4

WIRING

DIAGRAM

When there is a need for hot water while

the heating is on, it is only necessary to

turn on a hot tap. The heating will be inter-

rupted momentarily while the hot water is

being delivered. The boiler will switch

back automatically to heating when the

tap is turned off.

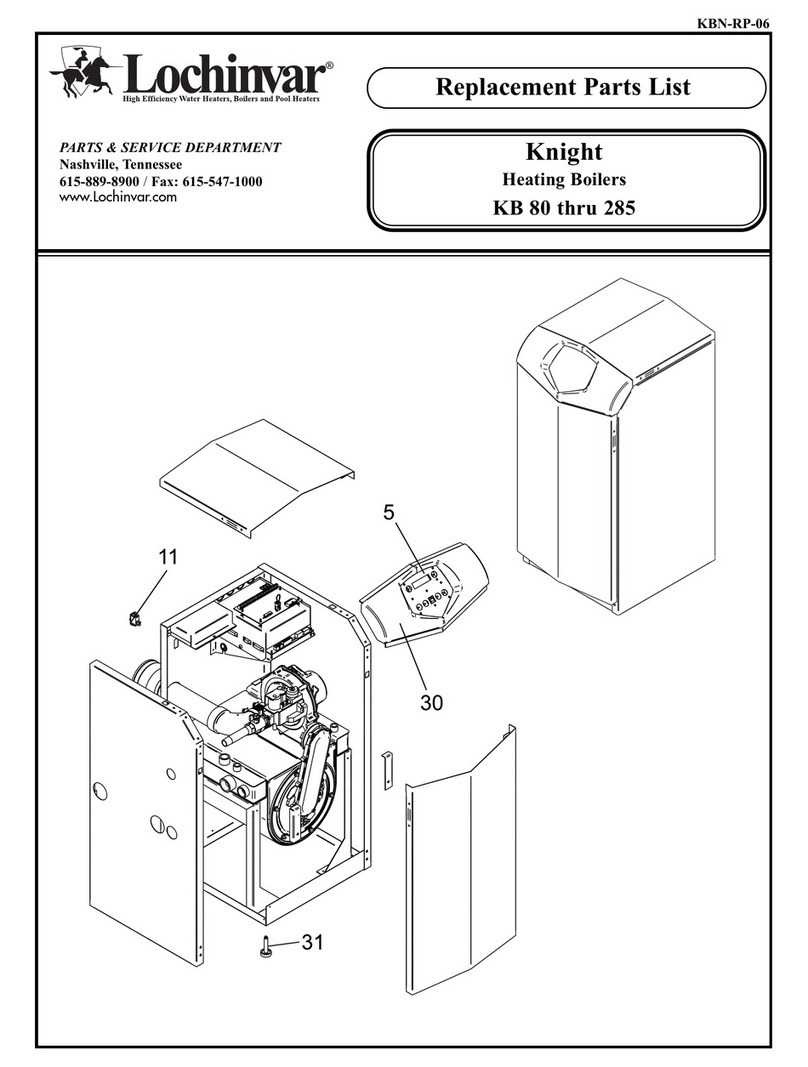

Note: If the boiler has been turned off for

some time the first attempt to light it may

result in a lockout If this happens

press the reset button 30and the boiler

will light.

To Turn Boiler Off Completely

1) Turn the main switch 23 to the off posi-

tion O.

2) Turn the gas tap 36 (fig.2) OFF.

Domestic Hot Water Mode

In order to supply hot water, the main

switch 23 (fig. 4) must be in ON position I.

This will be confirmed by the green indica-

tor light 27 (fig. 4). Turn DHW temper-

ature adjustment knob 24 clock wise to

establish the green DHW indicator 32 (fig.

4).

The hot water temperature in the mini

cylinder can be adjusted between 40 and

60°C using control knob 24 (fig 4).

When a tap or shower is turned on, the

flow of mains water, above 2 litres per

min., will activate the 3 way valve 17

(fig. 4) to move to the DHW position. The

pump will now circulate primary water

heated by the main heat exchanger

through the secondary heat exchanger.

The first stage solenoid a(fig. 6) and safe-

ty solenoid c(fig. 6) open together to allow

gas to the burner. The ignition sequence

begins and a continuous high speed spark

ignites the gas. As soon as a flame is

detected the orange indicator bulb 28

(fig.4) will light and the second stage sole-

noid b(fig. 6) opens to allow the full gas

rate. If a flame is not detected, after 8 sec-

onds, the security solenoid closes and

shuts off the gas. The red lockout indica-

tor bulb 29 (fig.4) will show. Over 2

l/min, the domestic hot water temperature

is controlled by the hot water control ther-

mistor 9(fig.6) and the heating control

thermistor 16(fig.6), but dependant upon

to the position of the DHW temperature

adjustment knob 24 (fig.4). This system

anticipates the changes of temperature in

the secondary heat exchanger and

ensures accurate temperature regulation.

When the tap is closed the burner is extin-

guished and the pump stops. (unless the

mini cylinder thermistor is calling for heat,

in which case the burner will remain on at

a low rate and the pump will continue run-

ning until the mini cylinder thermistor is

satisfied). The boiler will now stay in the

hot water mode for 30 seconds to be

ready for a subsequent draw off

Priority is given to a demand for hot water.

This will interrupt the central heating for

the duration of hot water delivery or recov-

ery of the mini cylinder.

When the boiler has been in standby in

Hot Water Mode for some time or when

drawing DHW at flow rates of less than

2 l/min the temperature in the mini cylin-

der will eventually decrease and the

TSS®control thermistor 18 (fig.6) will call

for heat. Bringing the pump and burners to

operate, until the cylinder thermistoris sat-

isfied. this is quite normal.

Central Heating Mode

To be able to supply heating, the main

switch 23 (fig.4) must be in Iposition. This

will be confirmed by the green indicator

light 27 (fig.4.) Turn the temperature

control knob 25 clock wise to establish the

green heating indicator 33(fig.4).

When there is a demand for heating

(either from the room thermostat or the

clock) and the boiler temperature control

is calling for heat. The pump starts allow-

ing the ignition sequence to begin. The

first stage solenoid a(fig.6) and safety

solenoid c(fig.6) open together to allow

gas to the burner. The ignition sequence

begins and a continuous high speed spark

ignites the gas. As soon as a flame is

detected the orange indicator bulb 28

(fig.4) will light. After 45 seconds the sec-

ond stage solenoid b(fig.6) opens to allow

the full gas rate. If a flame is not detected,

after 8 seconds, the security solenoid

closes and shuts off the gas. The red lock-

out indicator bulb 29 (fig.4) will show.

The central heating flow temperature is

controlled by the central heating control

thermistor 16 (fig.6). The boiler has been

designed to minimise cycling and will not

attempt to relight for at least 3 minutes

after the boiler thermostat has been satis-

fied (it is possible to reduce the time to 30

s if necessary). When the room thermo-

stat is satisfied the burner will switch off

and the pump will remain running for a fur-

ther 4 minutes before it to stops.

NB : It is possible to override the 3 minute

delay by pressing the RESET button 30

(fig. 4)