Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 111 Catalog No. 534-80230 Printed in U.S.A. Form 48/50H,P-14SI Pg 1 3-05 Replaces: New

Book1144

Tab 1a1b6a6b

Installation Instructions

Power Exhaust Part Numbers: CRPWREXH018B00,

CRPWREXH019B00, CRPWREXH020B00

Barometric Relief Part Number: CRBARRLF003B00

CONTENTS

SAFETY CONSIDERATIONS ......................1

GENERAL ...................................... 1,2

INSTALLATION ................................. 2-6

Barometric Relief Damper ........................6

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical compo-

nents. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service

personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels attached to

the unit, and other safety precautions that may apply.

GENERAL

Consult price pages for the economizer accessory if the unit

is not already equipped. Refer to Table 1 for a complete list of

parts contained in each kit.

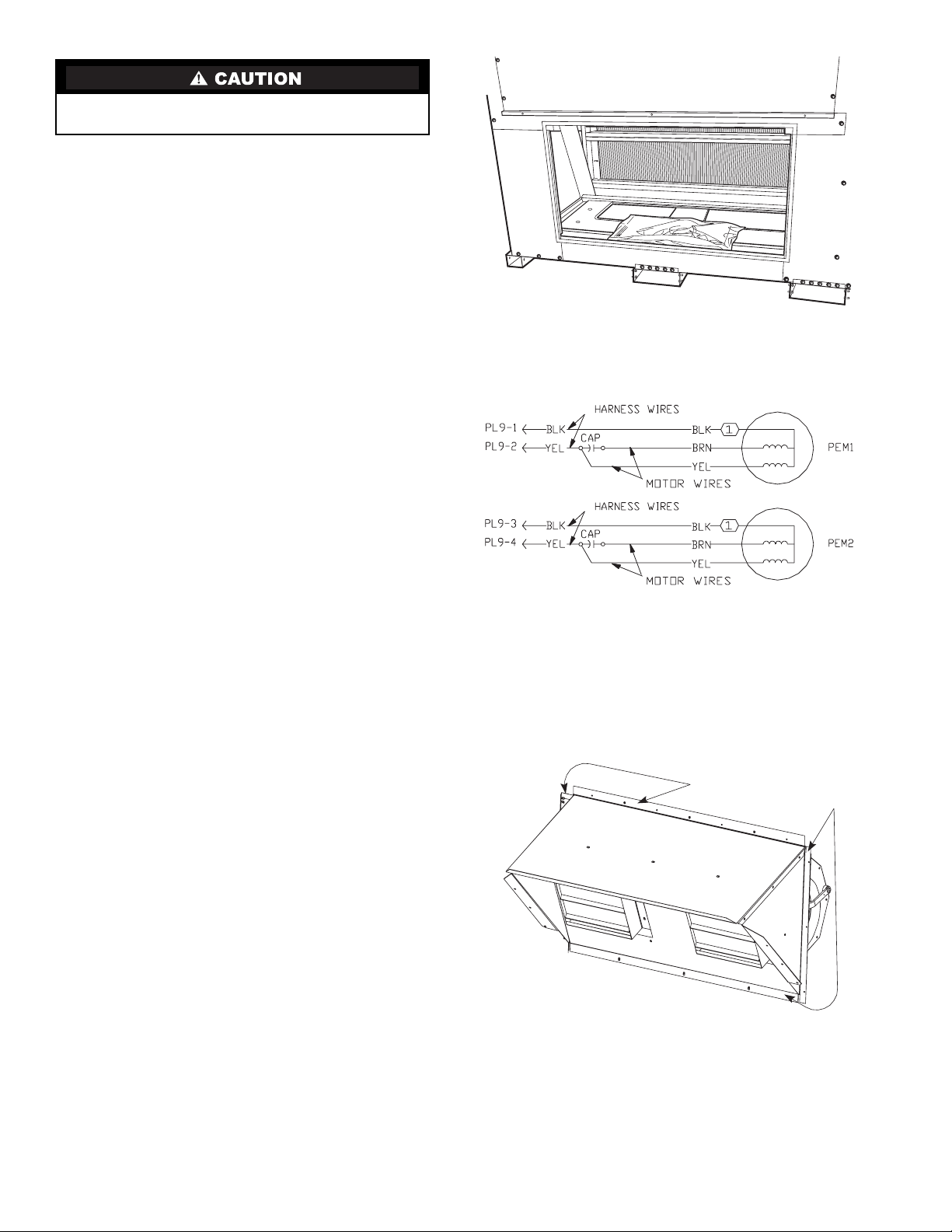

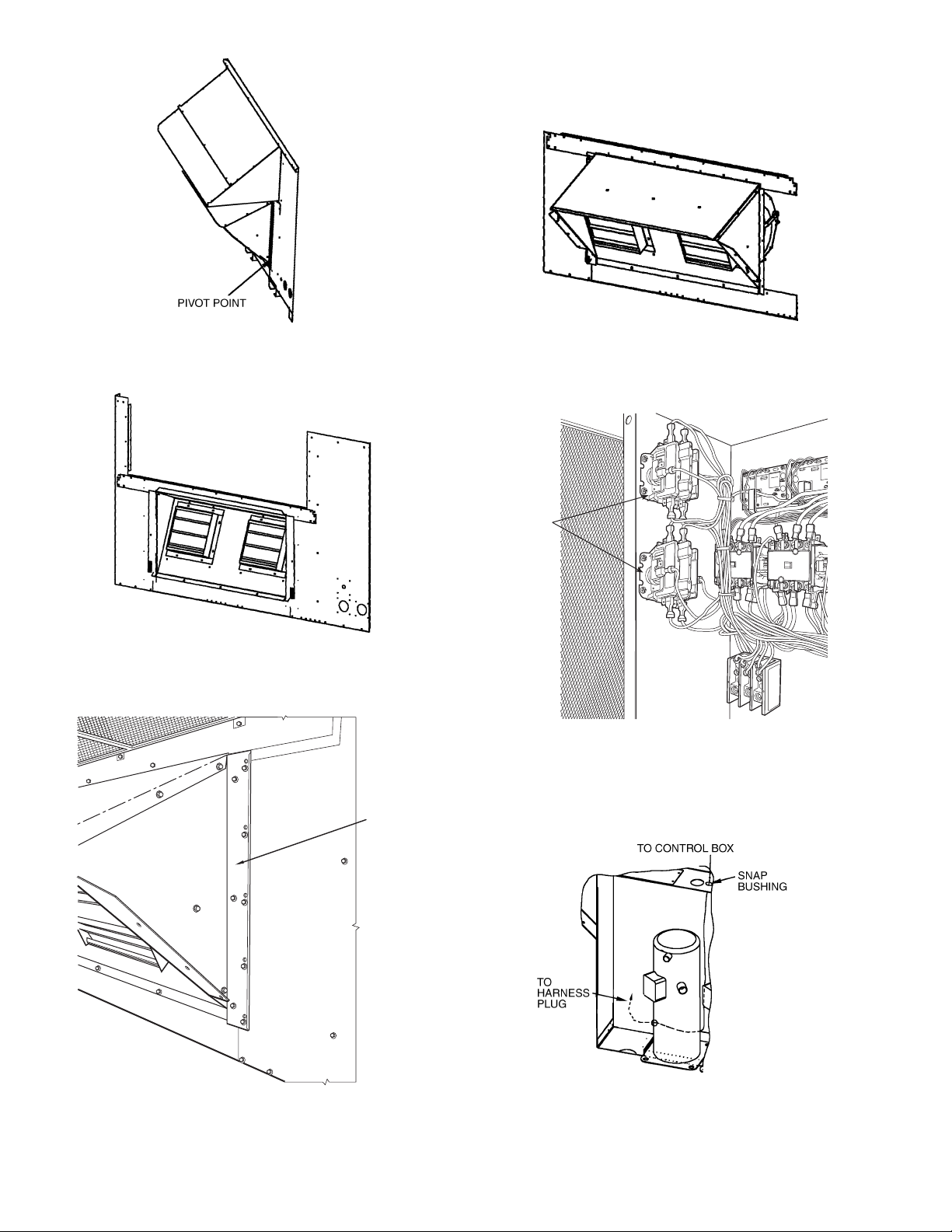

Each hood assembly has 2 power exhaust blowers.

Brackets, wires and extra gasket screws are also included in the

package.

POWER EXHAUST PACKAGE USAGE

Table 1 — Power Exhaust/Barometric Relief Parts List

IMPORTANT: There are two different design revision

48/50HG units currently being produced. Because of

these differences, there are two different versions of

this accessory. This accessory literature covers acces-

sories manufactured for units with design revision 1.

Design revision 0 units are not covered in this acces-

sory book.

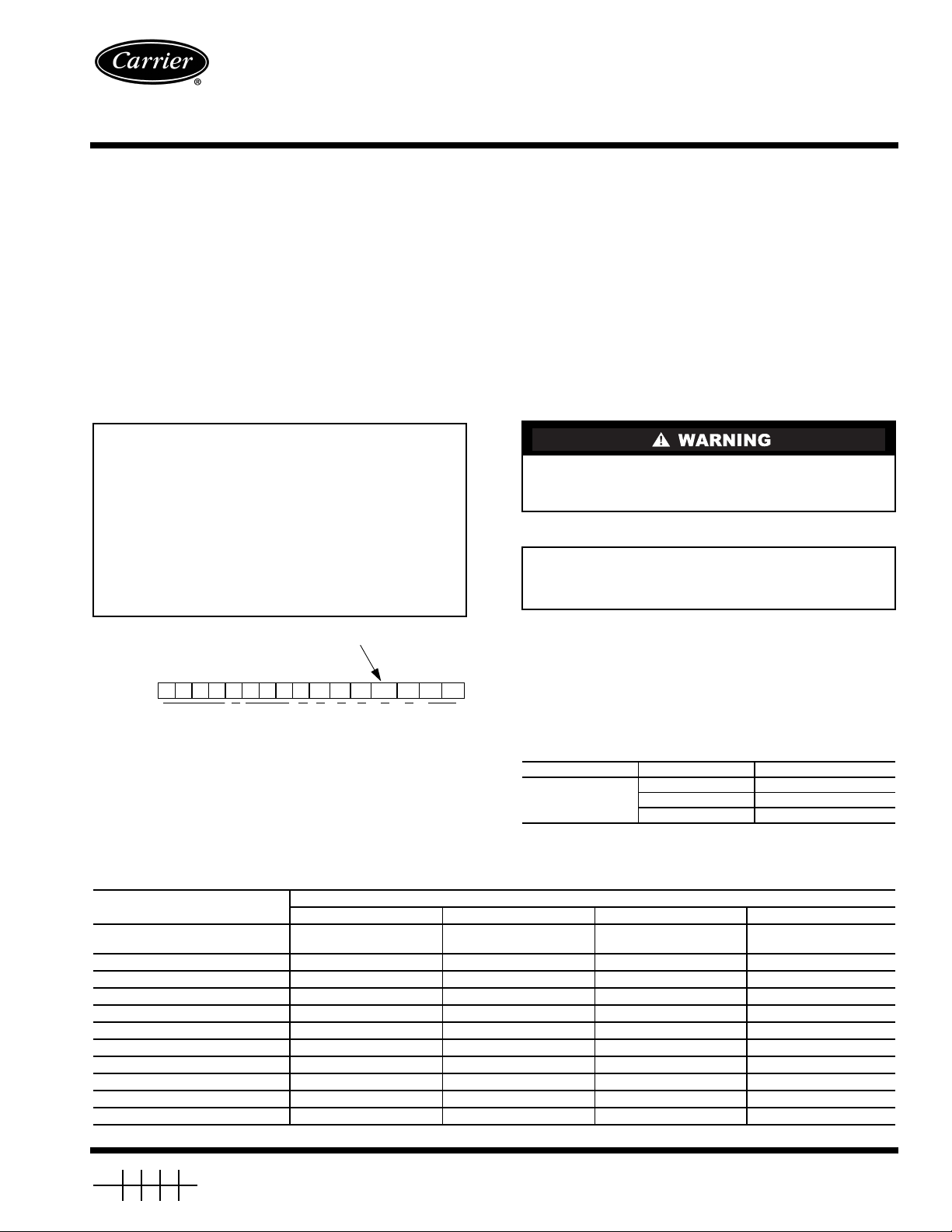

To determine the design revision, refer to the full unit

model number. See Fig. 1 for an example of an HG

model number. The design revision number in the model

number nomenclature is located in position 13.

Turn off main power to the unit and tag disconnect switch

before performing service or maintenance operations. Elec-

trical shock could cause personal injury or death.

IMPORTANT: The power exhaust accessory requires

the use of the economizer. Power Exhaust will not

operate without the use of an economizer.

UNIT VOLTAGE PART NUMBER

48/50HG014-028,

48/50PG20-28

208/230 V CRPWREXH018B00

460 V CRPWREXH019B00

575 V CRPWREXH020B00

ITEM DESCRIPTION DESCRIPTION (QUANTITY)

CRPWREXH018B00 CRPWREXH019B00 CRPWREXH020B00 CRBARRLF003B00

Blower/Damper

Assembly

Power Exhaust

(208/230 V)

Power Exhaust

(460 V)

Power Exhaust

(575 V) Barometric Relief

Contactor HN52KC010 (2) HN52KC010 (2) HN52KC010 (2) —

Screw 8-18 x 1/2

″AL56AU166 (4) AL56AU166 (4) AL56AU166 (4) —

Power Wiring Harness 50TG402807 50TG402807 50TG402807 —

Control Wiring Harness 50TG403083 50TG403083 50TG403083 —

Snap Bushing HY93NH091 HY93NH091 HY93NH091 —

Plug Plate 50TG500128 50TG500128 50TG500128 —

Left Hand Bracket 50TG502765 50TG502765 50TG502765 50TG502765

Right Hand Bracket 50TG502865 50TG502865 50TG502865 50TG502865

Screw - 1/4

″x3/4

″AL31AZ308 (9) AL31AZ308 (9) AL31AZ308 (9) AL31AZ308 (9)

Seal Strip ————

48/50HG014-028, 48/50PG20-28

with

COMFORT

LINK™ Controls

Power Exhaust and

Barometric Relief Accessory

Fig. 1 — Model Number Chart

PositionNo.12345678 9 10 11 12 13 14 15 16

Example:48HGD016AA C 611AA

DESIGN REVISION NUMBER