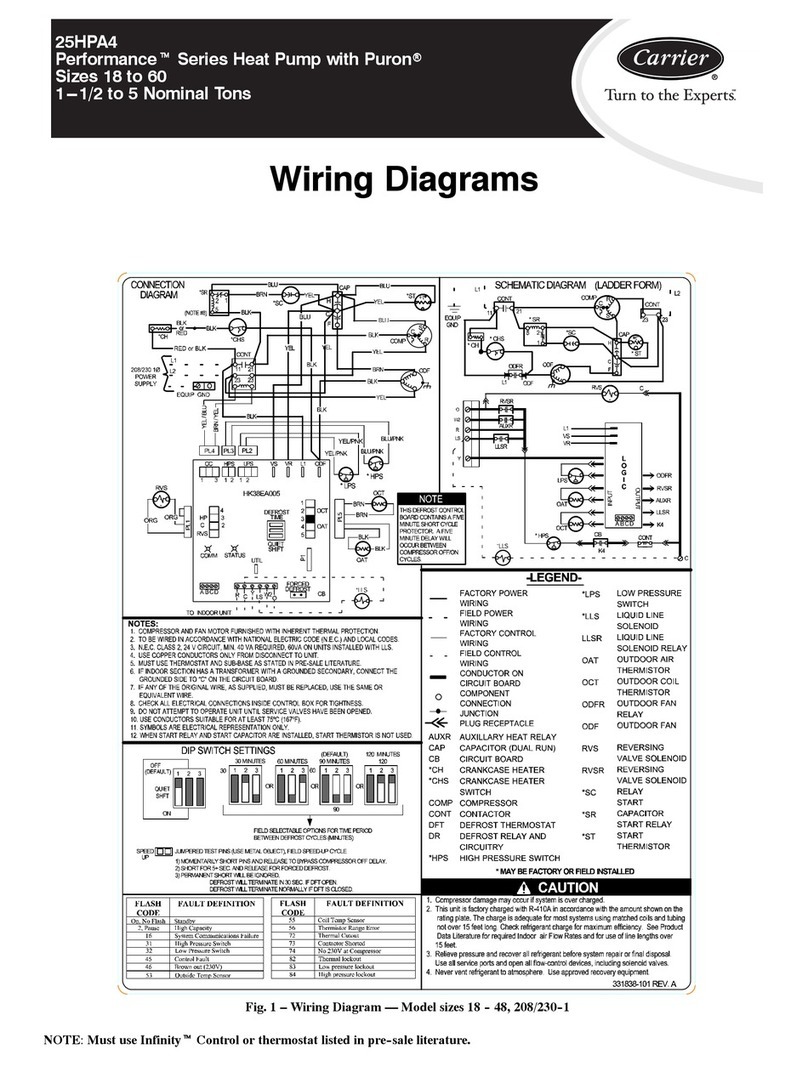

Fig. 5—Label Wiring 327413-101 A05018

FIELD SELECTED TIME PERIOD

BETWEEN DEFROST CYCLES (MINUTES)

JUMPERED TEST PINS (USE METAL OBJECT), FIELD SPEED-UP CYCLE

HEAT CYCLE: 90 MIN. ACCELERATED TO 21 SEC.

60 MIN. ACCELERATED TO 14 SEC.

50 MIN. ACCELERATED TO 12 SEC.

30 MIN. ACCELERATED TO 7 SEC.

10 MIN. ACCELERATED TO 2 SEC.

DEFROST CYCLE:

90

30

SPEED

UP

FACTORYPOWERWIRING

FIELDPOWERWIRING

FACTORYCONTROLWIRING

FIELDCONTROLWIRING

CONDUCTORONCIRCUIT

BOARD

COMPONENTCONNECTION

1/4-INCHQUICKCONNECT

TERMINALS

FIELDSPLICE

JUNCTION

CAPACITOR(DUALRUN)

CRANKCASEHEATER

COMPRESSOR

CONTACTOR

CIRCUITBOARD

DEFROSTTHERMOSTAT

DEFROSTRELAYAND

CIRCUITRY

DISCHARGETEMP.SWITCH

HIGHPRESSURESWITCH

LOWPRESSURESWITCH

OUTDOORFANMOTOR

REVERSINGVALVE

SOLENOID

CAP

*CH

COMP

CONT

CB

DFT

DR

*DTS

*HPS

*LPS

OFM

RVS

*MAYBEFACTORYORFIELDINSTALLED.

-LEGEND-

327413-101 REV. B

SCHEMATIC DIAGRAM (LADDER FORM)

CONNECTION DIAGRAM

1. Compressor damage may occur if system is over

charged.

2. This unit is factory charged with R-22 in accordance

with the amount shown on the rating plate. The

charge is adequate for most systems using

matched coils and tubing not over 15 feet long.

The best performance will be achieved when the

unit operates with a suction gas superheat at the

compressor inlet of 5 ºF at normal rating conditions

of the air conditioning and refrigeration, institute

(ARI). This chart may be used to approximate the

charge if ARI rating conditions cannot be obtained.

ARI rating conditions are equivalent to DOE test "A"

conditions. See product data literature for required

indoor air flow rates and for use of line lengths over

15 Ft.

3. Relieve pressure and recover all refrigerant before

system repair or final unit disposal. Use all service

ports and open all flow-control devices, including

solenoid valves.

1. Compressor and fan motor furnished with

inherent thermal protection.

2. To be wired in accordance with National

Electric Code (N.E.C.) and local codes.

3. N.E.C. class 2, 24V circuit, min. 40 VA required.

4. Use copper conductors only, from disconnect

to unit.

5. Must use thermostat and sub-base as stated

in pre-sale literature.

6. If indoor section has a transformer with a

grounded secondary, connect the grounded

side to "C" on the circuit board.

7. If any of the original wire, as supplied, must

be replaced, use the same or equivalent wire.

8. Check all electrical connections inside control

box for tightness.

9. Do not attempt to operate unit until service

valves have been opened.

10. It is imperative to connect 3Ø field power

to unit with correct phasing. The Phase

Rotation Monitor will not allow the contactor

to be energized if thephasing is not correct.

If phasing is reversed, simply interchange any two

of the three power connections on the field side.

11. Use conductors suitable for at least 75ºC (167ºF).

NOTES:

CAU

TIO

N

COOLING ONLY

PROCEDURE

EVAPORATOR ENTERING AIR ºF WB.

TEMP °F

OUTDOOR

50

TABLE I - SUPERHEAT CHARGING TABLE

(SUPERHEAT ºF AT LOW-SIDE SERVICE PORT)

52 54 56 58 60 62 64 66 68 70 72 74 76

55 9 37

60 7

65 -- 6

70 -- -- 7

75 -- -- -- 6 9 12 15 18 21 24 28 31 34 37

80 -- -- -- -- 5 8 12 15 18 21 25 28 31 35

85 -- -- -- -- -- -- 8 11 15 19 22 26

90 -- -- -- -- -- -- --------------

-- -- -- -- -- -- --

--

--

--

--

--

----

--

----

--

----

--

------

--

-- --

--

5 9 13 16 20 24 27 31

95 6

100 8 12 15 20 23 27

5 9 13 17 22 26

68

--

--

-- --

-- -- --

105

110

115

918987858381797775

40 898785838179777573

38 878583817977757371

36 858381797775737169

34 838179777573716967

32 817977757371696765

30 797775737169676563

28 777573716967656361

26 757371696765636159

24 737169676563615957

22 71

6967656361595755

20 696765636159575553

18 676563615957555351

16 656361595755535149

14 636159575553514947

12 615957555351494745

10 595755535149474543

8575553514947454341

6555351494745434139

4535149474543413937

25149

47454341393735

0

85.782.479.276.073.070.067.164.2

SUCTION PRESSUR E AT SERVICE PORT PSIG.

TEMP. °F

61.5

SUPERHEAT

45

43

41

39

42

40

35

32

29 4038

35

3330 38

3633 3633

30

27 30

2724

33

18 29

30

22 25

14

10

23

2520

18

14

1511

2723

23

18

1512

10 26

23

20

17

14

12

24

21

19

16

13

10 21

19

16

13

10

TABLEII - REQUIREDSUCTION TUBETEMPERATURE ºF

(MEASUREDATLOW-SIDESERVICEPORT)

L3

L2

L1

GND

EQUIP

CONT

11 21

T3

T1

T2

OF2OF1

DR CONT

*CH

23 13

OFM

COMP

CAP

C

RVS

OO

W2

RR

Y

Y

C

DFT

DFT

DR

T1 C

LOGIC

*HPS

*LPS *DTS

CONT

BRN

OFM BRN

RED or BLK YEL

BLK

BLU

L2

A

LE

R

T

!

(

N

OTE

#11

)

23

13

21

11

L3

L1

EQUIP GND

SUPPLY

POWER

208/230 3Ø

CONT

CAP

COMP

T2

T1 T3

*CH

BLK

RED

or

BLK

BLK

YEL

ORG

ORG or

or

RVS

BLK

BLK

DFT BLK

or

PNK

PNK

or

BLK

WHT

YEL

CB

DR

OF1

OF2

CY OW2R

Y

T1

LOGIC

50 90

30

SPEED

UP

R

C

C

DFT

O

PNK PNK

HK32EA001

*LPS *HPS

YEL

YEL BLU

BRN

YEL

ORG

ORG

GLER

W2

OYC

TERMINAL BLOCK

INDOORUNIT

RED

ORNBLK

G

W3

LER

W2

OYC

INDOOR THERMOSTAT (NOTE #5)

YEL

or

BLU

BLK YEL

1. Operate unit a minimum of

10 minutes before checking

charge.

2. Measure suction pressure

by attaching a gage to

suction valve service port.

3. Measure suction temperature

by attaching an accurate

thermistor type or electronic

thermometer to the suction

line at service valve.

4. Measure outdoor air dry-bulb

temperature with a

thermometer.

5. Measure indoor air (entering

indoor coil) wet bulb

temperature with a sling

psychrometer.

6. Refer to table I. Find out-

door temperature and

evaporator entering air wet-

bulb temperature at this

intersection note the super-

heat.

7. Refer to table II. Find super-

heat temperature located in

step 6 and suction pressure,

at this intersection note

suction line temperature.

8. If unit has a higher suction

line temperature than charted

temperature, add refrigerant

until charted temperature

is reached.

9. If unit has a lower suction

line temperature than charted

temperature, remove and

recover refrigerant until

charted temperature is

reached.

10. If outdoor air temperature

or pressure at suction valve

changes, charge to new

suction line temperature

indicated on chart.

11. This procedure is valid when

indoor air flow is within

+/- 21% of its rated cfm.

50

**

**

** BOARD MAY HAVE 60

AS MIDDLE SELECTION

**

6