CONTENTS

1.

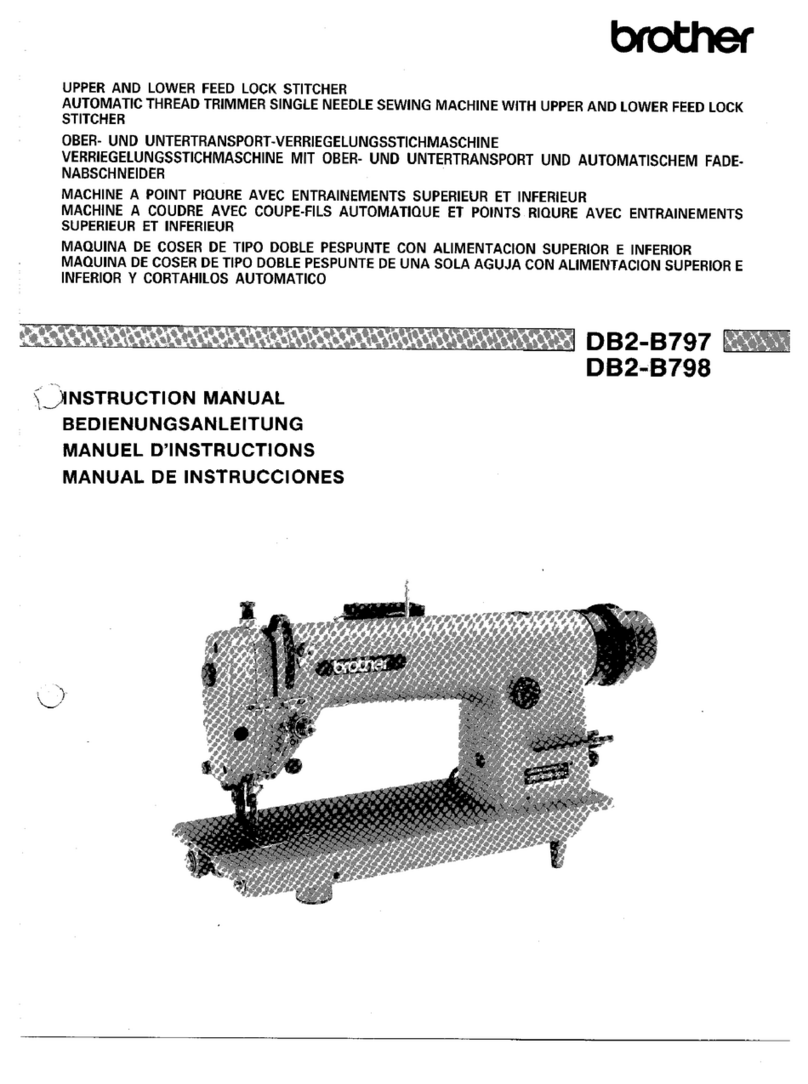

Specifications ....................................................................................................... ·················· 1

2. Features

...............................................................................................................................

..................

2

3. Operation ........................... .

..

········

....................

············

··············.

""

..................

·····...........

~

A)

Se\\'in,L(

speL'd

.............

. .

...........

2

B)

Motor,

motor

pulley

and

helt

..........................................................................................................

'>

Ci Setting

U))

..

.....

..

......

,,

D) Oiling. drnining and maintt•mmr:e....................................................................................

..

.....

..

......

,,

E)

Necdk• r:oolt•r

dt'l"iLt'

.......................................................................................................................

-1

F)

~lachi•w

"P"·ating

di•·cction ......... .

..............................................................................................

:J

G)

In~talling

needlt• ................................................................................................................................

;1

II) Thn•ading .............................................................................................................................

r;

I l

Stitr:he~

......................................................................................................................................

r;

.1)

ThrL'<td

ten~i4>n

.............................................. ............ 7

\.

Adju~tnll'nl

of

thrL•ad

take-up.................... ........................................................................ 7

'1

Adju~ting-

thr<.'ad

takl'·ltp and thre;td guide ..... ............................................... 7

:t

Adju~ting-

thrl'ad tl'nsion screw .......................

..

..................................... 7

KJ

Adjustnwnt on

pre~~un·

of presser foot: Installing and remo\"ing

ft•ed

dogs: and Height

of

feed dogs H

r-..

L)

Adjusting

~!itch

width................................................................................................................ H

·.

'

?\I) Adjusting stitch lt•ngth ........................................................................................................................ 9

?-;)

Adju,Ling diffcrc.,tial feed .................................................................................................................. 9

4. Adjustment................................................... ..............................................,.......................................

10

Al llt•ight of lll'l'dlt• .................................................................................................................................

lf)

Bl Relation

hl't\l'l'L'll

llt't•dk• and llll<kr loopt•r ........................................................................................

Hl

Cl

ln~talling

nt•edil' guard rear........................ .............................................................................

10

Dl

ln~talling

lll'l'dk guard front........................ ...........................................................................

II

El

Relation of needk• with under and

on·r

l11opt•r

.................................................................................

11

Fl

ln~talling

and nwinlt•mtncl' of lmin•s.................................................................................................

11

1

5.

Trouble shooting............................................................. .......................................................................

1~

Al

Thn•ad break......,..............................................................................................................................

1~

B) Skip

~!itching..........................................

.................................................................................

1:!

C)

:\"ecdlc

brt•a\;;

....................................................................................................................................

12

D)

ftnperfect chaining-off......................................................................................................................

1:1

El

Improper thn•ad tension...................................................................................................................

13

Fl

l'ttor trinllning perfonnance.............................................................................................................

13

(;)

Irregular

~\itches

..............................................................................................................................

1:1

Ill

Em•"ice

nT;ukb

along

>titchc~

........ ............................. .........................................

..

.............

J.J

I)

1\"l'L'<llt•

produces too large holes....................................................................................................... U

~

6.

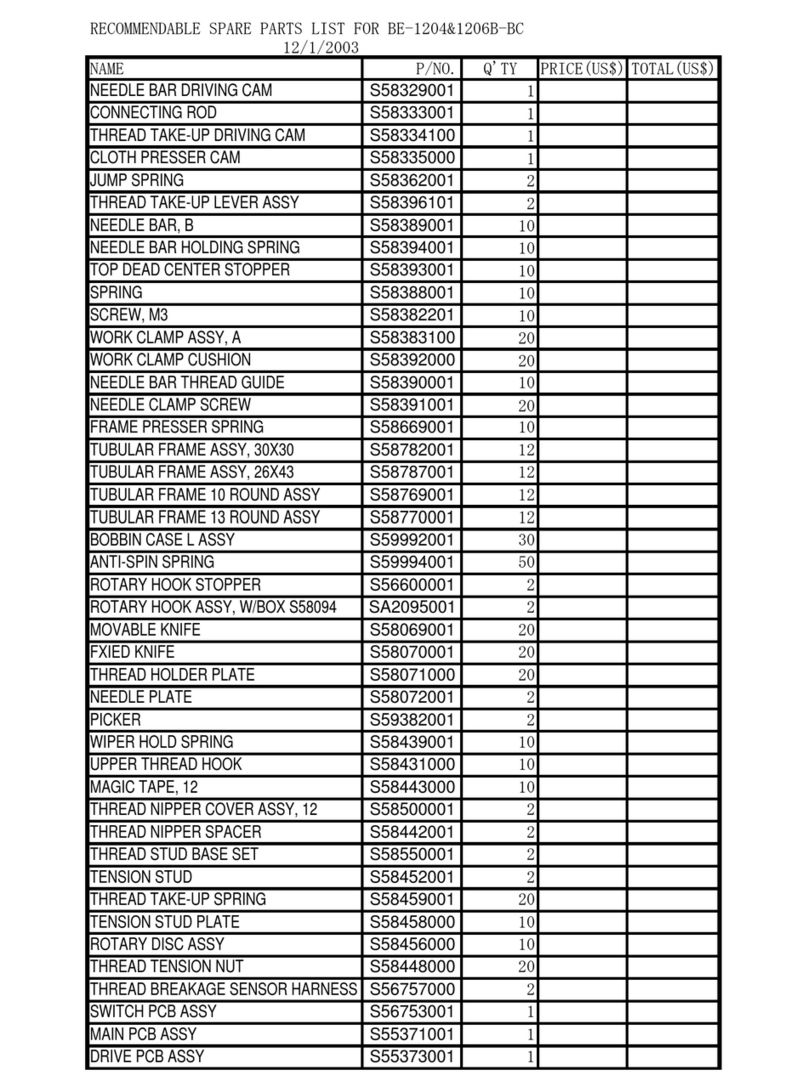

Parts list ..............................................................................................................................................Fi

From the library of: Superior Sewing Machine & Supply LLC