40KMC 310/40KMQ

General information 310

Unit operation and maintenance

Read this instruction manual thoroughly before using the unit.

• This unit complies with UL 1995 directive (Usa and Canada).

• Check that the main power supply voltage and frequency are as

required for the unit; the power source must be sufficient to

operate all other appliances connected to the same line.

Also ensure that local building codes and NEC (National electrical

code) requirements have been followed for the main supply circuit.

• To avoid personal injury or damage to unit,do not service until all

power sources are shut down, locked out, and tagged out.

Failure to do so could result in personal injury or unit damage.

WARNING:

To prevent fire, explosion or injury, do not operate the unit near

dangerous substances or esposed to lighting equipment.

• All operation and maintenance manuals must be carefully looked

after and kept with the equipment, should the unit change owners.

• Check that local building codes and NEC (National electrical code)

requirements for the installation have been followed. In particular,

ensure that a properly sized and connected ground wire is in place.

• Only use the unit for factory approved applications: the unit

cannot be used in laundry premises.

• Do not use damaged equipment. In case of malfunction, turn the

unit OFF and disconnect the main supply.

• Disconnect the main power supply prior to any maintenance

operations or prior to handling any internal unit parts.

• The manufacturer declines any liability for damage resulting from

modifications or errors in the electrical or refrigerant connections,

made during the installation, or from improper use of this equipment.

This will invalidate the unit warranty conditions immediately.

• This unit will only work safely and correctly, if installed and tested

by qualified personnel.

• Do not open the remote control to avoid possible damage.

In case of malfunction contact a qualified service engineer.

• This unit contains moving parts. Ensure that these parts are kept

out of the reach of children.

• Maintain the room temperature at general comfort conditions,

especially when children, elderly or handicapped persons are present.

• In order to ensure correct use, the air conditioner must operate

within the temperature limits indicated in the "Operating Limits"

table, included in the Technical manual. Failure to observe these

limits may cause unit malfunction or water leakage.

• In order to avoid electric shock, fire or injury, stop the unit and

disconnect the safety switch in case of abnormal events (such as

smell of burning) and call Carrier Service for further instructions.

• A routine maintenance should be carried out on the unit to check the

correct operation of the electric connections and protection devices.

• Extraordinary maintenance operations must be carried out by

specially trained personnel.

• Do not attempt to repair, move, modify or re-install the unit on your

own. To avoid electric shock or fire make sure these operations

are carried out by qualified personnel only.

• Contact the qualified service if one of the following events takes place:

- hot or damaged power supply cable;

- unusual noise during operation;

- frequent operation of the protection devices;

- unusual smell (such as smell of burning).

WARNING:

Never operate unit without a filter or with grille removed. Damage

to the unit or personal injury may result.

WARNING:

If air filter is not replaced in the unit, dust and dirt gather in air

conditioner and operation becomes impaired.

• A mist or cloud of vapor may be emitted from the unit, when

switching from a cooling operation to a reverse cycle heating

operation. This will occur when the unit has been operating in

cooling mode for awhile and then is switched to heating. The

combination of the evaporated indoor coil condensate and the dry

room air, may result in a cloud of vapor being emitted from the

unit. There is no need for concern.

• Inspect equipment for damage during transport. In case of

damage file an immediate claim with the shipping company.

• Non-routine maintenance of the refrigerant circuit must only be

carried out by qualified personnel.

•All of the manufacturing and packaging materials used for

this appliance are biodegradable and recyclable.

• Dispose of the packaging material and of the remote control

batteries in accordance with local requirements.

• This equipment contains refrigerant that must be disposed of

correctly. When disposing of the unit at the end of its operational

life, take the unit to an authorised waste disposal centre, for

correct disposal procedures.

z_ WARNING:

The unit must always be switched OFF using the Room

Controller. Do not switch OFF the split system by

disconnecting the electric power supply.

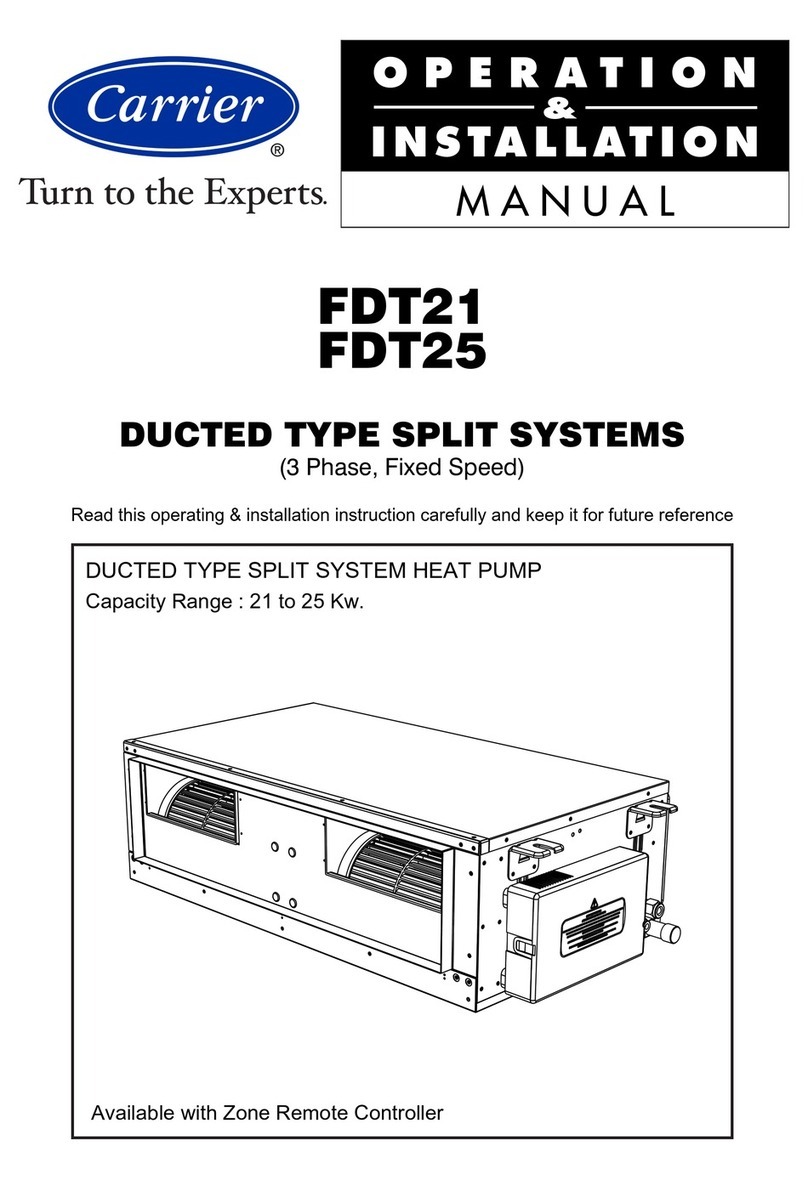

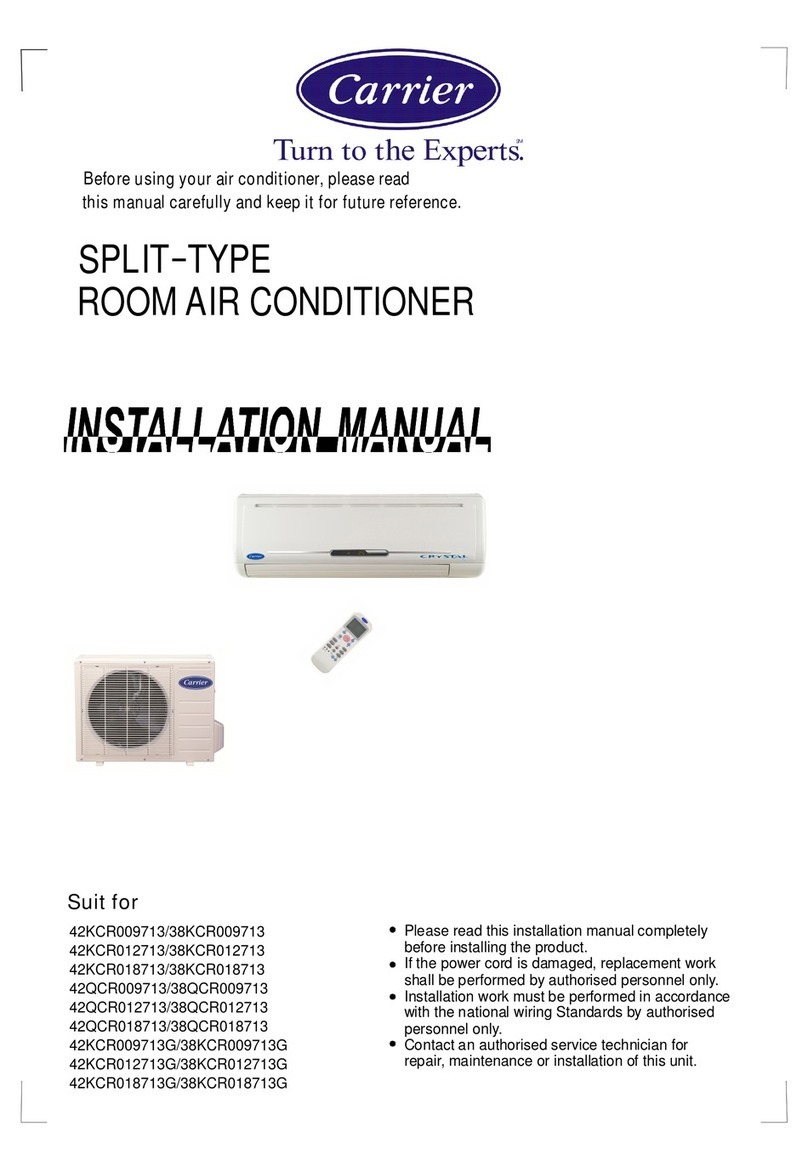

System description

A. Outdoor unit

B. Indoor unit

C. Room Controller

(if foreseen)

t. Air return

2. Air filters

3. Air supply

4. Operation indicator light

and receiver of remote

control signals (if foreseen)

5. Nameplate

6. Interconnecting tubing

7. Condensate drain (open)

12 3 4 5

/ /

/// /

GB- 2