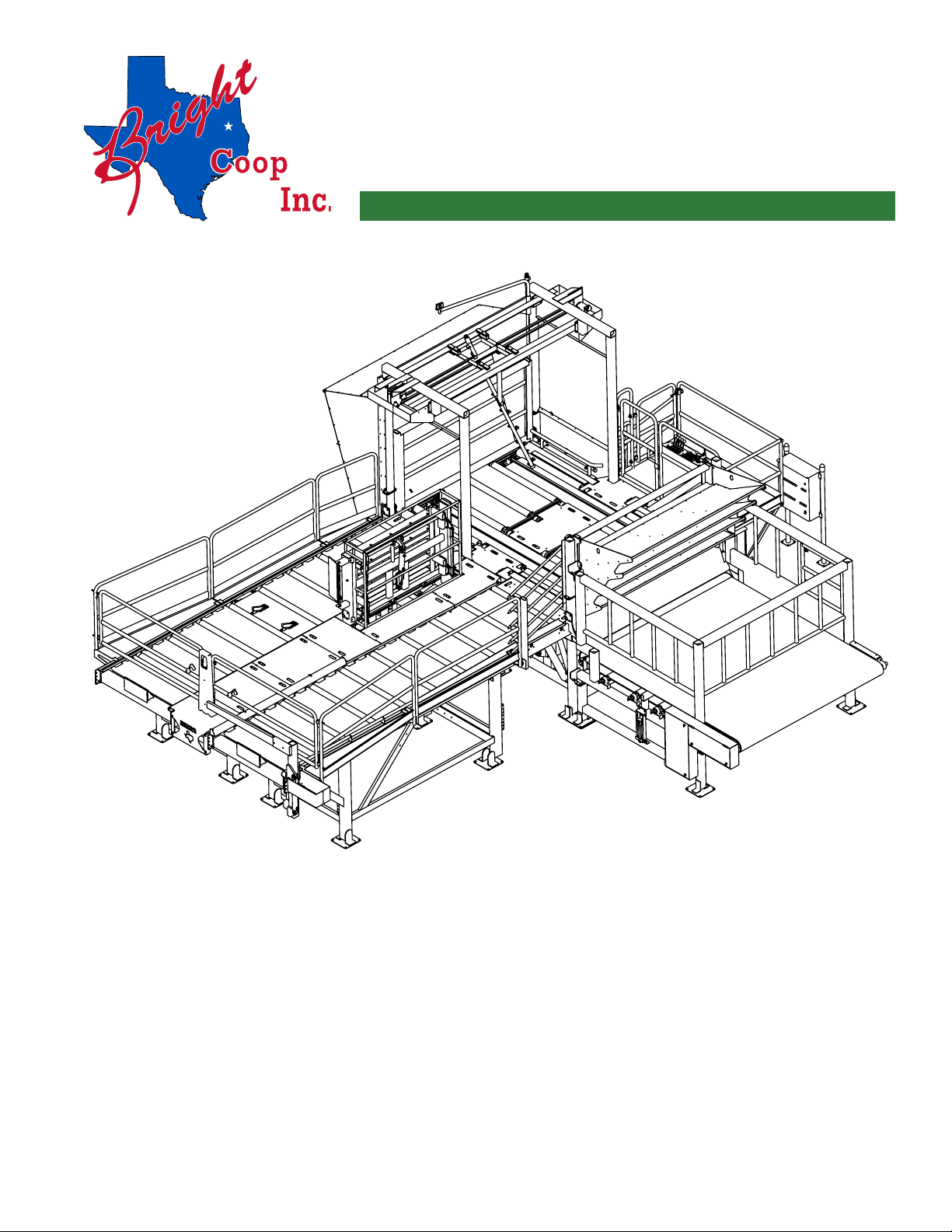

Operator's & Maintenance Manual

Cage Unloading System

3

CONFIGURATION............................................................................................................................................................................ 4

QUICK REFERENCE ........................................................................................................................................................................ 5

IMPORTANT! PRECAUTIONS & DANGERS ............................................................................................................................... 7

FOR THE OPERATOR ............................................................................................................................................................ 7

FOR MAINTENANCE PERSONNEL ..................................................................................................................................... 8

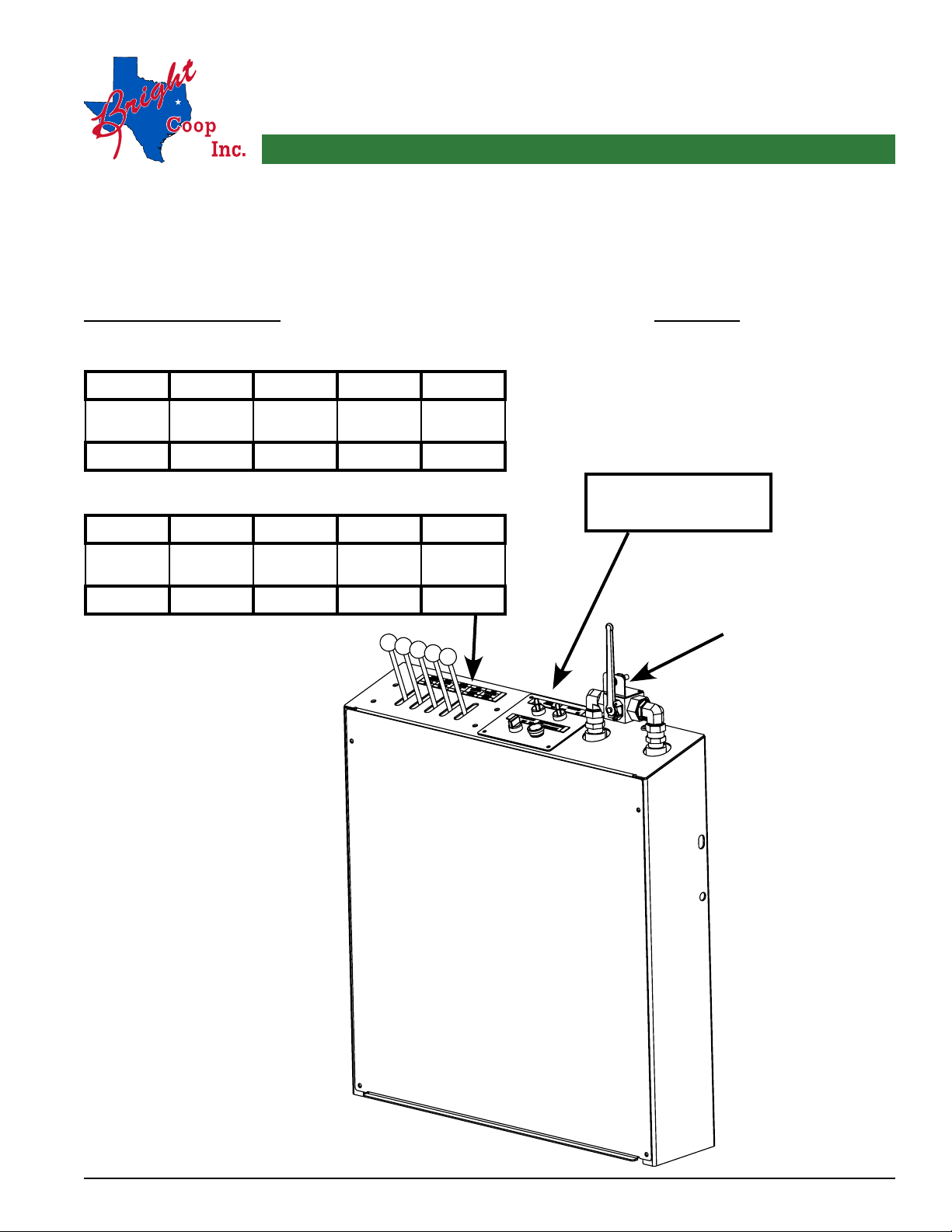

OPERATOR CONSOLE FUNCTIONS & CONTROLS................................................................................................................... 9

LEVER FUNCTIONS.............................................................................................................................................................. 11

UNLOADING SYSTEM WITHOUT CAGE WASHING SYSTEM...................................................................................... 15

UNLOADING SYSTEM WITH CAGE WASHING SYSTEM ............................................................................................. 17

OPERATING PROCEDURES......................................................................................................................................................... 20

VISUAL INSPECTION PRIOR TO OPERATION............................................................................................................... 20

UNLOADING SYSTEM WITHOUT CAGE WASHING SYSTEM...................................................................................... 21

UNLOADING SYSTEM WITH CAGE WASHING SYSTEM ............................................................................................. 30

MAINTENANCE.............................................................................................................................................................................. 40

MAINTENANCE, UNLOADING SYSTEM........................................................................................................................... 40

MAINTENANCE SCHEDULE QUICK REFERENCE.......................................................................................................... 47

RECOMMENDED HYDRAULIC FLUID .............................................................................................................................. 48

WARRANTY AND LIMITATIONS OF LIABILITY..................................................................................................................... 49

DUMPER TROUBLESHOOTING ................................................................................................................................................... 51

SCHEMATICS.................................................................................................................................................................................. 60

ELECTRICAL SCHEMATIC (TRANSFER CHAIN) (091-21963-01).................................................................................. 61

ELECTRICAL SCHEMATIC (TRANSFER CHAIN) (091-21963-02).................................................................................. 63

ELECTRICAL SCHEMATIC (TRANSFER CHAIN AND WASHER) (091-21964-01)...................................................... 65

ELECTRICAL SCHEMATIC (TRANSFER CHAIN AND WASHER) (091-21964-02)...................................................... 67

ELECTRICAL SCHEMATIC HYDRAULIC POWER UNIT (091-22900)........................................................................... 69

ELECTRICAL SCHEMATIC SMART RELAY (091-21961T) ............................................................................................. 71

ELECTRICAL SCHEMATIC SMART RELAY (091-21961W) ............................................................................................ 73

HYDRAULIC SCHEMATIC CAGE UNLOADING SYSTEM WITHOUT WASHER (091-23900) ................................... 75

Table of Contents