15-1, Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan.

Phone: 81-52-824-2177 Fax: 81-52-811-7789 http://www. brother. com/

To preserve environment, this catalog is produced using the ECF paper (Elemental Chlorine-Free) and SOY INK.

CHINA

HONG KONG

ASIA

MIDDLE EAST

EUROPE

AMERICA

TURKEY

BROTHER (CHINA) LTD.

http://www.brothergroup.com.cn/cn/area_top.html

BROTHER INTERNATIONAL (HK) LTD.

http://www.brother.com.hk/

BROTHER INTERNATIONAL SINGAPORE PTE LTD.

http://www.brother.com.sg/

BROTHER INTERNATIONAL (GULF) FZE

http://www.brother.ae/

BROTHER INTERNATIONALE INDUSTRIEMASCHINEN G. m. b. H.

http://www.brother-ism.de

BROTHER INTERNATIONAL CORPORATION

http://www.brother-usa.com/

BROTHER INTERNATIONAL CORPORATION TURKISH LIAISON OFFICE

+86-21-3133-2101

+852-3589-9040

+65-6536-8891

+971-4-8835878

+49-2822-6090

+1-908-704-1700

+90-212-495-3971

Printed in Japan 2008.10. I8090939B Vol.1

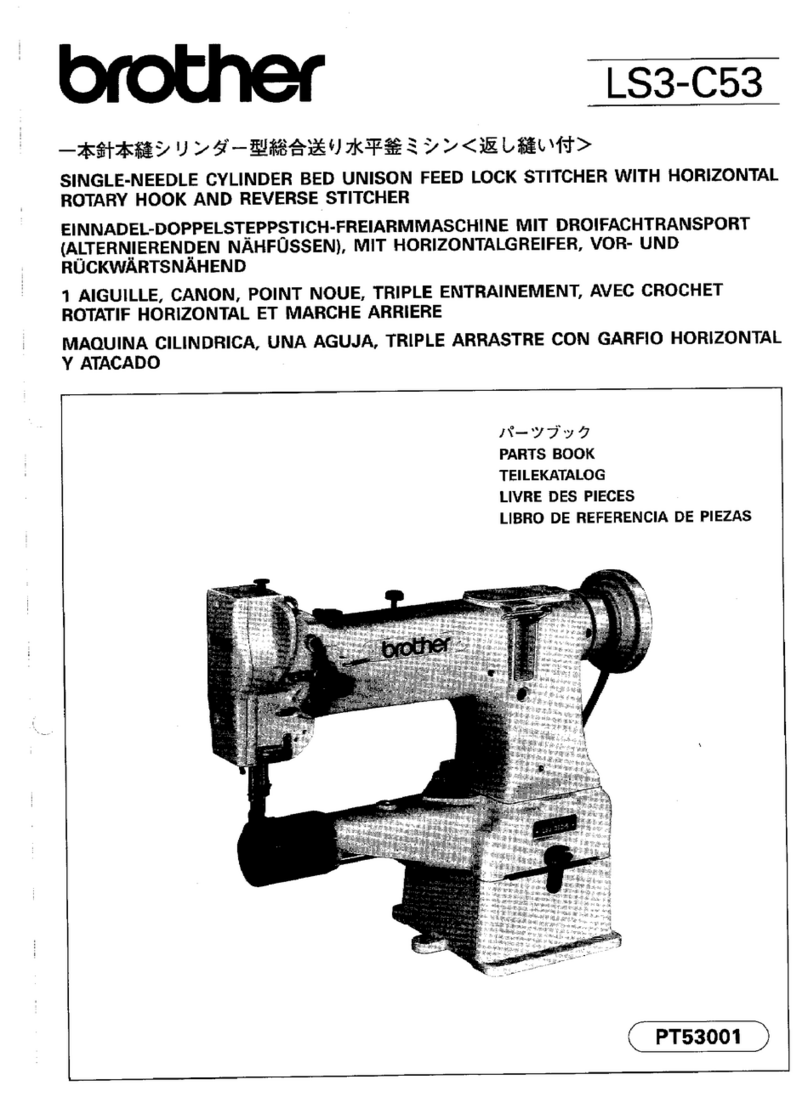

Please read instruction manual before using the machine for safety operation.

Brother Industries, Ltd. Machinery & Solution Company

Mizuho, Minato and Kariya plants acquired ISO 9001 and 14001 certifications.

Product specifications are subject to change for improvement without notice.

Photographs are for illustration purposes. They may not represent actual operating conditions and may display optional parts.

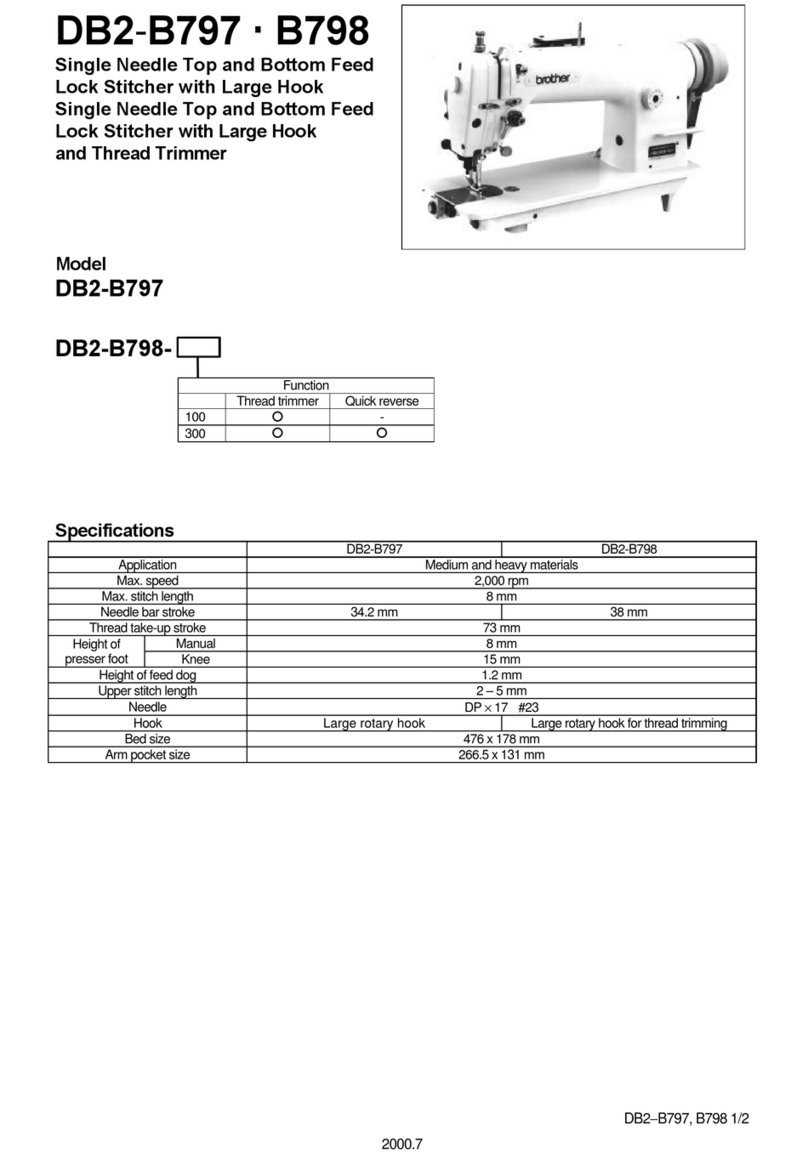

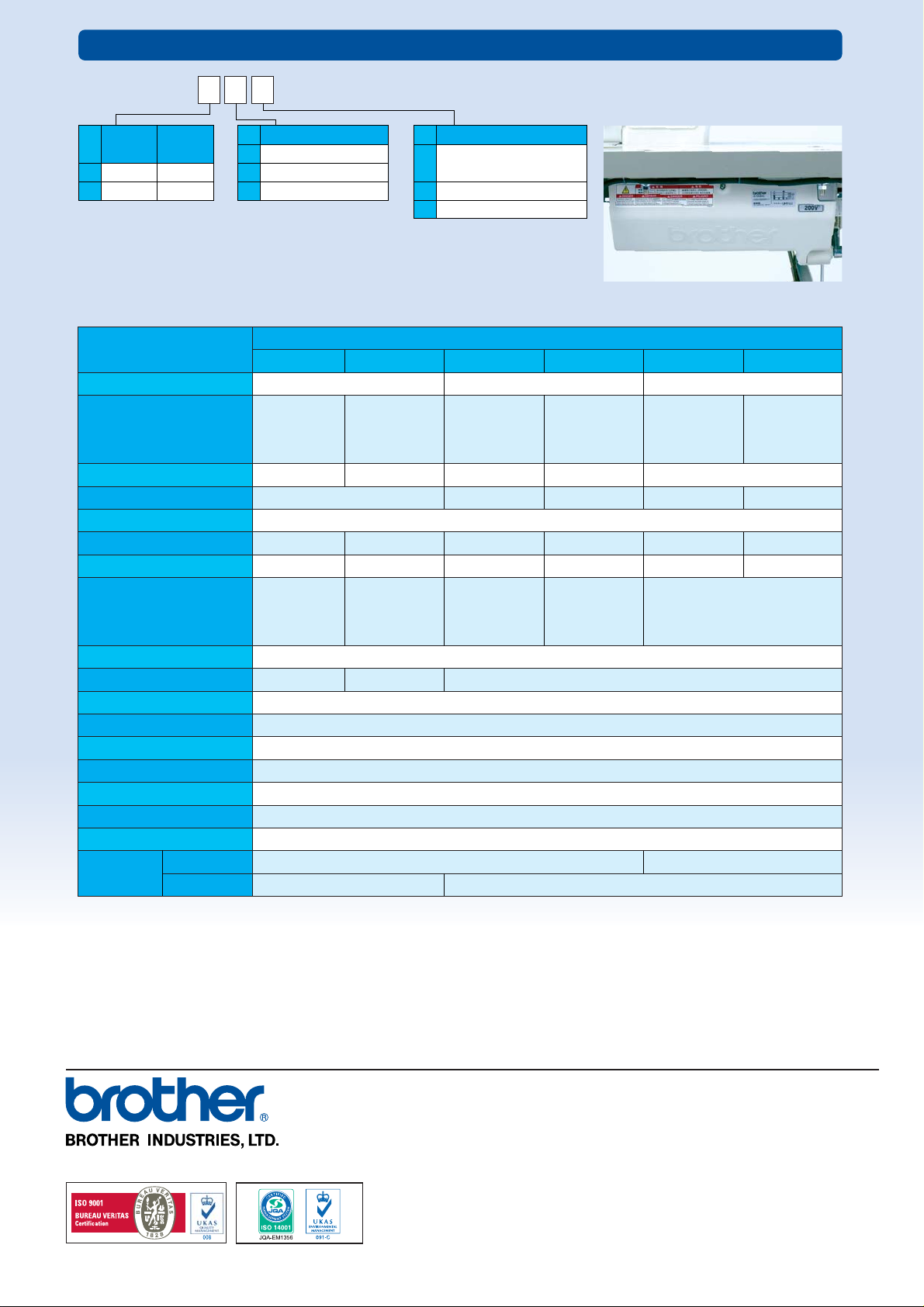

Specifications

S-7200C-

Single needle direct drive straight

lock stitcher with thread trimmer

0

3

5

Minimum lubrication

Semi dry

Complete dry

Quick

back Thread

wiper Lubrication type

S

3

5

Light-weight and

difficult-to sew materials

Medium materials

Heavy materials

Use

X-7200C

Controlbox

3

4

○

○

Lubrication type

Application

Max. sewing speed

Max. stitch length

Presser foot height

Needle bar stroke

Needle (DBx1・DPx5)

Rotary hook*2

Feed dog

Height of feed dog

Weight

Arm pocket size

Bed size

Bobbin winder

Machine head driving system

Motor

Power supply

-305, -405 -33S, -43S -333, -433 -45S -453

Medium

materials Medium

materials

5,000 rpm*1

4.2mm 4.2mm5mm 5mm

4,500 rpm*14,000 rpm 4,000 rpm

Heavy

materials

Light materials

and difficult-to

sew materials

Light materials

and difficult-to

sew materials

Minimum lubrication Semi dry Complete dry

High-speed spindle oil

Rotary hook

Needle bar High-speed spindle oil Brother's special grease

ー

Presser bar lifter: 6mm, knee lifter: 16mm(Solenoid-type presser foot lifter: 10 mm)

-303, -403

Medium

materials

5,000 rpm*1

5mm

#11〜#18(Nm75〜110)

Lubricated/

For medium

materials

0.8mm

31mm

1.2mm

Lubricated/

For Heavy

materials

#19〜#22(Nm120〜140)

35mm

Lubricated/

For light

materials

NS#9〜#11(Nm65〜75)

29mm

0.8mm

Lubrication-free RP hook

NS#9〜#11

29mm

4 rows

Lubricated/

For medium

materials

#11〜#18

31mm

#11〜#18

31mm

Machine head 45 kg, Control box 3.1 kg, Operation panel 0.4 kg (G10), 0.6kg (G50)

Width: 300mm, Height: 139mm

517.5mm x 178mm

Built-in on the machine arm

Direct drive

AC servo motor (4-pole, 450W)

Single phase 100-120V,200-240V,3-phase 200-240V,380-415V,350VA

S-7200C

*1 When sewing at a sewing speed of 4,000rpm and above, set the stitch length to 4.2mm and under.

*2 When using a lubrication-free rotary hook, operate the machine at a sewing speed of 4,000rpm and under.

Lubrication

oil

ー

○