PGUI / PGUI32 Training Manual

1.1 3

Table of Contents

1. Introduction.......................................................................................................................................................5

1.1 Program Purpose.........................................................................................................................................5

1.2 Training Manual Purpose............................................................................................................................5

1.3 Requirements...............................................................................................................................................6

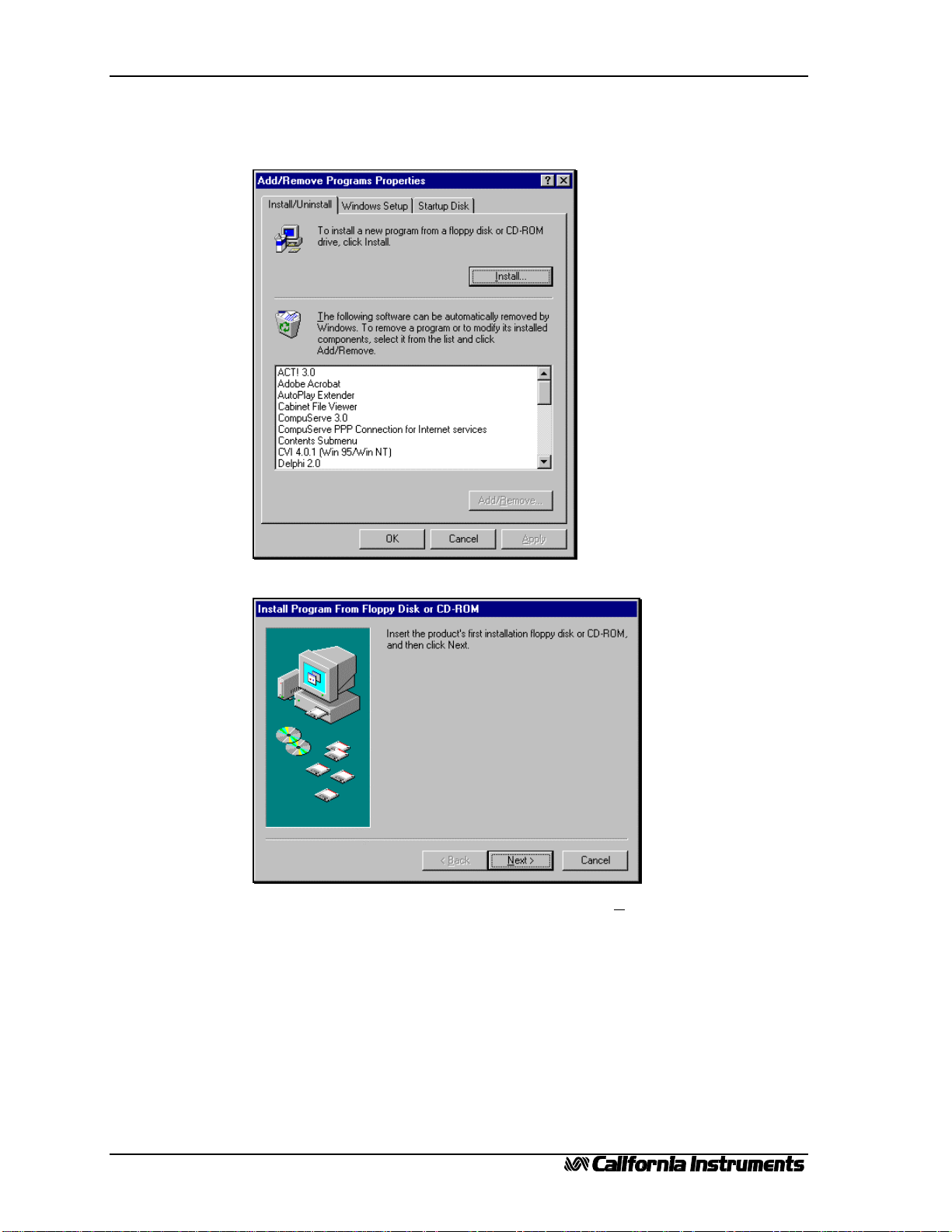

2. PGUI Installation ..............................................................................................................................................9

2.1 Windows 95Installation procedure...........................................................................................................9

2.2 Windows 3.1Installation procedure........................................................................................................13

3. PGUI Main Window.......................................................................................................................................15

3.1 Steady State Control..................................................................................................................................16

3.2 Front Panel Lock.......................................................................................................................................17

3.3 Status Bar..................................................................................................................................................17

3.4 Command Menu........................................................................................................................................18

3.5 Toolbar......................................................................................................................................................18

3.6 Next...........................................................................................................................................................18

4. System Menu...................................................................................................................................................19

4.1 Interface ....................................................................................................................................................19

4.2 Configuration Settings...............................................................................................................................21

4.3 Power-On Settings.....................................................................................................................................22

5. Measurements .................................................................................................................................................23

5.1 Enable and Disable Measurements............................................................................................................23

5.2 Recording Measurement Data to disk. ......................................................................................................24

6. Transient Programming...................................................................................................................................27

6.1 Voltage Transients ....................................................................................................................................27

6.2 Frequency Transients ................................................................................................................................29

6.3 Voltage and Frequency Transient..............................................................................................................30

6.4 Data Entry Mode Options .........................................................................................................................31

6.5 Saving Transient programs........................................................................................................................32

7. AC Source Setup Files ....................................................................................................................................33

7.1 Saving front panel setups ..........................................................................................................................33

7.2 Recalling front panel setups......................................................................................................................34

8. Conclusion ......................................................................................................................................................35