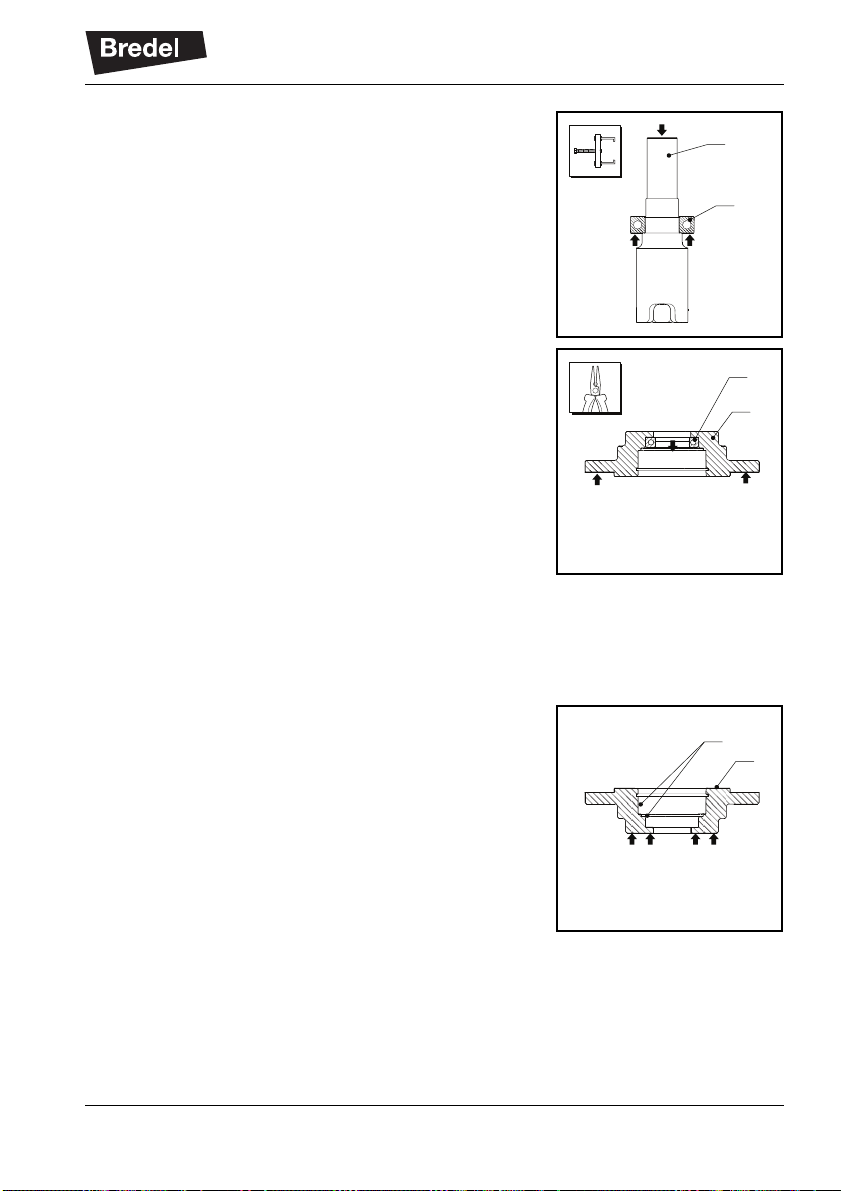

5. Remove bearing (B) from shaft (A). Use a

suitable pulling device.

6. Remove seal (A) from hub (B). If the seal is to

be replaced pliers can be used.

4.5 Assembling the Bare Shaft Kit

Check the bearing and the seal before reuse. If

necessary use a new bearing and a new seal.

1. Place the hub (B) on a flat surface, with the

bearing side upward. Clean the contact

surfaces (A) for bearing and seal and put some

transmission oil on these surfaces.

A

B

B

A

B

A

MAINTENANCE

16

2. Use a suitable tool (A) to press seal (B) into the

hub until it hits the collar. Keep the closed side

of the seal upward.

3. Put an excessive amount of grease on the lip of

the seal.

4. Clean the contact surfaces (A) for bearing and

seal on the shaft (B). Put some grease on these

surfaces.

5. Place shaft (C) on a flat surface with the key

end upward. Press bearing (B) on the shaft with

a suitable tool (A) until it touches the rim.

6. Place the hub (C), with the bearing side upward,

on a flat surface with a hole.

Place shaft (D), with the key end pointing down,

into the hub (C).

Press bearing (B), with a suitable tool (A), into

the hub until it touches the bearing rim.

BA

B

A

A

B

C

A

B

C

D

MAINTENANCE

17

7. Place key (B) onto the shaft.

8. Place retaining ring (A) into the hub.

9. Mount a coupling half on the shaft end. See

section 3.2.1 step 1.

4.6 Mounting the Bare Shaft Kit onto the Pump

For this procedure the pumphead should still be placed

on blocks with the support set resting on the

pumphead´s rear side. One coupling half is still

mounted on the drive shaft end.

If necessary apply a new spider for the flexible coupling.

1. Place the bare shaft kit (A) with the 3-teeth

coupling end into the pump and assure that the

teeth correctly mesh with the holes in the rotor

inside the pump.

2. Place washers and nuts (B).

3. Tighten the nuts in at least two crosswise

cycles. In the last cycle tighten them with the

correct torque. See section 6.3.

4. Use a hoist to turn the pumphead with support

set to horizontal position.

5. Fill the pumphead with lubricant. Refer to the

manual of the pump.

6. Connect the suction and discharge lines and

open any shut-off valves in these lines. Refer to

the manual of the pump.

B

A

A

B

11

3

3

4

22

4

This manual suits for next models

2

Table of contents

Other Bredel Water Pump manuals

Popular Water Pump manuals by other brands

Pentair

Pentair Shurflo 358 Installation and operation manual

Fountain TECH

Fountain TECH FT-1900 user guide

Grundfos

Grundfos ALPHA1 L Series Installation and operating instructions

Viking pump

Viking pump 4223AX Series Technical & service manual

Edwards

Edwards E2M28 instruction manual

BATHMATE

BATHMATE HYDROVIBE user guide