Brinly FB-42RY User manual

1

Call Customer Service, Toll-Free: 877-728-8224

Important: This manual contains information for the safety

of persons and property. Read it carefully before

assembly and operation of the equipment!

Visit us on the web!

www.brinly.com

1018348-C

FRONT

MOUNT BLADE

MODEL:

FB-42RY

• Assembly

• Installation

• Operation

• Repair Parts

OWNER’S MANUAL

2

INTRODUCTION

================================================================================================

SAFETY

================================================================================================

1018348-C

SAFETY LABELS AND NOTATION

CAUTION: Keep feet and hands clear of

blade while raising and lowering the blade.

Pay close attention to your surrounding and

people in your immediate area at all times.

This symbol will help to point out important

safety precautions throughout this manual. It

means: ATTENTION! BECOME ALERT! Your

safety is involved.

TABLE OF CONTENTS

SAFETY .......................... 2-3

PARTS LIST

AND REFERENCE .................. 4-5

ASSEMBLY ....................... 7-15

OPERATION ..................... 16-17

STORAGE..........................18

MAINTENANCE .....................19

LIMITED WARRANTY.................20

RECORD PURCHASE INFORMATION

Record your purchase information in

the spaces provided below:

DATE OF PURCHASE _____________________________

COMPANY NAME _____________________________

COMPANY PHONE _____________________________

SERIAL NUMBER _____________________________

The safety labels shown in this section are placed in important

areas on your product to draw attention to potential safety hazards.

On your product safety labels, the words DANGER, WARNING

and CAUTION are used with the safety-alert symbol. DANGER

identies the most serious hazards.

The operator’s manual also explains any potential safety hazards

whenever necessary in special safety messages that are identied

with the word, CAUTION, and the safety-alert symbol.

CUSTOMER

RESPONSIBILITIES

• Please read and retain this manual. The instructions enable you to assemble and

maintain your blade properly.

• Please carefully read and observe the SAFETY section of this manual.

• Follow a regular schedule in maintaining and caring for your Brinly-Hardy Blade.

Congratulations on the purchase of your new Brinly-Hardy Front-Mount Blade! This product has been designed, engineered and

manufactured to give you the best possible dependability and performance.

English Manual

3

SAFETY

================================================================================================

1018348-C

GENERAL NOTES (OPERATION)

Caution should be taken when using any attachment. This

attachment combined with the weight distribution, turning

radius, and speed of vehicle can result in severe injury or death

to operator, damage to vehicle, and/or attachment if not used

properly. Follow all safety precautions noted in the vehicle owner’s

manual, including the following precautions:

• Only use this product in the vehicle’s tow mode/speed setting

or less than 5 mph. Do not exceed 5 mph.

• Operating speed should always be slow enough to maintain

control. Travel slowly, using caution when traveling over rough

terrain. Avoid holes, rocks and roots.

• Slow down before you turn and do not turn sharply.

• Use caution when operating around retaining walls and other

raised embankments.

• Do not use attachment on steep slopes. A heavy load could

cause loss of control or overturn attachment and vehicle.

• Keep all movement on slopes slow and gradual. Do not make

sudden changes in speed, directions or turning.

• If you start and stop suddenly on hills, you may lose steering

control.

• Do not start or stop suddenly when going uphill or downhill.

Avoid uphill starts.

• Slow down & use extra care on hillsides. Use extreme caution

while operating near drop-offs.

• Do not drive close to creeks, ditches and public highways.

• Watch out for trafc when crossing roadways.

• Use care when loading or unloading the vehicle into a trailer

or truck.

• When reversing, back up straight using caution.

• Stop on level ground, disengage drives, set the parking brake,

and shut off engine before leaving the operator’s position for

any reason.

• Use this attachment for intended purpose only.

• Always wear substantial slip-resistant footwear. Do not wear

loose-tting clothing, tie back long hair and do not wear jewelry.

• Keep your eyes and mind on your vehicle, attachment and

area being covered. Do not let other interests distract you.

• Stay alert for holes and other hidden hazards in the terrain.

• Keep the vehicle and attachment in good operating condition

and keep safety devices in place.

• The vehicle and attachment should be stopped and inspected

for damage after striking a foreign object. Any damage should

be repaired before restarting and operating the equipment.

• Keep all parts in good condition and properly installed. Fix

damaged parts immediately. Replace worn or broken parts.

• Replace all worn or damaged safety and instruction decals.

Keep all nuts, bolts and screws tight.

• Do not modify the attachment or safety devices. Unauthorized

modications to the vehicle or attachment may impair its

function, safety and void the warranty.

VEHICLE AND ITS SAFETY

• Know your vehicle controls and how to stop safely. READ

YOUR VEHICLE OWNER’S MANUAL before operating.

• Check the vehicle’s brake action before you operate. Adjust or

service brakes as necessary.

• Stopping distance increases with speed and weight of load.

Travel slowly and allow extra time and distance to stop.

• Do not shift to neutral and coast downhill.

• Do not allow adults to operate the vehicle without proper

instruction or without having read the owner’s manual.

• Do not allow children to operate the vehicle.

PROTECT THOSE AROUND YOU

• Before you operate any feature of this attachment or vehicle,

observe your surroundings and look for bystanders.

• Keep children, bystanders and pets at a safe distance away

while operating this or any attachment.

• Use care when reversing. Before you back up, look carefully

behind for bystanders.

KEEP RIDERS OFF ATTACHMENT & VEHICLE

• Do not carry passengers.

• Do not let anyone, especially children, ride in/on this attachment,

the vehicle or mount bracket.

• Riders are subject to injury such as being struck by foreign

object and/or being thrown off during sudden starts, stops

and turns.

• Riders may also obstruct the operator’s view resulting in this

attachment being operated in an unsafe manner.

English Manual

4

PARTS LIST AND REFERENCE

================================================================================================

1018348-C

EXPLODED VIEW

REF PART NO. DESCRIPTION QTY

11017741-01 Rod, Hinge Plated 1

21017835-10 Painted Mount, Front 1

31018092-01 Rod, Transport Plated 1

41018104 Hardware Bag * 1

1018352 Parts Bag * 1

51018105-10 Painted Bracket, Pivot 1

61018109-10 Painted Bracket, Lower PV 1

71018110-10 Painted, Bracket Up Pivot 1

81018111-10 Painted, Hinge Weldment 1

91018115-01 Tube, Pivot Plated 2

10 1018116-10 Ribs, Painted 2

REF PART NO. DESCRIPTION QTY

11 1018347 Blade, 42” 1

12 1018118-10 Wear Bar, 42” Painted 1

13 1018119-10 Painted Plate, Bottom 1

14 1018120-10 Painted Tube, Raise 1

15 1018121 Trip Spring 1

16 1018122-10 Painted Tube, Handle 1

17 1019274-10 Painted Plate, Handle 1

18 B-7215-10 Spring Bracket 1

19 B-723P-01 Thick Washer, 3/8” 1

20 1018106-10 Painted Cam Weldment 1

Tools Required

for Assembly:

• 3/4” Socket & Wrench

• 9/16” Socket & Wrench

• 1/2” Socket & Wrench

• 7/16” Socket & Wrench

• 12 mm Wrench

• Ratchet Wrench

• Pliers

• Gloves

* Not shown

11

12

14

16

15

17

13

6

8

7

5

2

3

1

9

10

20

18

19

English Manual

5

PARTS LIST AND REFERENCE

================================================================================================

1018348-C

EXPLODED VIEW - HARDWARE BAG

REF PART NO. DESCRIPTION QTY

21 1000225 Handle Grip * 1

22 1017742 U-bolt 2

23 11M0816P Bolt, Carriage 1/4" x 1" 2

24 11M1012P Bolt, Carriage 5/16 x 3/4 5

25 11M1216P Bolt, Carriage 3/8 x 1 4

26 2M0828P Bolt, Hex Head 1/4 x 1-3/4 1

27 2M1024P Bolt, Hex Head 5/16 x 1-1/2 2

28 2M1212P Bolt, Hex Head 3/8 x 3/4 4

29 2M1220P Bolt, Hex Head 3/8 x 1-1/4 1

30 2M1232P Bolt, Hex Head 3/8 x 2 3

31 2M1620P Bolt, Hex Head 1/2 x 1-1/4 2

32 2M1632P Bolt, Hex Head 1/2 x 2 1

33 45M0909P Washer, SAE Flat, 1/4" 4

34 45M1313P Washer, SAE Flat-3/8 6

REF PART NO. DESCRIPTION QTY

35 45M1717P Washer, Flat 1/2" 1

36 B-1675P Nut, Hex Lock, 3/8"-16 2

37 B-1677P Nut, Hex Lock, 1/2"-13 1

38 B-3861 Pin, Hitch 1/2" X 2-1/2" 1

39 B-4785 Nut, Nylon Lock 1/4-20 7

40 B-4786 Nut, Nylon Lock 5/16-18 7

41 B-4820 Nut, Nylon Lock, 3/8"-16 11

42 B-5096Y Nut, Nylon Lock, 1/2"-13 2

43 B-6298 Bolt, Hex Hd 3/8 x 3-3/4 1

44 B-6299 Nut, Keps Hex, 3/8-16 3

45 D-146P Hairpin Cotter, 1/8”, #211 5

46 B-7291 Bolt, 3/8 x 2-1/2 1

* Not shown

22 35 42

28

24

37

44

30

23

36 43

29

25

38

45

31

26

39

46

32

27

40

41

33

34

English Manual

6

1/2”

**

3/8”

**

5/16”

**

1/4”

**

0”

2”

4”

1”

3”

5”

1018348-C

THIS SECTION CAN BE USED

TO IDENTIFY BOLTS:

Check the bolt size by placing the

head or the threaded end over the

matching diagrams to the left.

THIS SECTION CAN ALSO

ASSIST WITH IDENTIFYING

WASHERS:

Exterior circumference of washers

can vary. These dimensions are a

measurement of the internal diameter

of the washer.

Example =

Hex Head Bolt

1/4” x 1”

Example =

Hex Head Bolt

1/4” x 1”

Each spread of the assembly has a guide to help with hardware identication.

THIS SECTION CAN BE

USED TO IDENTIFY BOLTS:

Check the bolt length by measuring the

length of each bolt with this ruler.

1/4”

Example =

1/4” Washer

1/4”

English Manual

7

ASSEMBLY

=========================================================================================

1018348-C

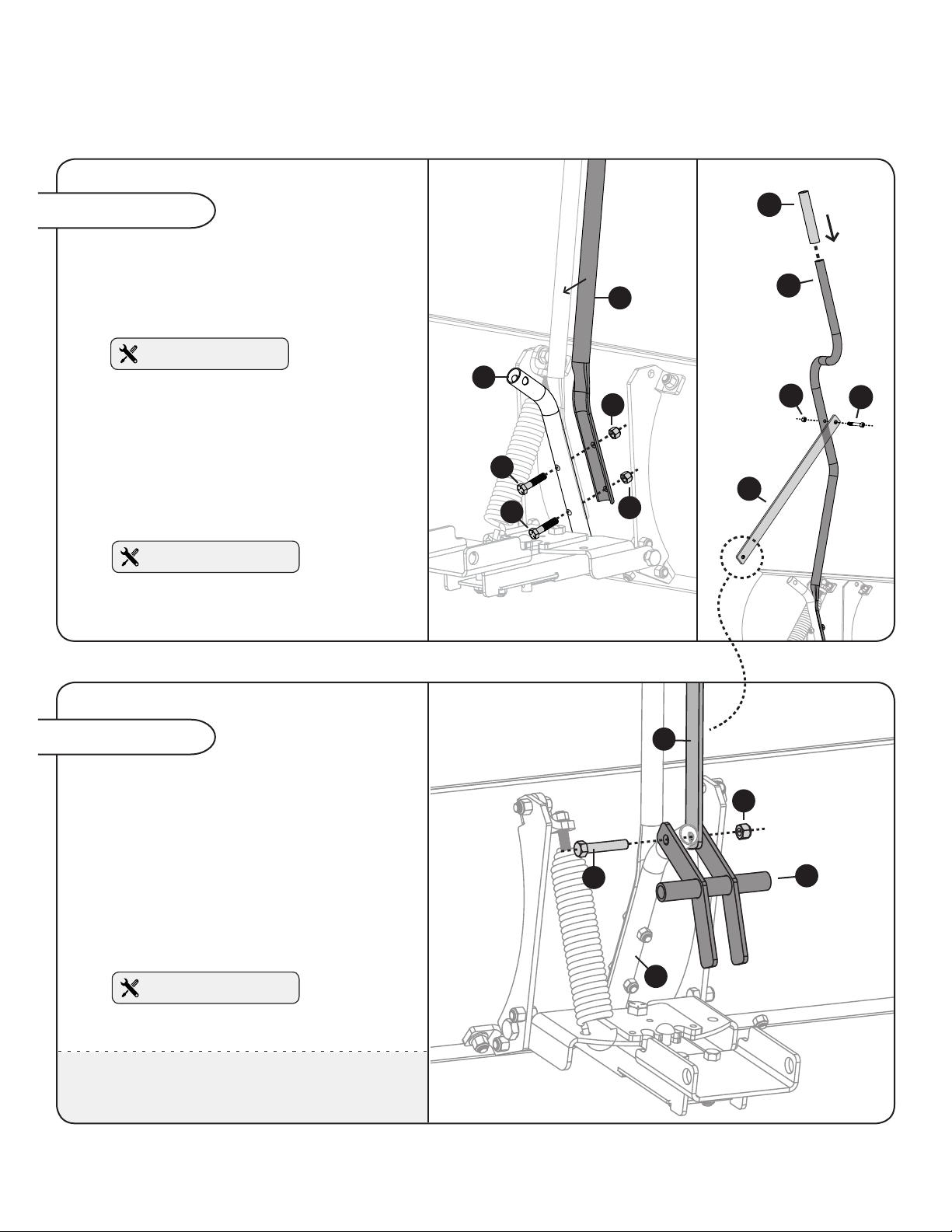

3. Attach pivot bracket (5) to the

mount plate (2) using:

- x2 Carriage Bolts (23) – 1/4” x 1”

- x2 Nylon Lock Nuts (39) – 1/4”

Assembly Step 2 39

23

39

23

52

7/16” Wrench

For the rst step, you’ll need

to remove hardware from the front

of your mower.

12mm Wrench

A

A

BB

Assembly Step 1

Unscrew the two skid plate bolts (A)

and two sets of washers (B).

1. Loosely start to attach the mounting

plate (2) to your mower by reusing the

removed hardware (A & B) as well as

U-bolts found in the hardware bag:

- x2 U-Bolts (22)

- x4 Washers (33) – 1/4”

- x4 Nylon Lock Nuts (39) – 1/4”

7/16” Wrench

2. Align the bottom of the mounting plate (2)

parallel to the ground and make sure the

front of the mounting plate is touching the

inside edge of the bumper tubing. Tighten

all hardware.

39

33

22

2

A

A

BB

2

The bottom of the mounting

plate (2) needs to be parallel to the ground.

English Manual

8

ASSEMBLY

================================================================================================

1018348-C

Blade Assembly

1. Attach ribs (10) to the

blade (11) using:

- x4 Carriage Bolts (25) – 3/8” x 1”

- x4 Washers (34) – 3/8”

- x4 Nylon Lock Nuts (41) – 3/8”

Note: Do not fully tighten (yet),

these ribs may need to shift slightly

during Assembly Step 11.

Note: Ensure the ribs (10) are

aligned correctly. The ends with

three small cutouts on the rib

need to be at the base of the

blade. See illustration:

Assembly Step 3

25

25

34

34

41

11

34

41

41

34

41

10 10

25

25

9/16” Wrench

Assembly Step 4

24

24

24

24 24

40

40

40

40 40

11

12

1/2” Wrench

Blade Assembly

2. Attach wear bar (12) to bottom

of blade (11) using:

- x5 Carriage

Bolts (24) – 5/16” x 3/4”

- x5 Nylon Lock

Nuts (40) – 5/16”

English Manual

9

**Exterior circumference of washers can vary.

These dimensions are a measurement of the

internal diameter of the washer.

0”

2”

4”

1”

3”

5”

1/2”

**

3/8”

**

5/16”

**

1/4”

**

ASSEMBLY

================================================================================================

1018348-C

Push Arm Assembly

1. Attach upper push bracket (7)

to lower push bracket (6) and bottom

plate (13) using:

- x2 Hex Head Bolts (30) – 3/8” x 2”

- x2 Nylon Lock Nuts (41) – 3/8”

Assembly Step 6

Blade Assembly

3. Install bolt and nut stops to the blade ribs (10) using:

- x4 Hex Head Bolts (28) – 3/8” x 3/4”

- x4 Nylon Lock Nuts (41) * – 3/8”

*Note: Nuts need to be on the outside

edges of the blade ribs.

4. Set blade aside.

Assembly Step 5

10 10

41

28

28

41

7

6

13

41

30

41

30

41

41

9/16” Wrench & Socket

9/16” Wrench & Socket

10

**Exterior circumference of washers can vary.

These dimensions are a measurement of the

internal diameter of the washer.

1/2”

**

3/8”

**

5/16”

**

1/4”

**

0”

2”

4”

1”

3”

5”

ASSEMBLY

================================================================================================

1018348-C

Push Arm Assembly

2. Attach pivot weldment (8) to the push

arm assembly using:

- x1 Hex Head Bolt (32) – 1/2” x 2”

- x1 Washer, Flat (35) – 1/2”

- x1 Washer, Thick (19)

- x1 Lock Nut, Hex* (37) – 1/2”

NOTE: Do not over tighten,

the two brackets should be able

to move freely of one each other,

but not so loose that there is play

in the joint.

8

37

32

35

19

push arm

assembly

Adding the Handle

1. Rotate the pivot weldment (8)

2. Start to run hex head bolt,

3/8” x 3 3/4” full thread (43)

through the rst hole of the push

arm assembly & add:

- x1 Hex Nut (44) – 3/8”

External-teeth need to be facing

away from the head of the bolt.

Assembly Step 8-A

43

44

8

rotate

the pivot

weldment

rotate

the pivot

weldment

pivot

weldment

3/4” Wrench & Socket

Assembly Step 7

9/16” Wrench & Socket

*Not the Nylon Lock Nut (42).

11

ASSEMBLY

================================================================================================

1018348-C

43

44

14

Adding the Handle

3. Align the lower handle tube (14)

as illustrated here and continue to

run the hex head bolt (43) through

the base of the tube.

Assembly Step 8-B

43

14

9/16” Wrench & Socket

4. After the bolt (43) extends

through the tube, add:

- x1 Hex Nut (44) – 3/8”

External-teeth facing the

lower handle tube (14).

5. Continue running the bolt (43) through the

push arm assembly. Secure in place using:

- x1 Lock Nut, Hex* (36) – 3/8”

6. Use the two Hex Nuts (44) to the

center and secure in place the lower

handle tube (14) within the opening

of the push arm assembly.

(See detail to the right).

Adding the Handle

7. Drop hitch pin (38) into the center hole of

the push arm assembly and secure with a

hairpin (45).

Assembly Step 9

43

4436

14

43 36

14

44 44

45

38

push arm

assembly

English Manual

*Not the Nylon Lock Nut (41).

12

ASSEMBLY

================================================================================================

1018348-C

Joining the Push Arm

to the Blade

2. Slide push arm assembly between ribs

and align with the pivot tubes that were

inserted on Step 9. Attach using:

- x2 Hex Head Bolts (31) – 1/2” x 1 1/4”

- x2 Nylon Lock Nuts (42) – 1/2”

3. Tighten the ribs to the

blade completely. (41).

Assembly Step 11

31 31

41 41

push arm

assembly

42 42

3/4” Wrench & Socket

Joining the Push Arm

to the Blade

1. Insert spacer / pivot tube (9)

into the large holes on the lower

part of the ribs (10) on the back

of the blade.

Assembly Step 10

10 1010 10

999

9

9-A 9-B

English Manual

13

**Exterior circumference of washers can vary.

These dimensions are a measurement of the

internal diameter of the washer.

0”

2”

4”

1”

3”

5”

1/2”

**

3/8”

**

5/16”

**

1/4”

**

ASSEMBLY

================================================================================================

1018348-C

Joining the Push Arm to the Blade

5. Mount trip spring by treading 3/8” x 2 1/2” full

threaded bolt (46) and 3/8” washer (34) so that the

head of the bolt is captured

inside of spring (15).

6. Hook the opposite

end of the spring

(15) through the

pivot weldment (8).

7. Insert the bolt through

the trip bracket (18) that

was installed on Assembly

Step 12.

Tread and tighten the 3/8”

toothed nut (44) until the

spring is touching the

bracket.

Assembly Step 13

18

46

15

44

34

8

9/16” Wrench & Socket

8. Tighten the nut and bolt that were added

on Assembly Step 12.

Joining the Push Arm to the Blade

4. Attach spring trip bracket (18) using:

- x1 Hex Head Bolt (29) – 3/8” x 1 1/4”

- x1 Washer, Flat (34) – 3/8”

- x1 Nylon Lock Nut (41) – 3/8”

DO NOT tighten completely (yet).

18

41

34

29

9/16” Wrench & Socket

Assembly Step 12

14

ASSEMBLY

================================================================================================

1018348-C

Assembly Step 15

36

30

17

14

20

From Step 14, rotate the base of the

reinforcement bracket (17) to align with the

lower handle tube (14).

Straddle these two parts with the pivot

weldment (20) as illustrated. Attach using:

x1 Bolt (30) – 3/8” x 2”

+ x1 Lock Nut (36) – 3/8”

7/16” Wrench & Socket

9/16” Wrench & Socket

1. Attach the upper handle tube (16) to

the lower handle tube (14) using:

- x2 Bolts (27) – 5/16” x 1 1/2”

- x2 Nylon Lock Nuts (40) – 5/16”

2. Slide grip (20) over the end of the

upper handle tube (16).

As illustrated, loosely attach* the slotted

end of the reinforcement bracket (17) to the

upper handle tube (16) using:

x1 Bolt (26) – 1/4” x 1 3/4”

+ x1 Nylon Lock Nut (39) – 1/4”

Assembly Step 14 20

16

17

39 26

16

14

27

27

40

40

1/2” Wrench & Socket

NOTE: DO NOT TIGHTEN BOLT (30)

FULLY. This part needs to pivot.

English Manual

*This bolt (26) will be secured on step 15.

Fully secure Bolt 26 from Step 14.

15

**Exterior circumference of washers can vary.

These dimensions are a measurement of the

internal diameter of the washer.

0”

2”

4”

1”

3”

5”

1/2”

**

3/8”

**

5/16”

**

1/4”

**

ASSEMBLY

================================================================================================

1018348-C

push arm

assembly

mower

bracket

45

45

1

Assembly Step 16

Mounting the Blade

1. Face the back of the

blade assembly toward

the bracket that you

added to your mower

in Assembly Steps 1-2.

2. The push assembly will

easily slide within the lower

tabs extending from the

mower bracket.

3. After aligning the

two sets of bracket holes,

insert the plated hinge rod /

pin (1) and secure with two

hairpin cotters (45), one on

each end.

Assembly Step 17

Mounting the Blade

4. Line up pivot

weldment (20) with the

pivot bracket (5) and

insert pin (3).

5. Secure with two hairpin

cotters (45).

5

20

3

45

45

16

OPERATION

============================================================================================

1018348-C

CAUTION: Keep feet and hands clear of blade while raising and lowering the blade.

Pay close attention to your surrounding and people in your immediate area at all times.

NOTE: Do not adjust angle of blade while in transport position.

Operation Step 1

Transport Position

1. To raise your blade into transport position, pull the upper handle toward operator.

Note: Ensure the handle has been pulled back far enough to engage the

self-locking feature.

Changing the Blade Angle

1. Turn key switch off & engage parking brake, then lower

the blade to the ground.

2. Simply remove the hair pin beneath the push assembly

arm (see g 2.1) and pull hitch pit out (g 2.2).

3. Rotate blade to desired location (g 2.3).

4. Replace the hitch pin and secure hair pin underneath in

order to lock the blade in position.

Operation Step 2

Fig 2.2

Fig 2.1

Fig 2.3

English Manual

pull toward

operator

Fig 1

17

OPERATION

============================================================================================

1018348-C

CAUTION: Keep feet and hands clear of blade while raising and lowering the blade.

Pay close attention to your surrounding and people in your immediate area at all times.

CAUTION

1. INSPECT THE AREA

Before operating the snow blade, inspect the area to be worked carefully. Avoid curbs and other

heavy obstructions.

2. KNOW THE TERRAIN

Avoid exceptionally sharp slopes or drop offs which may be hidden by the snow, never run the

snow blade into heavy material at high speed.

3. LOWER THE BLADE

Always lower blade to ground before leaving mower

4. START SLOW

Always begin at low speeds and gradually increase as required. Do not exceed 5 mph.

Do not attempt to move snow all in the same direction, causing an excessive buildup, which would

become larger with each pass.

5. RAISE THE BLADE

Raise blade when moving in reverse

6. SNOW REMOVAL

The blade is intended for snow removal only

English Manual

18

STORAGE

============================================================================================

1018348-C

Storage Step 1

5

20

3

45

45

Removing Blade

1. Turn key switch off and

engage the parking brake, then

lower the blade to the ground.

2. Remove the two hairpin

cotters (45).

3. Remove the pin (3) from the

pivot weldment (20) and pivot

bracket (5).

Removing Blade

4. Set aside the two hairpin

cotters (45) from each end

and remove the plated hinge

rod / pin (1).

5. The push arm assembly

and mounting bracket will

easily separate.

6. Leave the mounting and

pivot brackets attached to

the mower.

pivot

bracket

mounting

bracket

45

45

1

Storage Step 2

CAUTION: Keep feet and hands clear of blade while raising and lowering the blade.

Pay close attention to your surrounding and people in your immediate area at all times.

English Manual

19

MAINTENANCE

================================================================================================

1018348-C

1. CLEAN AND DRY

The key to years of trouble-free service is to

keep you plow clean and dry

2. MOVING PARTS

After the rst 30 minutes of use, check all of the

fasteners for tightness. Thereafter, periodically

check all fasteners for tightness.

3. MOVEMENT

Check all moving parts for free movement and if

necessary, lubricate with oil.

4. BUILD-UP

Periodically remove debris build up

5. RUST

For rust appearing on painted surfaces, sand

lightly and point affected area with enamel.

6. ROTATION

After the wear bar has worn considerably, it

should be rotated (from bottom to top) to provide

a “new” edge. Remove the ve carriage bolts

(5/16”), rotate the blade, and then reassemble

the unit with the “new” edge on the surface.

CAUTION: Keep feet and hands clear of blade while raising and lowering the blade.

Pay close attention to your surrounding and people in your immediate area at all times.

English Manual

20

MANUFACTURER’S LIMITED WARRANTY

FOR BRINLY ACCESSORIES

Brinly-Hardy Company • 3230 Industrial Parkway • Jeffersonville, IN 47130 • (877) 728-8224 • brinly.com

1018348-C

The limited warranty set forth below is given by Brinly-Hardy

Company with respect to new merchandise purchased and used

in the United States, its possessions and territories.

Brinly-Hardy Company warrants the products listed below against

defects in material and workmanship, and will at its option, repair or

replace, free of charge, any part found to be defective in materials

or workmanship. This limited warranty shall only apply if this product

has been assembled, operated, and maintained in accordance

with the Operator’s manual furnished with the product, and has not

been subject to misuse, abuse, commercial use, neglect, accident,

improper maintenance, alteration, vandalism, theft, re, water, or

damage because of other peril or natural disaster.

Normal Wear Parts or components thereof are subject to separate

terms as follows: All normal wear parts or component failures will

be covered on the product for a period of 90 days.

Parts found to be defective within the warranty period will be

replaced at our expense. Our obligation under this warranty is

expressly limited to the replacement or repair, at our option, of parts

found to be defective in material and workmanship.

HOW TO OBTAIN SERVICE: Warranty parts replacements

are available, ONLY WITH PROOF OF PURCHASE, through our

Customer Service Department. Call 877-728-8224.

This limited warranty does not provide coverage in the following

cases:

a) Routine maintenance items such as lubricants and lters.

b) Normal deterioration of the exterior nish due to use or

exposure.

c) Transportation and/or labor charges.

d) The warranty does not include commercial and/or rental use.

No implied warranty, including any implied warranty of

merchantability of tness for a particular purpose, applies

after the applicable period of express written warranty above

as to the part as identied below. No other express warranty

whether written or oral, except as mentioned above, given by

any person or entity, including a dealer or retailer, with respect

to any product, shall bind Brinly-Hardy Co. During the period

of the warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the sole

and exclusive remedy arising from the sale. Brinly-Hardy Co.

shall not be liable for incidental or consequential loss or

damage including, without limitation, expenses incurred for

substitute or replacement lawn care services or for rental

expenses to temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions or limitations may not apply

to you.

During the warranty period, the exclusive remedy is replacement

of the part. In no event shall recovery of any kind be greater that

the amount of the purchase price of the product sold. Alteration of

safety features of the product shall void this warranty. You assume

the risk and liability for loss, damage, or injury to you and your

property and/or to others and their property arising out of the

misuse or inability to use this product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased as

a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specic legal rights, and you may also

have other rights which vary from state to state.

IMPORTANT: The Warranty period stated below begins with

the PROOF OF PURCHASE. Without the proof of purchase, the

Warranty period begins from the date of manufacture determined

by the serial number manufacturing date.

WARRANTY PERIOD:

The warranty period for the product shown in this manual is as

follows: Steel Frame Parts: 2 Years. Tires, Wheels and Drive are

normal wear parts – 90 days.

English Manual

Table of contents

Languages: