Bridge BP-100HS-A Instruction Manual

Directions for installation and maintenance

2

Contents

1. Introduction ………………….…………………………….……..………….

p3

2. Caution…………………………………………………….………………….…..

p3

3. Delivery control …………………………………………........................

p4

4. Technical description …………………………….……………………..

p4

Technical characteristics

Outside

Inside

Explored view

Wire control operation

General diagram of the refrigerating circuit

Safety and control systems

5. Installation ……………………….………………………………….......

p14

Rules of installation

Hydraulic connections

Electric connections

6. Water flow and refrigerating circuit pressure........................

p17

7. Environment problem ………………………………………............

p18

8. Maintenance and inspection ……………….…………………..…

p19

9. Electric diagram ……………………………………………….……..…

p21

3

1- Introduction

We thank you for having chosen our Heat pump.

This installation and maintenance notice contains the necessary

information to its installation (delivery control, the installation, the

connections) and to its repair. It is a complementary document to

the user’s manual which describes its instructions for use.

We invite you to read it first.

2-

Caution

This document is an integral part of the product and it must stays in

the technical room.

This Heat pump is exclusively for heating swimming pools.

Any other use not in conformity and random will be considered as

dangerous and unsuitable.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person

responsible for their safety.

The assembly, the electric connection and the start-up must be

carried out by specialized and professional person.

The appliance shall be installed in accordance with national wiring

regulations.

It is essential to maintain the temperature in the swimming pool

lower than the recommended value by the swimming pool’s

manufacturer.

Please make sure that minimum water flow speed is 8m³/h.

In a concern to a constant improvement, our products can be

modified without notice; the present pictures in this note or the

characteristics which are described are not contractual.

4

3- Delivery’s control

At the delivery time, check the condition of packing; in case of

damages, have reservation about them to the carrier, before 48

hours and by registered letter with acknowledged receipt.

Before any manipulation, check the complete state of the machine.

4

-

Technical description

Characteristics:

MODEL

BP-100HS-A

Power supply

230V~, 50Hz

Heating consumption power *

(kW)

1.85

Heating restored power *(kW)

11

Heating nominal intensity *(A)

8.8

Heating consumption power **

(kW)

1.75

Heating restored power **(kW)

8.2

Heating nominal intensity **(A)

8

Air flow (m3/H)

2600

Noise level (d(B)A)

<54

Refrigerant gas

R32

Rate of average filling of gas (g)

750

CO2 equivalent [T]

0.51

Net weight of the unit (kg)

54

Overall sizes L x W x H (cm)

90 x 31 x 62

possible variations of value according to climatic conditions

*: A26W26 **A15W26

5

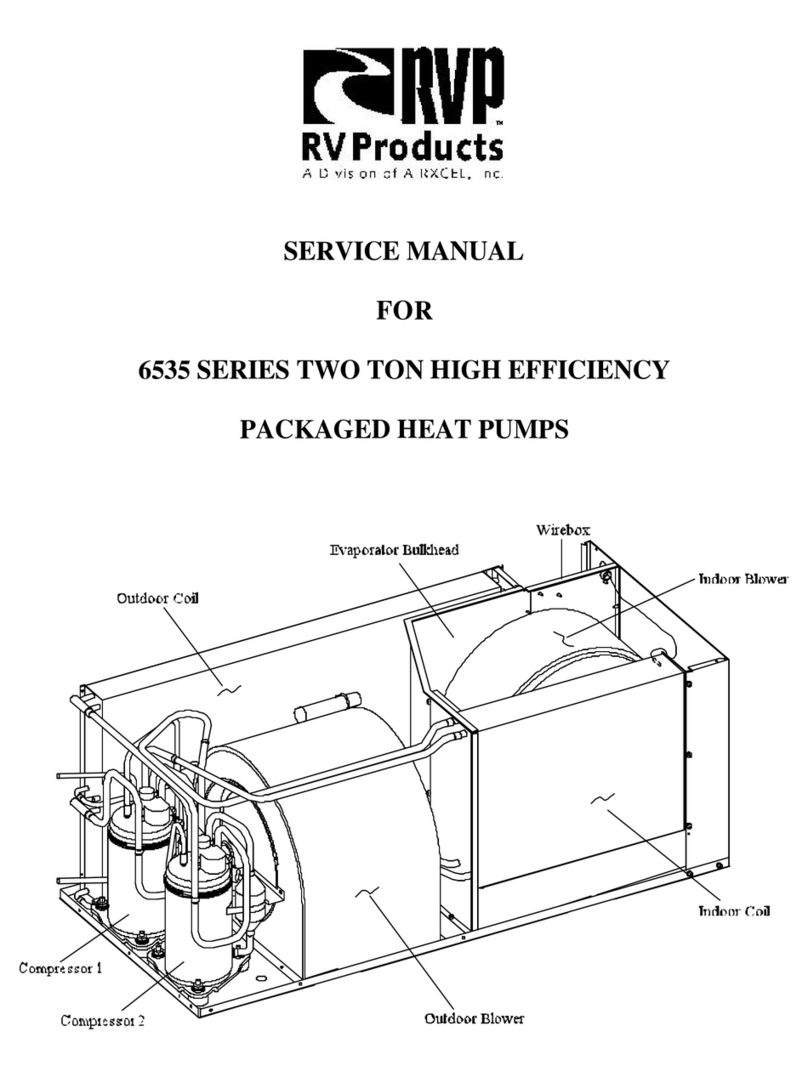

Outside:

Inside:

(Front sheet cover and panel removed)

1

Fan protection grid

2

Front panel

3

Top cover

4

Control panel

5

Refrigerant pressure manometer

6

Fast connection for water outlet

7

Fast connection for water intlet

8

Wire connection for power supply

9

Evaporator

10

Fan

11

Compressor

12

High and low pressure interruptor

13

Titanium heat exchanger

14

Temperature sensor of swimming pool water

15

Four way valve

16

Ambient temperature sensor

17

Defrost sensor

18

Water flow switch

6

7

Wire control operation

The function of the LCD display and control:

Set the operation parameter:

◎Long Press “ ” button to enter operation parameter setting interface.

◎Press " " to check parameter(parameter from 0-28, see Operation Parameter Table).

◎Under parameter, press " " to start setting(the parameter displayed blinks), press " " or "

" to set data for parameter from 0-28, press " " again to exit the current parameter

settings.

◎In operation parameter setting interface, press “ ” or “ ” button exit to man interface, No

operation is maintained in the parameter interface.

NO

Meaning

Range

Change

Factory setting

0

Automatic restart

0/1

YES

1

1

Daily cycle mark

0/1

YES

1

2

Water temperature difference to restart

2~10°C

YES

2

3

Water temperature difference to restart Y

0~3°C

YES

0

4

Turnround of defrosting Under heat mode

30~90 min

YES

40 min

5

Defrosting start temperature

-30~0°C

YES

-7°C

6

Defrost exit temperature

2~30°C

YES

20°C

7

Time of exit defrost Under heat mode

1~12 min

YES

8 min

8

Compressor protection Exhaust temperature

95~120°C

NO

95°C

9

Max set water temperature

40~65

YES

40°C

10

Water pump mode

0/1

YES

1

11

Constant temperature water pump stop time

3~20 min

YES

15

13

Mode (cool/coo & heat/ heat)

0/1/2

YES

1

14

EEV action cycle

20~90s

NO

40

15

Heating Target Superheat

-5~10°C

NO

0°C

16

Acceptable exhaust temperature when EEV

adjustment

80~110℃

NO

95℃

17

Defrosting EEV aperture setting

20~450

NO

400

8

18

Min. EEV aperture setting

50~200

NO

100

19

EEV manual step number

20~450

NO

350

20

EEV manual/automatic

0/1

NO

1

21

Water inlet temperature

-9~99°C

Measured value

23

Heating coil temperature

-9 ~ 99°C

Measured value

24

Compressor Exhaust temperature

-9 ~ 125°C

Measured value

25

Ambient temperature

-9 ~ 99°C

Measured value

26

Return gas temperature

-9 ~ 99°C

Measured value

27

Actual open steps of EE valve

100~500

Measured value

28

Cooling coil temperature

-9 ~ 99°C

Measured value

9

Real-time clock setting

Press“" button to set clock,

“" symbol will flash during this setting,

Press " " button, it will enter hour setting,

press “ ” or “ ” buttons to change the value.

Press " " button once more, it will enter minute setting.

Also press “ ” or “ ” buttons to change the value.

After setting, press “ ” button to back to default screen.

Timer setting

Press“" button to set clock, if the clock without setting,

Press “"button again to first group timer setting,

Press and hold " " to shift the timer On/OFF,

While the timer is ON, " " symbol will flash,

Once the timer ON, press " " to set the hour for Timer switch ON,

Press “ ” or “ ” buttons to change the value.

Press " " button once more to set the minute for Timer switch ON.

Press " " button again, it will enter Timer switch OFF setting.

Same as the Timer switch ON.

During timer setting, press “"button,it will enter next group timer setting.

There are 3 group of timer Settings.

Long press " " to cancel the group setting when the group "" symbol flashes.

Key lock:

Long press “ ” button 5 seconds, To set keylock.

Long press “ ” button 5 seconds again to release keylock.

10

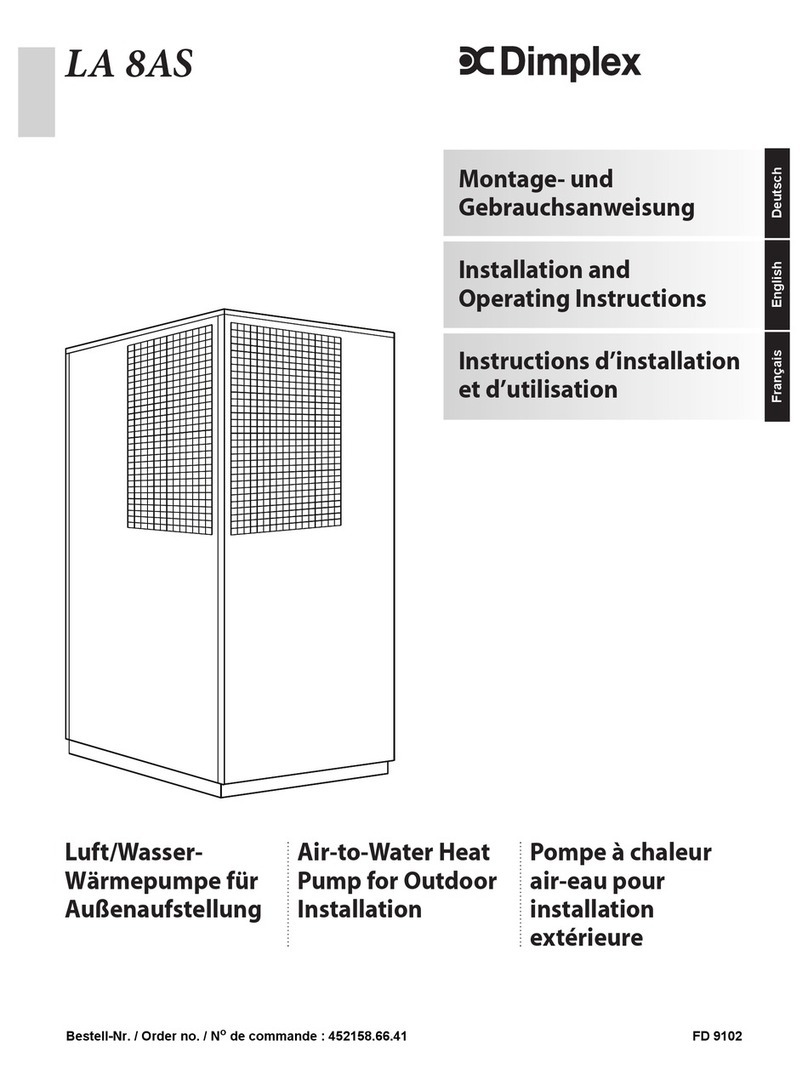

General diagram of the refrigerating circuit

The heat pump is reversible allowing the swimming-pool’s heating or

cooling:

Swimming-pool water’s heating mode:

The cold and liquid refrigerant fluid absorbs the heat contained in the air through the evaporator

(gilled radiator), in which it is vaporizing; it is then put up in pressure and in temperature by the

compressor which sends it in the condenser (exchanger) where it loses its heat (in giving it to the

water of swimming pool) and comes back in liquid state; it loses its pressure and still cools in the

expansion capillaries before turning back to the evaporator for a new cycle.

Hot water

Cold water

Hot air

Cold air

Compressor

Single

way

valve

Condenser

(exchanger)

4 way valve

Pressure and gas

intake

Evaporator

(gilled

radiator)

Expansion

capillary

11

Swimming-pool water’s cooling mode:

The 4way valve reverses thecirculation of the refrigerant fluid; the fluid vaporizes in the exchanger

(evaporator) in getting the heat of the water, goes through in the compressor which reheats it and

through in the gilled radiator (which becomes condenser) where it comes back to liquid state.

Cold water

Heat water

Cold air

Hot air

Compressor

Evaporator

(exchanger)

4 way

valve

Evaporator

(gilled

radiator)

Pressure and gas

intake

Single

way

valve

Expansion

capillary

12

Safety and control systems

Heat pumps are equipped with the following standard protection

systems:

1. Water flow switch

Thanks to this flow switch, the heat pump will not work when the filter pump is not working (and

the water is not circulating). This system prevents the heat pump from heating only the water flow

in the heat pump itself. The protection also stops the heat pump if water circulation is cut off or

stopped.

2. Refrigerant gas high and low pressure protection

The high pressure protection makes sure the heat pump is not damaged in case of over

pressurisation of the gas. The low pressure protection emits a signal when refrigerant is escaping

from the conduits and the unit cannot be kept running.

3. Overheating protection on the compressor

This protection protects the compressor from overheating.

4. Automatic defrost control

When the air is very humid and cold, ice can form on the evaporator. In that event, a thin layer of

ice appears that will grow increasingly bigger as long as the heat pump is running. When the

temperature of the evaporator has become too low, automatic defrost control will be activated,

which will reverse the heat pump cycle so that hot refrigerant gas is sent through the evaporator

during a brief period of time to defrost it.

13

5. Anti-frost protection during winter

This protection can only be activated if the heat pump is in STAND-BY mode.

5.1 First anti-frost protection

If the filter pump is controlled by the heat pump (regardless of the value for parameter 9) and

when the water temperature lies between 2 and 4 °C and the air temperature is lower than

0 °C, the filter pump will be automatically turned on to prevent the water from freezing in the

piping. This protection is deactivated when the temperature rises again.

5.2 Second anti-frost protection

If the water temperature drops even more, that is, below 2 °C (during long frost periods), the heat

pump will also start running to heat the water until its temperature approximates 5 °C. When this

temperature is reached, the heat pump will stop, but anti-frost protection will remain active until

conditions change.

6. 3-fase protection

If the phases are connected in the wrong order due to electrical mis-wiring, this protection

will interrupt

the power supply to prevent mechanical deformation. There will be an EE 4 error code on

the display.

14

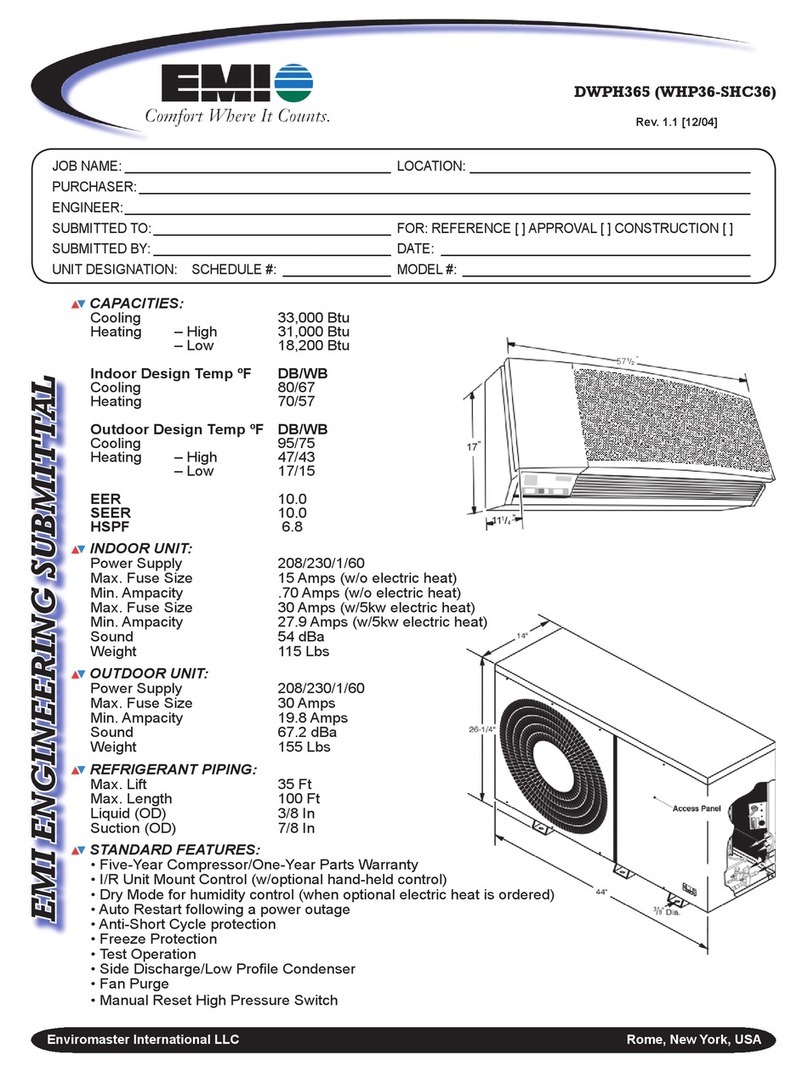

5- Installation

Rules of installation:

Electric and hydraulic connections must be carried out according to standards in

effect (NF C 15 100, CE I 364).

The machine must be installed outside.

The machine must be posed on its anti-vibratory studs, set and lying flat and on a

massive base (concrete slab); this base must have a sufficient height to prevent

any entry of water by the bottom of the machine. Height must be adjusted to fit

the connector collecting the condensates.

The obstacles such as wall and vegetation must be separated from the machine as

indicated on the diagram below.

Exhausting Blowing

side side

Do not to install the Heat pump in a confined place (the fan would recycle its air

and the Heat pump would be down performance).

The fan should not blow towards the windows or crossing point.

Safety distance between the swimming pool and the foot bath: the fitter must

imperatively refer to the standard C15-100 section 702; the machine should not be

installed in volume 1 surrounding the swimming pool but at least in volume 2 so at

a distance of 3 m minimum of the swimming pool and foot bath.

Other precautions of installation:

- Do not to install the machine near a way with circulation of car in order to avoid

mud projections.

- Avoid directing blowing against dominant winds.

- If the machine is intended to be used in winter, put it in a place protected from the

falls of snow.

- The machine must be able to be supervised in order that children do not play

around

2,5 m mini

0,5 m mini

0,3 m mini

0,5 m mini

Swimming-Pool

Technical room

Chemical treatment

Blowing

By-pass

Heat Pump

Drain of the

condensates: insert

the plastic elbow in

the hole of

evacuation of the

bottom and connect

the pipe if need.

Hydraulic connections: To

respect imperatively

Connection is carried out with a by-pass located on

the circuit of filtration, upstream appliances of the

chemical treatment of water.

Connect intake/outlet water PVC pipes DN50 to the

openings of the machine in following the inlet /

outlet indications (grease the worms before

screwing)

Filte

r

15

16

Electric connections:

CAUTION: before connecting the machine, make sure that the feeder is

disconnected to the electrical network.

The electric installation must be carried out by an experienced electrician and the

supply must come from a severing equipment and differential protection; the

whole must be carried out according to standards' in force in the country where

the material is installed.

Characteristics of the electric supply:

- 230 V +/- 10%, single-phase current, or 380 V +/- 10%, three-phase current,60 Hz

- Mode of neutral TT and TN.S; the circuit of heat pump must be connected to an

earth circuit.

Characteristic minimum of the protection:

- Protection must be of 16 A, by circuit breaker or fuse; it must protect the Heat

pump exclusively; the circuit breaker must be specified with curve D, the fuse

must be specified Am.

- Differential protection : 30 mA (the length of cable between the connector block

of the heat pump and the protection of should not exceed 12 m).

Control :

The heat pump is fitted out with a water flow detector which function is to apply

the signal to the electronic card when the water flow is sufficient.

We recommend when it is possible to control the heat pump to the filtration

pump (by contacting relay non supplied to insert in the feeding circuit of the heat

pump).

The remmonded water flow speed is 8m³/h.

Removed control panel:

An extension cord allows the removal of the panel in inserting it in a standard

electric box into the technical local; the option is supplied with a cover allowing to

seal the aperture let by the removal of the control panel.

16

16

6- Water Flow and refrigerating circuit pressure

After putting into service, do the settings of pressure of the refrigerant

circuit for having an optimal operating of the heat pump, as following:

Stage 1:

Before starting the Heat Pump, ambient

temperature around 20°C, refrigerant meter

shows pressure from 14 to 16kg/cm².

Stage 2:

Close completely the by-pass valve and open

large inlet and outlet valves of the Heat

Pump; in these conditions the totality of the

water flow goes by the Heat Pump.

Put into service the Heat Pump in heating mode, wait for the indicated

pressure being stabilized; the correct setting of the pressure is from 21 to

35 kg/cm²;

In most of cases (pump of filtration given a flow until 9m³/h) you do not have

to open the by-pass valve.

If the stabilized pressure is under 21kg/cm², the progressive opening of the

by-pass valve will allow rising this pressure.

The adjustment of the by-pass valve done, you have in principle no reason

to modify it during the season. See the paragraph “Environment problem”

too.

18

17

16

7 –Environment problem

Under certain external conditions the heat exchanges between the refrigerant and

the water on one hand and between the fluid and the air on the other hand are

insufficient; the consequence is that the refrigerating circuit runs up in pressure

and the compressor consumes more electricity.

The temperature sensors compressor outlet and the magnetic circuit breaker on

the compressor power supply protect the compressor from these extreme

conditions; the error messages

E 3

occur.

The condition causing this situation is as follows:

In heating mode:

- insufficient water flow:

close the by-pass valve for increasing the refrigerant exchange →water

In cooling mode:

- too heavy water flow: open the by-pass valve for decreasing the water flow and

so the exchange water →refrigerant

- insufficient air flow: be sure that the real net of condenser are not blocked.

Note: these error codes are likely to occur if temperature of swimming pool water

is high and the ambient air is hot.

18

16

8. Maintenance and inspection

8.1 Maintenance

•Check the water inlet and drainage often. The water and air inflow into the system

should be sufficient so that its performance and reliability does not get compromised.

You should clean the pool filter regularly to avoid damage to the unit caused by clogging

of the filter.

•The area around the unit should be spacious and well ventilated. Clean the sides of the

heat pump regularly to maintain good heat exchange and to save energy.

•Check if all processes in the unit are operational and pay special attention to the

operation pressure of the refrigerant system.

•Check the power supply and cable connections regularly. Should the unit begin to

function abnormally or should you notice a smell from an electrical component, arrange

for timely repair or replacement.

•Winterizing : make sure to purge all the water from the heat pump and other systems

in order to prevent frost damage.

•You should also purge the water if the unit will not work for an extended period of time.

You should check

all parts of the unit thoroughly and completely fill the system with

water before turning it on again

afterwards.

8.2 Troubleshooting guide

Improper installation may result in an electrical discharge that could lead todeath of –or

serious injury to -pool users, installers or others due to electrical shock and may also cause

damage to property.

DO NOT attempt to modify the internal configuration of the heat pump.

1. Keep your hands and hair clear of the fan blades to avoid injury.

2. If you are not familiar with your pool filtering system and heat pump:

a. Do not attempt to adjust or service without consulting your dealer or your professional

pool or air conditioning contractor.

b. Read the entire installation and user manual before attempting to use, service or adjust

the unit.

c. Start the heat pump at least 24 hours after its installation in order to prevent

damage to the compressor.

Note: Switch off the power prior to maintenance or repairs.

19

16

8.3 Overview of possible error codes displayed on the screen

Go back to chapter 4 “Protection systems” for more detailed information.

The heat pump screen displays one of the following codes:

Display

Problem

Cause

Solution

P1

“HEATING COIL

PIPE” sensor out of

order

Sensor open or short-circuited

Check or replace the sensor

P2

“Compressor exhust”

sensor out of order

Sensor open or short-circuited

Check or replace the sensor

P3

“WATER IN” sensor

out of order

Sensor open or short-circuited

Check or replace the sensor

P5

“Return Gas”sensor

out of order

Sensor open or short-circuited

Check or replace the sensor

P7

“AIR” sensor out of

order

Sensor open or short-circuited

Check or replace the sensor

P9

Low pressure

protection

Not enough refrigerant gas

Have the heat pump checked

by a refrigeration technician

Leak in the cooling conduits

Have the heat pump checked

by a refrigeration technician

Pb

“COOLING COIL

PIPE” sensor out of

order

Sensor open or short-circuited

Check or replace the sensor

PC

First anti-frost

protection active

Low temperatures for water

and air

No action required

PC

Second anti-frost

protection active

Low temperatures for water

and air

No action required

PL

Insufficient water flow

Insufficient water flow

Check the water flow

Waterflow switch out of order

Replace the Water flow switch

E3

compressor exhaust

temperature is too

high

Water temperature and

environmental temperature is

too high

Set to the safety of water

temperature.

Refrigerant leakage

Check and repair.

Insufficient water flow

Check the water flow

E4

High pressure

protection

Insufficient water flow

Check the water flow

Pressureswitch out of order

Replace the pressure switch

Have

E8

Too much refrigerant gas

present

the heat pump checked by a

refrigeration technician

20

Table of contents

Other Bridge Heat Pump manuals

Popular Heat Pump manuals by other brands

STIEBEL ELTRON

STIEBEL ELTRON WPL 47 Operation and installation manual

WarmPool

WarmPool OPTIMUS E7 quick start

Bosch

Bosch BOVA Series installation instructions

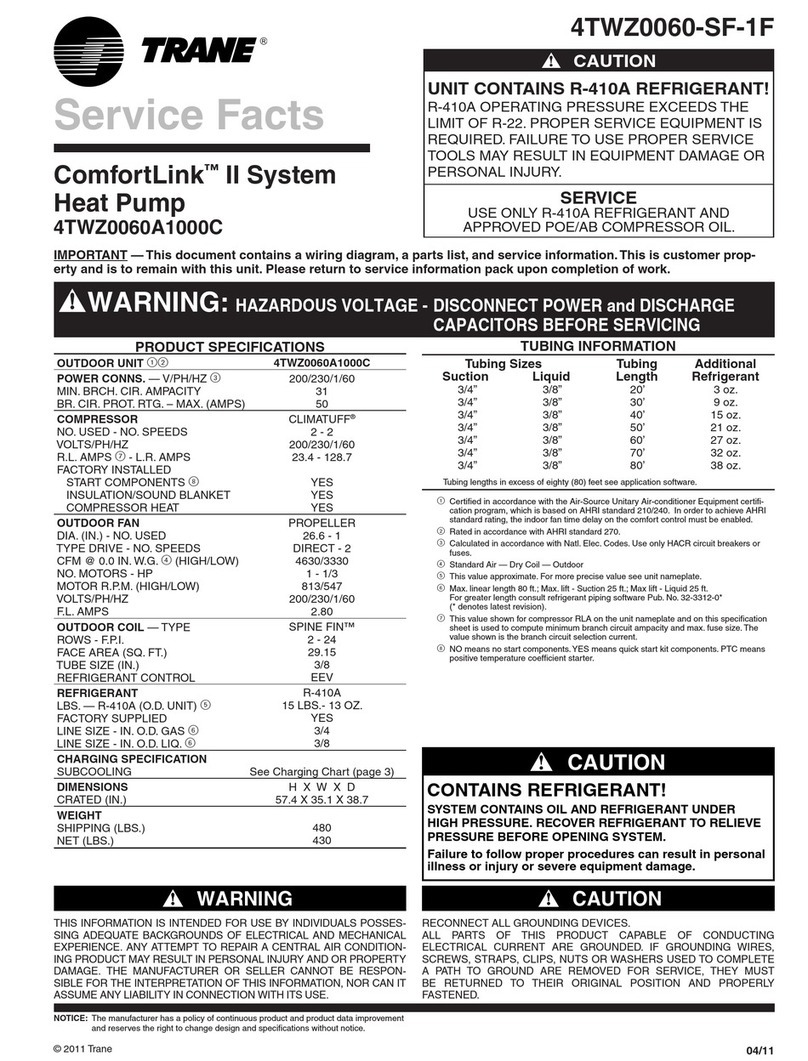

Trane

Trane ComfortLink II 4TWZ0060A1000C Service facts

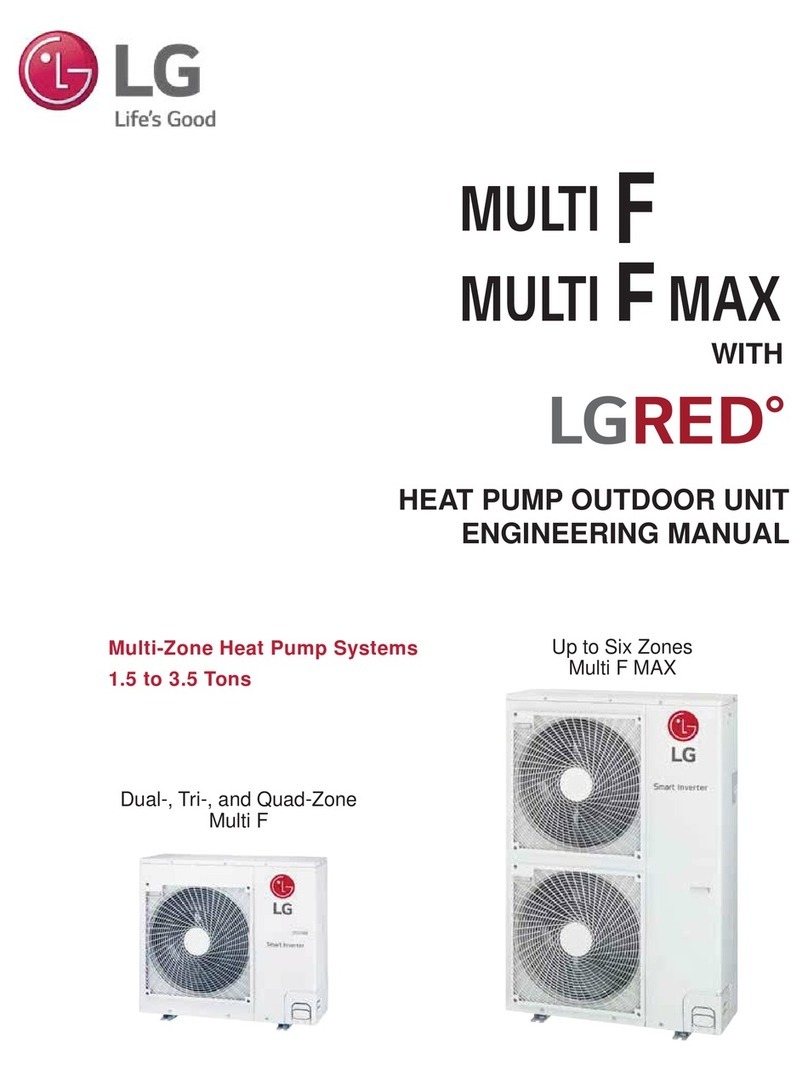

LG

LG MULTI F MAX Engineering manual

Bryant

Bryant Heat Pump Guide to operating and maintaining yo