38YDB

Sizes 024–060

Two-Speed Heat Pump with Puron®

Wiring Diagrams

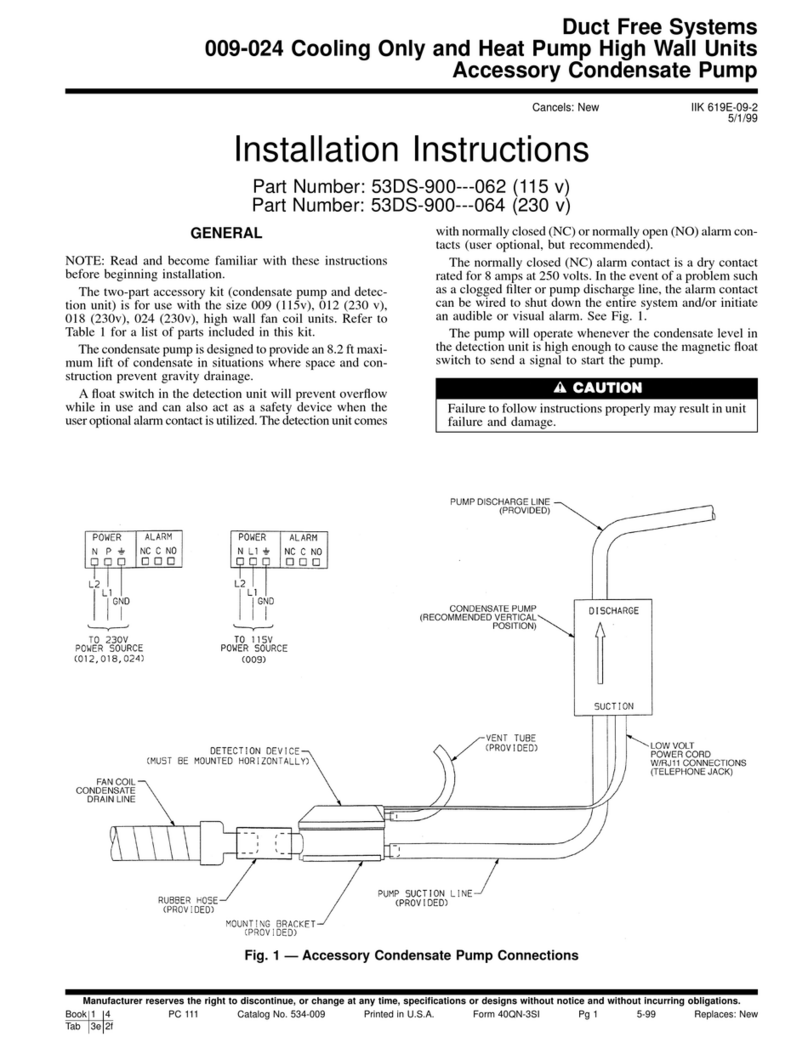

Fig. 1—Wiring Diagram–024, 036, 048

A00219

OFM

CCH

TOINDOORUNIT

CONNECTION DIAGRAM

-t°

LPS

HPS

RVS

NOTES:

1. Compressor furnished with inherent thermal protection.

2. Fan motor furnished with inherent thermal protection.

3. To be wired in accordance with National Electric Code

and local codes.

4. Outdoor unit control requires a minimumof 27 VA,

24 VAC control power.

5. Use copper conductors only. use conductors suitable

for at least 75°C (167°F).

6. If indoor section has a transformer with a grounded

secondary, connect the grounded side to "C".

7. If any of the original wire, as supplied, must be replaced,

use the same or equivalent wire.

8. Check all electrical connections inside control box for

tightness.

9. Do not attempt to operate unit until service valves have

been opened (back seated)

10.Must use thermostat listed in pre-sale literature.

11.Compressor windings shown for 2 cylinder operation.

For 1 cylinder operation reverse R and S markings.

FUNCTION LIGHT (STATUS) DEFINITION

CODEON UNIT NO DEMAND / STAND BY

LOW-CAPACITY OPERATION

HIGH-CAPAC ITY OPERATION

OUTDOOR THERMISTOR FAILURE

COILTHERMISTOR FAILURE

THERMISTOR OUTOF RANGE

LOW PRESSURE SWITCH TRIP

HIGH PRESSURE SWITCH TRIP

COMPRESSOR VC/VHTRIP

BOARD FAILURE

326367-101 REV. A

-LEGEND-

FAN

CAP

C

O

W

Y2

Y1

RA B C D

OAT

-t°

LOHI

CL

CH

D C C

OCT

-t°

LPS

HPS

OAT

-t°

LOHI

TO INDOOR UNIT

RED CCH

FAN CAP

YEL

RED

BRN

OFM

BLK

BLU/PNK

BLU/PNK

YEL/PNK

YEL/PNK

CONSTANT FLASH / NO PAUSE

ONE FLASH W/ PAUSE

TWO FLASHES W/ PAUSE

THREE FLASHES W/ PAUSE

FOUR FLASHESW/ PAUSE

ALT 3 & 4

ALT 5 & 1

ALT 5 & 2

ALT 6

CONSTANT LIGHT NO PAUSE / NO FLASH

BRN

BRN

BLK

BLK

BLK ORN

RVS

ORN RED BLU

CH11

21

23

23

YEL

BLK BLK

BLK

C L

11

21

H

C

START

COMP

RELAY

BRN

CAP

L2

L1

EQUIP GND

DUAL CAPACITY

A B C D

BLU

BRN

BRN

BLK

YEL

BRN

RVSSEVHP/AC C

OCT

DUAL CAPACITY

CONTROL COMP

CAP FAN

CAP

CH CL

COMPONENT ARRANGEMENT

UNITS 036, 048

VPSBLK

VPS

UNIT OPERATION/SEE UNIT INSTALLATION INSTRUCTIONS FOR DETAILS

1 MINUTE TIME DELAY -

WHEN CHANGING FROMLOWTO HIGH, ORHIGHTO LOW,THERE ISA 1 MINUTE TIMEDELAY.NOTE,

DURING CAPACI TY CHANGE DELAY THE OUTDOOR FAN WILL REMAIN RUNNING.

CRANKCASE HEATER -

OPERATES DURING OFF CYCLE.

DEFROST TIME SELECTION -

(SHOWN AS DT ON BOARD) THE DEFROST INTERVAL TIME CAN BE FIELD-SELECTED, DEPENDENT

UPON LOCAL/GEOGRAPHIC REQUIREMENTS. IT IS FACTORYSE T AT 90 MINUTES AND CAN BE CHANGED TO

EITHER 30, 60 OR 120 MINUTES.

DEFROST -

DEFROSTWILL ONLY BE PERFORMED AT OUTDOORTEMERATURES LESS THAN 50°F. DEFROST WILL INITIATE WHEN

TIME SELECTEDHAS ELAPSED ANDTHE COIL TEMPERATURE IS LESSTHAN 30°F. (±2°) ANDWILL TERMINATE AT

80°F. (±5°). UPON DEFROSTTERMINATION THE OUTDOOR FAN WILL DELAY 20 SECONDS BEFORE STARTI NG.

FIELD INITIATED FORCED DEFROST -

(SHOWN AS FORCED DEFROST ON BOARD) BY PLACING A JUMPER ACROSS THE FORCED

DEFROSTTERMI NALS FOR 5 SECONDS, OR LONGER, AND THEN REMOVING THE JUMPER, THE UNIT WILL INITIATE A

DEFROST CYCLE REGARDLESS OF COIL TEMPERATURE. THE DEFROSTCYCLE WILL TERMINATE AT 80°F (±5°).

IF COIL TEMPERATURE IS ABOVE 30°OR OUTDOOR AMBIENT TEMPERATURE IS ABOVE 50°F, DEFROST MODE WILL

TERMINATE AFTER 30 SECONDS OF ACTIVE MODE.

12345 12

PL2

1

2

3

1

2

1

2

4

5

1

C

O

W

Y2

Y1

R

1

RVSSEVHP/AC CC

C

VH

L 2

ODF

CCH

VC

12345

PL1

PL1

PL3

12

PL2

PL5

1

2

3

1

2

1

2

4

5

YEL

BLU

BLU

BRN

BRN

1

2

YEL

5

BRN

BLU

START

CAP

NOTE #11

SCHEMATIC DIAGRAM (LADDER FORM)

H

C

C L

21

11

COMP

CAP

COMP

L2

CH

21

11

L1

23

23

CH

DUAL CAPACITY

EQUIP

GND

START

RELAY

1

2

5

START

CAP

R

S

C

208 / 230 - 1 - 60

POWERSUPPLY

START

CAP

START

RELAY

DUAL

CAPACITY

CONTROL COMP

CAP

FAN

CAP

CH CL

COMPONENT ARRANGEMENT

UNIT 024 ONLY

START

CAP

START

RELAY

VH

L 2

ODF

CCH

VC

RED

YEL

BLK

BLU

BRN

PL5

PL4

COMM STATUS

FORCED

DEFROST

TIME (MIN)

DEFROST

BLK

PL4

PL3

YEL

RED

LPS

HPS

OAT

OCT

LPS

HPS

OAT

OCT

FACTORY POWER WIRING

FIELD POWER WIRING

FIELD CONTROL WIRING

FACTORY CONTROL WIRING

COMPONENT CONNECTION

FIELD SPLICE

JUNCTION

CONTACTOR L OW CAPACI TY (24 V COIL)

CRANKCASE HEATER

CONTACTOR HI GH CAPACI TY (24 V COIL)

CAPACITOR

DUAL CAPACI TY CONTROL

SYSTEM COMMUNICATION

COMPRESSOR

HIGHPRESSURESWITCH

LOW PRESSURE SWITCH

THERMISTOR (OUTDOOR AIR)

THERMISTOR COIL

OUTDOORFANMOTOR

REVERSINGVALVE SOLEN OID

SYSTEM FUNCTION LIGHT

VAPOR PRESSURESWITCH

COMM

COMP

HPS

LPS

OAT

OCT

OFM

RVS

STATUS

VPS

CL

CCH

CH

CAP

DCC

COMP

YEL

R

S

C

BLU

BLU

BL

U

Visit www.carrier.com

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a 5a PC 101 Catalog No. 533-80064 Printed in U.S.A. Form 38YDB-3W Pg 1 8-02 Replaces: 38YDB-2W