3

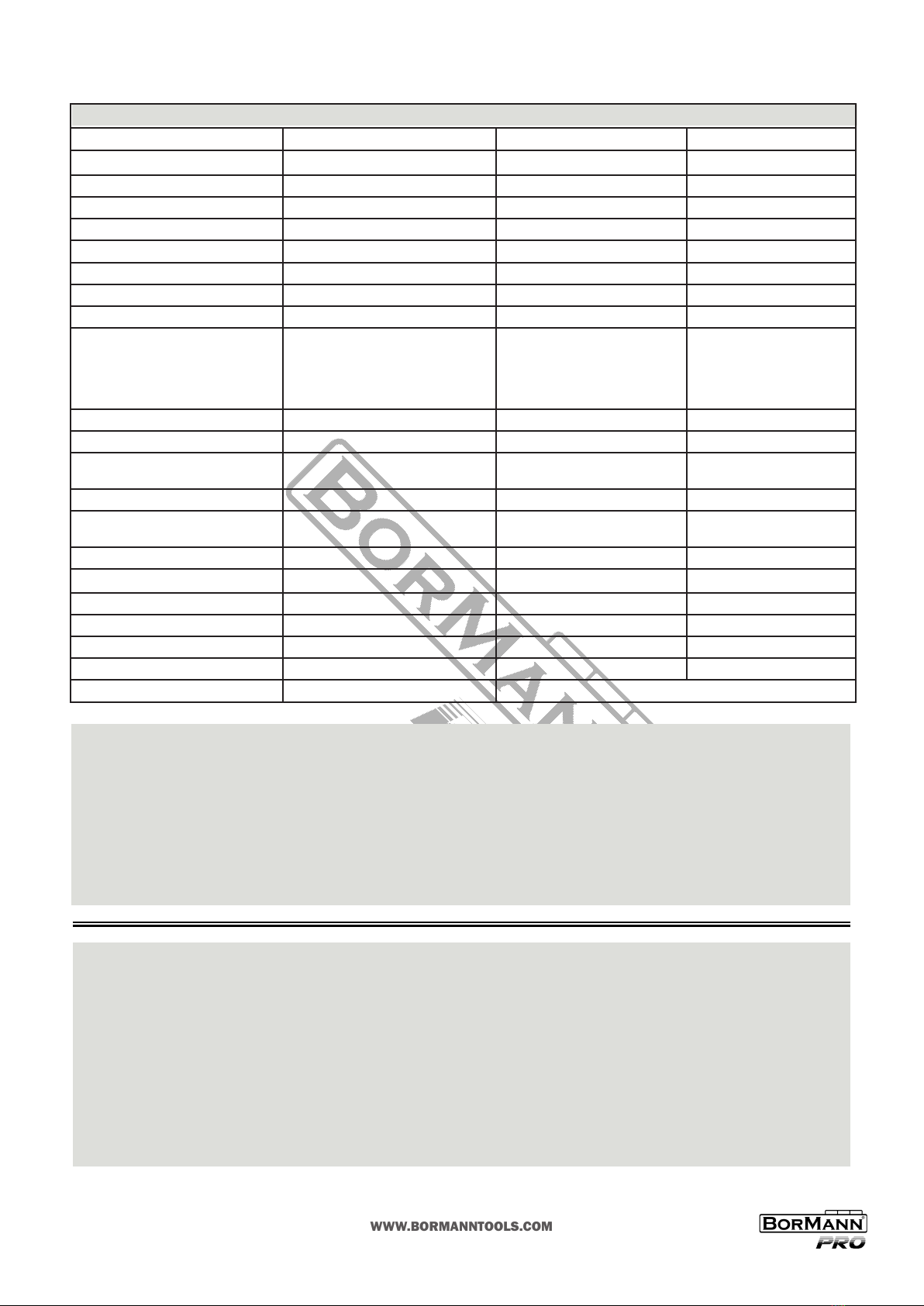

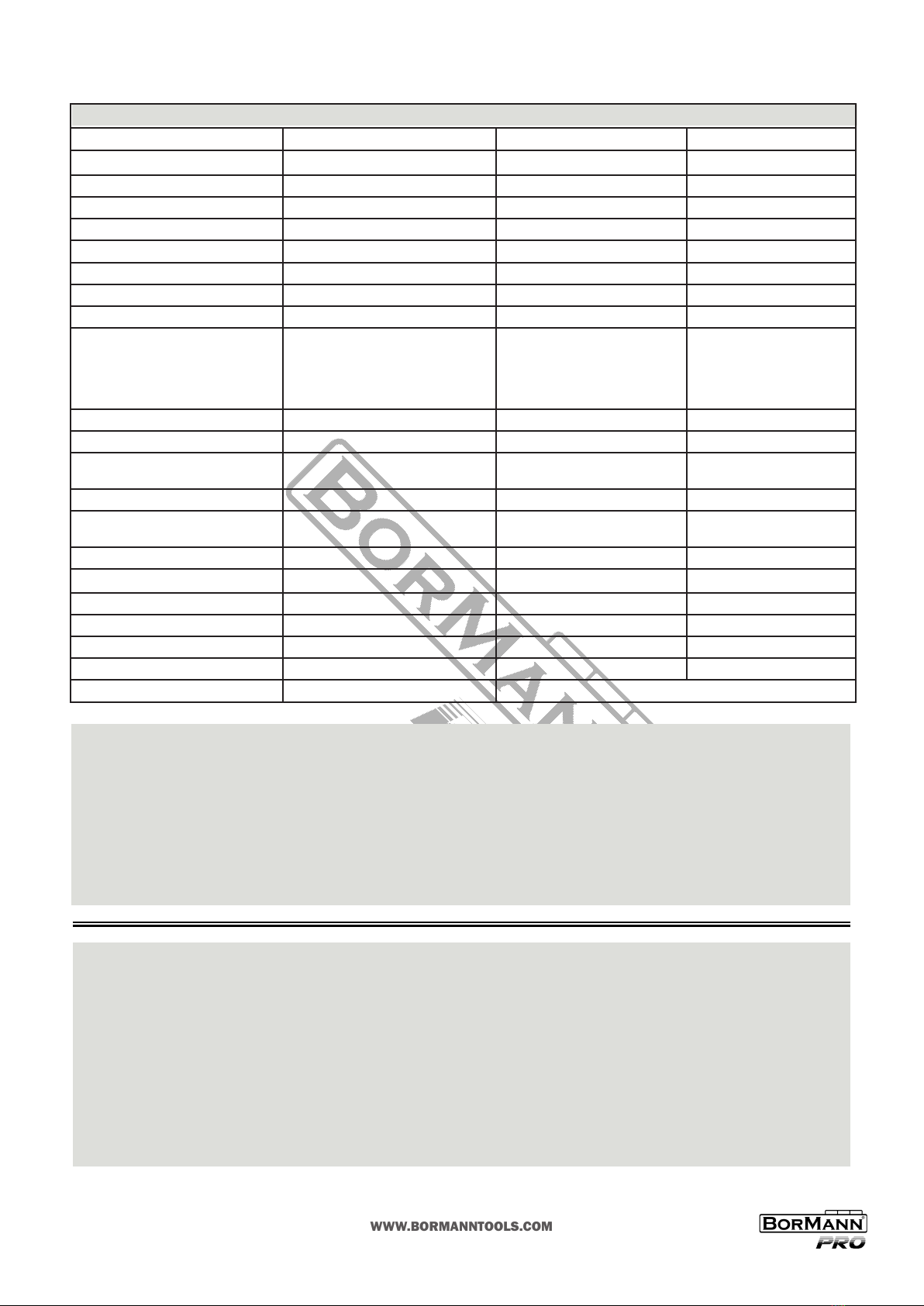

Technical Data / Τεχνικά Δεδομένα

Model Μοντέλο BGB9000 BGB9500

Nominal voltage & Frequency Ονομαστική τάση & Συχνότητα 230 V - 50 Ηz 230 V - 50 Hz

Nominal power output (kW) Oνομαστική ισχύς (kW )

5,0 kW 6,0 kW

Maximum power (kW) Mέγιστη ισχύς (kW)

4,5 kW 5,5 kW

DC Voltage (Volt) Τάση DC (Volt) 12 12

DC Current (Ampere) Ρεύμα DC (Ampere) 6 6

Power Coecient Συντελεστής ισχύος 1 1

Voltage Regulaon Ρύθμισης Τάσης ΑVR AVR

Engine Model Mοντέλο Κινητήρα 186F 188F

Engine Type Tύπος Κινητήρα

4 stroke, 1-cylinder, air-cooled

4χρονος, μονοκύλινδρος,

αερόψυκτος

4 stroke, 1-cylinder, air-cooled

4χρονος, μονοκύλινδρος,

αερόψυκτος

Rotaon speed (rpm) Στροφές (rpm) 3000 3000

Displacement (cc) Kυβικά (cc) 420 474

Cooling System Σύστημα Ψύξης Air-Cooled

Αερόψυκτος Κινητήρας

Air-Cooled

Αερόψυκτος Κινητήρας

Oil tank capacity (lt) Xωρητικότητα δεξαμενής λαδιού (lt) 1,65 1,65

Starng system Σύστημα εκκίνησης manual/electrical start

χειροκίνητη/ηλεκτρική εκκίνηση

electrical start

ηλεκτρική εκκίνηση

Fuel Kαύσιμο Diesel Oil / Πετρέλαιο Diesel Diesel Oil / Πετρέλαιο Diesel

Fuel tank capacity (lt) Χωρητικότητα δεξαμενής καυσίμου (lt) 12,5 25

Fuel Consumpon (g/kWh) Kατανάλωση καυσίμου (g/kWh) ≤ 400 ≤ 370

Noise @ 7 meters distance (db(A)) Θόρυβος (στα 7 μέτρα) (db(A)) ≤ 82 ≤ 70

Dimensions (L x W x H) (mm) Διαστάσεις (L x W x H) (mm) 800 x 520 x 600 890 x 620 x 840

Weight (kg) Bάρος (kg) 110 155

Οther necessary details 'Aλλες σημαντικές πληροφορίες Βaery, ATS socket, wheels / Mπαταρία, πρίζα ΑΤS, τροχοί κίνησης

*Ο κατασκευαστής διατηρεί το δικαίωμα να πραγματοποιήσει δευτερεύουσες αλλαγές στο σχεδιασμό του προϊόντος και στα τεχνικά χαρακτηριστικά χωρίς

προηγούμενη ειδοποίηση, εκτός εάν οι αλλαγές αυτές επηρεάζουν σημαντικά την απόδοση και λειτουργία ασφάλειας των προϊόντων. Τα εξαρτήματα που

περιγράφονται / απεικονίζονται στις σελίδες του εγχειριδίου που κρατάτε στα χέρια σας ενδέχεται να αφορούν και σε άλλα μοντέλα της σειράς προϊόντων

του κατασκευαστή, με παρόμοια χαρακτηριστικά, και ενδέχεται να μην περιλαμβάνονται στο προϊόν που μόλις αποκτήσατε.

* Λάβετε υπόψη ότι ο εξοπλισμός μας δεν έχει σχεδιαστεί για χρήση σε εμπορικές, επαγγελματικές ή βιομηχανικές εφαρμογές. Η εγγύησή μας θα ακυρωθεί

αν το προϊόν χρησιμοποιείται σε εμπορικές, επαγγελματικές ή βιομηχανικές επιχειρήσεις ή για ανάλογους σκοπούς.

* Για να διασφαλιστεί η ασφάλεια και η αξιοπιστία του προϊόντος καθώς και η ισχύς της εγγύησης όλες οι εργασίες επιδιόρθωσης, ελέγχου, επισκευής ή

αντικατάστασης συμπεριλαμβανομένης της συντήρησης και των ειδικών ρυθμίσεων, πρέπει να εκτελούνται μόνο από τεχνικούς του εξουσιοδοτημένου

τμήματος Service του κατασκευαστή.

* Χρησιμοποιείτε πάντα το προϊόν με τον παρεχόμενο εξοπλισμό. Η λειτουργία του προϊόντος με μη-προβλεπόμενο εξοπλισμό ενδέχεται να προκαλέσει βλά-

βη ή ακόμα και σοβαρό τραυματισμό ή θάνατο. Ο κατασκευαστής και ο εισαγωγέας ουδεμία ευθύνη φέρει για τραυματισμούς και βλάβες που προκύπτουν

από την χρήση μη προβλεπόμενου εξοπλισμού.

* The manufacturer reserves the right to make minor changes to product design and technical specicaons without prior noce unless these changes signif-

icantly aect the performance and safety of the products. The parts described / illustrated in the pages of the manual that you hold in your hands may also

concern other models of the manufacturer's product line with similar features and may not be included in the product you just acquired.

* Please note that our equipment has not been designed for use in commercial, trade or industrial applicaons. Our warranty will be voided if the machine is

used in commercial, trade or industrial businesses or for equivalent purposes.

* To ensure the safety and reliability of the product and the warranty validity, all repair, inspecon, repair or replacement work, including maintenance and

special adjustments, must only be carried out by technicians of the authorized service department of the manufacturer.

* Always use the product with the supplied equipment. Operaon of the product with non-provided equipment may cause malfuncons or even serious injury

or death. The manufacturer and the importer shall not be liable for injuries and damages resulng from the use of non-conforming equipment.