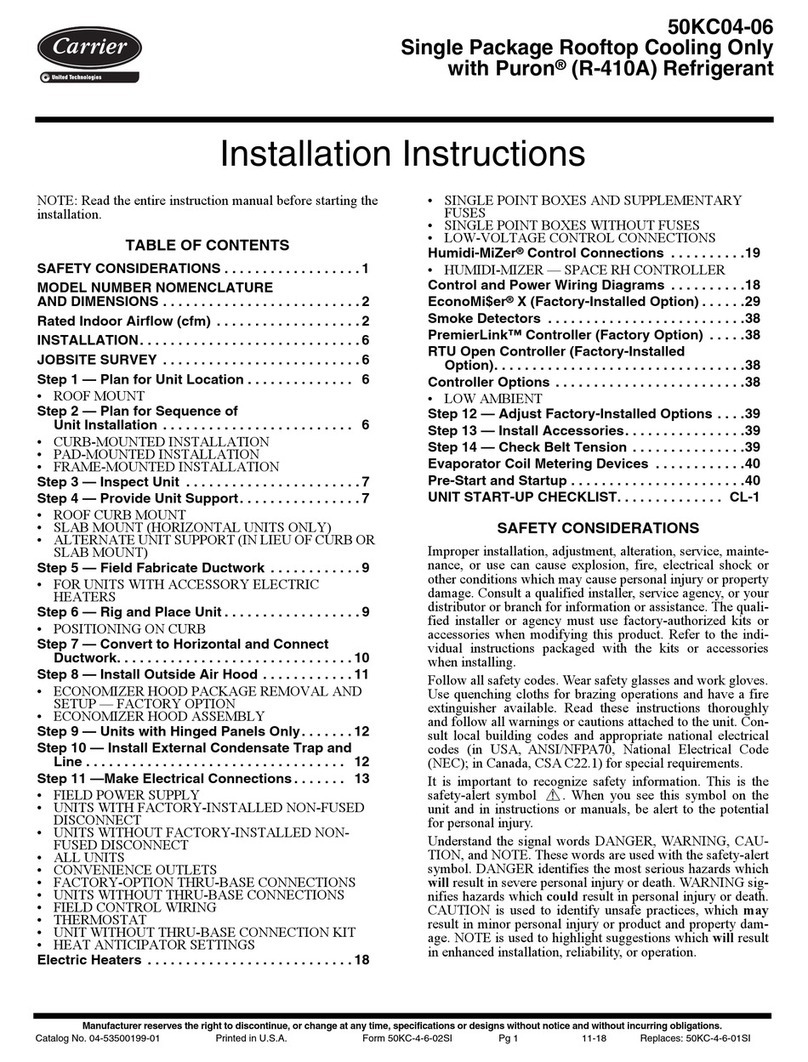

Belk_re pel'fl_rming service or maintenance operations on

system, turn o1"1power to unit. Turn off accessory heater

power switch, if applicable. Electrical shock can cause

personal injury.

Recognize salety in%rmation. This is the sali:ty-alert symbol/_ .

When you see this symbol in instructions or manuals, be alert to

the potential lk_rpersonal injury.

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the sali:ty-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identily unsali: practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

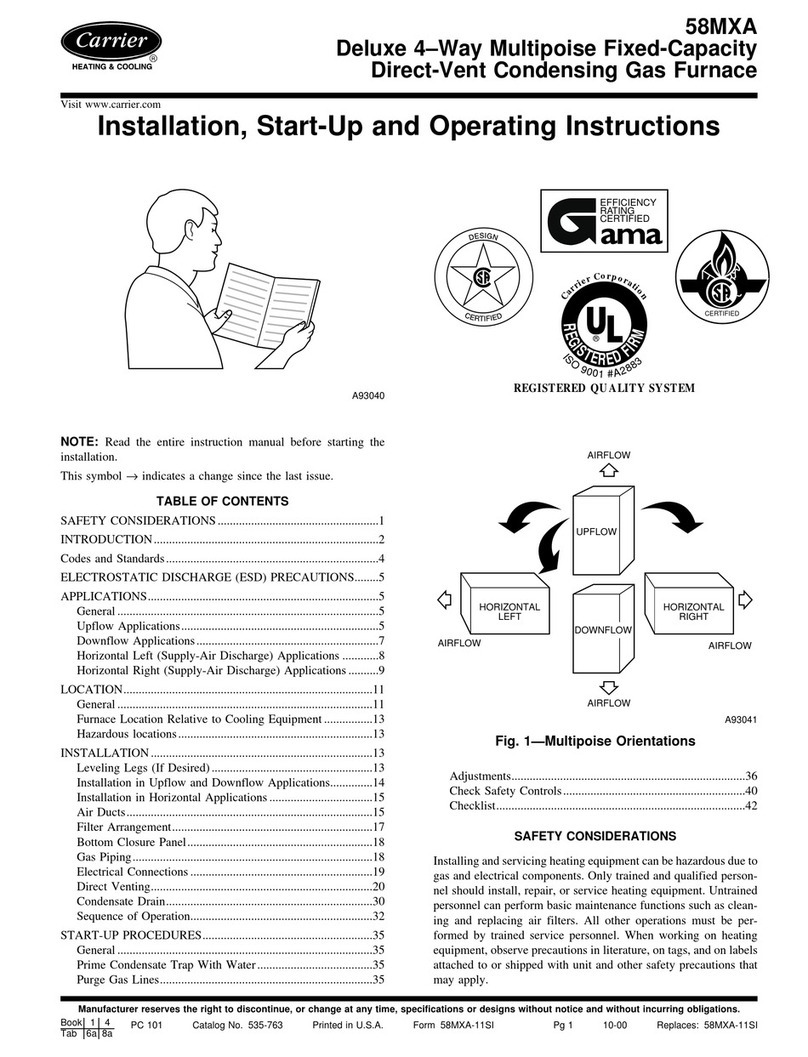

These instructions cover mininmm requirements and conli_rm to

existing national standards and salety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept tapwith changing residen-

tial construction practices. We require these instructions as a

mininmm lk_ra salt: installation.

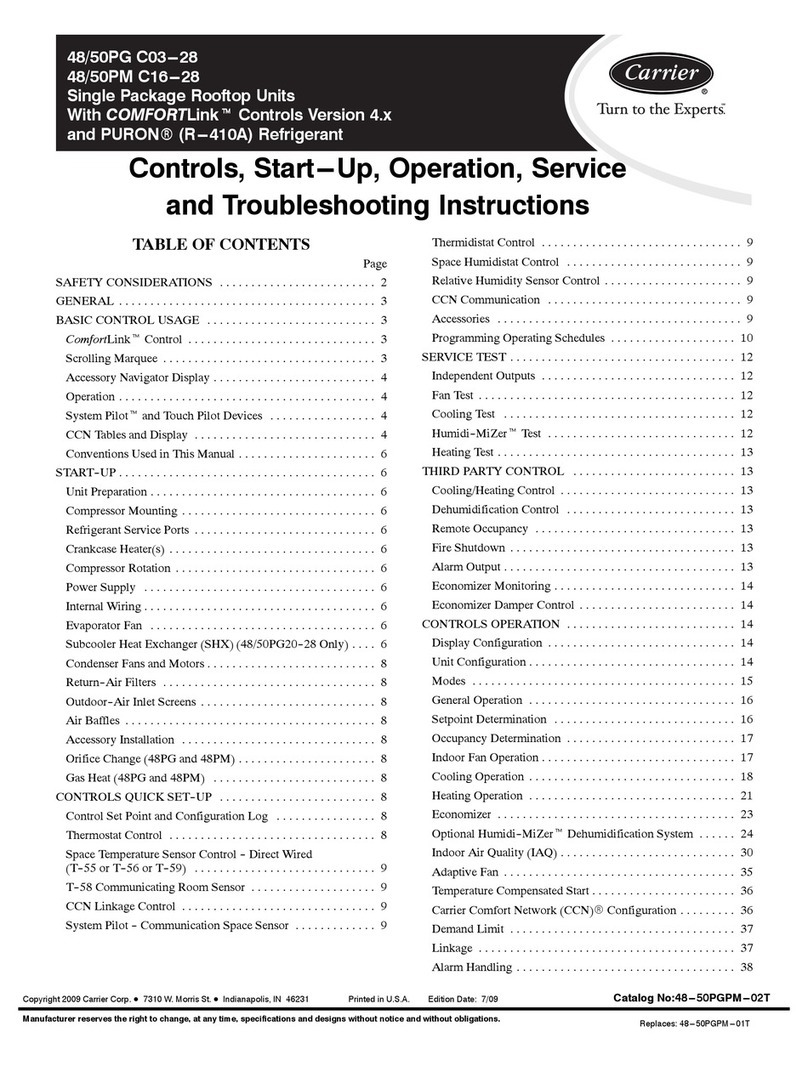

iNTRODUCTiON

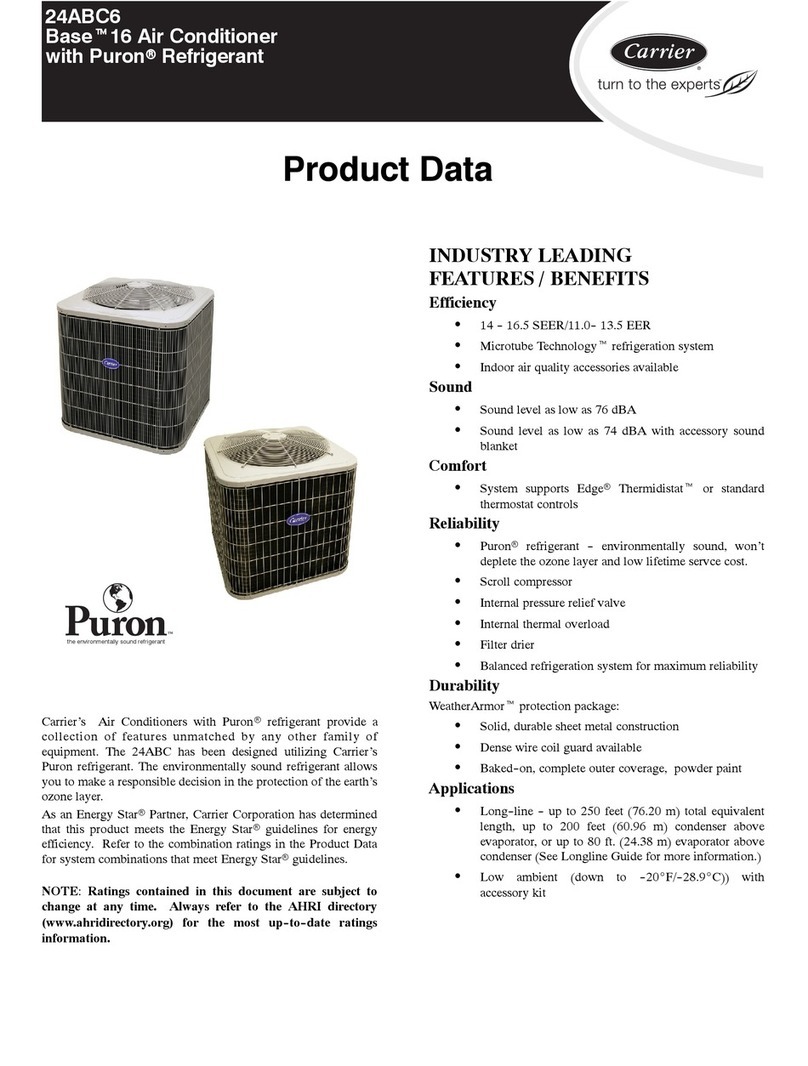

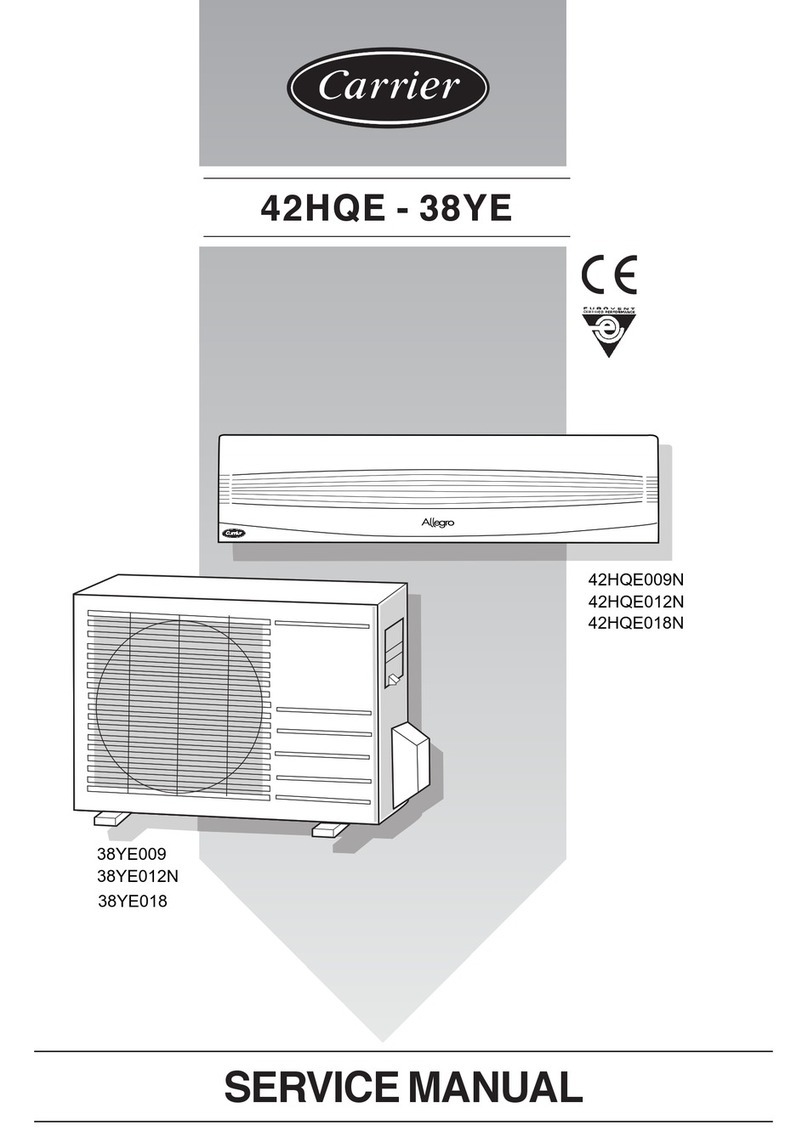

The 50GS and 50GX units (see Fig. 1)are fully sellCcontained, and

designed Ik_r outdoor installation. See Figs. 2 and 3 Ik_r unit

dimensions. All unit sizes have discharge openings liar both

horizontal and downflow conl'igurations, and are factory shipped

with all downflow duct openings covered . Units may be installed

either on a rooftop, ground-level cement slab, or directly on the

ground if local codes permit. (See Fig. 4A Ii}l"roof curb dimen-

sions.)

RECEIVING AND INSTALLATION

Step liCheck Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on the unit

identification plate. Check this inli_rmation against shipping pa-

pers.

INSPECT SHIPMENT

Inspect liar shipping damage while unit is still on shipping pallet.

11'unit appears to be damaged or is torn loose fi'ona its anchorage,

have it examined by transportation inspectors belk)re removah

Forward claim papers directly to transportation company. Manu-

facturer is not responsible lk)r any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest Carrier Air Conditioning olTice if' any item is missing. To

prevent loss or damage, leave all parts in original packages until

installation.

Step 2iprovide Unit Support

ROOF CURB

Install accessory roof curb in accordance with instructions shipped

with curb (See Fig. 4A). Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is critical

liar a watertight seal. Install gasketing material supplied with the

roof curb. hnproperly applied gasketing also can result in air leaks

and poor unit perlormance.

Curb should be level to within 1/4 in. (See Fig. 5A). This is

necessary liar unit drain to function properly. Relier to accessory

roof curb installation instructions lk_r additional inlk_rmation as

required.

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a nfininmm of

4 in. thick with 2in. above grade (See Fig. 5B). The slab should

extend approximately 2 in. beyond the casing on all 4 sides of the

unit. Do not secure the unit to the slab e.rcvpt when required by

local codes.

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground if' local codes permit. Place the unit on level ground

prepared with gravel liar condensate discharge.

Step a--Provide Clearances

The required minimum service clearances are shown in Fig. 2 & 3.

Adequate ventilation and outdoor air lnust be provided. The

outdoor fan draws air through the outdoor coil and discharges it

through the top fan grille. Be stare that the fan discharge does not

recirculate to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is 36

in. above the unit top. The maximum horizontal extension of a

partial overhang lnust not exceed 48 in. For extended overhangs,

provide a nfininmm clearance of 48 in.

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor-air inlet or the fan discharge may be

detrimental to compressor liti_.

Do not place the unit where water, ice, or snow I]'om an overhang

or roof' will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. Slab-mounted units

should be at least 4 in. above the highest expected water and runolT

levels. Do not use unit if' it has been under water.

Step 4--Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not cozmect dtlcmork to unit. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All ductwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof' openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space nmst be insulated

and covered with a vapor barrier. If' a plenum return is used on a

vertical unit, the return should be ducted through the roof deck to

comply with applicable fire codes. A minimum clearance is not

required around ductwork. Cabinet return-air static shall not

exceed -.25 in. wg.

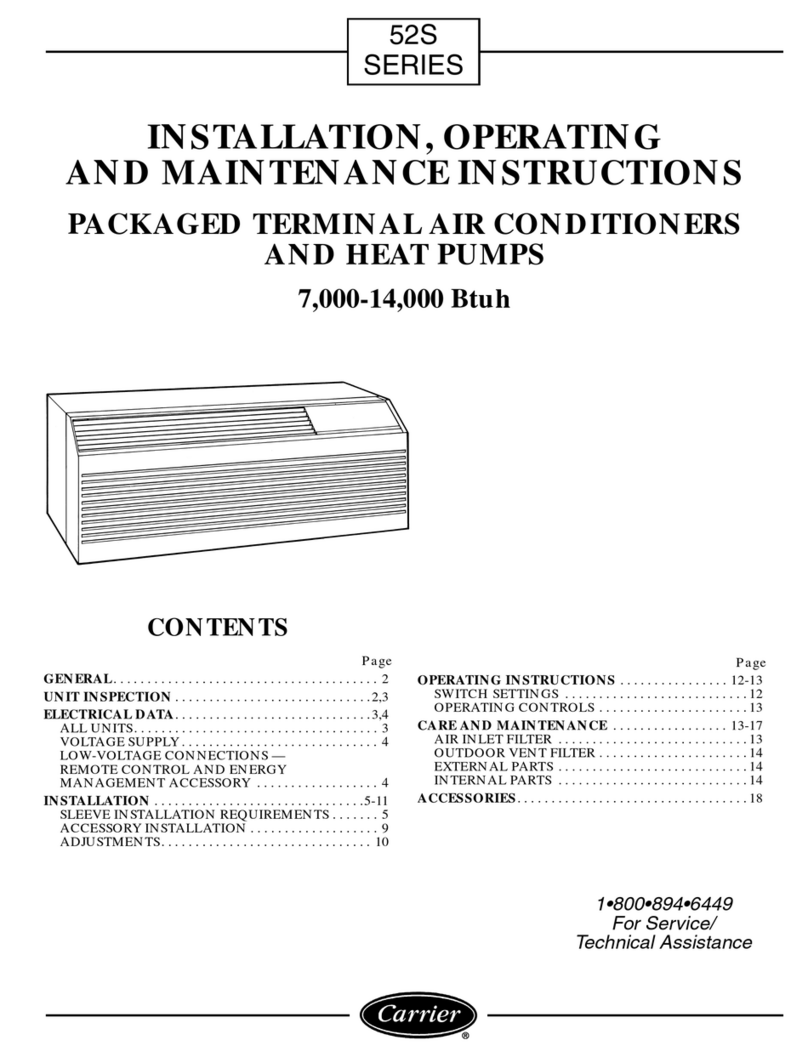

Step 5iRig and Place Unit

Rigging and handling of this equipment can be hazardous Ii_r many

reasons due to the installation location (rool&, elevated structures,

etc.)

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other salk_ty precautions that might apply.

Follow all applicable saMy codes. Wear safi_ty shoes and work

gloves.

Never stand benealh rigged nni/s or lili over people. ]

Never exceed 200 lbs. per brackel liliing {brce. [

J