0-4

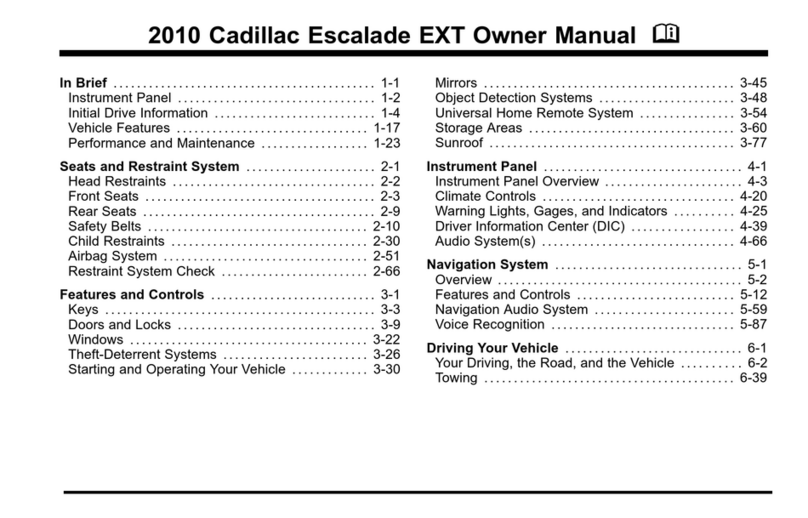

GENERAL INFORMATION, MAINTENANCE AND LUBRICATION

GENERAL DESCRIPTION AND SPECIFICATIONS

Hoist Recommendations

(Except Eldorado)

CAUTION: Failrrrr to follow the recommenda-

tions orrtlined below ma)' reszrlt in unsatisfactory

vehicle performance, or a durability failure which

may result in loss of control of the vehicle.

Description

Fleetwood Sixty Special

Brougham

Calais Sedan

Calais Coupe

Sedan de Ville

Coupe de Ville

Eldorado Coupe

Eldorado Convertible

Fleetwood Seventy-Five

The preferred type of hoist for lifting 1973Cadillacs

is one that engages the front suspension and rear axle, or

all four wheels.

The front lower suspension arm is designed with a

flattened portion on the flange of the arm for use with

lifting equipment that engages the suspension system.

When using lifting equipment of this type, make certain

that the car is properly centered over the hoist and that

the hoist arms are positioned under the flattened portion

of the flange, Fig. 0.3, outboard of the safety locaters. If

the hoist arms are not properly positioned in relation to

the lower support arms, damage to the steering linkage

or brake lines could result, or the car may shift on the

hoist.

Overall

Length

(Inches)

231.5

228.5

228.5

228.5

228.5

222.0

222.0

250.0

250.0

253.9

CAUTION: The rear lower control arms should

never be used asa liftpoint.

Vehicle

Identifi-

cation

Number

6869

6C49

6C47

6D49

6D47

6L47

6L67

If a frameengaging hoist is used, certain precautions

must be observed. The shaded areas of the frame, Fig.

04,indicate the only acceptable positions for lift pads.

Pads must be used in these areas with maximum surface

contact and must contact only those parts of the frame

indicated.

Overall

Height

(Inches)

55.5

54.6

54.1

54.6

54.1

53.9

54.3

57.8

57.7

-

Sedan

Fleetwood Seventy-Five

Limousine

Commercial Chassis 6290

(NOTE: Certain cars are equipped at these loca-

tions with special brackets used for rail shipment. If such

a situation is encountered, be sure to engage bracket

fully rather than at the edges.)

151.5

151.5

157.5

WEIGHT

4999

4850

4797

4882

4822

4777

4863

Do not use a frame-engaging hoist to raise the Fleet-

wood Seventy-Five Sedan and Limousine or the Com-

mercial Chassis.

Maxi-

mum

Width

(Inches)

79.8

79.8

79.8

79.8

79.8

79.8

79.8

79.8

79.8

-

Wheel-

base

(Inches)

133.0

130.0

130.0

130.0

130.0

126.3

126.3

CAUTION: The shock

absorbers

act

as rebound

stops for the rear suspension Under no circum-

stances should the rear end ofcar be raised so that

rrar suspension is in rebound position while dis.

connecting shock absorbers.

Hoist Recommendations

(Eldorado Only)

Tread

Width

CAUTION: Failure to follow the recommenda-

Front

63.3

63.3

63.3

63.3

63.3

63.66

63.66

63.3

63.3

63.3

tions outlined below mav result in unsatisfactory

vehicle performance, or a durability failure which

may result in loss of control of the vehicle.

Rear

63.3

63.3

63.3

63.3

63.3

63.59

63.59

63.3

63.3

65.0

The preferred type of hoist for lifting the 1973

Eldorado is one that engages the front suspension and

rear axle or all fourwheels.

Use of a suspension-engaging hoist requires that

certain procedures bc observed.

Be sure front hoist saddle adapters engage lower

suspension arm just inboard of stabilizer linkage (both

sides), Fig. 0-5, to prevent damage to steering linkage. At

the rear, Fig. 0-6, place "saddles" of hoist in maximum

"in" ~ositionto prevent dama~eto Automatic Level

contrb~overtravei lever bracket, fuel lines, and brake

Fig.

0-3

Front Hoist

Saddle

Position-Except Eldorado lines.

-~

~~

~

~

-~~~

.

-

-

--