2.OVERLOAD INDICATOR LIGHT

The overload indicator light flickers when an overload of a connected

electrical device is detected. This situation shall not be kept for a long

time and it just needs to decrease the loads to its normal range and

the overload indicator light will go off.

When the load is detected to exceed the maximum power or the AC

output voltage is reduced, the overload indicator light will come on

and the electronic breaker will then activate, stopping power to the

generation in order to protect the generator and any connected

electric devices. The output pilot light (Green) will be off, the overload

indicator light will turn RED. It is needed to process as follows,

(a) Turn off any connected electric devices

(b) Reduce the total wattage of connected electric.

(c) Check for blockages in the cooling air inlet, muffler air

exhaust pipe opening and the control unit.

(d) After inspection, press the reset button to restore the power

supply of the generator.

CAUTION:

⚫The generator AC output automatically resets when the engine is stopped and then restarted.

⚫The overload indicator light may come on for a few seconds at first when using electric devices that require a large

starting current, such as a compressor or a submergible pump. However, this is not a malfunction.

3. DC APPLICATION (option)

This usage is applicable to 12V battery charging only.

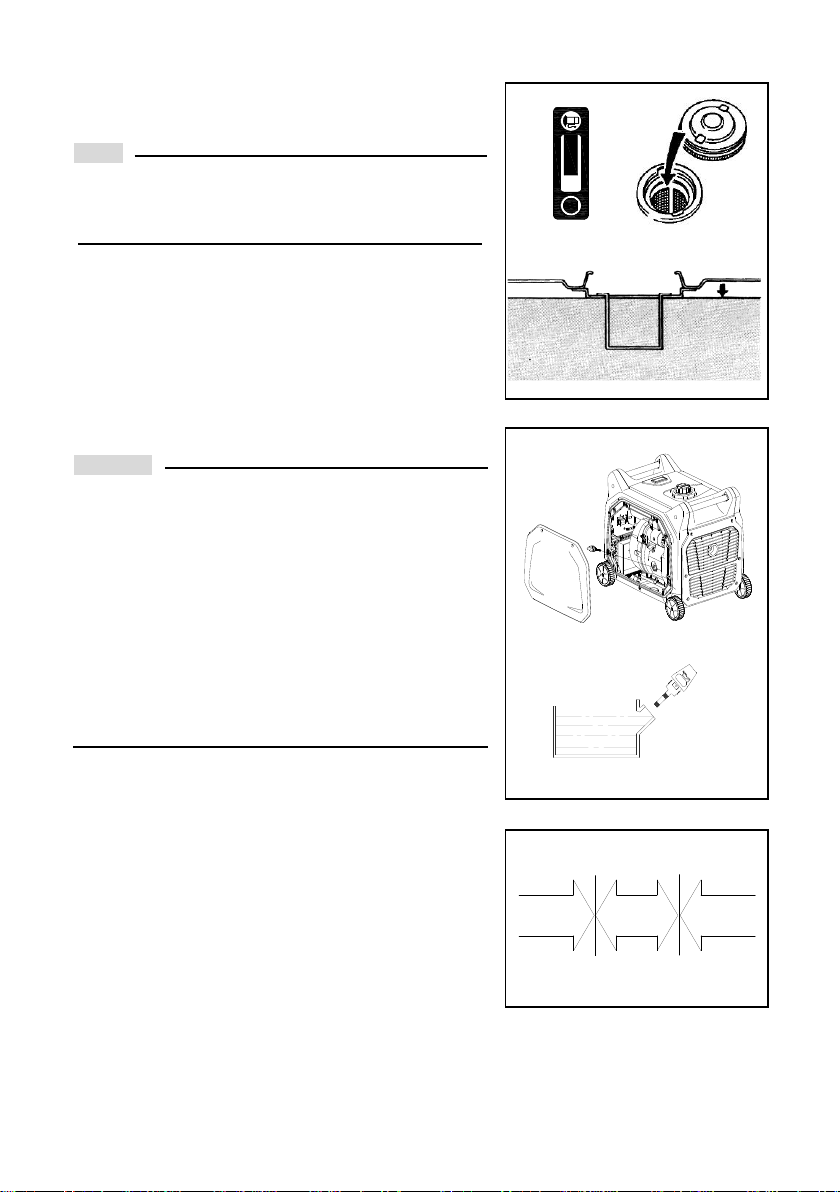

(a) Charging instruction for battery

⚫Disconnect the leads for the battery.

⚫Make the battery fluid filler cap loose fully.

⚫Fill distilled water to the upper limit, if the battery fluid is low level.

⚫Measure the specific gravity for the battery fluid by using the

hydrometer, and calculate the charging time in according with the

table shown on right side.

⚫The specific gravity for the fully charged battery shall be within 1.26

to 1.28. It is recommended to confirm every an hour.