Table of Contents

PNEG-2145 21' Diameter Gamma Roof Assembly Instructions 3

Contents

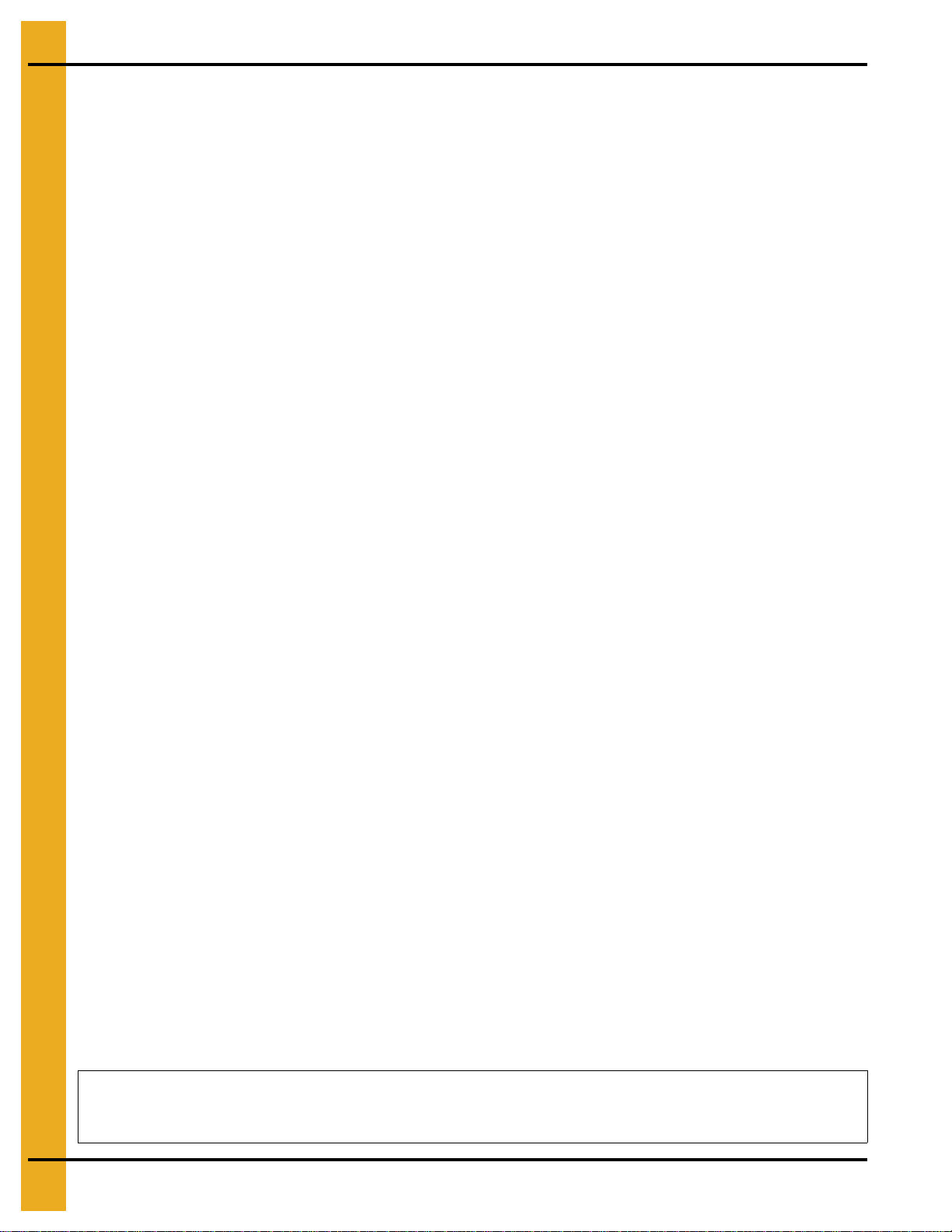

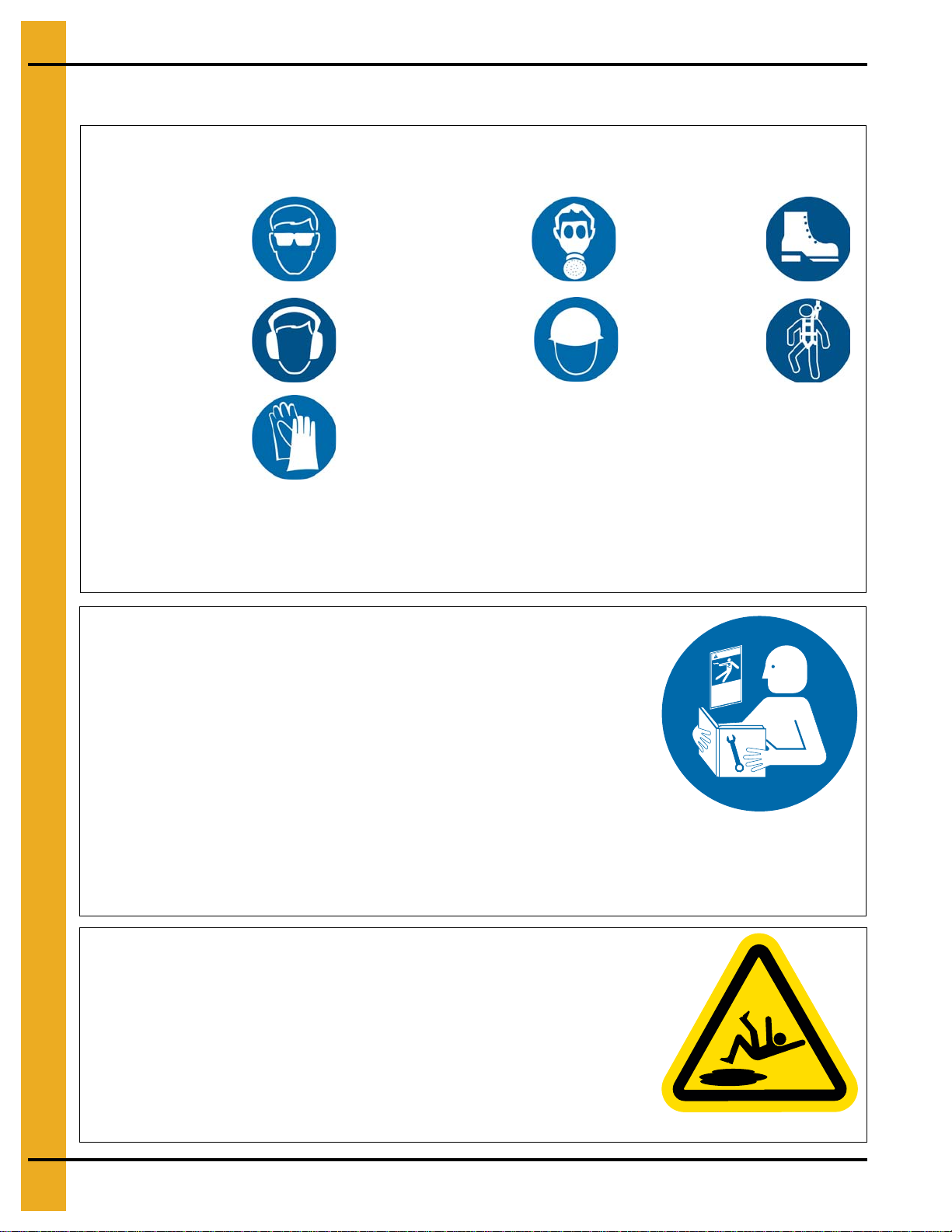

Chapter 1 Safety ..................................................................................................................................... 4

Safety Guidelines .................................................................................................................................. 4

Cautionary Symbols Definitions ............................................................................................................ 5

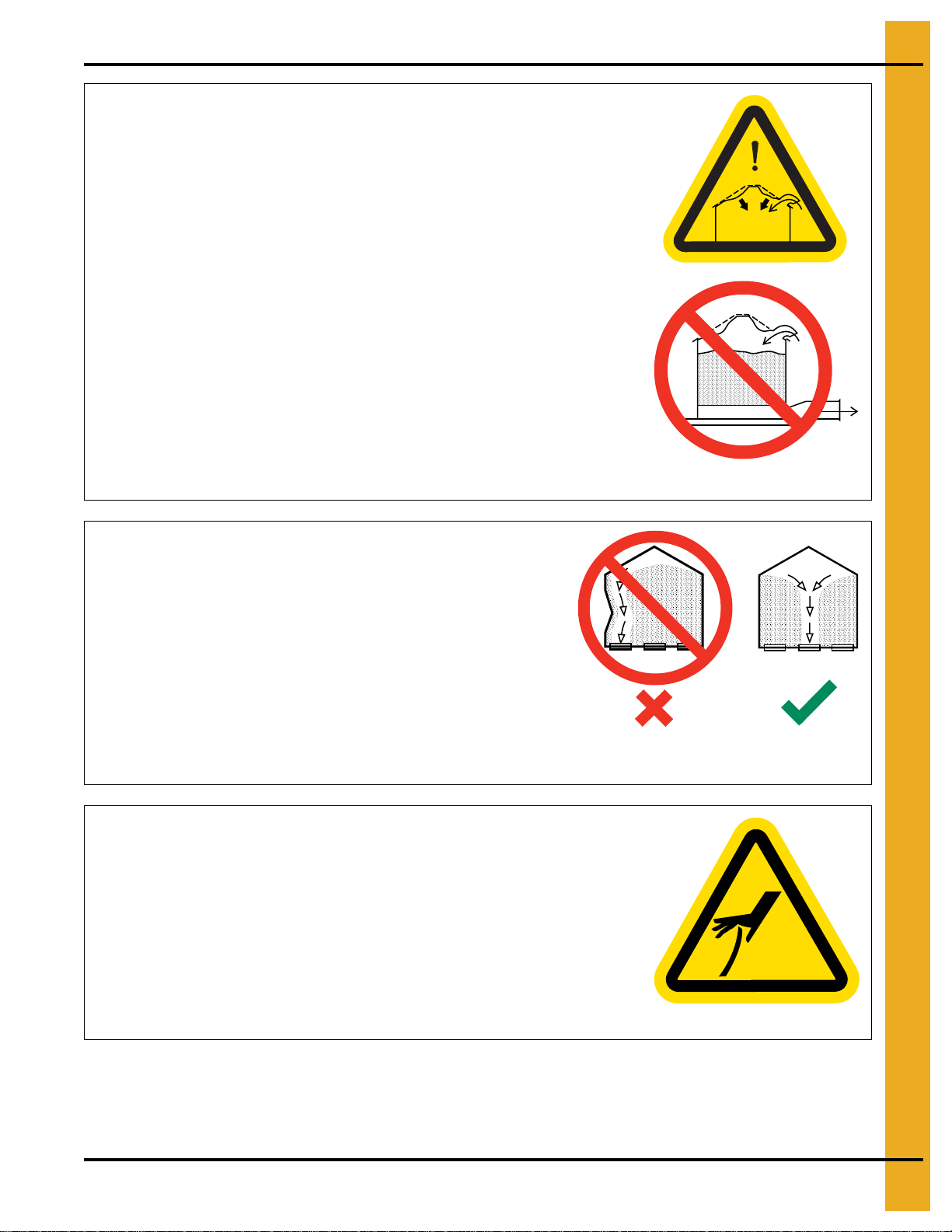

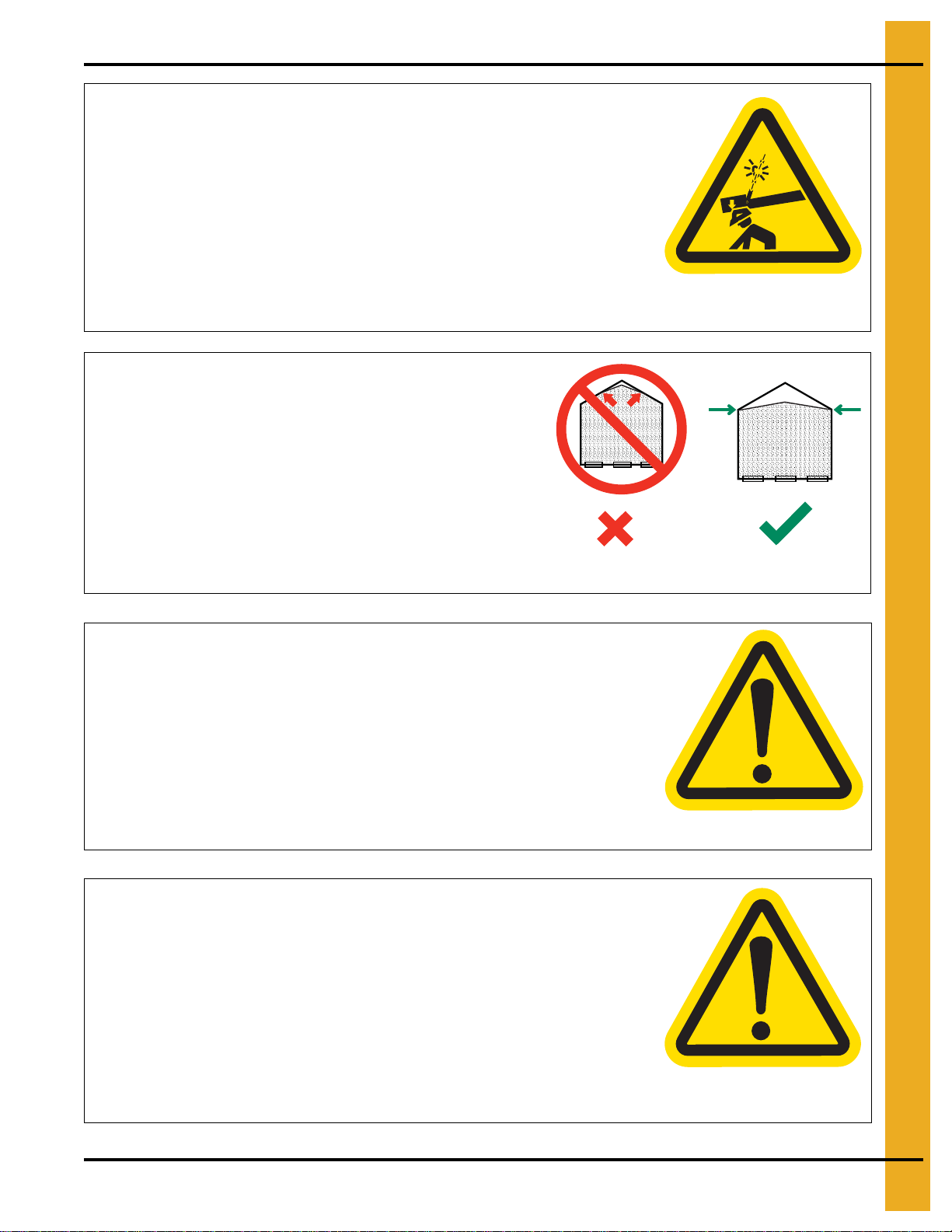

Safety Cautions ..................................................................................................................................... 6

Safety Sign-Off Sheet ......................................................................................................................... 10

Guidelines for Proper Storage of Grain Bin Materials Prior to Construction ....................................... 11

Chapter 2 Decals .................................................................................................................................. 12

Chapter 3 Hardware Requirements .................................................................................................... 14

Bolt Torque Specifications .................................................................................................................. 14

Chapter 4 Roof Assembly .................................................................................................................... 15

Installing the Roof Rafter Bracket to the Top Outside Stiffener .......................................................... 15

Installing the Eave Clip and Intermediate Eave Angle to the Sidewall Sheet ..................................... 18

Attaching the Peak Ring Attach Clips to the Rafter ............................................................................. 20

Attaching the Center Collar to Peak Ring Weldment .......................................................................... 21

Peak Ring/Center Collar Placement ................................................................................................... 22

Attaching the Rafter assembly to Roof Rafter Bracket ........................................................................ 23

Attaching the Rafter Assembly to Peak Ring Weldment ..................................................................... 24

Installing the Tension Rods ................................................................................................................. 25

Assembling the Purlin ......................................................................................................................... 26

Installation of the Roof Panel Support Clips ........................................................................................ 28

Attaching the Roof Panels ................................................................................................................... 29

Installing the Roof Flashing ................................................................................................................. 32

Roof Ring Location (Optional) ............................................................................................................. 34

Installing a Roof Ring .......................................................................................................................... 35

Chapter 5 Warranty .............................................................................................................................. 37