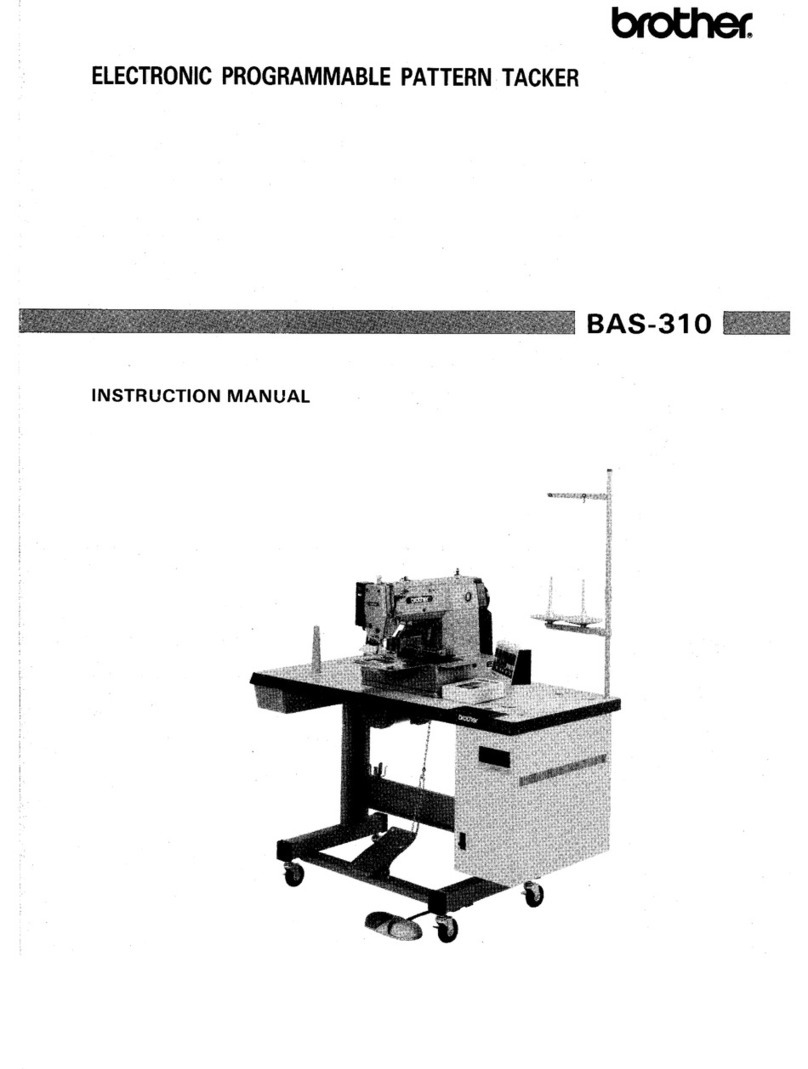

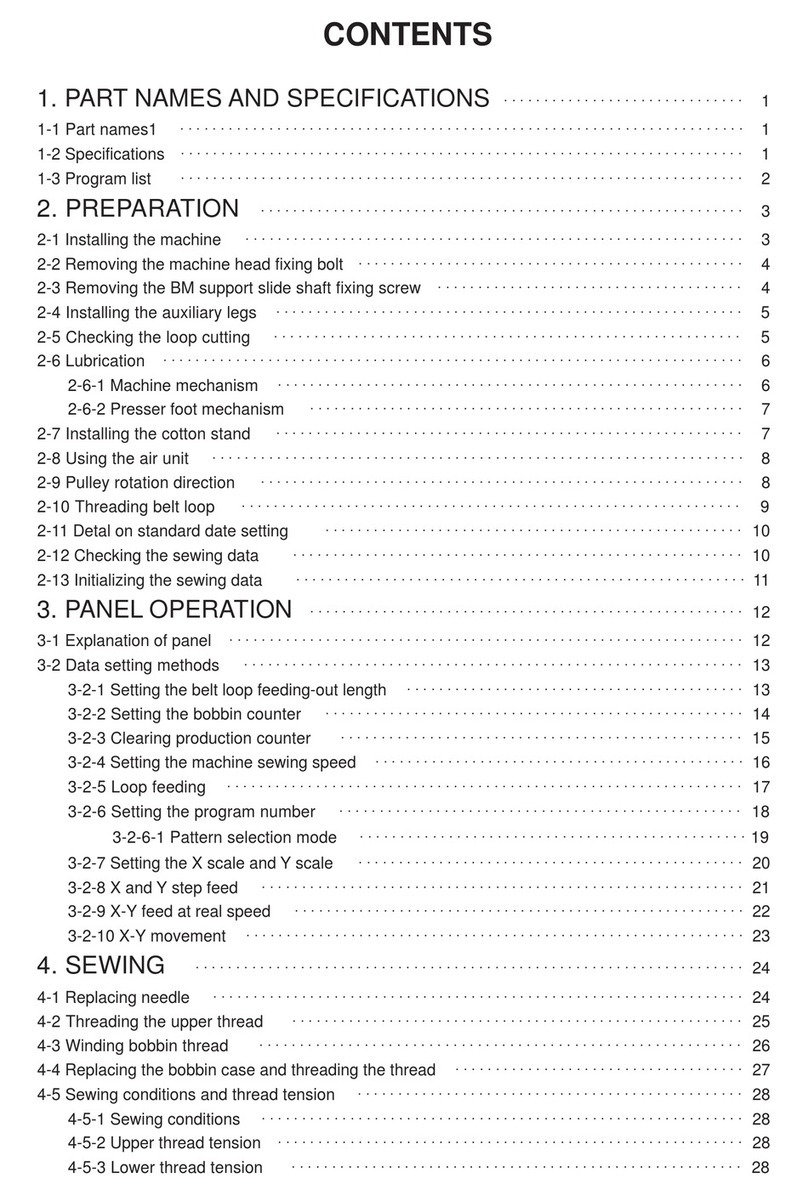

[ OPERATION OF TREADLE PEDAL

®

@

1

----~

~

~~

~

--

Ill Trea

dl

e (- 100, - 200)

1. Make sure

whether

slow speed

motor

runs

smooth

l

y,

pressing the treadle pedal 0 lightly

to

®.

Pressing

the

treadle pedal 0 again

to

@ ,

then

high speed

motor

runs.

]

@

2. Make sure

whether

the sewing machine stops

at

the

needle down p

os

ition,

the

treadle pedal 0 is positioned

at

the

neutral

(when

you

release the treadle pedal 0 ) @

after

pressing

the

treadle pedal 0

at

the front.

3.

In

case

the

treadle pedal 0

is

pressed

at

the rear

end

@(o

r back

at

the

neutral @

after

the

treadle pedal 0

is

pressed

at

the rear

end

@), thread trimmer is once t

urn

and

the

needle is

up

and

then

the

machine is stop.

Ill Treadle

(-

500

,

-600)

1. Lightly depress the

upper

plate

f}

of

the

treadle pedal 0

to

position

@,

the presser f

oo

t

co

me

s down.

2. Make sure whether sl

ow

speed

motor

runs smoothly, pressing

the

treadle pedal 0 lightly

to®.

Pressing

the

treadle pedal 0 again

to

@ ,

then

high speed

mot

or

runs.

3.

Make sure

whether

the sewing

ma

chine stops

at

the

needle down position,

the

treadle pedal 0 is positioned

at

the neutral

(when

you

release

the

treadle pedal 0 ) @

after

pressing

the

treadle pedal 0

at

the front.

4. When the

upper

plate 8

of

the

treadle pedal 0 is positioned

at

® , presser foot lifts

up

.

5. In case

the

tr

eadle pedal 0 is pressed at

the

rear

end

@(o

r back

at

the neutral

@a

fter

the

treadle pedal 0 is pressed at

the rear

end

@), thread trimmer is

once

turn

and

th

e needle is

up

and

then the machine is

sto

p.

[ ADJUSTING SYNCHRONIZER

Adj

u

sting

position

of

thr

ead

trimming

signal

Needle

down

pos

ition

Needle

up

posi

tion

1

8-22

mm

9-11

mm

---

~

1)

Turn

off

the power switch by all means. (In case

of

adjust each the hole l.C, turn

of

f

the

power switch

by

all means.)

2) Remove

th

e cover

of

the synchronizer.

3)

Turn the pulley towa

rd

yo

u and p

la

ce the needle bar lowest position. At th

is

tim

e,

the magnet 0 must be in line with

the t

hr

ead trimming the

ho

le I.C 8 .

In

case

of

the magnet 0 is not in line with the thread t

ri

mming the hole

I.

C 8 ,loosen clamping screw

@)

and adjust by

moving the

thr

ead trimming the hole I.C.

(4)

Turn on the power switch a

nd

stop the machine at the needle down position.

At

this time, the needle bar should stop at

the position of I

8-

22 mm above the upper face

of

the needle plate.

If the needle bar

is

not stop

at

the

fi

xe

d position, loosen

cl

amping screw 0 and adju

st

by

moving the nee

dl

e down the

hole I.C @ .

(5)

Stop the

ma

chine at the needle

up

position. At this tim

e,

the needle point should st

op

at the position

of

9 - I I mm

above the

upp

er face

of

the needle plate.

If the needle

po

sition

is

not s

top

at

the

fi

xed position, loosen clamping screw

(3

and adjust

by

moving the needle up

the ho

le

I.C

f}

.

*

Ym.1

move the hole I.C @ ,

f}

to the machine rotating direction, then the needle

bar

is down.

Wh

en

yo

u move the hole

I.C @ ,

f}

to the rever

se

direction, then the n

ee

dle bar is raised.

0

0

*

For

prevent the bobbin run idle wh

en

thread trimmed,

there

is

the

bo

bbin presser O.

*

Wh

en

thr

ead trimmed, loosen cla

mp

ing screw 8 and adju

st

by moving the bobbin presser 0 back

or

fo

rth

.