14 December 2010

Due to continued product improvement, Broady’s reserves the right to change product specifications without prior notification.

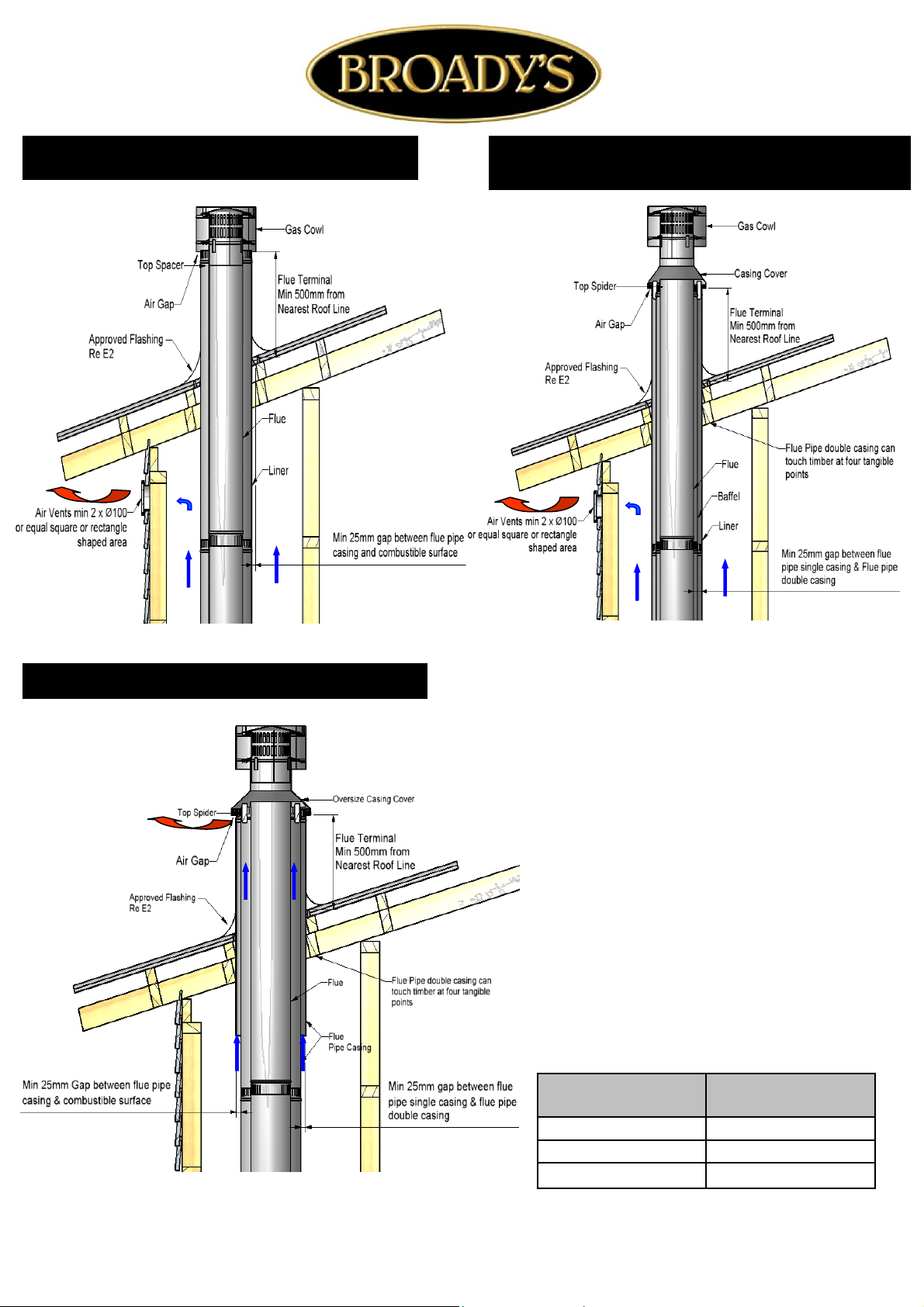

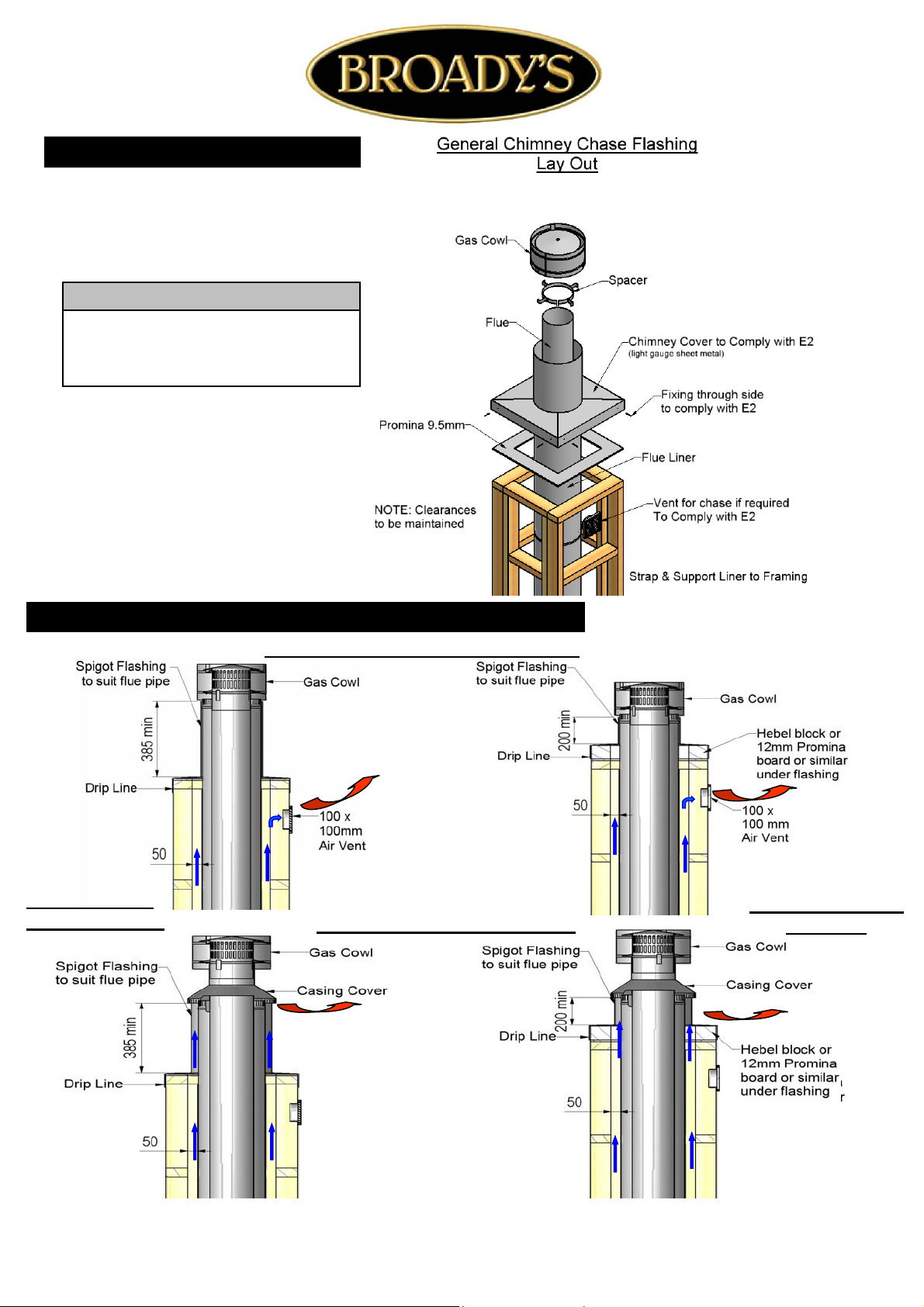

All Dimension are in mm………….Copyright ©

2

POINTS TO CONSIDER PRIOR TO INSTALLATION

INSTALLATION ORDER OF OPERATIONS

Location of the Fire. Open Fires are better located at one end of a room or area, as they project the heat away from their opening .

Venting to the Cavity.

This air is to allow the Cavity to Vent the Warm Air. This Warm Air helps keep the Fire and Flue System form getting to Cold . If the Flue and Fire get to Cold the System

may soot often and require cleaning. Each Fire has different ways of venting the cavity .

The Topography of the Land .

The slope and position of the Land in relation to the Home has a bearing on how the wind will interact with the Fire and Flue System. Care needs to be taken to ensure

that the Flue Termination is in the correct position to maximise performance .

The Prevailing Wind.

Care needs to be taken to ensure that the Flue Termination is in the correct position as wind and gusts that hits the Flue and Cowl System may overcome the Cowl and

draft back down the Flue into the Home. This can be a combination of down draft and high pressure.

Hearth and Plinth:

The height of the Hearth off the Floor. The Finishing that is to be used on the hearth is to be allowed for at the design stage.

Positioning of the Flue System:

There is a maximum distance that an Offset Flue can be Installed. Reference to AS/NZS : 2918 , NZS 5261:2003

Flue and Fire Clearance:

To be maintained to the Manufactures Instructions.

Pressure Differential, Venting & External Air into the Building :

All fires need air to burn and draw correctly, Kitchen Fans, Air Conditioning units, High Wind Zones, Naturally forming Draft spaces, can all have an effect on the

pressure difference from inside the building to the outside. A lower pressure in the building may induce a draft down the flue system and back into the building

causing the fire to smoke or spill into the building. Care needs to be taken at the design and installation stage to adequately vent the building, or some mechani-

cal system to ensure that there is always a neutral or positive pressure at the fireplace and a negative pressure at the flue outlet. This will ensure that the draft in

the flue system is always to the outside.

“CAITEC AIR” the limits and requirements. See details in these Spec’s or contact your local Agent.

Wind Noise:

You may encounter wind noise in some installations. It is recommended to use an enclosed chase with a chimney pot to help reduce noise.

There will always be some noise from the flue systems of all fireplaces.

Prior to Construction and Installation Important Notes:

1. Consult a Certified Craftsman Gas Fitter for correct Gas Installation.

2. Install to NZS 5261: 2003 (or current standard).

3. Install to manufacture’s specifications.

4. All New Installations require a permit.

5. Allow for gas supply to heat cell at R.H. rear, and power supply to L.H. rear if required (check product).

6. For special requirements concerning materials (Timber Mantle and Surrounds) within close proximity of Broady`s products, please contact

our local Broad

`s

Technical Consultant .

7.

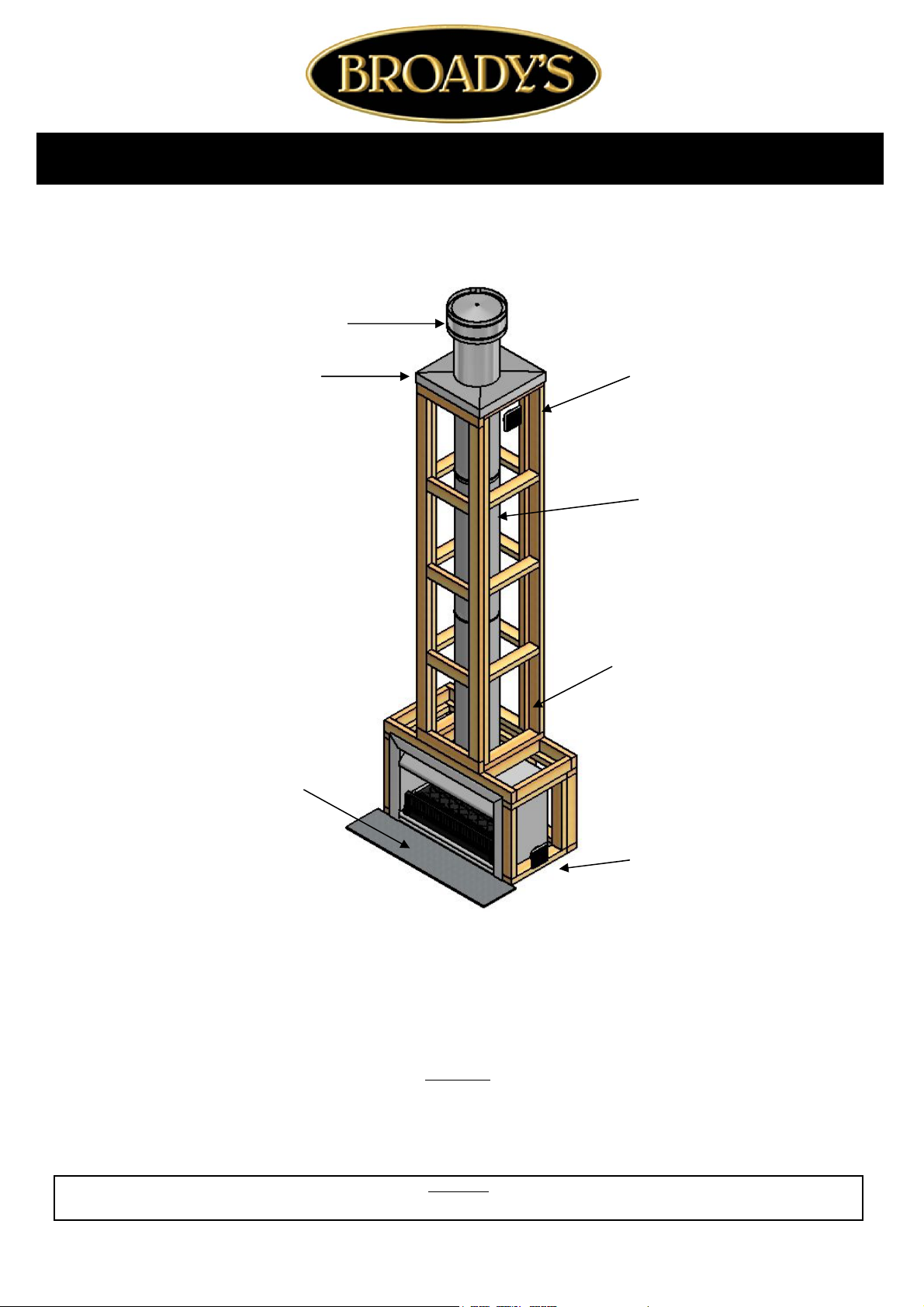

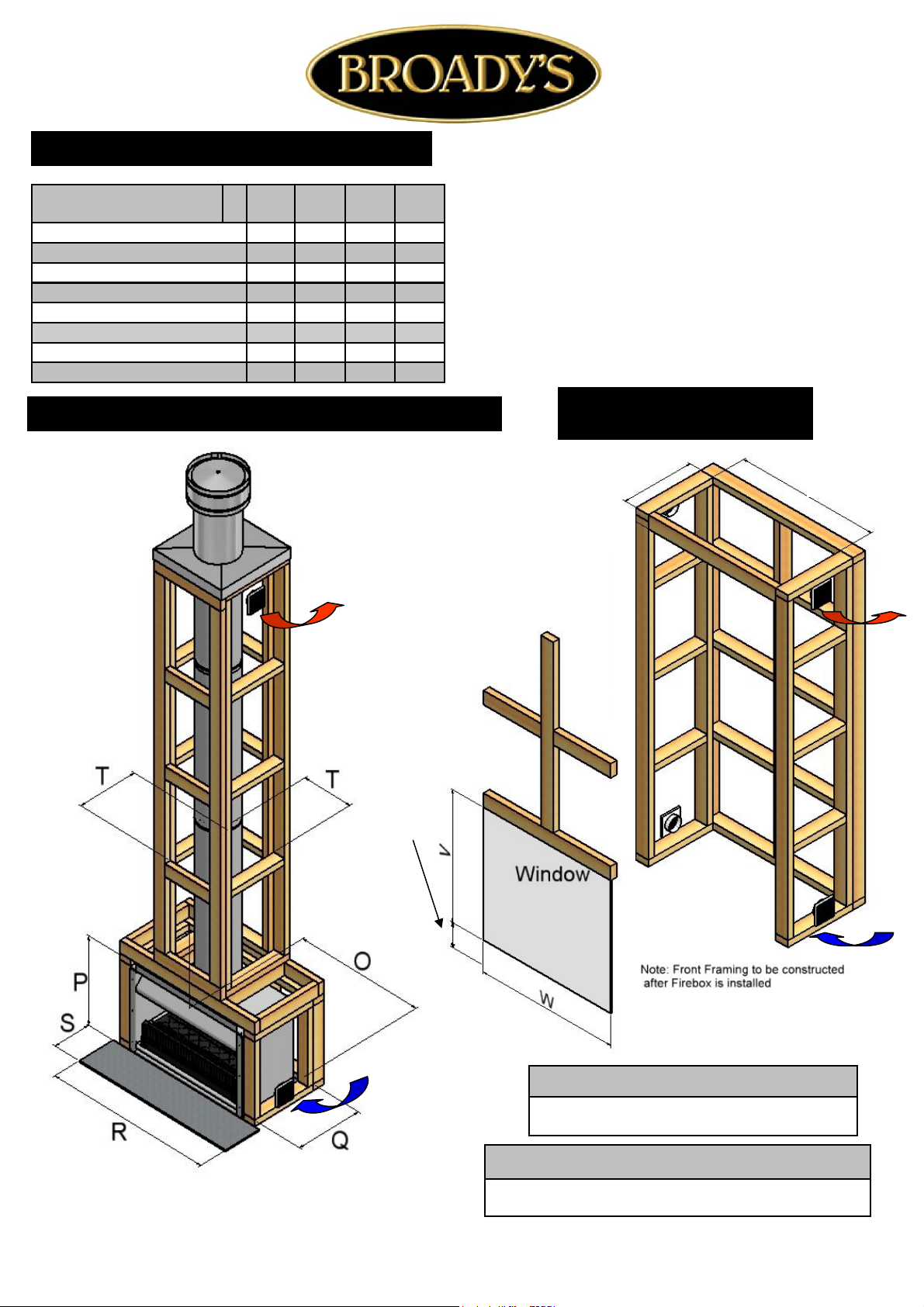

Stage 1: Frame Construction Procedure by Builder.

1. Mark out Flue Centre.

2. Mark out Heat Cell Clearance requirements.

3. Build Timber Framing to Heat Cell Clearances and Chimney Chase Clearance requirements.

4. Ensure that the front face of Heat Cell Clearance alcove is left open and unframed to enable Installation of the Firebox. The Chimney Chase is left unlined for Installa-

tion of the Flue.

5. Construct Plinth only, to required height. *

Stage 2: Install Procedure by Certified “Broadys Installer”only.

1. Fit Fire to Plinth.(Ensure Gas Supply Line is fed through R.H. Side of Firebox.)

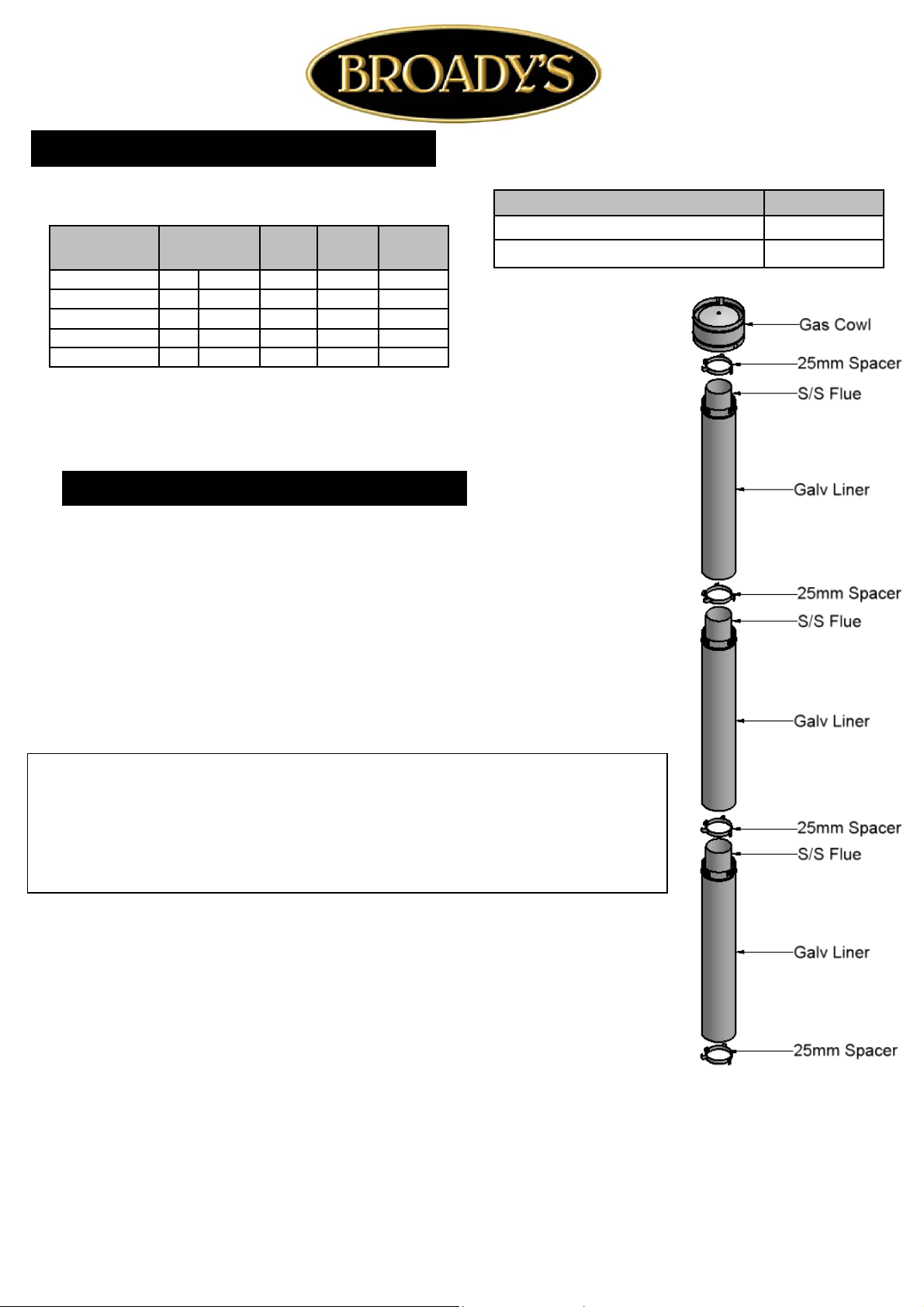

2. Fit Flue System.

3. Fit Cowl and Flashing System.

4. Fit Vents to Heat Cell Alcove and Chimney Chase, to cool the Heat Cell and ensure efficiency of CAITEC Technology.

5.

Stage 3: Finishing Procedure by Builder.

1. Construct Hearth to required thickness. *

2. Finish Framing of Heat Cell Alcove.

3. Close in Heat Cell Alcove and Chimney Chase.

4. Finish Heat Cell Alcove and Hearth to customer’s requirements (e.g. paint / tiles).

5. * Note: Certified Installer can Install Hearth and Plinth.

Maintenance.

Visually Inspect Fireplace and Flue System.

Ensure that Firebox is operated according to the Manufacture’s Instructions.