LK3-B434E Mark II

CONTENTS

1. NAME OF EACH PART ............................... 01

2. SPECIFICATIONS ......................................... 02

2-1. Specifications ....................................... 2

2-2. Examples of sewing patterns ............. 3

3. INSTALLATION ............................................. 04

3-1. Power table ........................................... 4

3-2. Installing the motor ............................. 5

3-3. Installing the motor pulley .................. 5

3-4. Installing the control box .................... 6

3-5. Installing the rubber cushions ............ 7

3-6. Installing the oil pan ............................ 7

3-7. Installing the cushions......................... 7

3-8. Installing the machine head ............... 8

3-9. Installing the head rest ........................ 8

3-10. Installing the liquid cooling tank,

optional ................................................. 8

3-11. Installing the operation panel ............. 9

3-12. Connecting the ground wire ............... 9

3-13. Connecting the cords........................... 10

3-14. Piping (for pneumatic) ......................... 12

3-15. Installing the V-belt .............................. 14

3-16. Installing the belt cover ....................... 15

3-17. Installing the foot switch ..................... 15

3-18. Installing the motor cover ................... 16

3-19. Installing the spool stand .................... 16

3-20. Installing the needle sub plate ........... 17

3-21. Installing the eye guard ...................... 18

4. LUBRICATION ............................................... 19

4-1. Lubrication points ................................ 19

5. OPERATION .................................................. 20

5-1. Name and function of each

operation panel item ........................... 20

5-2. Operating procedure............................ 22

5-3. Operating the foot switch ................... 23

5-4.

Operating the emergency stop switch ...

24

6. CHECKING THE SEWING PATTERN ....... 25

7. CORRECT USE ......................................... 26

7-1. Selecting the needle and thread ........ 26

7-2. Installing the needle ............................ 26

7-3. Threading the upper thread ................ 26

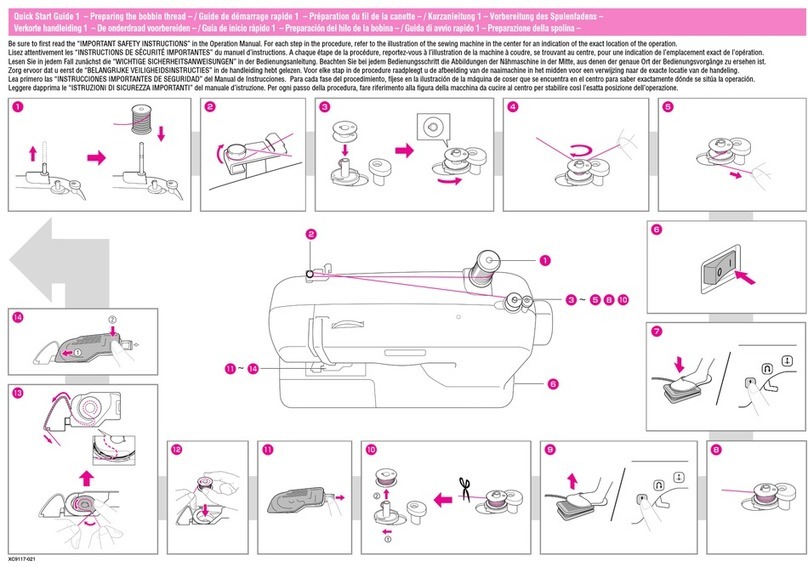

7-4. Winding the lower thread ................... 27

7-5. Replacing the bobbin case and

threading the thread ............................ 28

7-6. Sewing conditions and thread

tension................................................... 28

8. SEWING ................................................... 31

9. MAINTENANCE AND INSPECTION ....... 32

9-1. Cleaning the rotary hook .................... 32

9-2. Lubrication ............................................ 33

9-3. Draining the oil..................................... 34

9-4. Cleaning the control box air inlet

port ........................................................ 34

9-5. Cleaning the eye guard ....................... 34

9-6. Checking the needle ............................ 34

10.STANDARD ADJUSTMENTS ................. 35

10-1. Adjusting the needle bar height......... 35

10-2.

Adjusting the needle bar lift amount .....

35

10-3. Adjusting the driver needle guard ..... 36

10-4. Adjusting the needle clearance .......... 36

10-5. Adjusting the shuttle race thread

guide...................................................... 36

10-6.

Adjusting the thread take-up amount ....

37

10-7. Adjusting the movable knife ............... 37

10-8.

Adjusting the work clamp lift amount ...

40

10-9. Work clamp interchangeability ........... 41

10-10.

Adjusting the needle up stop position ...

41

10-11.Adjusting the thread wiper ................. 42

10-12.Checking the input sensor and

DIP switch input ................................... 43

10-13.Checking the input voltage ................. 44

10-14.Clearing all memory settings ............. 44

10-15.Moving stitch patterns......................... 45

10-16.Adjustment of air pressure

(for pneumatic) ..................................... 46

10-17.

Adjustment of inner clamping device ....

46

11.USING THE COUNTERS ......................... 47

11-1. Using the bobbin thread counter ....... 47

11-2. Using the production counter ............ 47

12.CHANGING FUNCTIONS USING

THE DIP SWITCHES ................................ 48

12-1. Operation panel DIP switches ............ 48

12-2. DIP switches inside the control

box ......................................................... 49

12-3. Using user programs ........................... 50

13.CHANGING SPECIAL FUNCTIONS

USING THE MEMORY SWITCHES ........ 52

13-1. Using the cycle sewing function ........ 55

14.SETTING THE WORK CLAMP MODE .... 57

14-1. Setting solenoid work clamp mode ... 57

14-2.

Setting pneumatic work clamp mode ....

57

14-3. Light work clamp ................................. 58

14-4. Setting reverse work clamp mode ..... 59

15.TABLE OF ERROR CODES ...................... 60

16.GAUGE PARTS LIST ACCORDING

TO SUBCLASSES .................................... 62

17.TROUBLESHOOTING ................................. 65

18.OPTIONAL PARTS ....................................... 68