Brice Rofry User manual

Operation and Safety Manual

Heavy Duty; Semi-Auto

Oven

Model

Rofry®

Error! Style not defined. 3

printed: 05/2013 Subject to change! RoFryUserManual.doc

1 Contents

1 Contents...................................................................................................................................... 3

2 Important References ................................................................................................................. 4

2.1 Fundamental Safety Notes................................................................................................... 4

2.2 Warranty and Liabilities ........................................................................................................ 5

2.3 Symbols and Notes .............................................................................................................. 5

2.4 Copyright .............................................................................................................................. 5

2.5 Special Safety References ................................................................................................... 6

3 Introduction ................................................................................................................................. 8

3.1 Introduction........................................................................................................................... 8

3.2 Special features.................................................................................................................... 8

3.3 Technical details................................................................................................................... 8

4 Installation and putting into operation ....................................................................................... 11

4.1 Unwrapping ........................................................................................................................ 11

4.2 Installation .......................................................................................................................... 11

4.3 Electrical connection .......................................................................................................... 11

4.4 Tap ..................................................................................................................................... 11

4.5 Sewage .............................................................................................................................. 12

4.6 Exhaust .............................................................................................................................. 12

4.7 Preparation of Using / Starting up ...................................................................................... 12

5 Operation .................................................................................................................................. 13

5.1 How RoFry®works ............................................................................................................. 13

5.2 Control Panel...................................................................................................................... 14

5.3 Description of operating elements...................................................................................... 16

5.4 Operation............................................................................................................................ 18

5.5 Programming...................................................................................................................... 19

6 Maintenance ............................................................................................................................. 21

6.1 Cleaning and Care ............................................................................................................. 21

6.2 Daily Cleaning .................................................................................................................... 22

6.3 Weekly Cleaning ................................................................................................................ 24

6.4 Trouble-Shooting................................................................................................................ 25

6.5 Wiring Diagram................................................................................................................... 26

6.6 Replacement of gaskets:.................................................................................................... 28

6.7 Spare Parts ........................................................................................................................ 31

6.8 Accessories ........................................................................................................................ 36

Error! Style not defined. 3

printed: 05/2013 Subject to change! RoFryUserManual.doc

1 Contents

1 Contents...................................................................................................................................... 3

2 Important References ................................................................................................................. 4

2.1 Fundamental Safety Notes................................................................................................... 4

2.2 Warranty and Liabilities ........................................................................................................ 5

2.3 Symbols and Notes .............................................................................................................. 5

2.4 Copyright .............................................................................................................................. 5

2.5 Special Safety References ................................................................................................... 6

3 Introduction ................................................................................................................................. 8

3.1 Introduction........................................................................................................................... 8

3.2 Special features.................................................................................................................... 8

3.3 Technical details................................................................................................................... 8

4 Installation and putting into operation ....................................................................................... 11

4.1 Unwrapping ........................................................................................................................ 11

4.2 Installation .......................................................................................................................... 11

4.3 Electrical connection .......................................................................................................... 11

4.4 Tap ..................................................................................................................................... 11

4.5 Sewage .............................................................................................................................. 12

4.6 Exhaust .............................................................................................................................. 12

4.7 Preparation of Using / Starting up ...................................................................................... 12

5 Operation .................................................................................................................................. 13

5.1 How RoFry®works ............................................................................................................. 13

5.2 Control Panel...................................................................................................................... 14

5.3 Description of operating elements...................................................................................... 16

5.4 Operation............................................................................................................................ 18

5.5 Programming...................................................................................................................... 19

6 Maintenance ............................................................................................................................. 21

6.1 Cleaning and Care ............................................................................................................. 21

6.2 Daily Cleaning .................................................................................................................... 22

6.3 Weekly Cleaning ................................................................................................................ 24

6.4 Trouble-Shooting................................................................................................................ 25

6.5 Wiring Diagram................................................................................................................... 26

6.6 Replacement of gaskets:.................................................................................................... 28

6.7 Spare Parts ........................................................................................................................ 31

6.8 Accessories ........................................................................................................................ 36

4 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

2 Important References

2.1 Fundamental Safety Notes

2.1.1 Consider notes in the operating manual

Precondition for the safe and trouble free use of this unit is the knowledge of the fundamental safety

notes and safety regulations.

The operating instruction contains the most important references to operate the unit safely.

These operating instructions, particularly the safety references, are to be considered by all persons,

who work on the unit.

Furthermore the rules and regulations to avoid accidents are to be considered.

2.1.2 Obligation of the operator

The Operator is obliged to only let persons work with the unit who:

•Are familiar with the fundamental regulations of work safety and accident avoiding and who have

been instructed how to operate the unit.

•Read and understood the chapter about safety and warning notes and have confirmed this with

their signature.

The safe conscious operation of the personnel has to be examined regularly.

2.1.3 Obligation of the personnel

All individuals who are authorized to work with the unit are obliged to:

•Pay attention to the fundamental regulations of work safety and accident avoiding,

•Read the chapter on work safety and warning notes in this manual and to confirm through their

signature that they have understood these, before actually operating the unit.

2.1.4 Possible risks

The RoFry®is built state of the art and in acknowledgement of all safety related rules. Nevertheless

is it possible that danger for body and lives of the user and/or third and/or impairments at the unit or

at other real values merge. The unit is to be used only :

•For the due use.

•In safety related flawless condition.

Disturbances which can hurt the safety are to be eliminated immediately.

2.1.5 Due use

Fundamentally our "General terms of sale and delivery" count. These are known to the operator at

the latest since signing of the contract. Claims to warranty and liability at persons-and property

damages are impossible, if they are to be led back to one or several of the following causes:

•Non due use of the unit.

•Improper assembling, starting up, operating and servicing of the unit.

•Operating the unit with defective safety devices or safety devices which have not been installed

properly and are in no working condition.

Error! Style not defined. 5

printed: 05/2013 Subject to change! RoFryUserManual.doc

2.2 Warranty and Liabilities

Fundamentally our "General terms of sale and delivery" count. These are known to the operator at

the latest since signing of the contract. Claims to warranty and liability at persons-and property

damages are impossible, if they are to be led back to one or several of the following causes:

•Non due use of the unit.

•Improper assembling, starting up, operating and servicing of the unit.

•Operating the unit with defective safety devices or safety devices which have not been installed

properly and are in no working condition.

•Disobeying of the references in the operating manual concerning transportation storage, installa-

tion, start-up, operation, maintenance and assembling of the unit.

•Unauthorized mechanical or electrical changes of the unit.

•Insufficient maintenance of wear and tear parts.

•Unauthorized repair.

•Force of nature and act of god.

2.3 Symbols and Notes

In the operating manual the following symbols and signs are used:

This symbol means a possibly or directly threatening danger for the life and the

health of persons and/or a possibly dangerous situation.

Ignoring of these references may result in consequences for your health and/or can

lead to property damages!

This symbol points to important references for the proper use of the unit.

Not paying attention to these references can lead to disturbances at the unit or in

the environment!

This symbol points to operation tips and especially useful information.

Help for optimum use of all functions of the unit !

2.4 Copyright

The copyright on this operating manual remains at the company UBERT GASTROTECHNIK GMBH.

This operating manual is intended only for the operator and his personnel. It contains instructions

and references which neither completely nor partially:

•be duplicated

•be circulated

•be otherwise made available to third parties.

Offences may violate applicable laws.

Error! Style not defined. 5

printed: 05/2013 Subject to change! RoFryUserManual.doc

2.2 Warranty and Liabilities

Fundamentally our "General terms of sale and delivery" count. These are known to the operator at

the latest since signing of the contract. Claims to warranty and liability at persons-and property

damages are impossible, if they are to be led back to one or several of the following causes:

•Non due use of the unit.

•Improper assembling, starting up, operating and servicing of the unit.

•Operating the unit with defective safety devices or safety devices which have not been installed

properly and are in no working condition.

•Disobeying of the references in the operating manual concerning transportation storage, installa-

tion, start-up, operation, maintenance and assembling of the unit.

•Unauthorized mechanical or electrical changes of the unit.

•Insufficient maintenance of wear and tear parts.

•Unauthorized repair.

•Force of nature and act of god.

2.3 Symbols and Notes

In the operating manual the following symbols and signs are used:

This symbol means a possibly or directly threatening danger for the life and the

health of persons and/or a possibly dangerous situation.

Ignoring of these references may result in consequences for your health and/or can

lead to property damages!

This symbol points to important references for the proper use of the unit.

Not paying attention to these references can lead to disturbances at the unit or in

the environment!

This symbol points to operation tips and especially useful information.

Help for optimum use of all functions of the unit !

2.4 Copyright

The copyright on this operating manual remains at the company UBERT GASTROTECHNIK GMBH.

This operating manual is intended only for the operator and his personnel. It contains instructions

and references which neither completely nor partially:

•be duplicated

•be circulated

•be otherwise made available to third parties.

Offences may violate applicable laws.

6 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

2.5 Special Safety References

2.5.1 Safety devices

•Before operating the unit all protective devices like door and exhaust-cover as well

as all removable parts must be installed correctly and be fully workable.

•Protective devices may only be removed:

•After stand still and

•Prevention of unintentional restart.

•If partial components are delivered, an authorized staff member or service tech-

nician has to execute assembly according to installation guidelines.

2.5.2 Informal safety steps

•The operating manual is to be kept constantly accessible in the operating area.

•In addition to the operating manual all generally acknowledged and all local regula-

tions for accident avoiding and environmental protection have to be applied with.

•All safety-danger labels at the unit are to be kept in readable condition.

2.5.3 Education of the personnel

•Only trained and instructed personnel may work at the unit.

•The responsibilities of the personnel are to be determined clearly for installing, start-

up, operation, assembling, and servicing of the unit.

•During instruction the personnel may only work at the unit under supervision of an

experienced person.

2.5.4 Unit-control

Under no circumstances it is allowed to make changes to the source-code of the soft-

ware!

Only instructed personnel are allowed to operate the controls.

2.5.5 Safety during regular operation

•The unit is only to operate if all protective devices are fully workable.

•Before starting the unit it is to ensure, that nobody becomes endangered by the start-

ing unit.

•At least once per shift the unit is to be examined with regard to visible damages and

functional ability of the safety devices.

2.5.6 Dangers caused by electric energy

•Any work on the electrical supply is to be executed only by a specialist.

•Likewise the electrical connection of this unit to the power supply must be executed

by an electro-specialist; the connection must follow the rules of the local determina-

tions.

•The electric installation is to be examined regularly. Loose connections and brazed

cables are to be eliminated immediately.

•If works at any life-parts are necessary, a second person who switches off the main

switch if necessary is to consult.

2.5.7 Special danger-spots

•The basket and/or basket holder is to disassemble only at a switched off unit!

•Do not reach into the open, hot oven chamber!

•Do not touch the pulled out, hot basket during unloading!

•Do not reach into the hot exhaust!

2.5.8 Service and maintenance, troubleshooting

Error! Style not defined. 7

printed: 05/2013 Subject to change! RoFryUserManual.doc

•Prescribed adjustment, service and inspection work is to be accomplished timely by

the manager or if necessary by an authorized service technician.

•The operating personnel is to be informed before the beginning of the maintenance

and service work.

•The unit is to be disconnected from the mains before maintaining, inspecting and

repairing is performed; the main switch is to be guarded against unintended pushing.

•Check all screw connections for tight fitting.

•After finishing maintenance check all safety devices for proper functionality.

2.5.9 Structural changes to the unit

•Do not perform any changes, extensions or conversions to the unit without the manu-

facturer’s permission, especially welding work at supporting parts.

•For all conversions a written permission of the company UBERT GASTROTECHNIK

GMBH is necessary.

•Change all parts of the unit, which are in improper condition.

•Use only original spare parts.

2.5.10 Cleaning of the unit and disposal of the waste

Used substances and materials are to be handled and disposed appropriately, especially

lubricants. Detergents have to follow the rules of food-hygiene

8 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

3 Introduction

3.1 Introduction

RoFry®offers due to its unique technology the possibility to fry regular products completely without

oil. The quality of the products fried without oil will always be the same high standard, no matter if

you take deep frozen or fresh goods, French fries or chicken nuggets, Asian specialties or fast food

products from USA.

The intelligent sensor avoids wrong handling and levels out different amounts and temperatures.

3.2 Special features

•compact design

•computer controlled

•self-diagnostic fault-finding-system

•easy to operate with two buttons

•no buying, storing, using and disposing of oil

•no tools are necessary to dismantle the machine for cleaning

•ideal size to install on a counter

•stainless steel design

•reduced emissions

•no need for fire-fighting appliances

3.3 Technical details

3.3.1 Capacity

The maximum capacity of RoFry®based on the product French fries is 2,5 kg deep frozen or fresh

products per load.

3.3.2 Dimensions [mm]

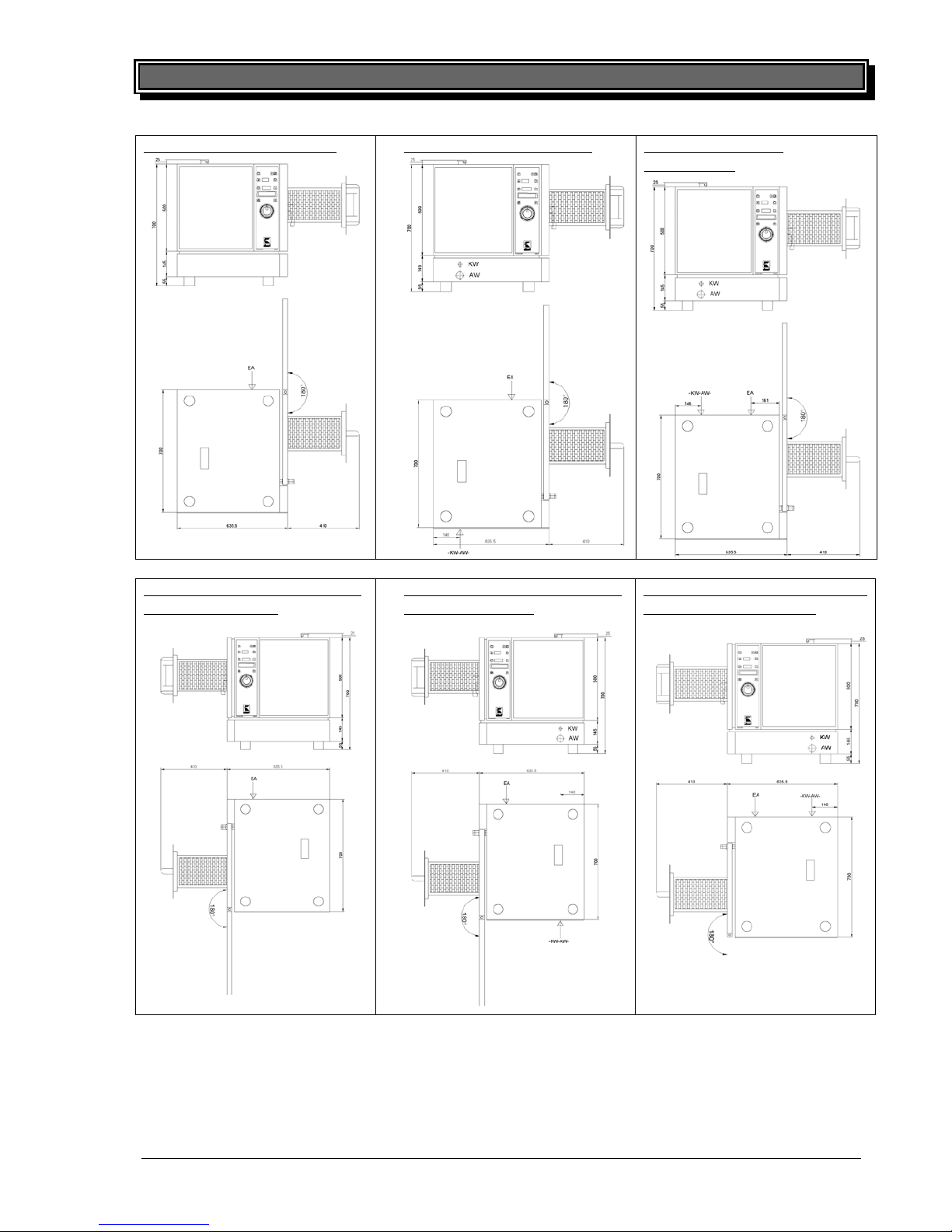

RF-300-ST (Front Loaded

Standard Version):

RF-300-TV (Front Loaded

Canister-Version):

RF-300-FC (Front Loading with

Water-Connection):

RF-330-ST (Right Hand RF-330-TV (Right Hand RF-330-FC (Right Hand

Error! Style not defined. 9

printed: 05/2013 Subject to change! RoFryUserManual.doc

Loaded Standard Version):

Loaded Canister-Version):

Loaded with Water-

Connection):

RF-360-ST (Left Hand Loaded

Standard Version):

RF-360-TV (Left Hand Loaded

Canister-Version):

•RF-360-FC (Left Hand Loaded

with Water-Connection):

10 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

3.3.3 Weight

(Net weight)

Front Loaded Version RF-300-

ST Standard-Version app. 78kg

TV Canister -Version app. 88,5kg

FC Water-Connected Versionapp. 88,5kg

Right Hand Loaded Version RF-330-

ST Standard-Version app. 78kg

TV Canister-Version app. 88,5kg

FC Water-Connected Version app. 88,5kg

Left Hand Loaded Version RF-360-

ST Standard-Version app. 78 kg

TV Canister -Version app. 88,5kg

FC Water-Connected Version app. 88,5kg

3.3.4 Electrical details

Type Version Load per Ph:

RF-300/330/360-ST/TV/FC: Europe-Version

400V / 15,5kW / 50-60Hz / 3Ph withN 25 A

3.3.5 Noise emission

Type noise emission

all types < 70 dBA

Error! Style not defined. 11

printed: 05/2013 Subject to change! RoFryUserManual.doc

4 Installation and putting into operation

In general all RoFry®units will be packed for safe transport after the final control in or-

der to reac

h you properly. Nevertheless we ask you to have a look at the machine on

arrival to detect any transport damages.

Note! Visible damages have to be reported immediately!

4.1 Unwrapping

•Open the box and remove the wrapping carefully.

•Take out all movable parts and make sure that they are complete.

•Remove all cartons and folio around RoFry®

•Pull the basket out of the unit with the black handle and remove all parts inside like operating

manual, legs, plugs etc.

4.2 Installation

•Install the legs and put the machine on the chosen place. Take care of the follow-

ing points:

•The RoFry® has to be placed on a horizontal level. Small unevenness can be cor-

rected by the adjustable legs.

•Make sure that all ventilation holes have at least 5 cm clear space.

•There has to be enough free space to load, unload, clean and maintain the unit.

•

The machine has to be placed in a way that the complete area around it can be

cleaned easily.

4.3 Electrical connection

Note! While working on the unit with opened side-panels take care that the unit is dis-

connected from the mains. Even if the unit is switched off, the cooling fan may start to

run. Not paying attention may result in injury!

Please learn the electrical data of your unit from the nameplate. It is located at all types behind the

grease tray.

•Check whether your local electrical power supply is in accordance with the data on the name

plate.

•Make sure the supply cable is protected for units with a supply voltage as listed below:

≤240V (4/5-wire, min. cross-section 4) separately with 40 Amps,

>240V (4/5-wire, min. cross-section 2,5) separately with 25 Amps

•Protection has to be done by use of a 3 pole line circuit breaker!

•The power supply needs to be manufactured from heat resistant, flexible cable. It is to be routed

to prevent any contact to hot parts.

•For further information please see the wiring diagram (below)

Note! After the unit is connected to the mains, check correct

rotation direction of the

main fan: Remove the basket from the unit

(pull the basket out of the unit with the

black handle, push the release and remove the basket).

Switch the unit on and look

into the chamber. The fan wheel needs to rotate clockwise.

If the rotation direction is

wrong, change two phases on the main terminal block (X1).

After finishing any installation work, maintenance or repair,

check whether the ground

wires are connected properly to the casing and the side covers.

4.4 Tap

12 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

Note! In general all Installation and Service work has to be done by an authorized

service technician! The following regulations have to be observed: DIN EN 1717 (alt

DIN 1988, Part4, technical regulations for drinking water installation/TRW.

•RoFry®requires a cold water connection; we recommend using a water-softening unit in case of

hard water above 8° dH (=Level 1).

•Use flexible pressure hose ½“ with ¾“ screw joint. A faucet as well as a flow-back-prevention has

to be provided on site.

•Water pressure should be between min. 100 kPa and max. 400 kPa. Use a pressure reducer in

case of water supply pressures above 400 kPa.

4.5 Sewage

Note! In general all Installation and Service work has to be done by an authorized serv-

ice technician! The following regulations have to be observed: DIN EN 1717 (alt DIN

1988, Part4, technical regulations for drinking water installation/TRW.

•The appliance needs an open sewage-connection, preferably ending in a funnel. UBERT recom-

mends a common flexible sewage-hose with ¾“diameter to be fixed to the sewage connection

coming with the machine.

4.6 Exhaust

For an average capacity utilization of 60 % (equals a continual preparation of 1000g frozen goods

of -18°C) there is an amount of exhaust of app. 130 m³/h that contains 6 kg water as hot steam. The

steam has to be disposed by an extraction system. The best solution for this is an adequate hood-

system. If this is not possible because of the rooming situation other solutions can be found. In this

case please contact our service members they will be glad to assist you.

4.7 Preparation of Using / Starting up

Before you can use the RoFry®you have to clean all removable parts carefully with a grease sol-

vent.

Note! Do not use flammable cleaners. Do not use high-pressure-, water pressure-or

steam jet-cleaning devices. You will have further information about this in the section

”cleaning and up keeping”.

After cleaning the RoFry®properly the smell will be minimal when using it the first time.

Only forthe Standard Version RF-3XX-ST:

Before using the RoFry®you should use the special RoFry®spray ”KOTE”. This is an anti adhesion

spray that prevents adhering of oil and food residues. Concerning this you will find more information

in the section ”cleaning and up keeping”.

Error! Style not defined. 11

printed: 05/2013 Subject to change! RoFryUserManual.doc

4 Installation and putting into operation

In general all RoFry®units will be packed for safe transport after the final control in or-

der to reach you properly. Nevertheless we ask you to have a look at the machine on

arrival to detect any transport damages.

Note! Visible damages have to be reported immediately!

4.1 Unwrapping

•Open the box and remove the wrapping carefully.

•Take out all movable parts and make sure that they are complete.

•Remove all cartons and folio around RoFry®

•Pull the basket out of the unit with the black handle and remove all parts inside like operating

manual, legs, plugs etc.

4.2 Installation

•Install the legs and put the machine on the chosen place. Take care of the follow-

ing points:

•The RoFry® has to be placed on a horizontal level. Small unevenness can be cor-

rected by the adjustable legs.

•Make sure that all ventilation holes have at least 5 cm clear space.

•There has to be enough free space to load, unload, clean and maintain the unit.

•The machine has to be placed in a way that the complete area around it can be

cleaned easily.

4.3 Electrical connection

Note! While working on the unit with opened side-panels take care that the unit is dis-

connected from the mains. Even if the unit is switched off, the cooling fan may start to

run. Not paying attention may result in injury!

Please learn the electrical data of your unit from the nameplate. It is located at all types behind the

grease tray.

•Check whether your local electrical power supply is in accordance with the data on the name

plate.

•Make sure the supply cable is protected for units with a supply voltage as listed below:

≤240V (4/5-wire, min. cross-section 4) separately with 40 Amps,

>240V (4/5-wire, min. cross-section 2,5) separately with 25 Amps

•Protection has to be done by use of a 3 pole line circuit breaker!

•The power supply needs to be manufactured from heat resistant, flexible cable. It is to be routed

to prevent any contact to hot parts.

•For further information please see the wiring diagram (below)

Note! After the unit is connected to the mains, check correct rotation direction of the

main fan: Remove the basket from the unit (pull the basket out of the unit with the

black handle, push the release and remove the basket). Switch the unit on and look

into the chamber. The fan wheel needs to rotate clockwise. If the rotation direction is

wrong, change two phases on the main terminal block (X1).

After finishing any installation work, maintenance or repair,check whether the ground

wires are connected properly to the casing and the side covers.

4.4 Tap

12 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

Note! In general all Installation and Service work has to be done by an authorized

service technician! The following regulations have to be observed: DIN EN 1717 (alt

DIN 1988, Part4, technical regulations for drinking water installation/TRW.

•RoFry®requires a cold water connection; we recommend using a water-softening unit in case of

hard water above 8° dH (=Level 1).

•Use flexible pressure hose ½“ with ¾“ screw joint. A faucet as well as a flow-back-prevention has

to be provided on site.

•Water pressure should be between min. 100 kPa and max. 400 kPa. Use a pressure reducer in

case of water supply pressures above 400 kPa.

4.5 Sewage

Note! In general all Installation and Service work has to be done by an authorized serv-

ice technician! The following regulations have to be observed: DIN EN 1717 (alt DIN

1988, Part4, technical regulations for drinking water installation/TRW.

•The appliance needs an open sewage-connection, preferably ending in a funnel. UBERT recom-

mends a common flexible sewage-hose with ¾“diameter to be fixed to the sewage connection

coming with the machine.

4.6 Exhaust

For an average capacity utilization of 60 % (equals a continual preparation of 1000g frozen goods

of -18°C) there is an amount of exhaust of app. 130 m³/h that contains 6 kg water as hot steam. The

steam has to be disposed by an extraction system. The best solution for this is an adequate hood-

system. If this is not possible because of the rooming situation other solutions can be found. In this

case please contact our service members they will be glad to assist you.

4.7 Preparation of Using / Starting up

Before you can use the RoFry®you have to clean all removable parts carefully with a grease sol-

vent.

Note! Do not use flammable cleaners. Do not use high-pressure-, water pressure-

or

steam jet-cleaning devices. You will have further information about this in the sec

tion

”cleaning and up keeping”.

After cleaning the RoFry®properly the smell will be minimal when using it the first time.

Only forthe Standard Version RF-3XX-ST:

Before using the RoFry®you should use the special RoFry®spray ”KOTE”. This is an anti adhesion

spray that prevents adhering of oil and food residues. Concerning this you will find more information

in the section ”cleaning and up keeping”.

Error! Style not defined. 13

printed: 05/2013 Subject to change! RoFryUserManual.doc

5 Operation

5.1 How RoFry®works

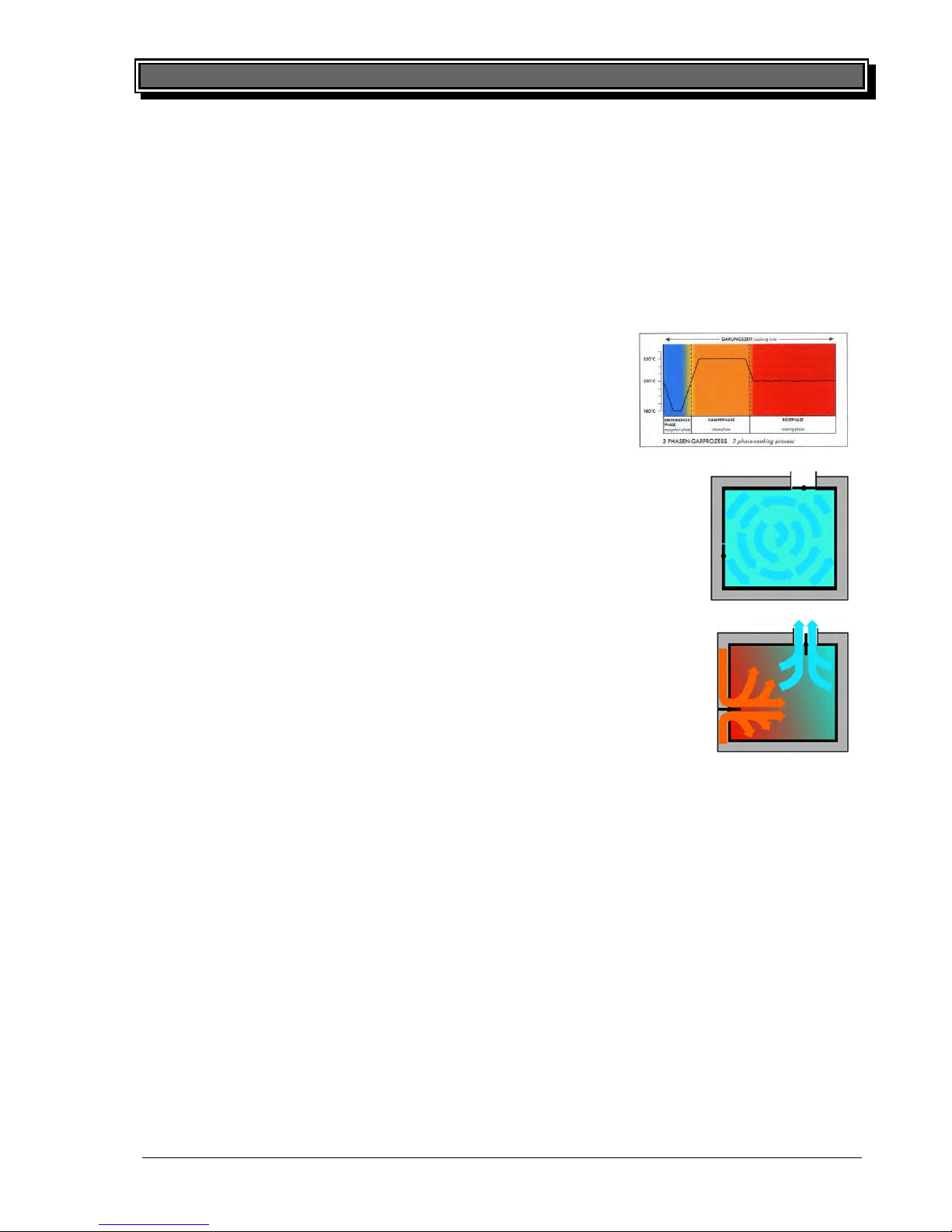

Once the device has been turned on, RoFry initializes. After pushing the STANDBY key is pushed,

RoFry enters the cold standby level. After confirming a program selection with the START key,

RoFry enters the hot standby level and is preheating to set temperature. This takes app. 2 minutes.

To fry food products, pull out the basket, put in the food to be prepared, push in the basket and push

the START key.

The basket starts to rotate and the main fan rotates full speed. The

air intake-and exhaust flaps are closed now. The temperature

drops. Now the computer control adjusts RoFry® automatically to

the amount and temperature of the food product by shortening or

lengthening the total cooking time to obtain a considerably even

product result.

The steam time phase starts. Now humidity is taken from the

product and turned into steam, cooking the product. During steam

time the temperatures in the chamber rise up to max. 20° C above

programmed operating temperature (if wanted). After the steam

time is finished, the flaps open again and the temperature will drop

to the start-level.

The roasting phase in which the goods get crispy begins. Now the

flaps are opened to let the vapor escape. Dry, preheated air is

blown via intake channel into the chamber. The flaps remain open

until the basket has been emptied.

14 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

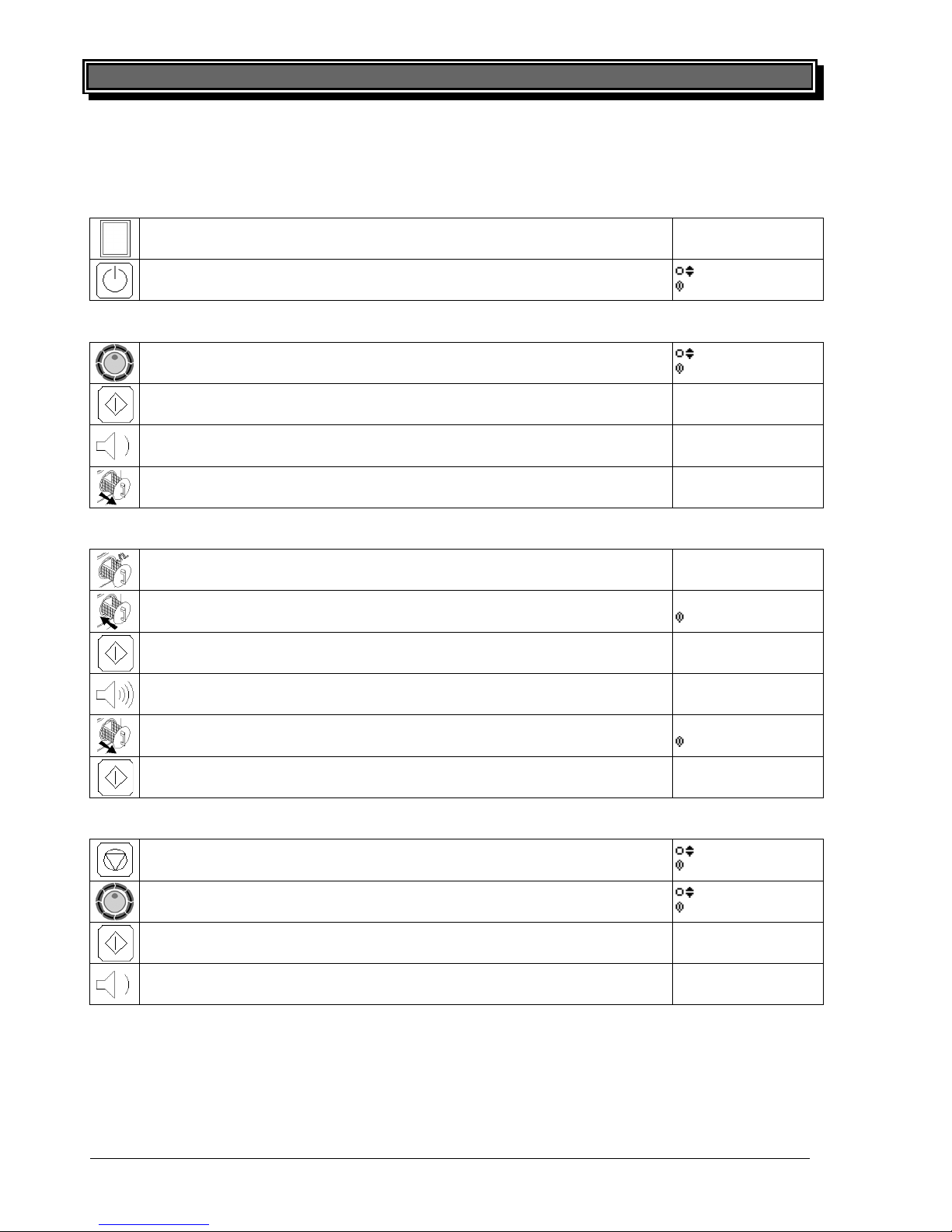

5.2 Control Panel

Following you will find an explanation a location of all components and their function to for optimum

use of RoFry®.

STANDBY

PROGRAMMING

CLEANING

TEMPERATURE

Temperature display

BASKET ROTATION

TIME

Time display

REFERENCE

Clear type display

STOP

START

Indicator LEDs

ENCODER knob

Error! Style not defined. 13

printed: 05/2013 Subject to change! RoFryUserManual.doc

5 Operation

5.1 How RoFry®works

Once the device has been turned on, RoFry initializes. After pushing the STANDBY key is pushed,

RoFry enters the cold standby level. After confirming a program selection with the START key,

RoFry enters the hot standby level and is preheating to set temperature. This takes app. 2 minutes.

To fry food products, pull out the basket, put in the food to be prepared, push in the basket and push

the START key.

The basket starts to rotate and the main fan rotates full speed. The

air intake-and exhaust flaps are closed now. The temperature

drops. Now the computer control adjusts RoFry® automatically to

the amount and temperature of the food product by shortening or

lengthening the total cooking time to obtain a considerably even

product result.

The steam time phase starts. Now humidity is taken from the

product and turned into steam, cooking the product. During steam

time the temperatures in the chamber rise up to max. 20° C above

programmed operating temperature (if wanted). After the steam

time is finished, the flaps open again and the temperature will drop

to the start-level.

The roasting phase in which the goods get crispy begins. Now the

flaps are opened to let the vapor escape. Dry, preheated air is

blown via intake channel into the chamber. The flaps remain open

until the basket has been emptied.

14 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.2 Control Panel

Following you will find an explanation a location of all components and their function to for optimum

use of RoFry®.

STANDBY

PROGRAMMING

CLEANING

TEMPERATURE

Temperature display

BASKET ROTATION

TIME

Time display

REFERENCE

Clear type display

STOP

START

Indicator LEDs

ENCODER knob

Error! Style not defined. 15

printed: 05/2013 Subject to change! RoFryUserManual.doc

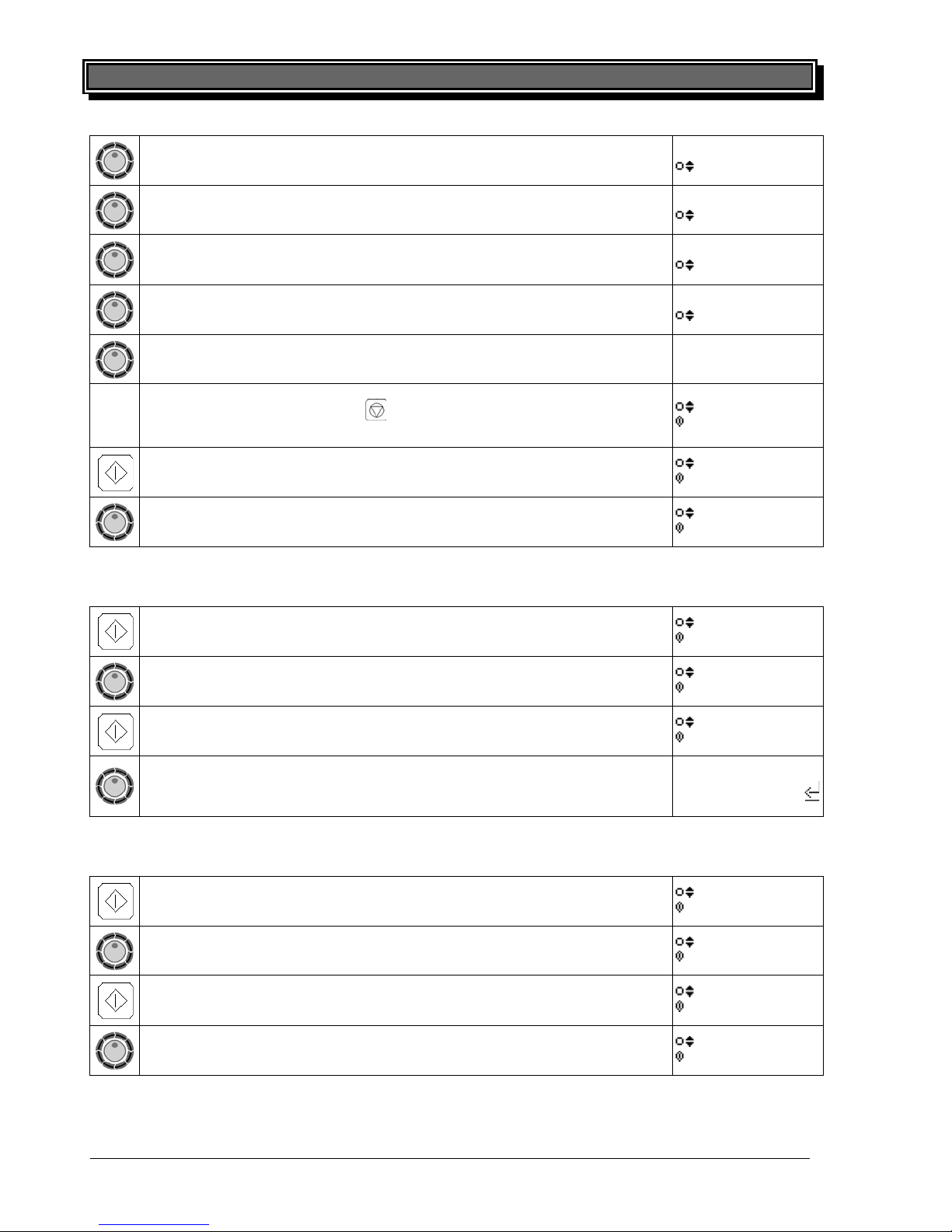

5.2.1 Function status of keys

To simplify operation of the RoFry, the function keys change colors to show their status.

Key LED off: Key cannot be selected (function is not available).

Key LED green: Key can be selected (function is available).

Key LED red: Key is selected (function is selected and active).

Indicator LEDs red spinning over green: A cooking program is running with basket rotation

Indicator LEDsflashing green: A cooking program is finished

5.2.2 Symbols of clear-type display

The following special characters (symbols)appear on the clear type display:

16 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.3 Description of operating elements

Following you will find the description of switches, keys, knob and displays

5.3.1 Basket handle

Pull out / push in the basket using the basket handle.

5.3.2 Door handle

NOTE: Only open the door using the door handle after the basket has been removed

completely from the equipment! Never use the door handle to carry the RoFry®!

5.3.3 Main switch

By pushing the main switch the device is being turned on or off.

5.3.4 STANDBY

By pushing the STANDBY key RoFry®will be activated (cold standby) and the program

that has been used the last time appears in the clear type display.

5.3.5 PROGRAMMING

By pushing the PROGRAMMING key the programming-mode will be activated and the

operator gets access to the programming-level.

5.3.6 CLEANING

By pushing the CLEANING key the cleaning-mode will be activated and the cleaning-

program that has been used the last time appears in the clear-type display.

5.3.7 TEMPERATURE

By pushing the TEMPERATURE key the set requested temperature of the current phase

appears on the Temperature display. The requested temperature appears as long as the

TEMPERATURE key is pushed.

5.3.8 Temperature display

Display of actual temperature or set temperature.

Error! Style not defined. 15

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.2.1 Function status of keys

To simplify operation of the RoFry, the function keys change colors to show their status.

Key LED off: Key cannot be selected (function is not available).

Key LED green: Key can be selected (function is available).

Key LED red: Key is selected (function is selected and active).

Indicator LEDs red spinning over green: A cooking program is running with basket rotation

Indicator LEDsflashing green: A cooking program is finished

5.2.2 Symbols of clear-type display

The following special characters (symbols)appear on the clear type display:

16 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.3 Description of operating elements

Following you will find the description of switches, keys, knob and displays

5.3.1 Basket handle

Pull out / push in the basket using the basket handle.

5.3.2 Door handle

NOTE: Only open the door using the door handle after the basket has been removed

completely from the equipment! Never use the door handle to carry the RoFry®!

5.3.3 Main switch

By pushing the main switch the device is being turned on or off.

5.3.4 STANDBY

By pushing the STANDBY key RoFry®will be activated (cold standby) and the program

that has been used the last time appears in the clear type display.

5.3.5 PROGRAMMING

By pushing the PROGRAMMING key the programming-mode will be activated and the

operator gets access to the programming-level.

5.3.6 CLEANING

By pushing the CLEANING key the cleaning-mode will be activated and the cleaning-

program that has been used the last time appears in the clear-type display.

5.3.7 TEMPERATURE

By pushing the TEMPERATURE key the set requested temperature of the current phase

appears on the Temperature display. The requested temperature appears as long as the

TEMPERATURE key is pushed.

5.3.8 Temperature display

Display of actual temperature or set temperature.

Error! Style not defined. 17

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.3.9 BASKET ROTATION

By pushing the ROTATION key the basket can be turned again after the regular empty-

ing if necessary.

5.3.10 TIME

By pushing the TIME key the set time of the current phase is displayed on the Time

display. The set time appears as long as the TIME key is pushed.

5.3.11 Time display

Display of remaining time, set time and reference time.

5.3.12 REFERENCE

By pushing the REFERENCE key in standby mode,the reference time of the selected

program is shown on the Time display.

5.3.13 Clear type display

In the first line of the Clear type display the cur-

rent program is shown. The second line shows

the current status of the program or a menu-

driven demand for further necessary operation

steps.

In the programming-mode the first line of the clear-type display shows the program level and

name. The second line asks for choosing of functions and input of values by the encoder

5.3.14 STOP

Push the STOP key to:

- Interrupt a currently running program.

- Deselect the program during hot standby.

- Quit programming in the programming level and jump back to the cold standby.

- Leave the programming level.

5.3.15 START

Push the START key to:

- Confirm selection of a program during cold standby.

- Start a program during hot standby.

5.3.16 ENCODER

By actuating the ENCODER all programs, menu points, temperatures, times,

basket rotation, automatic functions and volume control can be selected and

adjusted. When the ENCOEDER is turned clockwise the programs and menu

points are displayed numerically on the clear type display In case of turning

anticlockwise this is happening numerically reverse.

18 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.4 Operation

5.4.1 Activate equipment

Press main switch

INITIALIZING

Press STAND-BY key (as soon as it lights up green)

02:CHICK.NUGG.

CONFIRM

5.4.2 Select program

Select desired program by ENCODER

01:CHIPS

CONFIRM

Confirm selected program by START key

01:CHIPS

PREHEAT

Equipment heats up approx. 2-3 min.

01:CHIPS

STAND BY

Afterwards pull out the basket to the end stop

01:CHIPS

STAND BY

5.4.3 Frying

Fill in product

01:CHIPS

STAND BY

Push in the basket

01:CHIPS

START?

Start program by START key (not with AUTOSTART)

01:CHIPS

PROGRAM RUNS

Program runs until signal sounds

01:CHIPS

READY

Pull out the basket to the end stop

01:CHIPS

EMPTY

Empty basket by START key (not with AUTOEMPTY)

01:CHIPS

STAND BY

5.4.4 Switch between programs

Leave current program by STOP key

01:CHIPS

CONFIRM

Select desired program by ENCODER

02:CHICK.NUGG.

CONFIRM

Confirm selected program by START key

02:CHICK.NUGG.

PREHEAT

Equipment heats up a few seconds if necessary (continue with ”Fry-

ing“)

02:CHICK.NUGG.

STAND BY

Error! Style not defined. 17

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.3.9 BASKET ROTATION

By pushing the ROTATION key the basket can be turned again after the regular empty-

ing if necessary.

5.3.10 TIME

By pushing the TIME key the set time of the current phase is displayed on the Time

display. The set time appears as long as the TIME key is pushed.

5.3.11 Time display

Display of remaining time, set time and reference time.

5.3.12 REFERENCE

By pushing the REFERENCE key in standby mode,the reference time of the selected

program is shown on the Time display.

5.3.13 Clear type display

In the first line of the Clear type display the cur-

rent program is shown. The second line shows

the current status of the program or a menu-

driven demand for further necessary operation

steps.

In the programming-mode the first line of the clear-type display shows the program level and

name. The second line asks for choosing of functions and input of values by the encoder

5.3.14 STOP

Push the STOP key to:

- Interrupt a currently running program.

- Deselect the program during hot standby.

- Quit programming in the programming level and jump back to the cold standby.

- Leave the programming level.

5.3.15 START

Push the START key to:

- Confirm selection of a program during cold standby.

- Start a program during hot standby.

5.3.16 ENCODER

By actuating the ENCODER all programs, menu points, temperatures, times,

basket rotation, automatic functions and volume control can be selected and

adjusted. When the ENCOEDER is turned clockwise the programs and menu

points are displayed numerically on the clear type display In case of turning

anticlockwise this is happening numerically reverse.

18 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.4 Operation

5.4.1 Activate equipment

Press main switch INITIALIZING

Press STAND-BY key (as soon as it lights up green) 02:CHICK.NUGG.

CONFIRM

5.4.2 Select program

Select desired program by ENCODER 01:CHIPS

CONFIRM

Confirm selected program by START key 01:CHIPS

PREHEAT

Equipment heats up approx. 2-3 min. 01:CHIPS

STAND BY

Afterwards pull out the basket to the end stop 01:CHIPS

STAND BY

5.4.3 Frying

Fill in product 01:CHIPS

STAND BY

Push in the basket 01:CHIPS

START?

Start program by START key (not with AUTOSTART) 01:CHIPS

PROGRAM RUNS

Program runs until signal sounds 01:CHIPS

READY

Pull out the basket to the end stop 01:CHIPS

EMPTY

Empty basket by START key (not with AUTOEMPTY) 01:CHIPS

STAND BY

5.4.4 Switch between programs

Leave current program by STOP key 01:CHIPS

CONFIRM

Select desired program by ENCODER 02:CHICK.NUGG.

CONFIRM

Confirm selected program by START key 02:CHICK.NUGG.

PREHEAT

Equipment heats up a few seconds if necessary (continue with ”Fry-

ing“)

02:CHICK.NUGG.

STAND BY

Error! Style not defined. 19

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.5 Programming

5.5.1 Activate equipment

Press main switch INITIALIZING

Press STAND-BY key (as soon as it lights up green) 02:CHICK.NUGG.

CONFIRM

5.5.2 Enter programming level

Push and hold programming button (at least 3 seconds) CODE: 127

CONFIRM

Select code “100“ by ENCODER (100 is the factory default and could

have been changed!)

CODE: 100

CONFIRM

Confirm selected code by START key PROGRAM ROFRY

CONFIRM

5.5.3 Enter new program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key NEW PROG:

CONFIRM

Confirm“NEW PROG:“ by START key 08:POMMES FEIN

CONFIRM

Select product name

Confirm by START key

POMMES FEIN

6789_-+/().:<-->

If applicable, edit Product name by cursor, then move most right and

Confirm by START key 08:FRIES

STEAM TEMP.

Adjust the steam temperature shown in the temperature display.

Confirm by START key

08: FRIES

STEAM TIME

Adjust the steam time shown in the time display.

Confirm by START key

08: FRIES

ROASTING TEMP

Adjust the roasting temperature shown in the temperature display.

Confirm by START key

08: FRIES

RÖST ZEIT

Adjust the roasting time shown in the time display.

Confirm by START key

08: FRIES

OPTIONS N

To enter Options change to “OPTIONS Y”

Confirm by START key

08: FRIES

BATCH REFERENCE

Time for Batch Reference is “00:00“ in the time display.

Confirm by START key

08: FRIES

+FACTOR

Adjust +Factor shown in temperature display to “075“ by ENCODER

Confirm by START key

08: FRIES

-FACTOR

Adjust -Factor shown in temperature display to “075“ by ENCODER

Confirm by START key

08: FRIES

AUTOSTART N

20 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

Activate AUTOSTART by selecting(“Y“) or deactivate (“N“)

Confirm by START key

08: FRIES

AUTOEMPTY N

Activate AUTOEMPTY by selecting(“Y“) or deactivate (“N“)

Confirm by START key

08: FRIES

BASKET ROT. Y

Activate Basket Rotation (“Y“) or deactivate by selecting (“N“)

Confirm by START key

08: FRIES

ROT. DELAY

Adjust Rotation Delay shown in the Time display

Confirm by START key

08: FRIES

ROT. INTERVAL

Adjust Rotation Interval shown in the Time display

Confirm by START key

08: FRIES

STORE DATA

RoFry is storing the cooking program settings

(NOTE: In case the STOP key is pushed before the message

“STORE DATA” appears, all settings made so far, will get lost.

PROGRAM ROFRY

CONFIRM

To write /change / delete another cooking program:

Confirm“PROGRAM ROFRY“ by START key

09:POMMES FEIN

CONFIRM

To leave the programming level select “EXIT”.

Confirm by START key

EXIT

CONFIRM

5.5.4 Change a program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key

NEW PROG:

CONFIRM

Select “CHANGE PROG.“

CHANGE PROG.

CONFIRM

Confirm by START key

01:NUGGETS

CONFIRM

Select the cooking program to be changed

Confirm by START key >Refer to the chapter “Enter new pro-

gram“(above) for further steps

NUGGETS

6789_-+/().:<-->

5.5.5 Delete a program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key

NEW PROG:

CONFIRM

Select “DELTE PROG.“

DELTE PROG.

CONFIRM

Confirm by START key

01:NUGGETS

CONFIRM

Select the cooking program to be deleted

Confirm by START key

PROGRAM ROFRY

CONFIRM

Error! Style not defined. 19

printed: 05/2013 Subject to change! RoFryUserManual.doc

5.5 Programming

5.5.1 Activate equipment

Press main switch

INITIALIZING

Press STAND-BY key (as soon as it lights up green)

02:CHICK.NUGG.

CONFIRM

5.5.2 Enter programming level

Push and hold programming button (at least 3 seconds)

CODE: 127

CONFIRM

Select code “100“ by ENCODER (100 is the factory default and could

have been changed!)

CODE: 100

CONFIRM

Confirm selected code by START key

PROGRAM ROFRY

CONFIRM

5.5.3 Enter new program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key

NEW PROG:

CONFIRM

Confirm“NEW PROG:“ by START key

08:POMMES FEIN

CONFIRM

Select product name

Confirm by START key

POMMES FEIN

6789_-+/().:<-->

If applicable, edit Product name by cursor, then move most right and

Confirm by START key

08:FRIES

STEAM TEMP.

Adjust the steam temperature shown in the temperature display.

Confirm by START key

08: FRIES

STEAM TIME

Adjust the steam time shown in the time display.

Confirm by START key

08: FRIES

ROASTING TEMP

Adjust the roasting temperature shown in the temperature display.

Confirm by START key

08: FRIES

RÖST ZEIT

Adjust the roasting time shown in the time display.

Confirm by START key

08: FRIES

OPTIONS N

To enter Options change to “OPTIONS Y”

Confirm by START key

08: FRIES

BATCH REFERENCE

Time for Batch Reference is “00:00“ in the time display.

Confirm by START key

08: FRIES

+FACTOR

Adjust +Factor shown in temperature display to “075“ by ENCODER

Confirm by START key

08: FRIES

-FACTOR

Adjust -Factor shown in temperature display to “075“ by ENCODER

Confirm by START key

08: FRIES

AUTOSTART N

20 Error! Style not defined.

printed: 05/2013 Subject to change! RoFryUserManual.doc

Activate AUTOSTART by selecting(“Y“) or deactivate (“N“)

Confirm by START key

08: FRIES

AUTOEMPTY N

Activate AUTOEMPTY by selecting(“Y“) or deactivate (“N“)

Confirm by START key

08: FRIES

BASKET ROT. Y

Activate Basket Rotation (“Y“) or deactivate by selecting (“N“)

Confirm by START key

08: FRIES

ROT. DELAY

Adjust Rotation Delay shown in the Time display

Confirm by START key

08: FRIES

ROT. INTERVAL

Adjust Rotation Interval shown in the Time display

Confirm by START key

08: FRIES

STORE DATA

RoFry is storing the cooking program settings

(NOTE: In case the STOP key is pushed before the message

“STORE DATA” appears, all settings made so far, will get lost.

PROGRAM ROFRY

CONFIRM

To write /change / delete another cooking program:

Confirm“PROGRAM ROFRY“ by START key

09:POMMES FEIN

CONFIRM

To leave the programming level select “EXIT”.

Confirm by START key

EXIT

CONFIRM

5.5.4 Change a program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key NEW PROG:

CONFIRM

Select “CHANGE PROG.“ CHANGE PROG.

CONFIRM

Confirm by START key 01:NUGGETS

CONFIRM

Select the cooking program to be changed

Confirm by START key >Refer to the chapter “Enter new pro-

gram“(above) for further steps

NUGGETS

6789_-+/().:<-->

5.5.5 Delete a program

Presuming the programming level has already been entered

Confirm“PROGRAM ROFRY“ by START key NEW PROG:

CONFIRM

Select “DELTE PROG.“ DELTE PROG.

CONFIRM

Confirm by START key 01:NUGGETS

CONFIRM

Select the cooking program to be deleted

Confirm by START key

PROGRAM ROFRY

CONFIRM

Error! Style not defined. 21

printed: 05/2013 Subject to change! RoFryUserManual.doc

6 Maintenance

Following some advises concerning maintenance, care, trouble shooting and service for RoFry®.

6.1 Cleaning and Care

6.1.1 Safety advices

•Do not use inflammable detergents cleaners. Never use high-pressure-

, water

pressure-or steam jet-cleaning devices.

•Wear fire-safe, insulated gloves to prevent burnings when touching hot parts.

•Wear acid-proof gloves while cleaning the cold parts to prevent skin irritations.

6.1.2 General recommendations

•The unit has to be cleaned daily.

•Only use cleaners that are appropriate for food (neutral or alkaline detergents),

even if there are plain and persistent residues.

•After cleaning with special cleaners you have to wash all parts with clear water and

dry them afterwards so that there are no residues of the cleaner on these parts.

•It is absolutely necessary to watch out for some fundamental things to keep this

long-lived high-grade-steel-device working:

- always keep the high-grade-steel surface clean.

- watch out that there is always enough fresh air on the surface

- never contact the surface with rusty material

•Never use bleaching or chlorine cleaners.

6.1.3 Detergents

To make the cleaning fast and easy we have integrated some cleaners in our pro-

gram:

For TV/FC- Version

•RoFry®-Cleaner

•RoFry®-Descaler

•Stainless steel-cleaner:

You have to spray this from a distance of app. 25 cm on the surface and wipe it off

with a dry cleaning rag. If you want to clean only small parts you have to spray it di-

rectly on the cleaning rag and wipe it off this way. With this method it is possible to

clean RoFry® easily and without stripes.

For ST-Version:

•RoFry®-Spray ‘KOTE’:

By using this spray a film is built up that prevents that any particles of the food,

grease, oil etc. can stick on the surface.

Note! Never use KOTE for the basket and the basketholder.

•Soak-Tank:

This is for cleaning of all removable parts except the fresh air filter.

Table of contents

Popular Oven manuals by other brands

Toastess

Toastess TO-90S Instruction booklet

KitchenAid

KitchenAid KEBK101 Use & care guide

PizzaMaster

PizzaMaster PM 351ED Instructions for installation, operation and maintenance

KKT KOLBE

KKT KOLBE EU Series Service manual

Henny Penny

Henny Penny GCC-620 Specification sheet

Midea

Midea 310503 Installation instructions & user guide