- 10 -

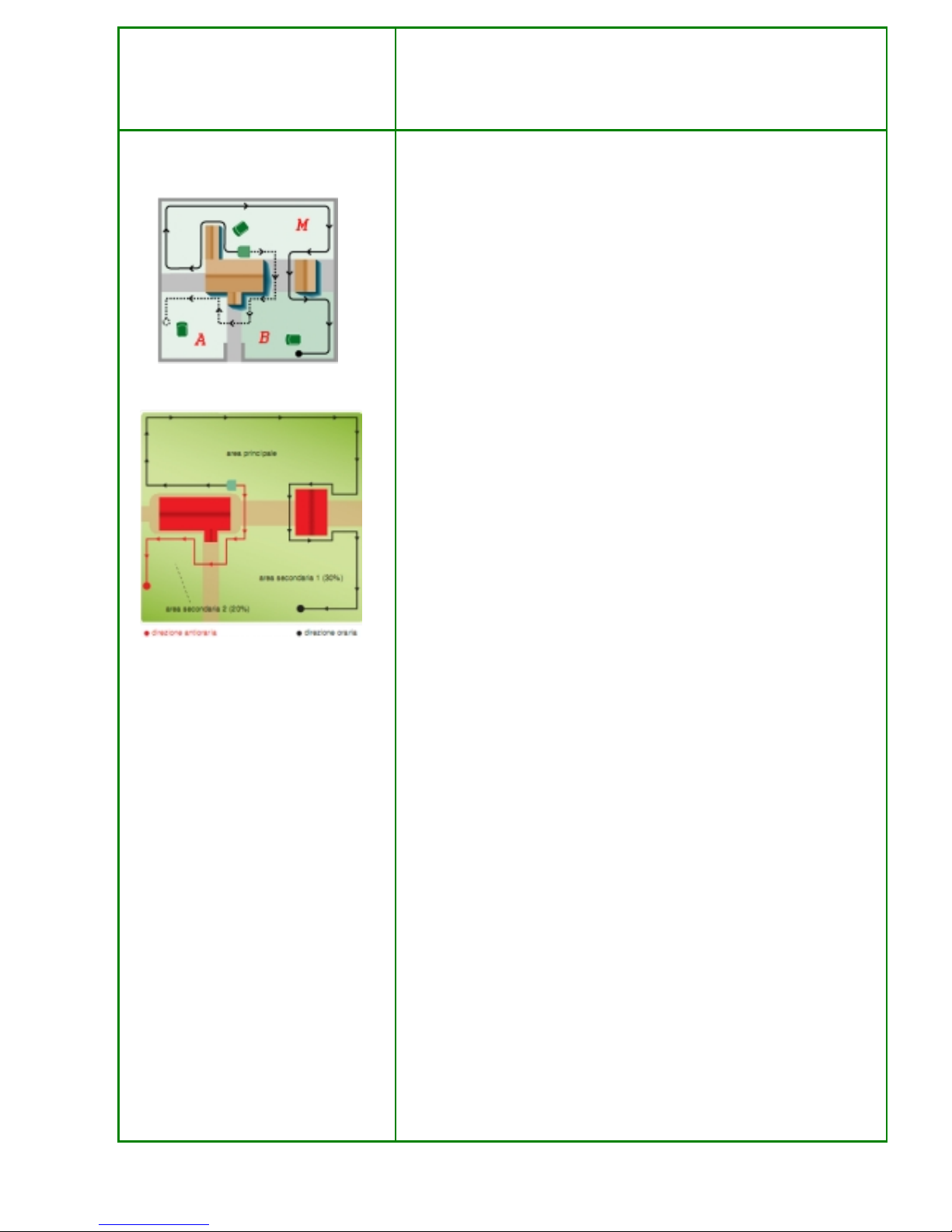

1000 800 200 40% 20%

1000 400 400 20% 20%

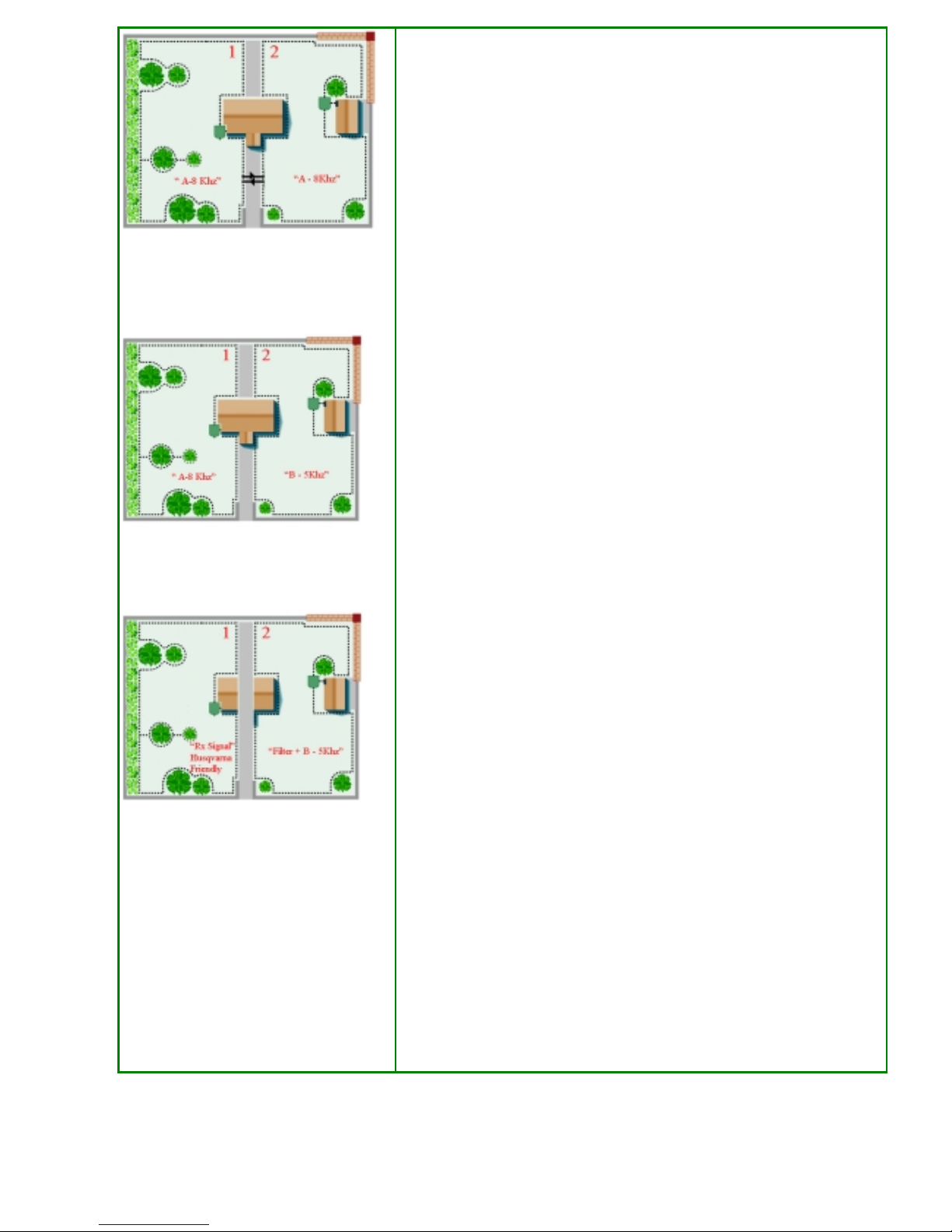

In case the primary area, where the recharging base is positioned, is smaller,

please set out the values as follows:

PA SA1 SAD1

1500 2000 60%

1000 2000 70%

500 2000 80%

In case the base is positioned in a closed and very narrow area and you need

to set out the robot for working in the secondary areas, it is possible to settle

the robot as follows:

PA SA1 SA2 SAD1 SAD2

0 2000 1000 70% 30%

Bluetooth Software installation in mobile

phones and Control over the robot

Software Icon on the mobile phone

Robot Search. Function for

activating new robots research and for

combining with them.

Quick Connection to the Robot

already previously combined.

Charge Key. It orders the robot to go

to the recharging base or, in case it is

already in the recharging base, it orders

the robot to come out.

“Configure” Key. It permits to enter

the User’s Programming.

In order to control the robot with your own mobile phone, you need first of

all to have a mobile phone supporting Bluetooth, Java and which permits the

Java applications to control the Bluetooth module. In technical terms, it is

necessary for the mobile to support this function “A midlet can use Bluetooth

(JSR-82)”. To install the software you need to have a PC with Bluetooth.

Download with “LAWN MOWER PROGRAMMER” the last release. Select

“Other”.

A folder will open: 3 short movies are available showing instructions on how

to install the software on the mobile in three different ways (according to the

Bluetooth module available on the PC).

In general the operation consists in selecting the file “BT-Remote-

Control.jar” and then select in the menu FILE->Send to->Bluetooth device.

At this point the procedure changes in relationship with the Bluetooth

module installed on the PC, but in general it consists in searching for the

mobile phone, selecting it, defining a connection password (for instance 1234)

and pressing the button “send”. Follow the instructions appearing on the

mobile. At this point the software has been installed in the mobile phone.

Each model of mobile phone has its own way for saving the received files.

Generally, they are saved in “Received Files, Applications, Collection or

Games”.

After having found and executed the received file, the first time it is

necessary to select the language and combine the phone with your robot.

• Switch the robot on and enter the User’s Menu.

• Select the option Bluetooth. Configuration.

• Select ID on which we want to set up the phone. (It is possible to set

up up to 3 handy phones enabled to drive the robot.) The connection

between robot and handy phone cannot take place contemporarily

with more than one handy phone.

• It begins to count 60 seconds down; the combining operation must

be completed within the 60 seconds, otherwise it is necessary to

repeat the operation.

• On the mobile phone, execute the application “Remote”.

• Select “Robot Search”. At the end of the research a list of the

individuated robots is displayed. Select the robot which we want to

connect to and press the OK key. Automatically the Robot have the

name of “ROBOT”.

• The Robot stops counting down and at this point the combination

has been pursued.

• Press the Pause key on the mobile to check it works properly.

• From now on, in order to connect with the Robot it is sufficient to

select in the mobile the option “fast” for a faster connection.