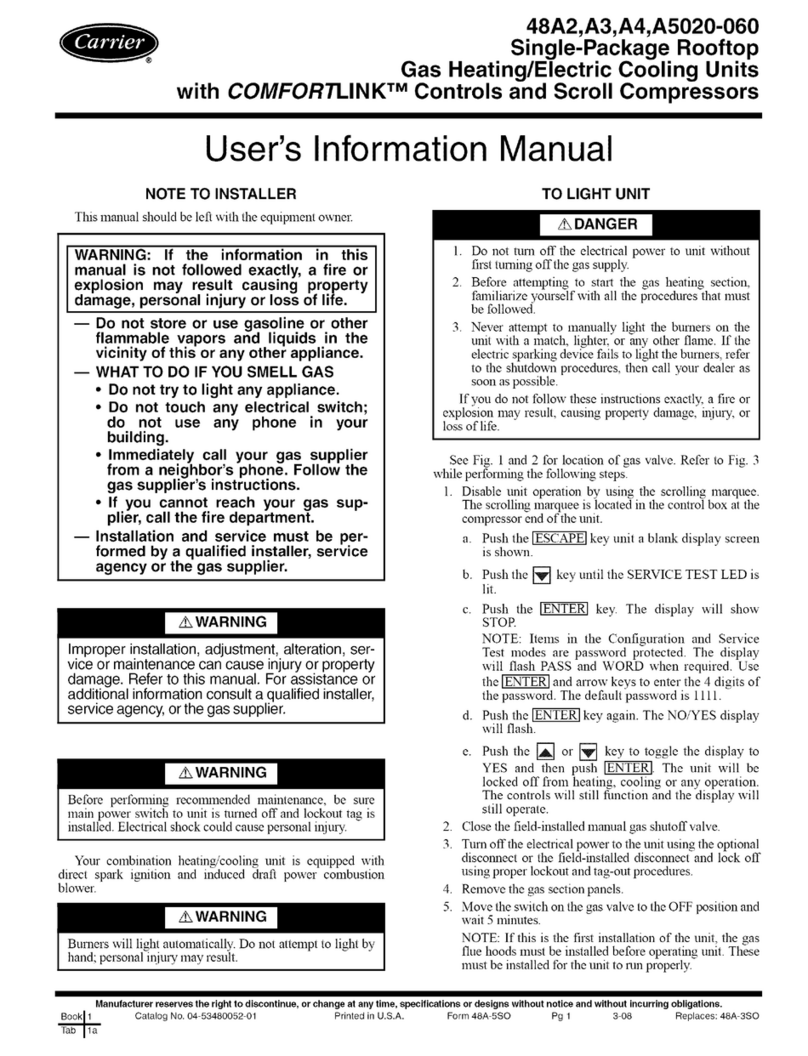

NOTE:Beforeproceedingwiththenextcheck,turnOFF

theelectricalpowersupplyto theunit. Removethe

controlaccessdoor.

() Duringtheheatingseason,checkthecontrolswitchon

thegasvalve.Isit intheONposition?If it isnot,besure

it hasnotbeenturnedoffforthepurposeofsafety.If no

safetyhazardsarepresent,followthestart-upprocedures

inthismanual.

( ) If yourunitstill failstooperate,callyourservicing

dealerfortroubleshootingandrepairs.Specifythemodel

andserialnumbersof yourunit.(Recordthemin this

manualinthespaceprovided.)If thedealerkalowsexactly

whichunityouhave,hemaybeabletooffersuggestions

over the phone,or save valuabletime through

kalowledgeablepreparationfortheservicecall.

IN CASE OF TROUBLE

If, after performing the above checks, unit performance is

unsatisfactory, shut off the unit and call your dealer.

Dealer's Name

Telephone No.

Unit Model

[_it Serial Number

REGULARDEALER

MAINTENANCE

Heat Exchanger

NOTE: To ensure dependable and efficient heating

operation, the heat exchanger should be checked by a

qualified maintenance person before each heating season,

and cleaned when necessary.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to

equipment.

This checkout should not be attempted by anyone not

having the required expertise and equipment to do the

job properly.

Checking and/or cleaning the heat exchanger involves

removing the gas controls assembly and the flue collector

box cover. When finished, the gas controls must be

reinstalled for proper operation. Also, the flue collector

box cover must be replaced correctly so that a proper seal

is maintained. Contact your dealer for the required

periodic maintenance. At the beginning of each

cooling/heating season and as conditions require.

Fans and Belts, and Fan Motor

Periodically check the condition of fan wheels and

housings, belt tension and fan motor shaft bearings. No

lubrication of condenser or evaporator fan bearings or

motors is required or recommended.

Evaporator and Condenser Coils

Cleaning of the coils should be done by qualified service

personnel. Contact you dealer for the required annual

maintenance.

Condensate Drain

The drain pan and condensate drain line should be

checked and cleaned at the same time the cooling coils are

checked by your dealer.

In addition to the type of routine maintenance you might

be willing to perform, your unit should be inspected

regularly by a properly trained and qualified service

technician. An inspection (preferably each heating/cooling

season, but at least every year) should include the

following:

• Inspection of all flue product passages, including the

burners, heat exchanger, and flue collector box.

• Inspection of all combustion- and ventilation-air

passages and openings.

• Close inspection of all gas pipes leading to and inside

your unit.

• Inspection and if required, cleaning of the condenser and

evaporator coils.

• Inspection, and if required, cleaning of the condensate

drain pan.

• Inspection and cleaning of blower wheel housing and

motor.

• Inspection of all supply- and return-air ducts for leaks,

obstructions, and insulation integrity. Any problems

found should be resolved at the time of inspection.

• Inspection of the unit base for cracks, gaps, etc., which

may cause a hazardous condition.

• Inspection of the unit casing for signs of deterioration.

• Inspection of all electrical wiring and components to

ensure proper connection.

• Inspection for leaks in the refrigerant circuit. Pressure

check to determine appropriate refrigerant charge.

• Inspection of fan wheels and housings, belt tension, and

fan motor shaft bearings.

• Operational check of the unit to determine working

conditions. Repair or adjustment should be made at the

time of inspection.

Your servicing dealer may offer an economical service

contract that covers seasonal inspections. Ask for further

details.

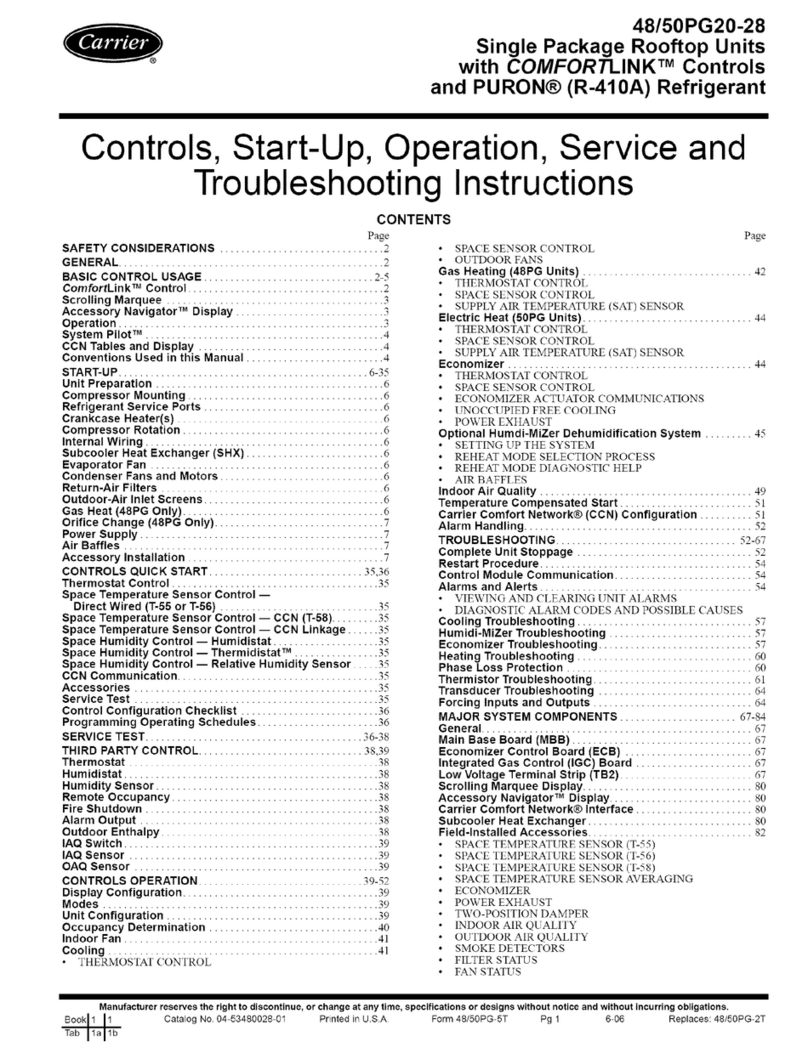

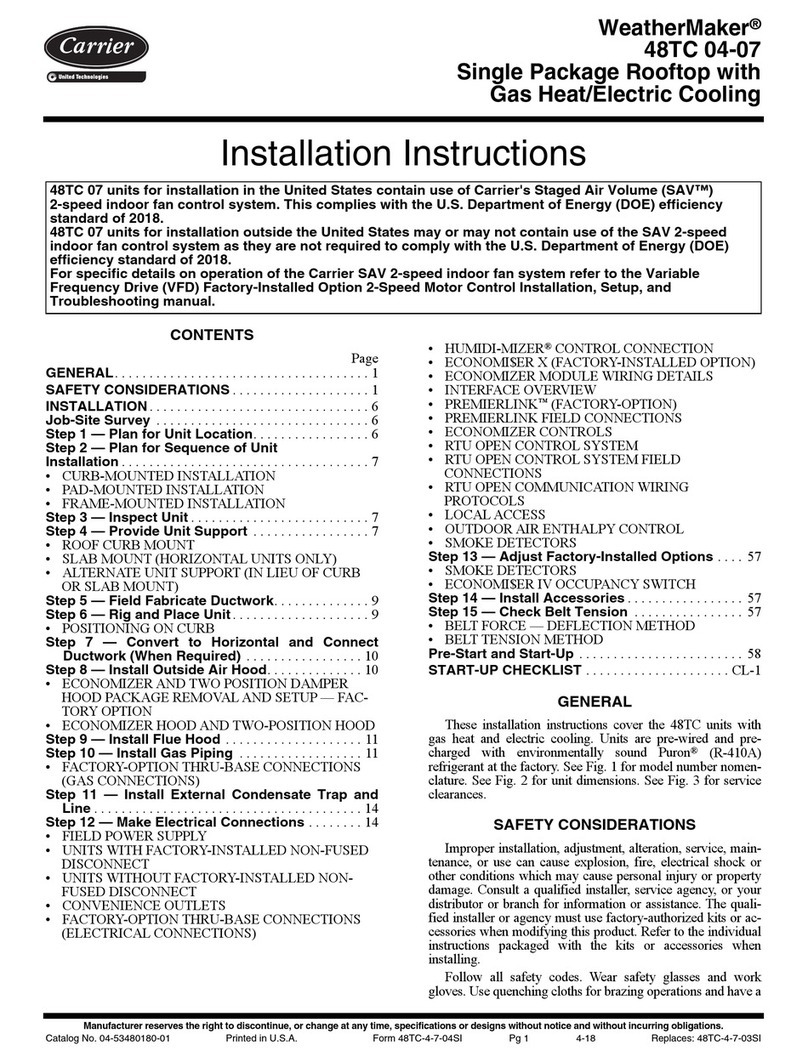

Complete service instructions can be found in the unit

Installation, Start-Up and Service Instructions.