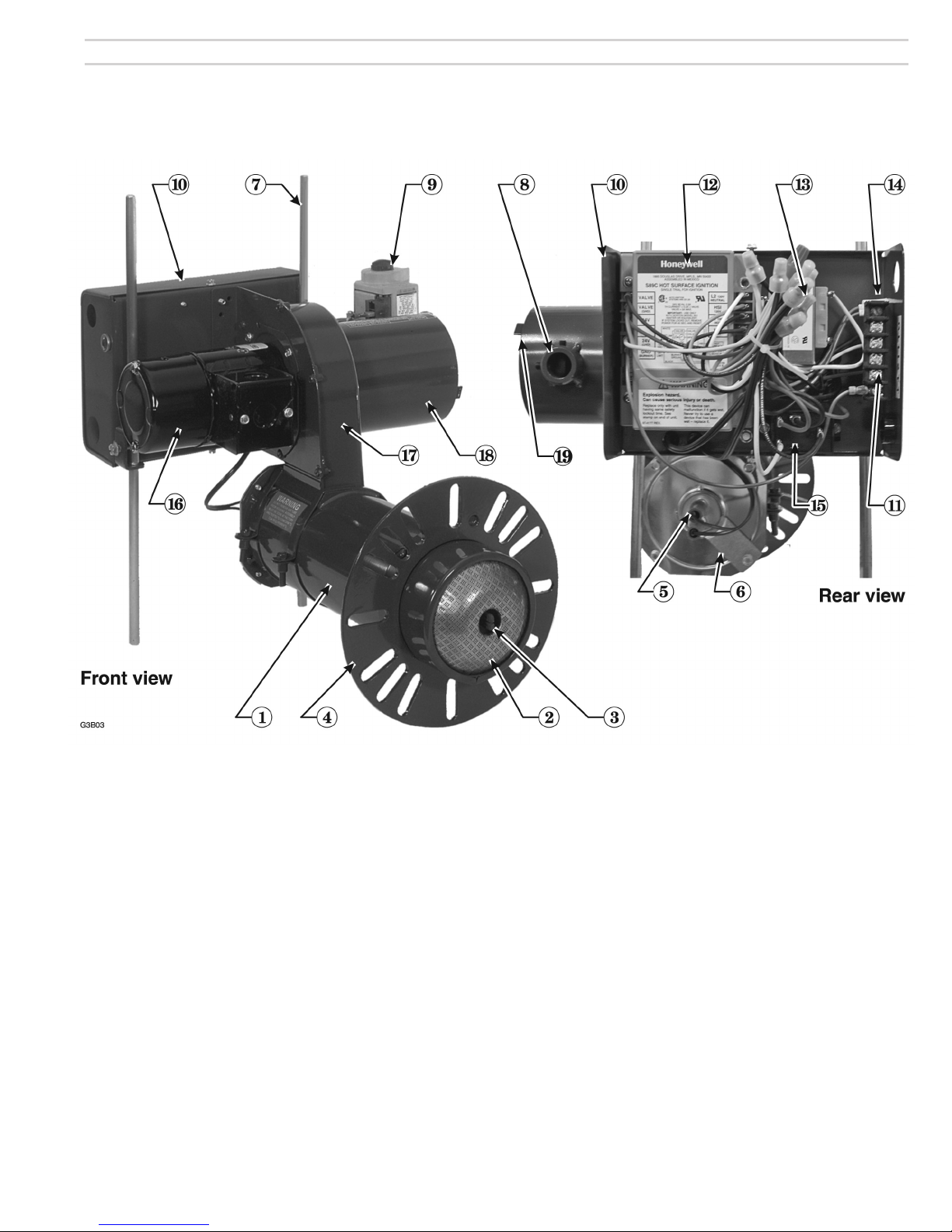

Model G3B Gas burner — Instruction manual

MNG3B Gas 041015

8

1. Prepare Site • Prepare Burner • Mount Burner (continued)

Mount burner in appliance

• Verifyapplianceburnerfrontplatedimensionsperpage21.

• Slidegasketsuppliedwithburneroverendofairtube.

• Insertburnerintoapplianceopeningandboltinplace.

Inspect burner and components

Drill or ream gas orifice to size (initial installation)

You must disconnect power to burner and close main manual

gas valve before proceeding. Failure to do so could result

in severe personal injury, death or substantial property

damage.

You must drill or ream the burner orifice to the size given in

Figure 4.The orifice is shipped with a pilot hole only. Firing the

burner with the orifice as shipped can result in damage to the

burner.NeverretheG3Bburnerbelow60,000Btuhinput.

The flameholder can overheat, resulting in potential severe

personal injury, death or substantial property damage.

1. After drilling or reaming orifice to correct size, thread orifice fitting into

orifice nipple as shown in Figure 4.

Install gas valve on burner

1. Read WARNING’s on page 9 before installing gas valve.

2. Applyasmallamountofpipedope(suitableforpropanegas)togas

valve outlet connection, gas line elbow and orifice nipple. Assemble

elbow and orifice nipple to gas valve.

To avoid damage to gas valve, do not hold valve with a pipe

wrench or over-tighten. Use only a crescent wrench or other

means. Failure to comply could result in severe personal

injury, death or substantial property damage.

3. Insert orifice nipple into burner gas connection and secure in place

using the two Allen screws.

4. Connect gas valve wires to gas valve.

Inspect/redrill gas orifice when required

1. Turnoffpowertotheburner/appliancebeforeproceeding.

2. Closemainmanualgasvalveingaslinetoburner.Thendisconnectthe

ground joint union to allow rotating burner combination gas valve.

You must disconnect power to burner and close main manual

gas valve before proceeding. Failure to do so could result

in severe personal injury, death or substantial property

damage.

3. LoosenAllenscrewssecuringgaslinetoburnergasconnection.

4. Remove combination gas valve (item 9, page 3) and gas piping to burner

gasconnection(item8,page3)onburnerairtube.

5. ReadcorrectoricedrillsizefromFigure4.Thencheckactualorice

size using that size twist drill bit.

• If gas orifice is smaller than required, redrill orifice to correct size,

ifnecessary.Replacegasvalveandpiping,usingonlypipedopelisted

forusewithliqueedpetroleumgases.

• If gas orifice is larger than required, obtain a replacement gas orifice

fitting. Drill orifice hole in replacement orifice fitting.

Hot surface ignitor

• Inspecttheburnerfromairtubeend.Thehotsurfaceignitormustextend

slightlypasttheendoftheburner.

• Carefullyinspecttheignitor,ensuringitisintact,withnocracksorvisual

signsofdegradation.

• Donottouchtheignitorwithbarehands.Bodyoilscancausedeterioration

ofthesiliconcarbide.

• Replaceignitorifthereareanysignsofdamage.

You must allow ignitor to cool before attempting to handle.

Failure to do so could result in severe personal injury or

damage to the ignitor.

Inspect components and wiring

• Visuallyinspectallburnercomponentsandwiring.

• Verifythatwiringisintactandleadsaresecurelyconnected.

• Verifythatallburnercomponentsareingoodcondition.

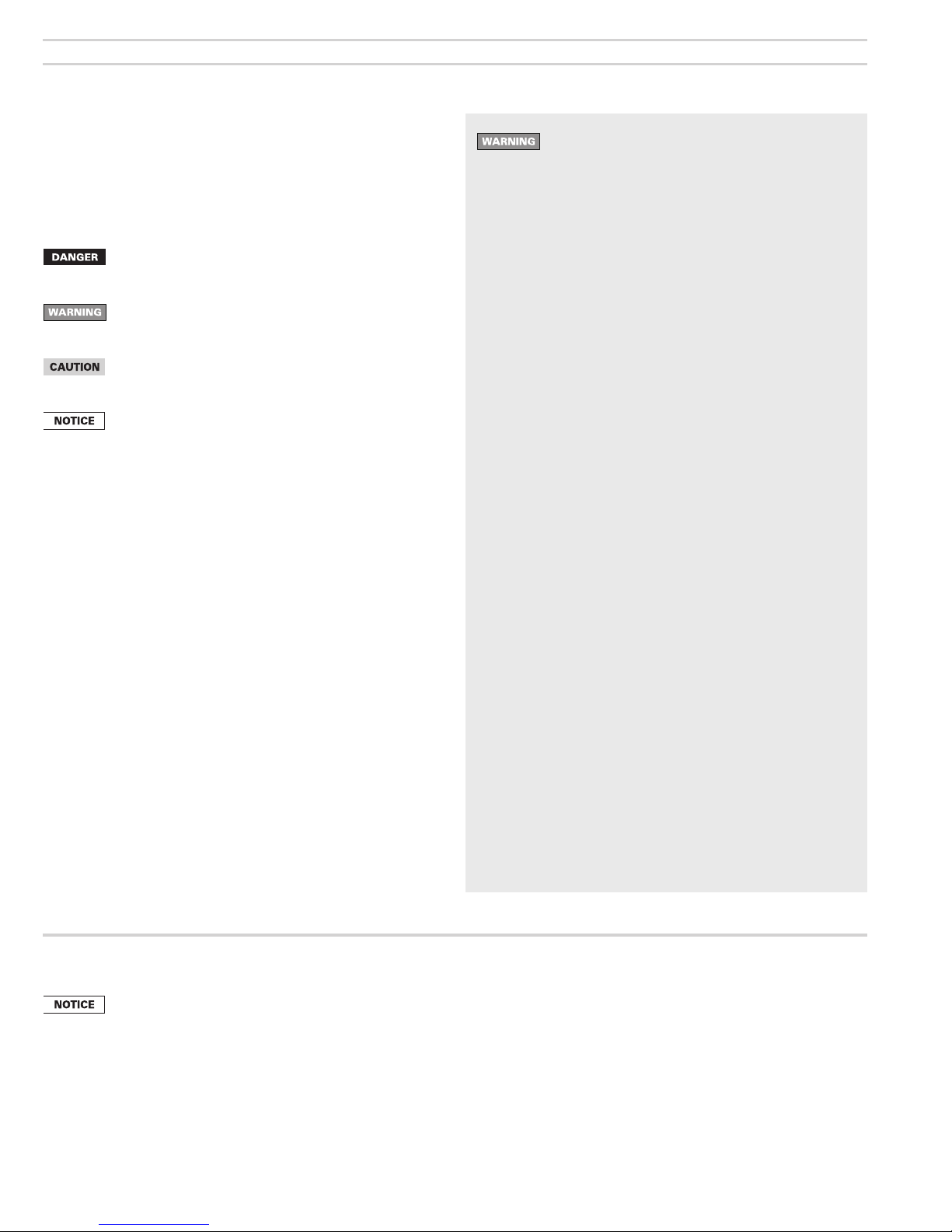

Figure 4 Orifice and gas valve installation

Input

Btuh

Burner orifice drill size

Diameter, inches

Air throttle

turns (appr.)

Notes 1 & 2

Note 1 Natural Gas Propane Gas

60,000 #28 (0.141) #33 (0.113) 0

70,000 #24 (0.152) Z\, (0.125) ½

80,000 #20 (0.161) #30 (0.129) ¾

90,000 #17 (0.173) #28 (0.141) 1

100,000 #14 (0.182) #25 (0.150) 1½

110,000 #11 (0.191) #22 (0.157) 1¾

120,000 #7 (0.201) #20 (0.161) 2¼

140,000 #3 (0.213) #16 (0.177) 3

160,000 A (0.234) #12 (0.189) 4¼

180,000 D (0.246) #7 (0.201) 9

Note 1: High altitude applications: The maximum burner input at sea level is 180,000 Btuh.

Reduce this capacity by 4% per 1,000 feet above sea level. Example — max.

capacity at 5,000 feet is 144,000 Btuh (20% reduction).

Note2: Usethisasthestartingsettingonly.Adjustairthrottle,ifnecessary,afterperforming

combustion testing (see page 14).