PhD Technology - Precision Hydronic Data

An intelligent system that delivers Precision Hydronic heating and hot water

needs while maximizing efciency by measuring and responding to the Data

parameters of your heating system.

PhD Technology is built around proven key components that when combined

make the Ultra the most advanced, reliable and efcient boiler available.

The key components

include...

A negative regulated gas valve that

Precisely delivers gas to the boiler;

A variable speed motor that matches

combustion output to your heating needs;

A venturi mixing body that Precisely mixes

air and gas providing higher efciency;

System intelligence with the Ultra Control

Module which maintains proper, efcient

and Precise Hydronic heat through inputs

of all system Data;

A cast aluminum mono block heat

exchanger designed to operate in low

temperature condensing applications;

Pre-mix stainless steel burner designed

for perfect ring rate modulation,

efciency, clean combustion and quiet

operation.

For fast and easy installation, combine an Ultra PLUS

Indirect-Fired Water Heater with your Ultra boiler installation.

Ultra PLUS water heaters come in three sizes:

PLUS 40

PLUS 60

PLUS 80

Combined with an Ultra boiler, the Ultra PLUS water heater

provides more domestic hot water when you need it, while

taking advantage of the extremely high efciency of the Ultra

boiler. A standard feature of the Ultra boiler control module

is domestic hot water priority control, providing quicker

response time for domestic hot water demands, along with

faster recovery times for the hot water tank.

The perfect match for an Ultra boiler is an Ultra PLUS Indirect-

Fired Water Heater.

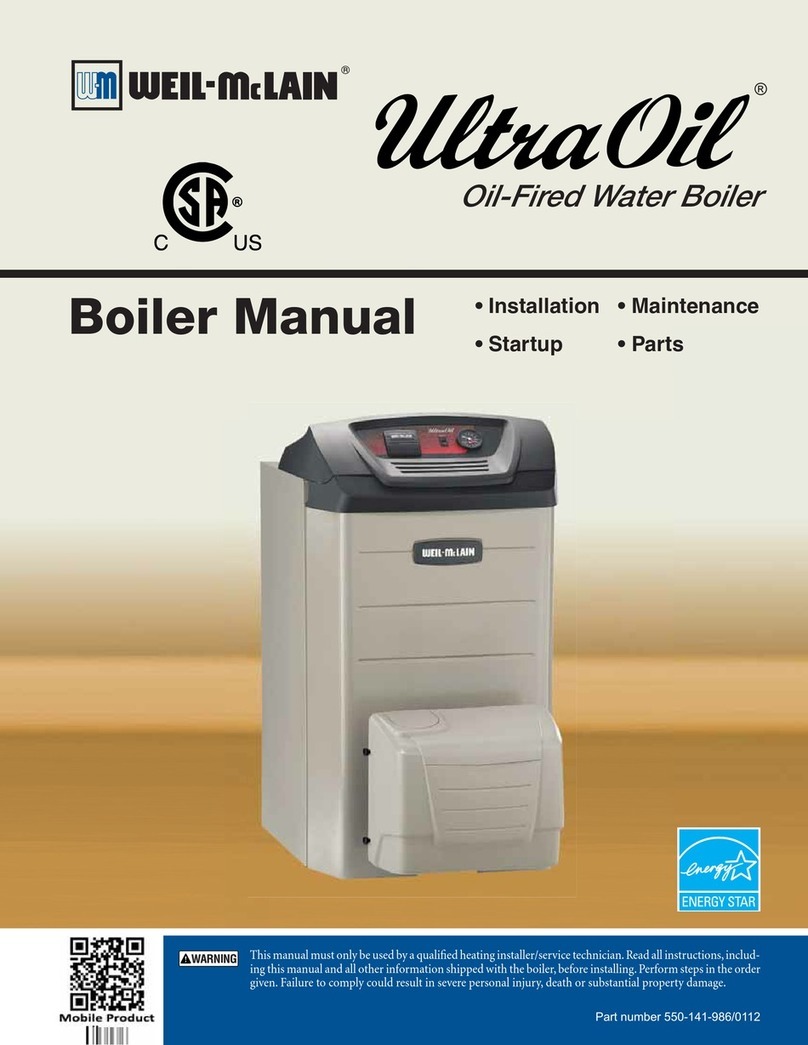

High Efciency And Environmentally Friendly

All Ultra boilers feature AFUE efciencies in the range of

92.0 - 93.0%. These are some of the highest efciencies in

the industry, however, Ultra boilers, when used in common

low temperature applications have annual efciencies of

98.0%. The Ultra boiler exceeds all of the requirements of

the Department of Energy’s ENERGY STAR program.

Besides being Ultra High Efcient, the Ultra boiler is

environmentally friendly. Through PhD Technology and the

use of our high grade burner, the Ultra boiler produces less

NOx while exceeding all current environmental codes and

is certied by South Coast Air Quality Management District

(Rule 1146.2) in California.

Weil-McLain Boiler

The Weil-McLain Ultra boiler has been designed for easy

installation. The Ultra boiler requires minimal clearance

and minimal oor space, and the same boiler can be

used in oor standing or wall hung applications.

Water and gas piping is conveniently arranged for connection

at the top or bottom of the boiler. In fact, when using the

boiler in a oor standing application, all boiler connections are

on the top of the boiler except for the condensate drain.

The electrical components have been pre-wired and labeled

on separate line voltage and low voltage terminal strips.

Terminal strips are provided for quick and easy eld wiring.

Venting has been simplied by using PVC for both exhaust

and combustion air. Slide the PVC into the top outlet ue

pipe adaptors and tighten the restraining ring. No messy

sealants required. You can even achieve vent runs up to the

equivalent of 100 feet.

The Ultra comes with a side mounted service receptacle on

a separate circuit for use with a condensate pump, service

equipment or service light.

The Ultra boiler is lightweight compared to a conventional

boiler. Side jacket handles are provided for easy handling

along with four adjustable boiler feet for easy placement and

leveling.

The 4-digit electronic display with

programming buttons and data port make

entering and receiving information very

easy. There are two levels of information:

User Level and Contractor Level. The User

Level is used to: Turn space and DHW

heating “on” or “off”; set space heating

temperature and boiler circulator operation;

display soft and hard lockout codes for easy

troubleshooting. The Contractor Level is

accessible through the use of a special

code that is entered through the front panel

or with a computer interface control kit and a

laptop computer. This access can be used

to customize the Ultra boiler to each specic

job application. Adjustments can be made

for high altitude, outdoor reset, boost timing

and much more...

The cast aluminum heat exchanger features

a mono block design. This low mass heat

exchanger heats faster, providing heat to the

system quicker. This aluminum block has

been specically designed to work in low

return temperature applications in condensing

mode.

The blower, gas valve and venturi all work

in concert to provide the proper fuel and air

mixture for precise combustion. The blower

pulls in air and gas through the venturi. The

air and gas mix inside the blower and are

pushed into the burner for combustion. The

gas valve senses suction from the blower,

allowing gas to ow only if combustion air is

owing and proper combustion is achieved.

The Ultra Control Module, a microprocessor

electronic control, responds to signals

from the room thermostat, supply water

temperature sensor, return water temperature

sensor, ue temperature sensor, domestic hot

water aquastat, summer/winter switch and

outdoor temperature sensor. The module

automatically adjusts blower speed and gas

ow rate to modulate boiler ring rate to closely

match boiler output for space heating or DHW

heating demand.

High grade stainless steel burner with woven

steel ber mesh. Burner uses pre-mixed

air and gas providing for a 20% to 100%

modulating ring rate. The Ultra burner

features long life, quiet operation, high

efciency and cleaner combustion for low

NOx applications.