Technical data

and start-up

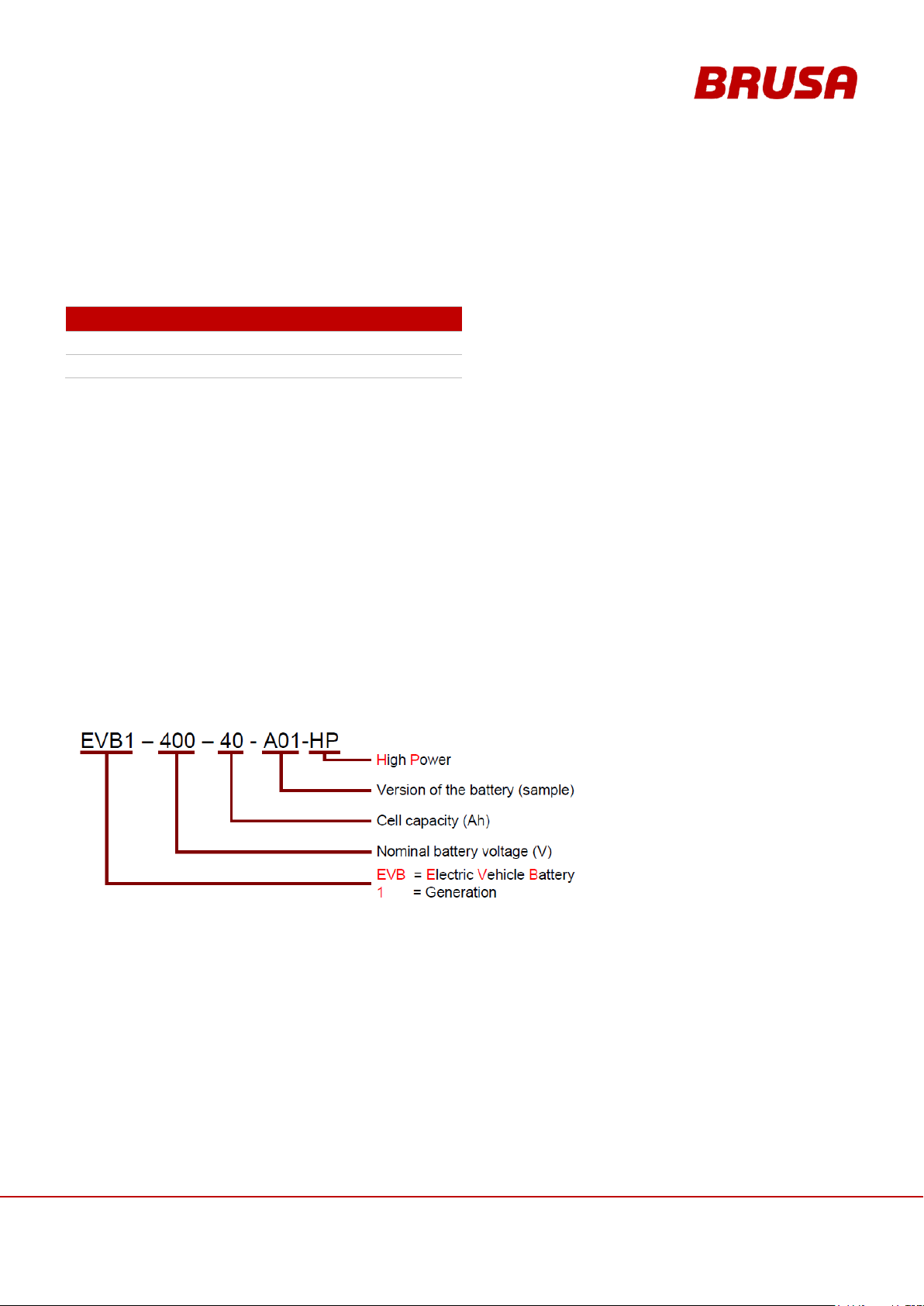

EVB1-350/400-40-HP

6.3 Warning Instructions on the Battery..........................................................................................29

6.4 Basic Principle for Vehicle Installation......................................................................................30

6.5 Safety measures for vehicle installation....................................................................................31

6.5.1 Principle of operation Interlock ..........................................................................................31

6.6 Basic Function Batterie EVB1-400/350-40-HP .........................................................................32

6.6.1 EVB1-400/350-40-HP Block Circuit Diagram.....................................................................33

6.6.2 Pre-charging Voltage.........................................................................................................34

6.6.3 Temperature Measurement / Temperature Monitoring ......................................................35

6.6.4 Balancing..........................................................................................................................36

6.6.5 Auto-reset of the Ah Meter ................................................................................................37

6.7 Overview of the Main Structural Components...........................................................................38

6.8 Dimensions and Installation Information...................................................................................39

6.8.1 Fixing Points......................................................................................................................39

6.8.2 Dimensions .......................................................................................................................40

6.8.3 Installation Position ...........................................................................................................40

6.9 Regulation and Control System................................................................................................41

6.9.1 Control via Terminal 15 (without CAN Bus) .......................................................................41

6.9.2 Control via Terminal 15 with Driving via CAN....................................................................42

7Connections.......................................................................................................................43

7.1 Circuit Connections..................................................................................................................43

7.2 Ground (GND)..........................................................................................................................44

7.3 Pin Assignment of Control Plug (Device-side)..........................................................................45

7.3.1 Pin 1 GND.........................................................................................................................46

7.3.2 Pin 2 AUX .........................................................................................................................46

7.3.3 Pin 3 EN............................................................................................................................47

7.3.4 Pin 4 PWML / PWM-out ....................................................................................................47

7.3.5 Pin 5 PWMP / PWM-out....................................................................................................48

7.3.6 Pin 9 CAN1L, Pin 10 CAN1H ............................................................................................48

7.3.7 Pin 8 APG, Pin 14 CANG, Pin 15 RS232G........................................................................49

7.3.8 Pin 11 RS232T, Pin 12 RS232R........................................................................................49

7.3.9 Pin 13 PRO.......................................................................................................................50

7.3.10 Pin 16 RFK1, Pin 17 RFK2, Pin 18 RFKC.........................................................................51

7.3.11 Pin 19 INT1, Pin 20 INT2...................................................................................................52