- 3 -

Safety Instructions (Installation)

Many of the parts of the permaport are heavy; do not lift any parts that are beyond

your capability, use additional help to maneuver parts into position.

When working near the water it may be advisable to tie a line to any parts that are

liable to sink until they are attached. These should be attached to inanimate secure

objects only.

Installation to the dock requires holes to be drilled and possibly wood to be cut,

these operations should only be carried out by competent persons.

Water and electricity do not mix well, do not use corded power tools, hand tools

are preferable or battery powered. Battery powered tools up to 20v are safe but

will be damaged if submerged.

If you have any doubt about installing the Permaport consult the Dock Specialist

that supplied the unit.

Safety Instructions (Use)

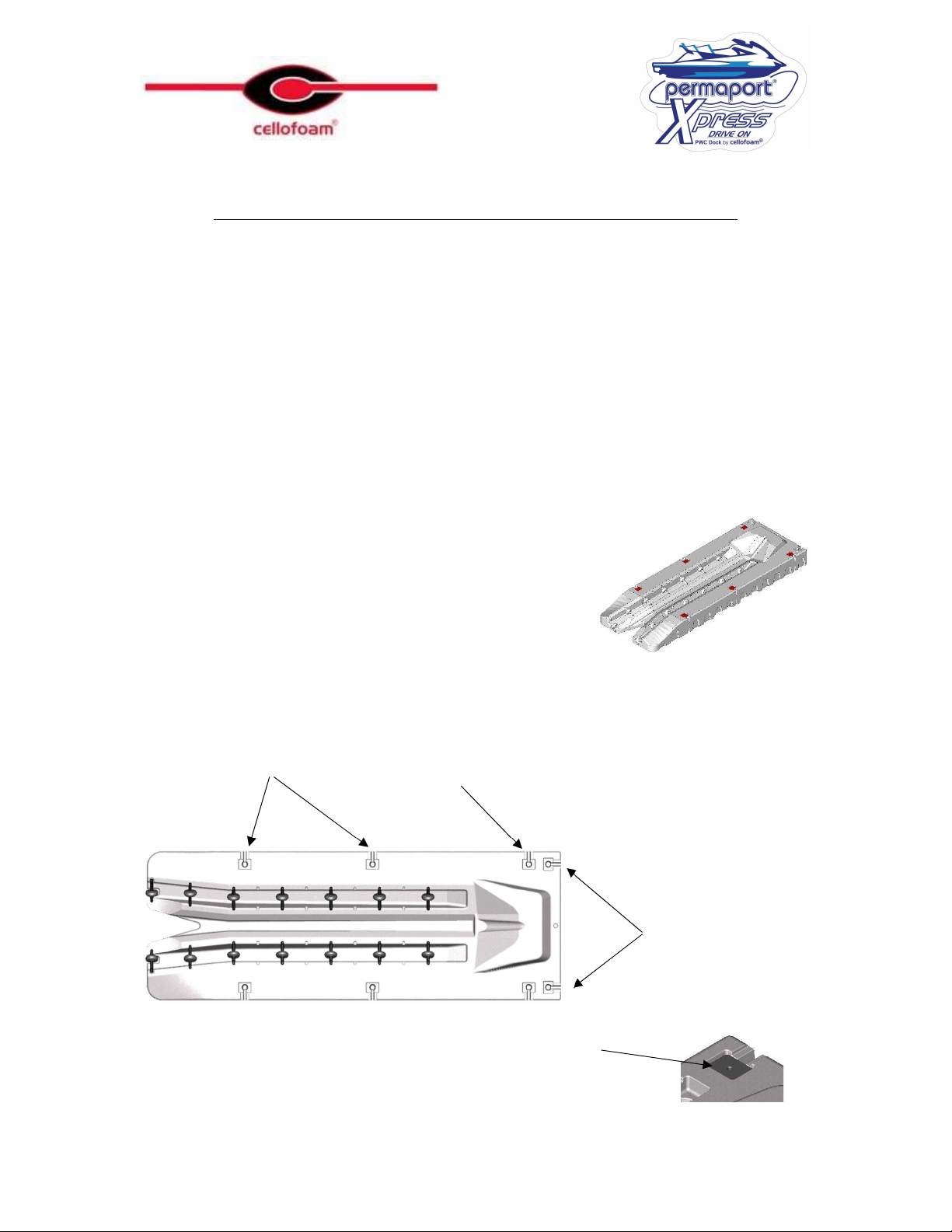

The Permaport has Heavy Duty Steel attachments for long life and durability.

These components are heavy and extend below the water line below the

Permaport. It is inadvisable to swim near, under or from the Permaport due to the

possibility of entrapment or injury from protruding parts.

Entry onto the Permaport is designed to be a low speed operation; it is advisable

that the Watercraft be brought to a complete standstill in line with the Permaport

with the bow keel touching the centered between the first set of rollers. A small

amount of throttle is all that is required in order to propel the watercraft on to the

Permaport. Do not vacate the watercraft until it is fully stationary and the engine

is turned off. WARNING: Over throttling the watercraft upon entry can result in

impacting the dock or sliding too far forward on the Permaport.

Do not load or unload the watercraft with passengers other than the driver.

Ensure that there are no obstructions or persons in the water near the Permaport or

on the Permaport when loading or unloading the watercraft.