Brewer's Ledge Treadwall PE User manual

INSTALLATION MANUAL

TREADWALL Model PE

Wall Mount

Brewer’s Ledge Inc. ● 34 Brookley Road ● Boston MA 02130 ● 800-707-9616 ● www.treadwall.com

TREADWALL

TREADWALL

®

PE wm Install Manual

The manual for the Treadwall PE

wall-mount is arranged as a check

list. As you go through we

encourage you to check off the

steps.

The Treadwall is a large, but not

complicated machine. None of the

steps in this manual are particularly

difficult, but it is important to follow

all of the steps carefully.

The order of assembly is important

at certain points, so read each

page. A video accompanies this

manual, A play-through before you

start is highly recommended.

Requirements:

Treadwall installation is a full day's work for two people. The installers should have

mechanical aptitude and some experience with mechanical assembly.

Two Stepladders eight foot and sturdy are required. If you don't have them, rent them!

Other tools:

VSR Electric drill with bits (and extension cord if it is not cordless)

#2 Phillips bit

Combination wrench set - particularly the sizes 3/8", 9/16", 3/4".

Socket wrench set - particularly the sizes 3/8", 9/16", 3/4".

Hammer

8" crescent wrench

Screwdrivers

Tape measure

Work gloves

A

llen wrench set

Pair of pliers with nippers

2 carpenter's aprons

Knife

Eye protection

Vice-grip pliers

Small jar or tube of Vaseline

Silicone spray lube

Hand cleaner

Spray cleaner and rags

Carpenter’s apron (to hold small parts and tools)

TREADWALL

A

BOUT THIS MANUAL:

This manual is extracted from the standard

Treadwall PE install manual with irrelevant

material deleted. Use the supplemental

instructions to install the main support frame,

and then continue with the following pages.

The pictures in this manual show a standard

Treadwall PE, but the main difference is in the

frame construction, and the relevant points are

well illustrated.

IMPORTAN

T

: The Treadwall

transformer is designed for use with

110 volt 60 or 50 cycle AC current.

It supplies 12 volts DC at 1.5 amps

to the Treadwall. Users with

different supply voltages must use

a conversion transformer or other

means to provide the proper

voltage.

Brewer's Ledge Inc •34 Brookley Road •Boston MA 02130 •800-707-9616 •www.brewersledge.com

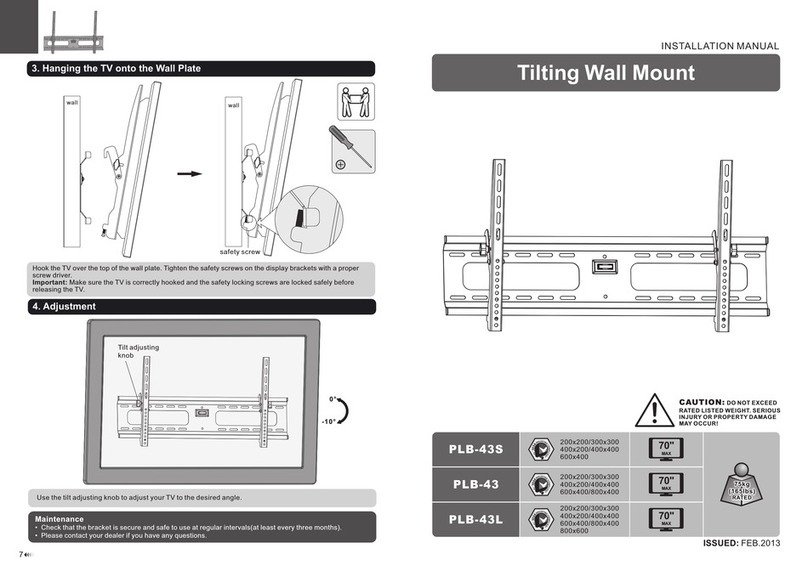

Supplemental instructions for the Wall -mounted Treadwall

The basic differences between a standard Treadwall and the wall-mounted version are in the

support frame and the angle-changing mechanism.

Support frame:

The wall-mount version has one-piece side frames that are considerably narrower than the

standard Treadwall frames. The frames are deep enough at the base to support the full weight

of the Treadwall, but in use, they must be attached to a backing wall for lateral support and to

provide front-to-back stability. The accompanying drawing, TWM-04, shows our

recommendations for attaching the frames to the wall. Using 2x8 backing plates as shown in the

diagram works very well and is highly recommended.

Steps:

1) Prepare backing plates and attach them to the wall as recommended

2) Assemble support frame – two large side frames and two horizontal bars in the back. The

horizontals have L-shaped brackets at the ends, and they should be oriented so that the “Ls”

are toward the back of the frames.

3) There are flat x-braces, as shown in the drawing TWMM-04. These braces are attached with

the same bolts that attach the horizontal bars to the frame. The bolt heads should be at the

back of the frame with the hardware in this order, from back to front: Bolt head – washer –

horizontal L-bracket – frame upright – x-brace – washer – lockwasher – nut.

4) Once assembled, the frame is free-standing, but there is not a great deal of lateral support

until the x-braces are tightened-up. Leave them a bit loose until the frame is mounted to the

wall.

5) Push the frame into place against the backing plates and drill ¼” pilot holes for the top four

lag screws. Screw the top horizontal to the top backing plate with 3/8 x 3 ½” lag screws with

washers and lockwashers. Use the provided shim-washers to space the horizontal out from

the backing plate by about 3/8” (4 washers at each lag bolt). This provides clearance for the

bolts at the ends of the horizontals.

6) The bottom of the frame can be slid back and forth with a chunk of 2x4 and a hammer until

the frames are true and perpendicular. Use a carpenter’s square to make sure the frame is

square with the horizontals. When it is all trued up, put in the bottom four lag-bolts. Shim

these lag bolts like the top ones.

7) Tighten the x-brace turnbuckles evenly.

Angle adjuster:

The rest of the Treadwall assembly is similar to the standard Treadwall, as shown in the

Treadwall Assembly Manual, with the exception of the angle adjuster. Drawing TWM-01 and

TWM-13 show how the wall-mount angle adjuster works. Simply bolt the angle bearings to the

channels as shown and attach the swinging link to the back frame. The Treadwall is easily

adjusted to a slab or overhanging angle by rotating the crank handle.

Encl: TWM-04, TWM-01, TWM-13, TWM-03

Other manuals for Treadwall PE

1

Table of contents