1 | P a g e

INSTALLATION AND MAINTENANCE MANUAL

VALVE REGULATED LEAD ACID BATTERY BAG 2V SERIES

I. Shipping and Storage

(1)

Do not place battery upside-down, and

avoid collision, in case battery may be broken.

(2)

Do not touch terminal and safety

valve when handling batteries.

(3)

Short circuit of the battery is strictly

forbidden because it is fully charged and filled

with acid.

(4)

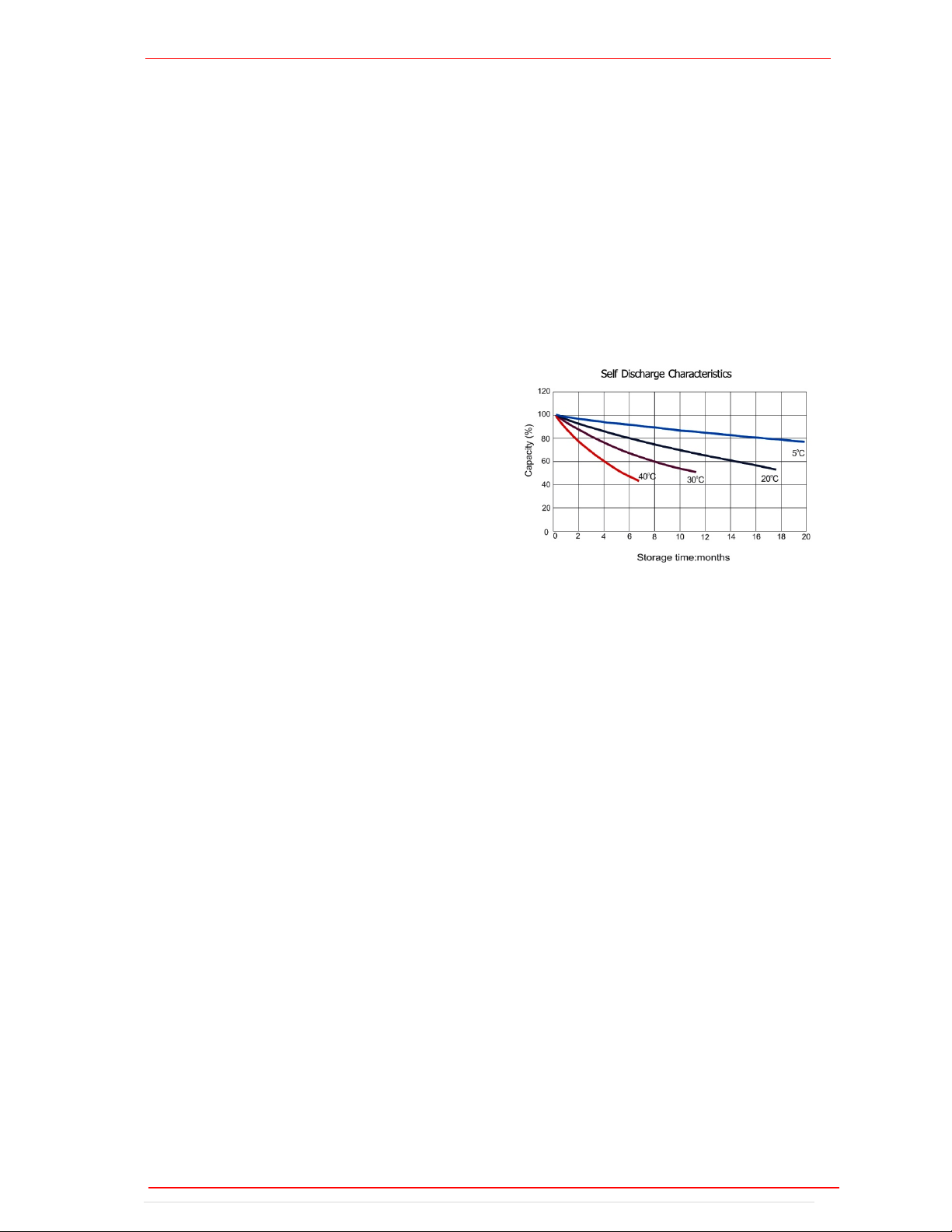

Storage temperature should range

between 0 - 35°C, direct sun light should be

avoided. If the storage temperature is too

high, big battery self-discharge may occur.

(5)

To avoid poor performance, the

storage time should not exceed 6 months

when the temperature is 25°C, and should be

shortened at higher temperature. Battery

stored for more than 6 months has to be re-

charged to ensure its good performance.

Storage room should be kept clean, dry and

with good ventilation.

II. Installation

1.

Unpacking and inspection

When unpacking, please check the battery for

possible damage and missing components.

Please carefully read this manual and the

connection drawing before installation.

2.

Installation procedure and method

(1) Select proper installing position: The

battery blocks should keep away from the fire,

source of heat, and transformer, power

switches, and fuses which are easy to have

sparks. The operating room should have good

air circulation, and be easy for heat diffusion.

To ensure the best work performance of the

battery, the ambient temperature should be

controlled between 20°C to 25°C.

(2) Battery racks and cabinets should be

fixed on the floor, (these racks and cabinets

can be designed according to customer's

requirement.), but the battery in bulks should

be assembled accordingly.

(3) Please refer to the attached

connection drawing before installing the

battery into the racks or cabinet, and connect

them with copper bar or cable. Before

connecting, the surface of terminal should be

coated with Vaseline.

(4) Check after installation

Check the fastening for tightness.

Check if the positive and negative connections

are conducted according to connection

drawing.

Check if the total battery voltage is correct.

(5) Install dustproof guard and close the

cabinet door.

3.

Installation cautions

(1) Select appropriate installation scheme

as per actual installation site. Please inform

the manufacturer of installation requirement

when ordering, so as to facilitate installation.

(2) To ensure the best performance of

battery, please select proper battery room. Do

not install battery inside sealed room or

equipment, good air circulation is required.

Keep away from apparatuses which may incur

sparks or fire. Avoid direct sun light. The

battery room should not have organic solvent

or any of corrosive gas.

(3) Do not connect different batteries

together.

(4) When connecting, avoid short-circuit

of battery. Position and connect battery

according to drawings. The batteries should

be over 8 to 12mm apart, and make sure there

is adequate air circulation underneath battery.

Installation tools should be insulated. When

the total battery voltage is higher than safety

voltage, installation personnel should wear

insulated clothes in case electric shock

occurs.

(5) Connectors should be clean, shortage

of flat washer or spring washer is not allowed.

All the fastenings should be tightened, or else

sparks may occur and damage the battery,

hence affecting battery performance. Also, do

not over tighten the fastenings, which may

damage the terminal.

(6) Before connecting the battery to the

power supply or the loading equipment, check

the polarity of the cells and monoblocs to

ensure correct installation, and cut all

switches to prevent personal injuries.

(7) Never clean the battery container with

organic solvent. Use only a damp cloth to

clean the cells and monoblocs.

(8) To avoid personal injuries, do not cut

battery, as there is corrosive liquid— sulfate

acid inside cell.

(9) Always keep clean areas around

battery valve to avoid dust blocking, which

may cause accident.

III. Operation and Maintenance

1.

Operating of Battery

(1) Float charging operation