BST ekr 500 User manual

ekr 500 web guiding controller EDV No.: MD.299.01.06

with removable control panel Issue: 29.07.2008

ekr 500

Web guiding controller

with removable control panel

Operating Manual

BST International GmbH

Heidsieker Heide 53

33739 Bielefeld, Germany

Phone: +49 5206/999 – 0

Telefax: +49 5206/999 – 999

E-Mail: [email protected]

The information and drawings contained in this document are the property of BST International GmbH. Any reproduction

of this document as a whole or in part without the written permission of BST International GmbH is prohibited.

Content 0

ekr 500 web guiding controller EDV No.: MD.299.01.06

with removable control panel Issue: 29.07.2008

Content

1Description 1

1.1 Symbols used in this manual 1

1.1.1 Warning signs 1

1.1.2 Using the keys 1

1.1.3 LED operating status indications 1

1.2 General 2

1.3 Intended use 3

1.4 System description 4

1.4.1 System structure 4

1.4.2 Functional principle 5

1.4.3 Connectable components 5

1.5 Terms used 6

1.5.1 Set position 6

1.5.2 Sensor 1 / Sensor 2 7

1.6 Control panel 8

1.6.1 Graphical display 8

1.6.2 Control panel 8

1.7 Safety information 10

1.8 ESD protection 12

1.9 Emissions 12

1.10 RoHS conformity 12

2Technical Data 13

2.1 Controller 13

2.1.1 Ambient conditions 13

2.1.2 Protection class 13

2.1.3 Power supply (terminal strip X6) 13

2.1.4 Analogue inputs (terminal strip X1, X2, X3) 13

2.1.5 Digital inputs (terminal strip X14) 14

2.1.6 Ouput motor output stage (terminal strip X7) 14

2.1.7 Output fault relay (terminal strip X10) 14

2.1.8 Control panel interface (terminal strip X8) 15

2.1.9 Weight, dimensions 15

2.2 Control panel 16

2.2.1 Ambient conditions 16

2.2.2 Protection class 16

2.2.3 Power supply 16

2.2.4 Display 16

2.2.5 Weight, dimensions 16

2.3 Sensors 18

2.3.1 Infrared sensors 18

2.3.2 Ultrasonic sensors 18

2.4 Electric-motor-driven actuators 19

2.5 Power pack 20

3Transport 21

3.1 Transport 21

3.2 Storage 21

4Assembly 22

4.1 Installation site requirements 22

4.2 Assembly of the controller 23

4.2.1 General 23

4.2.2 Mounting plan 23

4.2.3 Space needed to open the enclosure cover 23

4.2.4 Mounting 24

4.2.5 Turning the control panel 25

Content 0

ekr 500 web guiding controller EDV No.: MD.299.01.06

with removable control panel Issue: 29.07.2008

4.3 Assembly of the control panel 26

4.3.1 General 26

4.3.2 Wall mounting 27

4.3.3 Control console mounting 29

5Installation 31

5.1 General 31

5.2 Fitting the cable connections 31

5.3 Installation instructions for EMC-wiring 32

5.4 Overview processor board 33

5.5 Terminal assignment 34

5.5.1 Terminal overview 34

5.5.2 Terminal assignment 35

5.5.3 Plug assignments 38

5.6 Set DIL switches 40

5.6.1 DIL switch S4 40

5.6.2 DIL switch S5 41

5.7 Service indications 42

5.7.1 LEDs “Bus status” 42

5.7.2 LEDs “Device status“ 42

5.7.3 LEDs “Power supply“ 43

5.7.4 LEDs “Controller interlock“/ “OK signal“ 43

5.7.5 LEDs “Remote control“ 43

6Start-up 44

6.1 Start-up actuator 44

6.1.1 General 44

6.1.2 Determine sense of motor rotation 45

6.1.3 Determine guiding direction 45

6.1.4 Actuator without position feedback

(EMS 5 / 10 / 16) 46

6.1.5 Actuator with position feedback

(EMS 17, EMS 21, EMS 22) 48

6.2 Carry out material setup 52

6.3 Adjustment of gain 53

6.4 Start-up electronic remote precision adjustment (option) 54

7Operation 55

7.1 Operation display 55

7.1.1 Basic display 55

7.1.2 Special displays 56

7.2 Material Setup 60

7.2.1 General 60

7.2.2 Activate material setup 61

7.2.3 Procedure for web edge guiding 62

7.2.4 Procedure for web center-line guiding 64

7.3 Operating mode selection 68

7.3.1 Manual positioning 68

7.3.2 Automatic guiding 68

7.3.3 Center positioning 68

7.4 Setting the web set point 69

7.5 Optimise gain 71

7.6 Display of system information 72

7.7 Electronic remote precision adjustment (option) 73

8Remote control 74

Content 0

ekr 500 web guiding controller EDV No.: MD.299.01.06

with removable control panel Issue: 29.07.2008

9Default settings 75

9.1 Device addresses 75

9.1.1 Device address of the controller 75

9.1.2 Device address of the control panel 76

9.2 Keyboard bus terminating resistors 77

9.2.1 Controller terminating resistor 77

9.2.2 Control panel terminating resistor 78

9.3 Generating the default settings 79

10 Trouble shooting 80

11 Maintenance 84

11.1 General 84

11.2 Controller 84

11.3 Control panel 84

11.4 Sensors 85

11.5 Electric-motor-driven actuator 85

12 Decommissioning 86

I Index

A1 Annex 1 A1

Connecting plan

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 1/86

1 Description

1.1 Symbols used

in this manual

1.1.1 Warning signs Symbols are used in this operating manual in order to clearly

indicate particularly important places.

Attention!

You must obey this type of warning, in order to protect

yourself, as the operator, from bodily injuries arising

from mechanical movements.

Beware!

You must obey by this type of warning without fail, in

order to protect yourself, as the operator, from life

threatening injuries caused by electrical voltages.

Note

This symbol is used to point out additional useful tips,

which will help you to make optimum use of all of the

functions.

1.1.2 Using the keys Using the keys is represented by the following symbols in this

manual:

Press key.

Key combinations, keys have to be

pressed simultaneously.

1.1.3 LED operating status

indications Some keys on the control panel have LED’s (light-emitting diodes)

integrated in them. The different LED operating states are

represented as follows:

LED off

LED constantly lit = activated phase

LED flashing

!

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 2/86

1.2 General

The start-up, maintenance and installation

instructions described in this operating manual

must be strictly adhered to!

•The ekr 500 web guiding controller must be mounted and

operated only according to the knowledge of the relevant

operating manual.

This will help avoiding hazards and preventing damages to the

controller caused by improper assembly or operation.

•This operating manual, and particularly the safety instructions

must be observed by all persons working on or with the ekr 500

controller.

•Before operating the system for the first time as well as

before carrying out maintenance work you must read the

safety information provided by chapter 1.7 of this manual!

•Changing or loading firmware on this system must be carried

out exclusively by BST personnel or personnel duely

authorised to do so by BST. Non observance of this may

cause the loss of the warranty rights!

•The values and data shown in this manual (e. g. in the display)

are to be considered as examples, unless otherwise expressly

stated.

•The current version of the operating manual for the web guiding

controller ekr 500 in all available languages can be found on the

Internet at the following address:

http://www.bst-international.com

!

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 3/86

1.3 Intended use The ekr 500 is a microprocessor-controlled web guiding controller

with removable control panel. It may be used for

•web edge guiding

(guiding to the right or left web edge)

•web center-line guiding

The web guiding controller ekr 500 has been designed to be

installed in another machine or to be integrated with other

machines to form a single system in compliance with directive

98/37/EU (Machinery Directive).

It is forbidden to commission the system until the user/operator has

determined that the machine in which the system has been

installed, complies with the specifications given in this directive.

You are only allowed to use BST web guiding systems to correct

the position of web-shaped materials (e.g. those made from paper,

film, cardboard, rubber, etc.).

The controller and the control panel must never be installed in

potentially explosive areas.

Operation is only guaranteed if carried out using the BST web

guiding components listed in chapter 1.4.3 (“Connectable

components“).

BST web guiding systems have been designed and built in

accordance with state-of-the-art standards and the recognized

safety rules.

Nevertheless, its use may constitute a risk to life and limb of the

user or of third parties or damage the BST web guiding systems

and other equipment.

Therefore BST web guiding systems are only to be used if they are

working correctly and in a safe technical condition. Any part found

to be working incorrectly must be replaced immediately.

Only original spare parts are to be used for this. Spare parts

obtained from third parties cannot be guaranteed to comply with

the design and manufacturing conditions and safety regulations.

In this case any guarantee claims made against the BST web

guiding system will be invalidated.

Only qualified personnel who have been trained on the system are

allowed to undertake any work required on the BST web guiding

system (i.e. installation, commissioning, operation, maintenance, etc.).

Intended use also includes adhering to the instructions given in this

operating manual.

Using the machine for purposes other than those mentioned above

is contrary to its intended use. BST International GmbH does not

accept liability for any damage resulting from this type of use.

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 4/86

1.4 System description

1.4.1 System structure

1.4.1.1 General

The ekr 500 consists of the controller and the removable control

panel.

The controller enclosure contains all of the control electronics and

the connections for all of the necessary web guiding components

(sensors, actuator, servo center transducer, remote control).

1.4.1.2 Controller with mounted

control panel

Controller operation is carried out via the control panel that was

attached to the front of the controller in the factory.

Controller with mounted control panel

1.4.1.3 Controller with removed

control panel

If the installation requires a remote mounting of the control panel

due to space or access limits in the machine, it can be removed

und remotely mounted in the machine operator control station.

In this case the connection between the controller and control

panel is made using a cable extension that is available as an

optional extra.

Controller with removed control panel

The length of the cable used to connect the control

panel to the controller must never exceed 20 m.

Cable extension

(2 m, 5 m, 10 m)

Controller Control panel

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 5/86

1.4.2 Functional principle In automatic mode one or two edge sensors connected to the

controller scan the actual position of the web of material and

transmit this information to the position controller.

The position controller compares the actual position measured

against the required set position. If there is a difference between

the two values then the controller transmits a correction signal to

the actuator of the guiding device.

The actuator moves the guiding device (rotating frame guide or

swivel roll guide) until the web of material is in its set position again.

1.4.3 Connectable components The picture shows the components that can be connected to the

controller.

Controlle

r

ekr 500

A

ctuator without

position feedback

A

ctuator with

position feedback

EMS 5, EMS 10, EMS 16

Servo-cente

r

transducer

Remote control, keyboard lock

OK signal

Analogue edge sensors

IR 2001

IR 2002

IR 2005

US 2003

US 2007

US 2008

US 2009

24 V DC

Controller with

removed control

p

anel

OMG 4,

OMG 8

EMS 17,

EMS 21,

EMS 22

EFE 1 EFE 1000

Electronic remote precision adjustment

— optional —

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 6/86

1.5 Terms used

1.5.1 Set position The set position is the required position for the web of material in

the sensor scanning area. It can be set up in “Automatic“ mode

using the control panel arrow keys (see chapter 7.4).

The set position setting will be marked on the control panel display

by a white triangle being superimposed around the sensor symbol.

The relative coverage of the sensor scanning area will be

displayed as a percentage beneath the sensor symbol.

Examples:

0% covering

No material within

the sensor scanning area.

50% covering

Only one half of the sensor

scanning area is covered.

100% covering

Sensor scanning area is fully

covered.

Deviation between

set and actual position

Set position = Actual position

Center of

sensor scanning area

Relative coverage of the

sensor scanning area

Sensor scanning area Web of material

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 7/86

1.5.2 Sensor 1 / Sensor 2 In this operating manual, the sensors that are connected to the

controller are designated with “sensor 1“ and “sensor 2“.

According to the BST definition, the following link applies between

the selection buttons for the guiding mode and the sensors:

= Sensor 1 (left web edge)

= Sensor 2 (right web edge)

The following is valid in respect of the sensor mounting positions:

The sensor, which is located to the left of the material in the

web running direction (when looking from the material top

side), is sensor 1.

The material top side is the side of the material web which is not in

direct contact with the deflection pulleys of the guiding device.

Example 1: Example 2: Example 3:

As standard, sensor 1 must be connected to terminal strip X1,

while sensor 2 must be connected to terminal strip X2 of the

controller (see terminal assignments, chapter 5.5).

Sensor 1

Sensor 2

Sensor 1 Sensor 2

Sensor 1

Sensor 2

Pivot Deflection pulley

Guiding device

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 8/86

1.6 Control panel

The control panel contains all of the operating and display controls

needed to operate the web guiding system.

The signal settings on the controller’s remote

control inputs block any keys on the control panel

that have counter functions.

1.6.1 Graphical display The different operating statuses and all the relevant control

parameters are displayed on the control panel’s graphics display

during operation.

The symbol significances are described in chapter 7.1.

1.6.2 Control panel Located on the control panel are four different key groups that

have the following functions:

Green keys: Operating mode selection

Grey keys: Guiding mode selection

Blue keys: Setup mode

White keys: Manual positioning of the guiding device,

Guiding setpoint and gain adjustment,

Changing of parameter values

You will find the separate key significances listed in the table on

the following page.

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 9/86

Function Key Designation Description

Automatic

Automatic web guiding

Manual mode Manual positioning

of the guiding device

Operating mode

selection

Servo-center Center positioning

of the guiding device

Sensor 1

Guiding to the left web edge

Sensor 2

Guiding to the right web edge

Guiding mode

selection

Web center-line guiding

Manual positioning

of the guiding

device

Arrow key

left / right

Operating mode “Manual“:

•Manual positioning of the guiding

device to the left/right

Shifting of the

guiding setpoint

Arrow key

left / right

Operating mode “Automatic“:

•Shifting of the guiding setpoint

to the left/right

SETUP

Operating mode “Manual“:

•Call up setup selection menu

Operating mode “Automatic“:

•Activate gain adjustment

ENTER •Store value

and exit setup mode

Setup mode

Arrow key •Decrease/increase

parameter value

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 10/86

1.7 Safety information The safety relevant information in accordance with DIN EN 294,

DIN EN 349 and the industry specific safety regulations must be

taken into consideration when installing the BST equipment in the

production machine, these include:

•There must be a safe distance between the BST equipment and

the machinery already installed on-site, such as machine

panels, building structure, etc.

•Connection lines between the individual system components

must be laid so that nobody can trip over them, not pulled tight

and well anchored down.

•Ensure that there is sufficient free headroom.

If the height of free passage is restricted, the relevant building

components causing the restrictions must be padded and a

danger warning signs must be attached to them (yellow/black).

•As a matter of course, cable connectors (e. g. between

controller and sensors) should only be disconnected when the

system is no longer connected to the mains supply (mains plug

has been removed). Any infringements will result in the

warranty claim being invalidated.

•In principle, the controller does not have ATEX certification, i.e.

you are not permitted to use it in area where the danger of an

explosion exists!

•Any transport safety devices that were used must be removed

prior to commissioning.

Only trained specialist personnel are permitted to

undertake the assembly, installation and

commissioning!

Danger of cuts!

Never touch the edges of moving webs of material!

Danger of crushing!

Never reach inbetween the fixed lower frame and the

moving upper frame of the guiding device (rotating

frame guide or swivel roll guide).

Never reach into the moving rolls!

!

!

!

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 11/86

Please do not open the controller until the line voltage

is switched off.

When operation at open unit is necessary, only

protection class IP 20 is present.

There will be an increased risk of danger by line

voltage!

Before starting work, ensure the equipment is

electrically isolated. To this end always carry out the

following measures:

1. Switch off.

2. Prevent switching back on.

3. Check the equipment is isolated.

4. Earth.

5. Cover or shield any adjacent parts that are still live.

Only then you can carry out the relevant work.

Please do not use the guiding frame as a tread or a

Stepp ladder.

Do not remove any safety devices.

Positioning movements will be undertaken by the

actuator during functional testing away from the

production machine and/or during the commissioning!

The relevant safety arrangements must be

implemented during performance checks!

Monitor the overall safety concept of the production

machine during commissioning!

!

!

Description 1

12

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 1

with removable control panel Date: 29.07.08 Page: 12/86

1.8 ESD protection

Attention!

Hazards caused by electrostatic discharge

(ESD = Electro Static Discharge).

The device contains components which can be damaged by

electrostatic discharge. This component can receive permanent

damage, which can lead to loss of performance, failure or destruction

of the part, if it contacts electrostatically-charged persons or objects.

System component housings may only be opened at an ESD-

protecting workplace (ESD workplace in accordance with

DIN EN 61340-5-1). If there is no ESD-protected workplace

available, ESD precautionary measures in accordance with

DIN EN 61340-5-1 must be taken to ensure that electrostatic

charges are carefully discharged.

If making return shipments of electronic components or assemblies,

regulations in accordance with DIN EN 100 015 “Protection of

electrostatically-endangered components“ must be observed.

You should therefore only use the electrically conductive ESD

packaging provided for transport, and label it correctly.

BST International GmbH is not liable for any damages caused

by the nonobservance of the ESD protective measures

described here.

1.9 Emissions The A-related equivalent continuous sound level of the equipment

is less than 70 dB(A).

1.10 RoHS conformity We hereby declare that the ekr 500 web guiding controller does not

exceed the hazardous substance limits stipulated in EU Directive

2002/95/EU*.

* EU Directive for restricting the use of specific hazardous

substances used in electrical and electronic equipment,

“RoHS Directive“ (Restriction of Hazardous Substances).

Technical Data 2

8

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 2

with removable control panel Date: 29.07.08 Page: 13/86

2 Technical Data

2.1 Controller

2.1.1 Ambient conditions Environment temperature

in operation: 0 ... 45°C

Storage temperature: - 10°C ... + 70°C

Air humidity in operation: 5 ... 90%, without condensing

2.1.2 Protection class Protection class: IP 54

(considering the installation site

requirements, see chapter 4.1)

2.1.3 Power supply

(terminal strip X6) Voltage: 24 V DC ± 10% (including ripple)

Power consumption: max. 4 A (including actuator)

Connection: plugged in from the outside using a

3-pin plug as per CEN 175301-803

(DIN 43650)

2.1.4 Analogue inputs

(terminal strip X1, X2, X3) Sensors (terminal strip X1, X2)

Signal input sensor 1/2: 0 ... 10 V, ± 10 V or 0 ... 20 mA

(selectable via DIL switch)

Power supply: ± 12 V ± 5%

< 50 mA (+12 V)

< -50 mA (-12 V)

+24 V DC / max. Σ0,5 A

IR pulses: for IR 2001, IR 2002, IR 2005

+5 V (length ≈250 µs)

Connection: internal on cage clamp

Position feedback EMS 17/21/22, servo-center transducer OMG 4,

remote precision adjustment EFE 1 (terminal strip X3)

Signal input: ± 10 V

Power supply: ± 12 V

Connection: internal on cage clamp

Maximum power supply max. Σ+12 V: 150 mA

(X1 + X2 + X3) max. Σ-12 V: 100 mA

Technical Data 2

8

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 2

with removable control panel Date: 29.07.08 Page: 14/86

Servo-center transducer OMG 8 (terminal strip X10)

Signal input: according to Namur specification

Power supply: according to Namur specification

Connection: internal on cage clamp

2.1.5 Digital inputs

(terminal strip X14) Remote control, remote

precision adjustment EFE 1000: < 4 V (Low), > 8 V (High)

(terminal 74 – 81)

Controller interlock: < 4 V (Low), > 8 V (High)

Switched via the hardware, i.e. not

via the processor or the software.

Galvanic isolation: none!

Connection: internal on cage clamp

2.1.6 Ouput motor output stage

(terminal strip X7) Voltage: ± 24 V DC

(reduces the actuator’s maximum

actuating force if a lower supply

voltage is used)

Power consumption: max. 1.2 A (peak current 4 A)

Protection: Automatic electric switching off

after approx. 400 ms if overcurrent

occurs with motor current in one

direction (no polarity change):

> 1.9 A (EMS 21, EMS 22)

> 1.1 A (EMS 10, EMS 16, EMS 17)

> 0.4 A (EMS 5)

Connection: internal on cage clamp

2.1.7 Output fault relay

(terminal strip X10) Voltage: max. +24 V AC/DC

Power consumption: max. 1 A

Connection: internal on cage clamp

Technical Data 2

8

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 2

with removable control panel Date: 29.07.08 Page: 15/86

2.1.8 Control panel interface

(terminal strip X8) Voltage: + 24 V DC

(corresponds to the supply voltage)

Power consumption: max. 0.5 A

(protected by Polyfuse)

Bus interface: 500 kBaud,

no galvanic isolation

Connection: plugged in from the outside using a

4-pin micro style M8 connector

2.1.9 Weight, dimensions Weight: approx. 1.18 kg

(controller without control panel)

Dimensions: See page 17

Technical Data 2

8

ekr 500 web guiding controller EDV No.: MD.299.01.06 Chapter: 2

with removable control panel Date: 29.07.08 Page: 16/86

2.2 Control panel

2.2.1 Ambient conditions Environment temperature

in operation: 0 ... 45°C

Storage temperature: - 10°C ... + 70°C

Air humidity in operation: 5 ... 90%, without condensing

Protection class: IP 54

2.2.2 Protection class Protection class: IP 50

If the controller is installed with

mounted control panel the whole

unit is classed as protection class

IP 54.

2.2.3 Power supply Voltage: + 24 V DC

(power supplied by the controller)

2.2.4 Display Resolution: 128 x 64 pixel,

LED background illumination

2.2.5 Weight, dimensions Weight: approx. 0.26 kg

Dimensions: See page 17

Other manuals for ekr 500

5

Table of contents

Other BST Controllers manuals

Popular Controllers manuals by other brands

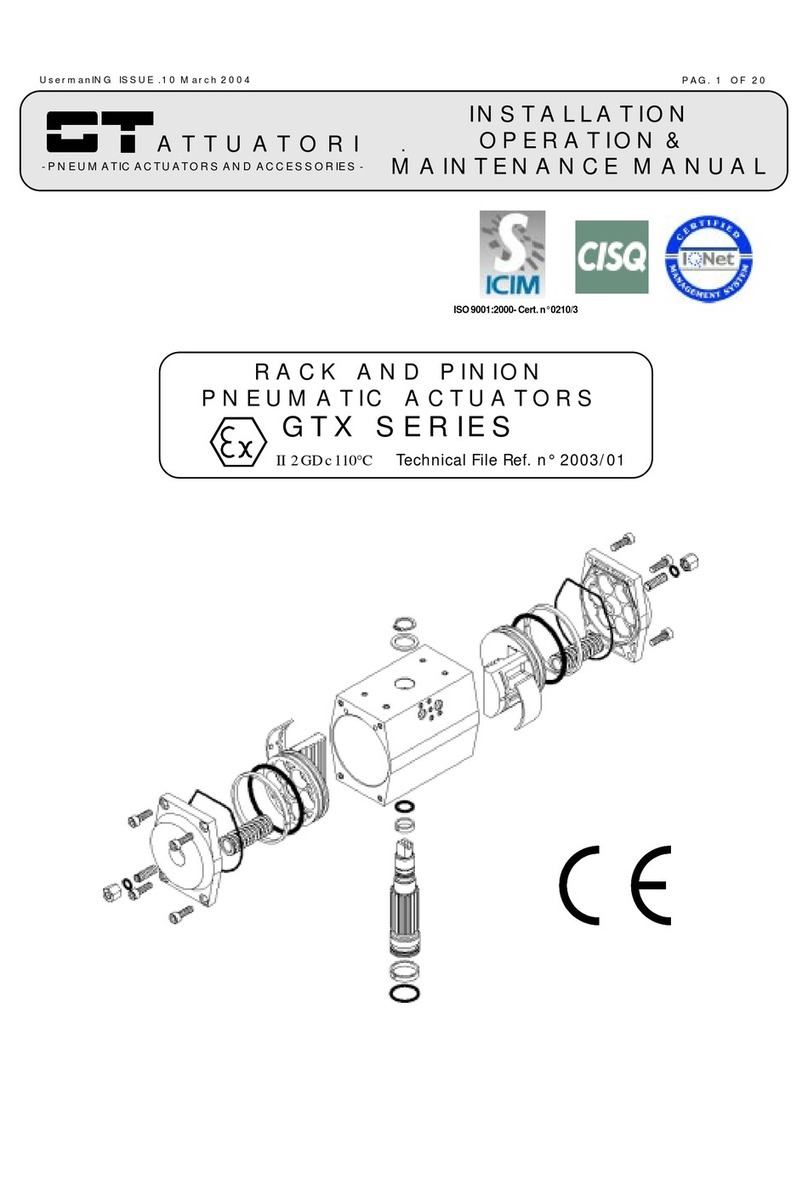

G.T. Attuatori

G.T. Attuatori GTX Series Installation, operation & maintenance manual

AUMA

AUMA GST 10.1 Operation & instruction manual

Honeywell

Honeywell HEGSA002 User manual user manual

zeeltronic

zeeltronic PCDI-RGT user manual

NetApp

NetApp E Series manual

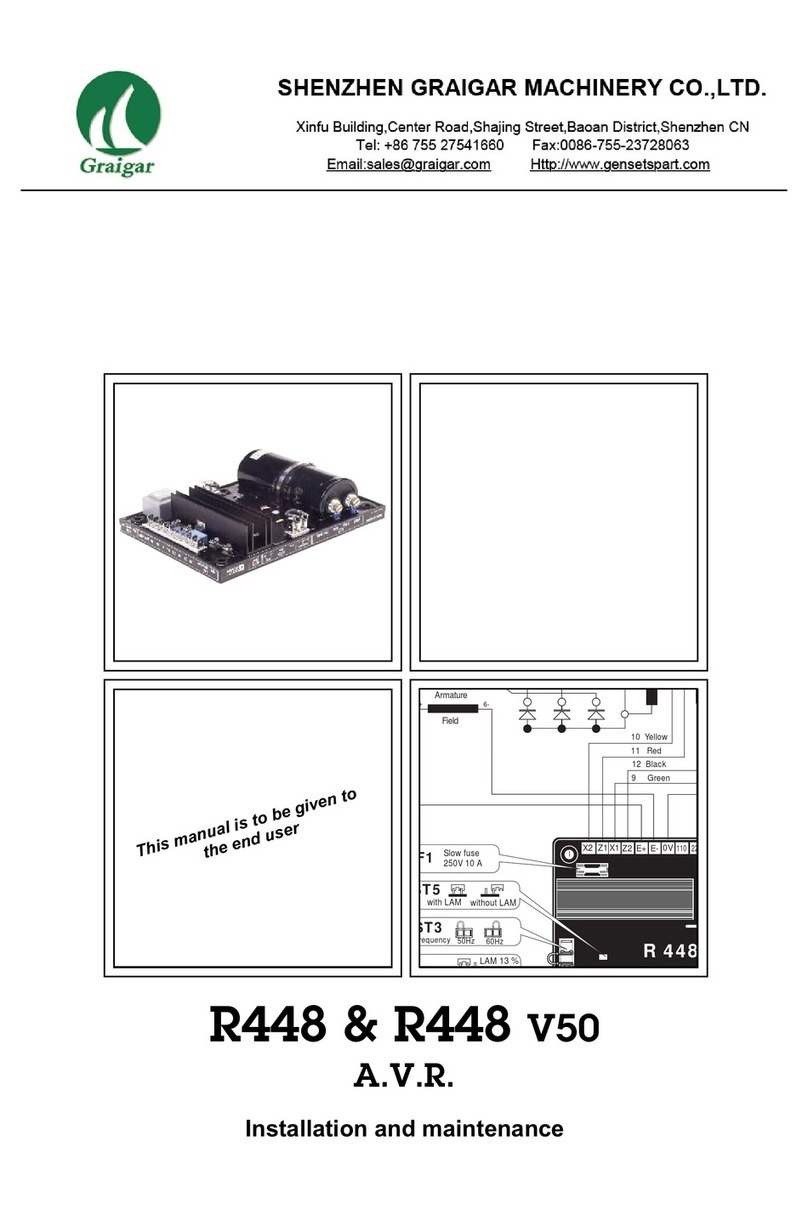

GRAIGAR

GRAIGAR R448 Installation and Maintenance