Repair Instructions – Cooking

2016-03-10 / DIS 184_58300000140186_ara_en_k Copyright by BSH Hausgeräte GmbH Page 1 of 181

1 Concerning this document 4

1.1 Important information......................................................................................4

1.2 Explanation of symbols...................................................................................4

2 Safety 6

2.1 Qualification.................................................................................................... 6

2.2 General safety information............................................................................. 6

2.3 Product-specific safety information.................................................................7

2.4 Measures after each repair............................................................................ 8

3 Design and function 9

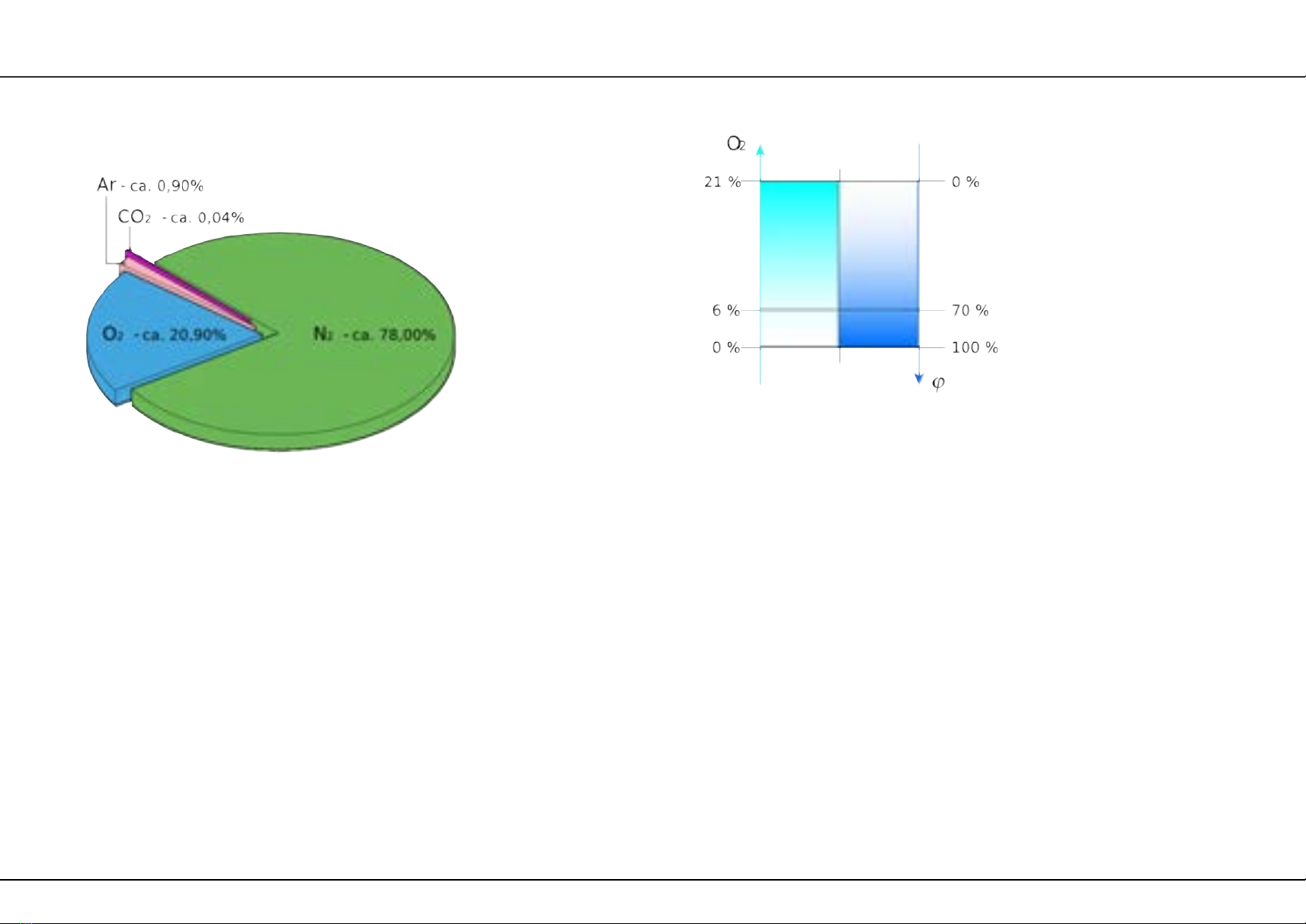

3.1 Baking sensor (Lambda sensor).................................................................... 9

3.2 Meat temperature probe (NTC)....................................................................13

3.3 Brushless direct current motor..................................................................... 14

3.4 Steam generation......................................................................................... 17

3.5 Steam generator........................................................................................... 18

3.6 Double pump................................................................................................ 20

3.7 EcoClean Direct............................................................................................21

3.8 Suitability of cookware..................................................................................22

3.9 Cooking compartment temperature sensor (Pt500 / Pt1000)....................... 25

3.10 Fold-down door.............................................................................................26

3.11 Magnetron..................................................................................................... 27

3.12 Swivelling panel............................................................................................ 29

3.13 Temperature regulation in the various operating modes.............................. 30

3.14 Temperature regulation in the various operating modes.............................. 35

3.15 Vapour extraction system............................................................................. 40

4 Fault diagnosis 43

4.1 Result faults................................................................................................ 43

Food is not cooked.......................................................................................43

Food is heated too slowly............................................................................ 43

Cleaning action is inadequate...................................................................... 43

Pieces of dough form a skin........................................................................ 43

Food dries out.............................................................................................. 44

4.2 Malfunctions................................................................................................ 45

Rails - Sloping down at the back/askew...................................................... 45

Rails - Flashovers/discoloured marks.......................................................... 45

Rails - Flashovers between rail and enamelled baking tray......................... 45

Rails - Jam/become caught..........................................................................46

Rails - Uneven running after pyrolysis......................................................... 46

Baking tray/universal pan warped, bent, bounces ...................................... 46

Operating ring can be rotated easily / no change on the display................. 46

Operating ring does not respond / no display.............................................. 47

Operating ring is hard to turn / remains stuck in a specific position............. 47

Operation is not interrupted when the door is opened................................. 47

Display background white/display hard to read............................................47

Fault code is displayed.................................................................................47

Appliance does not generate any steam......................................................48

Appliance continues to heat although the setpoint temperature has been

attained......................................................................................................... 48

Brightness of microwave differs from that of the oven................................. 48

No microwave output / 8A fuse was blown.................................................. 49

Folding panel only opens partially................................................................49

Folding panel opens at an angle..................................................................49

Folding panel does not close automatically................................................. 49

Cooling fan overruns for too long.................................................................49

NeffLight in the "slide and hide" door flashes briefly.................................... 50

Reset during operation in main menu "MyProfile"........................................50

Door (fold-down door) opens during operation (only microwave

appliances)....................................................................................................50

Door (fold-down door) cannot be closed (only microwave appliances)........ 50

Door (fold-down door) does not open 90°....................................................51

Door (fold-down door) closing is displayed (only microwave appliances).....51

Clock gains > 1 minute every day................................................................51

Time - ist fast / slow..................................................................................... 51

Water escapes into the cooking compartment via the steam inlet................52

Remove water tank is displayed when the pyrolytic self-clean system is

started........................................................................................................... 52

Fill water tank is displayed although the tank is still full............................... 52

Increased water consumption when operating in “steaming” mode............. 53

4.3 Noise............................................................................................................ 54

Rails squeaking............................................................................................ 54

High-frequency whistling sound....................................................................54

Cooling fan motor makes a high-frequency noise........................................54