3

ADDITIONAL SAFEGUARDS

DO NOT OPERATE APPLIANCE IF THE LINE CORD SHOWS ANY DAMAGE OR IF

APPLIANCE WORKS INTERMITTENTLY OR STOPS WORKING ENTIRELY.

EXTENSION CORDS

A short power-supply cord is to be provided to reduce the risk resulng from

becoming entangled in or tripping over a longer cord. Longer detachable power-

supply cords or extension cords are available and may be used if care is exercised in

their use. If a longer detachable power-supply cord or extension cord is used,

1) The marked electrical rang of the cord set or extension cord should be at least

as great as the electrical rang of the appliance, and

2) The extension cord should be a grounding-type 3-wire cord, and

3) The longer cord should be arranged so that it will not drape over the countertop

or tabletop where it can be tripped over, snagged, or pulled on unintenonally

(especially by children).

GROUNDING INSTRUCTIONS

This appliance must be grounded while in use.

CAUTION: To ensure connued protecon against risk of electric shock, connect to

properly grounded outlets only.

GROUNDING INSTRUCTIONS

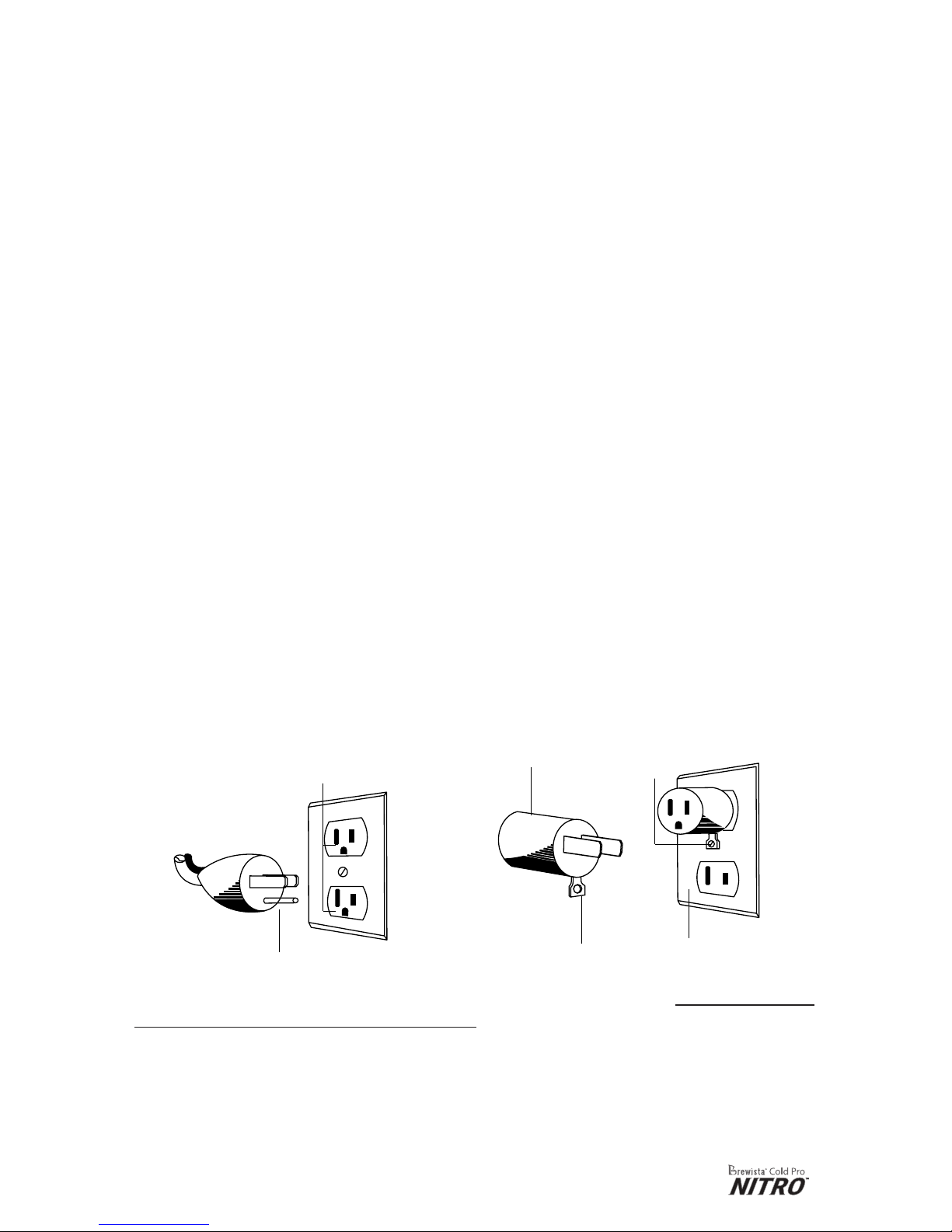

In North American markets the appliance has a plug that looks like Figure A. DO NOT

aempt to insert a power cord into an incompable outlet. Appliance damage,

electrical system damage or physical harm may result. An adaptor, as shown in

Figure B, should be used for connecng a 3-prong grounding plug to a 2-wire

receptacle. The grounding tab, which extends from the adaptor, must be connected

to a permanent ground such as a properly grounded receptacle as shown in Figure

C, using a metal screw.

Warning: It is best to use this appliance on a dedicated circuit or with all other

appliances o during this appliance’s use. It will not damage electrical systems but

cauon should be used to not overload this circuit with other appliances running at

the same me.

Circuit grounding conductor

connected properly

Grounding prong

(A) (B)