Installation

1. Siting

2. Ducting

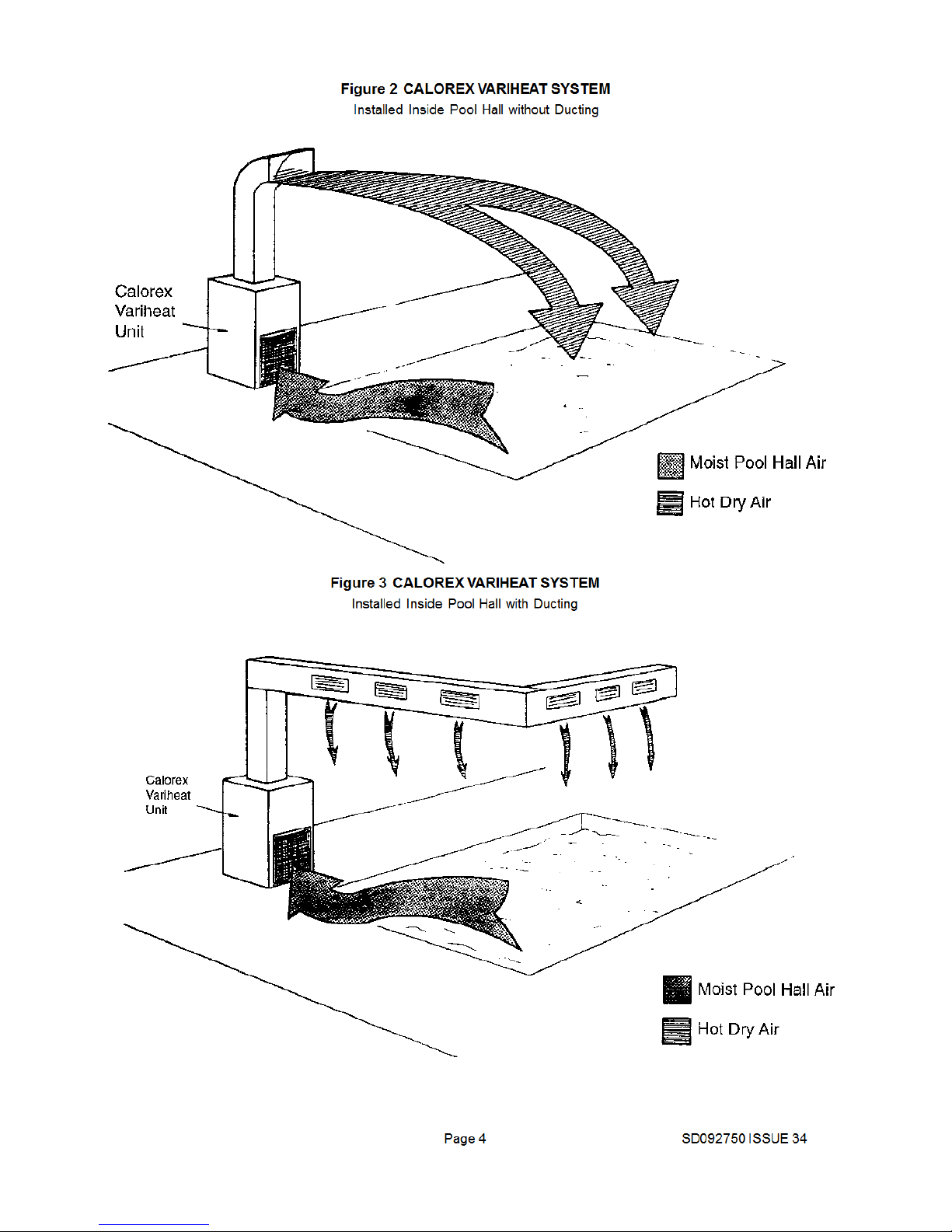

See Figs. 2, 3, 4, and 5.

a) Ensure heat pump on site is as ordered,

i.e. model electrical supply and factory

fitted options.

b) Inspect unit for damage, in paticular inspect

the evaporator (finned side) to ensure that it is

undamaged (minor indentations in the fins do

not affect performance). If severely damaged

endorse delivery note in presence of the driver

and send a recorded delivery letter to the

transport company giving details.

c) Protect the unit if installation is delayed.

d) Provide a firm level base capable of supporting

operational weight of unit. Spread load if on timber

floor.

e) Ensure water cannot collect under the unit. It

is recommended that units are installed on

plinths 100mm above finished floor level and

also to aid condensate drainage.

f) Allow adequate clearance to service panels on

unit; recommend 500mm minimum (see

installation drawings).

g) All Calorex heat pumps are designed to be as

quiet as practicable, however, due

consideration should be given to siting in order

to fully exploit this feature, i.e. orientate inlet/

outlet parallel to occupied premises.

h) Ensure loose debris will not block air filters or

grilles.

IMPORTANT

As Variheat units are handling air at Pool Hall

temperatures, they must be sited in a warm

environment, i.e. pool hall, or insulated plenum. They

must not be sited in cold areas, i.e subject to

ambient air.

The quantity of air flow handled by each Variheat

unit is given on the data sheet together with

the maximum pressure available from

the fan to overcome total ducting resistance to air

flow, i.e. inlet, discharge ducting, grilles, and where

installed, air heater batteries.

It is recommended that a reputable duct work

company is associated with the duct design/

manufacture and selection of grilles for the total

system.

Note:

1. The humidity sensing tube situated by the air inlet

is to be encompassed by or extended to any inlet air

ducting. Refer to installation drawings.

2. All units have discharge ducting spigots as

standard.

3. Inlet ducting spigots are available from stockists.

4. Final connections to Variheat spigots must be

made of flexible ducting (rubber or canvas) to

eliminate transmission of vibration down the duct.

5. Before any discharge ducting is attached remove

plate (if fitted) from machine outlet or fan grille.

6. After completion of installation including all grilles,

ductwork etc., ensure that the air flow through the

machine is as specified in the data sheet ±10%. If

air flow is high, damp outlet to obtain correct airflow.

If airflow is low or high the unit will not function

correctly.

But discharge from each unit must be kept separate and

must not be incorporated into one common duct system,

unless non return dampers are used for each machine.

Minimum Free Air m²

Model Inlet

AW/AC 550/800VH 0,35

AW/AC 1200VH 0,45

AW/AC 1400/1800VH 0,56

AW/AC 4000VH 1,1

In order that moisture can be removed and

humidity control can be effected within the pool

hall, it is essential that correct air movement and

distribution is achieved.

The Variheat unit must extract the humid air

generated at pool surface and discharge the drier

air to areas which are subject tio condensation

problems (windows etc and, or comfort zones,

spectators, sitting out areas.

This can generally only be achieved by use of

ducting and correct application of grilles/ louvres

to effect air distribution and movement to these

areas.

NOTE: Variheat unit and ducting will be at pool

hall temperature and will require insulation if

exposed to lower air temperatures.

Exhaust from Pool Hall - Humid Air

Should be taken as low as practicable to inlet of

Variheat unit. In many instances siting of Variheat

unit in hall or changing rooms can eliminate use

of duct work to inlet. If duct work is to be fitted, an

inlet duct should be ordered from Calorex

distributer.

Inlet to Pool Hall- Dry Air

Generally achieved by overhead ducting with

suitable grilles to give balance and direction of air

flow. Consideration must be given to duct position

in relation to pool surface, material and finishes

so as not to promote maintenance problems.

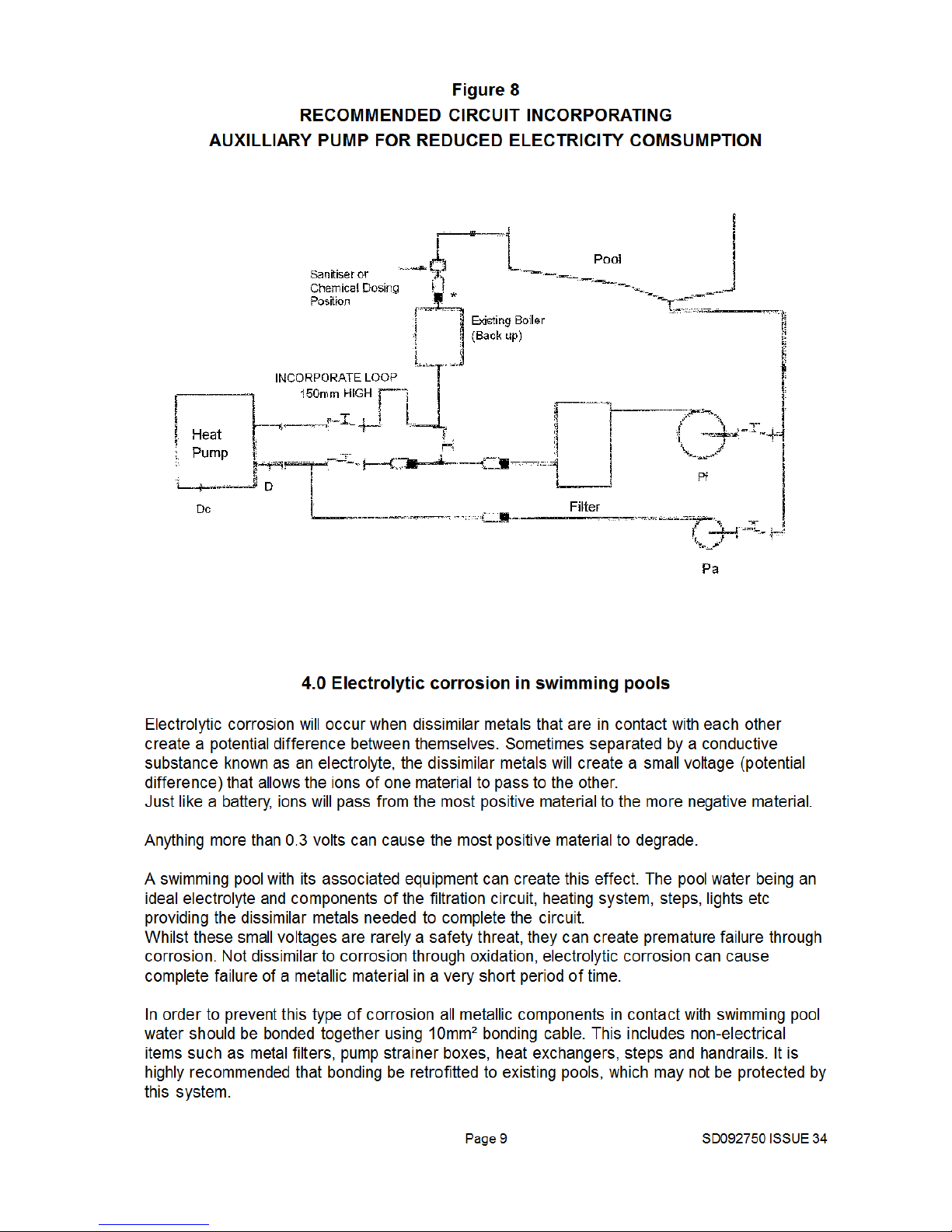

Table 1

Required free areas to provide airflow to and from

heat pumps when installed in and enclosed area or

where required to pass air through a wall etc.

Free area is the available area through which air can

pass through a grille or louvres.

Note: If multiple units are installed in an enclosed

area then the inlet free areas required for each unit

can be added together to form one inlet aperture.