Instruction manual WDU050, WDU075 & WDU100 Instruction manual WDU050, WDU075 & WDU10014 15

Please keep this instruction manual for future reference Please keep this instruction manual for future reference

6

NNOOTTEE:: Pay close attention to the order of the sink flange

parts, as they have been correctly assembled by the

factory.

A. Disassemble the sink flange assembly from the

disposer by turn ing the mount ring to the left (clockwise)

and removing it.

B. Rais e the mount ring toward the top of the sink flange.

Remove the cushion mount and the mount ring. You may

want to practice installing the cushion mount at this point

before you are under the sink.

C. Unscrew the support ring from the sink flange and

remove the fiber gasket. You are now left with the sink

flange and the rubber gasket.

DD..TThheerruubbbbeerrggaasskkeettiissuusseeddiinnsstteeaaddooffpplluummbbeerrss

ppuuttttyywwiitthhssttaaiinnlleesssssstteeeellssiinnkkss..SSoommeecceerraammiicc ssiinnkksswwiillll

rreeqquuiirreeppuuttttyy oorr ssiilliiccoonnee..

E. If no putty is used, insert the sink flange through the

rubber gasket into the sink opening. Do not turn the

flange once it is seated.

F. If you use putty instead of the gasket, form a ring

around the underside of the sink flange. Insert the flange

into the sink opening, press down hard to squeeze out

excess putty. From under the sink, trim off excess putty

flush with the bottom edge of the sink opening.

G.From underneath the sink, slip the fiber gasket onto

the exposed sink flange. With arrows pointing up, screw

the support ring onto the sink

flange and hand tighten until

the sink flange will not move.

(NNOOTTEE: If your sink is more than

15mm thick you will need to flip

the supporting ring so the arrows

are pointing down. This will provide a greater distance on

the sink flange allowing it to be used on sinks up to

approximately 22mm thick). At this point you may want to

insert the stopper into the sink and fill with water to

HH

a

n

d

-

t

i

g

h

t

e

n

s

i

n

k

f

l

a

n

g

gee

check the sink flange seal and ensure there are no leaks.

H.Place the mo unt ring over the sink flange and hold in

place while installing the cushion mount (large side

down). Make sure the groove on the inside of the cushion

mount fits over the lip on the

sink flange, similar to putting

the lid on a plastic container

Run your fingers around the entire

the mount ring can be pulled downward over the

cushion mount and will be Groove Top

free to t urn.

Components

SSiinnkkffllaannggee

aasssseemmbbllyy

Stopper

Removable

splash guard

Sink flange

Rubber sink

flangegasket

Sink

Fiber gasket

support ring

Note arrows

indicating up

(

)

Mount ring

Cushion mount

(note TOP mark))

Elbow fange

screw

Discharge

elbow

Elbow gasket

base (end bell) Rating Label in This Area

(Electrical Connections)

Hopper

Rubbergasket

Correctly Installed Sink Flange

Sink flange

Fiber gasket

Sink flange

Sink

Support ring

Mounting ring

should be free

to move up and down

Groove

Cushion mount

IInnssttaallllaattiioonnIInnssttrruuccttiioonnss

1 CCoommppoonneennttss aanndd iinnssttaallllaattiioonn

Disposer

Tightening

Ears

Dishwash discharge inlet

IInnttaallllaattiioonn ooff tthhee ssiinnkk ffllaannggee

Bottom bead of

cushion mount

Open area

No obstruction

Bottom bead

(Shown for proper orientation)

cushion mount with slight

pressure. Do not press too

hard. When the cushion

mount is properly seate d,

CCuusshhiioonnmmoouunnttddeettaaiill

Bottom bead

6

NNOOTTEE:: Pay close attention to the order of the sink flange

parts, as they have been correctly assembled by the

factory.

A. Disassemble the sink flange assembly from the

disposer by turn ing the mount ring to the left (clockwise)

and removing it.

B. Rais e the mount ring toward the top of the sink flange.

Remove the cushion mount and the mount ring. You may

want to practice installing the cushion mount at this point

before you are under the sink.

C. Unscrew the support ring from the sink flange and

remove the fiber gasket. You are now left with the sink

flange and the rubber gasket.

DD..TThheerruubbbbeerrggaasskkeettiissuusseeddiinnsstteeaaddooffpplluummbbeerrss

ppuuttttyywwiitthhssttaaiinnlleesssssstteeeellssiinnkkss..SSoommeecceerraammiicc ssiinnkksswwiillll

rreeqquuiirreeppuuttttyy oorr ssiilliiccoonnee..

E. If no putty is used, insert the sink flange through the

rubber gasket into the sink opening. Do not turn the

flange once it is seated.

F. If you use putty instead of the gasket, form a ring

around the underside of the sink flange. Insert the flange

into the sink opening, press down hard to squeeze out

excess putty. From under the sink, trim off excess putty

flush with the bottom edge of the sink opening.

G.From underneath the sink, slip the fiber gasket onto

the exposed sink flange. With arrows pointing up, screw

the support ring onto the sink

flange and hand tighten until

the sink flange will not move.

(NNOOTTEE: If your sink is more than

15mm thick you will need to flip

the supporting ring so the arrows

are pointing down. This will provide a greater distance on

the sink flange allowing it to be used on sinks up to

approximately 22mm thick). At this point you may want to

insert the stopper into the sink and fill with water to

HHaanndd

--

ttiigghhtteennssiinnkkffllaannggee

check the sink flange seal and ensure there are no leaks.

H.Place the mo unt ring over the sink flange and hold in

place while installing the cushion mount (large side

down). Make sure the groove on the inside of the cushion

mount fits over the lip on the

sink flange, similar to putting

the lid on a plastic container

Run your fingers around the entire

the mount ring can be pulled downward over the

cushion mount and will be Groove Top

free to t urn.

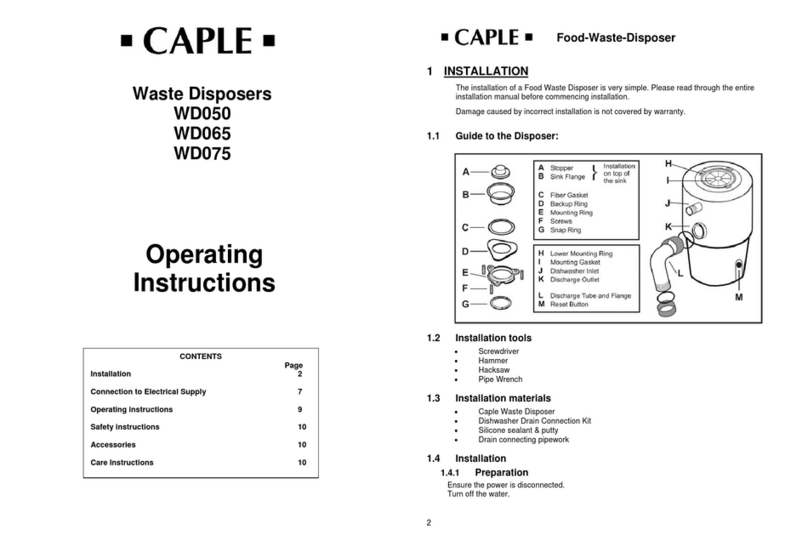

Components

SSiinnkkffllaannggee

aasssseemmbbllyy

Stopper

Removable

splash guard

Sink flange

Rubber sink

flangegasket

Sink

Fiber gasket

support ring

Note arrows

indicating up

(

)

Mount ring

Cushion mount

(note TOP mark))

Elbow fange

screw

Discharge

elbow

Elbow gasket

base (end bell) Rating Label in This Area

(Electrical Connections)

Hopper

Rubbergasket

Correctly Installed Sink Flange

Sink flange

Fiber gasket

Sink flange

Sink

Support ring

Mounting ring

should be free

to move up and down

Groove

Cushion mount

IInnssttaallllaattiioonnIInnssttrruuccttiioonnss

1 CCoommppoonneennttss aanndd iinnssttaallllaattiioonn

Disposer

Tightening

Ears

Dishwash discharge inlet

IInnttaallllaattiioonn ooff tthhee ssiinnkk ffllaannggee

Bottom bead of

cushion mount

Open area

No obstruction

Bottom bead

(Shown for proper orientation)

cushion mount with slight

pressure. Do not press too

hard. When the cushion

mount is properly seate d,

CCuusshhiioonnmmoouunnttddeettaaiill

Bottom bead

6

NNOOTTEE:: Pay close attention to the order of the sink flange

parts, as they have been correctly assembled by the

factory.

A. Disassemble the sink flange assembly from the

disposer by turn ing the mount ring to the left (clockwise)

and removing it.

B. Rais e the mount ring toward the top of the sink flange.

Remove the cushion mount and the mount ring. You may

want to practice installing the cushion mount at this point

before you are under the sink.

C. Unscrew the support ring from the sink flange and

remove the fiber gasket. You are now left with the sink

flange and the rubber gasket.

DD..TThheerruubbbbeerrggaasskkeettiissuusseeddiinnsstteeaaddooffpplluummbbeerrss

ppuuttttyywwiitthhssttaaiinnlleesssssstteeeellssiinnkkss..SSoommeecceerraammiicc ssiinnkksswwiillll

rreeqquuiirreeppuuttttyy oorr ssiilliiccoonnee..

E. If no putty is used, insert the sink flange through the

rubber gasket into the sink opening. Do not turn the

flange once it is seated.

F. If you use putty instead of the gasket, form a ring

around the underside of the sink flange. Insert the flange

into the sink opening, press down hard to squeeze out

excess putty. From under the sink, trim off excess putty

flush with the bottom edge of the sink opening.

G.From underneath the sink, slip the fiber gasket onto

the exposed sink flange. With arrows pointing up, screw

the support ring onto the sink

flange and hand tighten until

the sink flange will not move.

(NNOOTTEE: If your sink is more than

15mm thick you will need to flip

the supporting ring so the arrows

are pointing down. This will provide a greater distance on

the sink flange allowing it to be used on sinks up to

approximately 22mm thick). At this point you may want to

insert the stopper into the sink and fill with water to

HHaanndd

--

ttiigghhtteennssiinnkkffllaannggee

check the sink flange seal and ensure there are no leaks.

H.Place the mo unt ring over the sink flange and hold in

place while installing the cushion mount (large side

down). Make sure the groove on the inside of the cushion

mount fits over the lip on the

sink flange, similar to putting

the lid on a plastic container

Run your fingers around the entire

the mount ring can be pulled downward over the

cushion mount and will be Groove Top

free to t urn.

Components

SSiinnkkffllaannggee

aasssseemmbbllyy

Stopper

Removable

splash guard

Sink flange

Rubber sink

flangegasket

Sink

Fiber gasket

support ring

Note arrows

indicating up

(

)

Mount ring

Cushion mount

(note TOP mark))

Elbow fange

screw

Discharge

elbow

Elbow gasket

base (end bell) Rating Label in This Area

(Electrical Connections)

Hopper

Rubbergasket

Correctly Installed Sink Flange

Sink flange

Fiber gasket

Sink flange

Sink

Support ring

Mounting ring

should be free

to move up and down

Groove

Cushion mount

IInnssttaallllaattiioonnIInnssttrruuccttiioonnss

1 CCoommppoonneennttss aanndd iinnssttaallllaattiioonn

Disposer

Tightening

Ears

Dishwash discharge inlet

IInnttaallllaattiioonn ooff tthhee ssiinnkk ffllaannggee

Bottom bead of

cushion mount

Open area

No obstruction

Bottom bead

(Shown for proper orientation)

cushion mount with slight

pressure. Do not press too

hard. When the cushion

mount is properly seate d,

CCuusshhiioonnmmoouunnttddeettaaiill

Bottom bead

G. From underneath the sink, slip the fiber gasket onto the

exposed sink flange. With arrows pointing up, screw the

support ring onto the sink flange and hand tighten until the

sink flange will not move. (NOTE: If your sink is more than

15mm thick you will need to flip the supporting ring so the

arrows are pointing down. This will provide a greater distance

on the sink flange allowing it to be used on sinks up to

approximately 22mm thick). At this point you may want to

insert the stopper into the sink and fill with water to check

the sink flange seal and ensure there are no leaks.

H. Place the mount ring over the sink flange and hold in place

while installing the cushion mount (large side down). Make

sure the groove on the inside of the cushion mount f its

over the lip on the sink flange, similar to putting the lid on a

plastic container. Run your fingers around the entire cushion

mount with slight pressure. Do not press too hard. When

the cushion mount is properly seated, the mount ring can be

pulled downward over the cushion mount and will be

free to turn.

DISHWASHER CONNECTION (IF REQUIRED)

If you are connecting a dishwasher to you waste disposal unit, please complete the following steps.

If you are not connecting a dishwasher proceed to step 3 attaching the discharge elbow.

1. Knock out the plug:

Using a blunt instrument (for example a steel punch or

wooden dowel) knock out the entire plug. Do not use a

screwdriver or sharp tool. When the knocked out plug falls

into the disposer, you may remove it or simply grind it up

when you first use the appliance. This will not damage the

disposal unit in any way, but may take some time to grind

over several uses.

2. Connect the hose:

Connect the dishwasher hose using a hose clamp. If the hose size is different you will need a

stepped rubber adapter.

CONNECTING THE DISCHARGE ELBOW

Discharge elbow must be installed by a professional. Some installations (see page 9 for examples)

may require the use of a flexible drain pipe.

NOTE

If the dishwasher connection is made without removing the plug, the dishwasher may overflow.

1. Connect the discharge elbow to the disposer.

2. Make sure all plumbing connections are tight.

7

IInnssttaallllaattiioonnIInnssttrruuccttiioonnss

2 DDiisshhwwaasshheerr ccoonnnneeccttiioonn ((iiff rreeqquuiirreedd))

If you are connecting a dishwasher to you waste disposal unit, please complete the following steps. If you are

not connecting a dishwasher proceed to step 3 Attaching the discharge elbow.

Knock out plug

2 CCoonnnneecctt tthhee hhoossee

Hose Clamp Stepped Rubber Adapter

3 CCoonnnneeccttiinngg tthhee ddiisscchhaarrggee eellbbooww

CCoonnnneecctt tthhee ddiisscchhaarrggee eellbbooww*

.**

.

Connec t the discharge elbow to the disposer

Make sure all pl umbing connections are tight

Discharge

elbow

Rubber

gasket

*Discharge elbow must be installed byaprofessional.

** Some installations (see page 9 for examples) may

require the use of a flexible drain pipe.

NNOOTTEE:: If the dishwasher connection is

made without

removing the plug, the dishwasher may overflow.

1KKnnoocckk oouutt tthhee pplluugg

Using a blunt instrument (for example a steel punch or

wooden dowel) knock out the entire plug. Do not use a

screwdriver or shart tool. When the knocked out plug

falls into the disposer, you may remove it or simply grind

it up when you first use the applaince. This will not

damage the disposal unit in any way, but may take some

time to grind over several uses.

Connect the dishwasher hose using a hose clamp. If the

hose size is different you will need a stepped rubber

adapter.

Rubber Gasket

Metal Plate

Discharge

Elbow

7

IInnssttaallllaattiioonnIInnssttrruuccttiioonnss

2 DDiisshhwwaasshheerr ccoonnnneeccttiioonn ((iiff rreeqquuiirreedd))

If you are connecting a dishwasher to you waste disposal unit, please complete the following steps. If you are

not connecting a dishwasher proceed to step 3 Attaching the discharge elbow.

Knock out plug

2 CCoonnnneecctt tthhee hhoossee

Hose Clamp Stepped Rubber Adapter

3 CCoonnnneeccttiinngg tthhee ddiisscchhaarrggee eellbbooww

CCoonnnneecctt tthhee ddiisscchhaarrggee eellbbooww*

.**

.

Connect the discharge elbow to the disposer

Make sure all plumbing connections are tight

Discharge

elbow

Rubber

gasket

*Discharge elbow must be installed byaprofessional.

** Some installations (see page 9 for examples) may

require the use of a flexible drain pipe.

NNOOTTEE:: If the dishwasher connection is

made without

removing the plug, the dishwasher may overflow.

1KKnnoocckk oouutt tthhee pplluugg

Using a blunt instrument (for example a steel punch or

wooden dowel) knock out the entire plug. Do not use a

screwdriver or shart tool. When the knocked out plug

falls into the disposer, you may remove it or simply grind

it up when you first use the applaince. This will not

damage the disposal unit in any way, but may take some

time to grind over several uses.

Connect the dishwasher hose using a hose clamp. If the

hose size is different you will need a stepped rubber

adapter.