Century 974W25 User manual

INSTALLATION, OPERATION, MAINTENANCE & PARTS

NOTE: MANUAL including SPECIFICATIONS, subject to change without notice

All ratings specified are based on structural factors only,

not vehicle capacities or capabilities.

NOTES

OWNER’S MANUAL

Century Wrecker

Item No. 974W25

(Century Model 925)

LEGENDARY

FORM NO. 7205001

7 / 95

PRICE $15.00

CENTURY®

A Division of Miller Industries Towing Equipment Inc.

P.O. Box 120 •8503 Hilltop Drive

Ooltewah, Tennessee 37363

Phone (423)238-4171 •FAX (423)238-5371

CENTURY®

CENTURY®warrants to the original purchaser that each new CENTURY wrecker or other CENTURY

products will be free from defects in material and workmanship for a period of twelve (12) months from

date placed in service, but in no event shall such warranty period exceed twenty-four (24) months from

date of manufacture by CENTURY. The purchaser must promptly notify CENTURY in writing of any

failure in material or workmanship. In no event shall CENTURY accept such notification later than

twenty-four (24) months from date of delivery or twelve (12) months from date placed in service,

whichever is earlier.

CENTURY’s obligation under this warranty, statutory or otherwise, is limited to the repair or

replacement at the CENTURY factory, or at a point designated by CENTURY, of such part or parts as

shall appear upon inspection by CENTURY to be defective in material or workmanship. New or

remanufactured parts will be used for any replacement at CENTURY’s option.

This warranty is not transferable.This warranty does not obligate CENTURY to bear the cost of labor or

transportation charges in connection with the repair or replacement of any parts found to be defective,

nor shall it apply to a product upon which repairs or alterations have been made unless authorized by

CENTURY.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, CENTURY MAKES NO OTHER

WARRANTY, EXPRESS OR IMPLIED, AND HEREBY DISCLAIMS ALL OTHER WARRANTIES

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. CENTURY shall in no event be liable for claimed

downtime, claimed loss of profits or goodwill, or any other special, incidental, indirect, or consequential

damages concerning or relating to any product or parts, whether based on negligence, strict liability,

breach of contract, breach of warranty, misrepresentation or any other legal theory, regardless of

whether the loss resulted from any general or particular requirement which CENTURY knew or had

reason to know about at the time of sale.

CENTURY MAKES NO WARRANTY, EXPRESS OR IMPLIED, AS TO THE FINISHED PRODUCTS

MANUFACTURED OR SUPPLIED BY ANOTHER MANUFACTURER AND SUPPLIED BY CENTURY

TO PURCHASER, including, but not limited to, any vehicle to which a CENTURY product may be

affixed or any accessories or wire rope, and CENTURY EXPRESSLY DISCLAIMS ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AS TO

SUCH EQUIPMENT OR PRODUCTS. This language shall in no way affect or diminish the rights of the

purchaser to rely on such warranties as are extended by such manufacturers or suppliers. CENTURY

shall, to the extent permitted under applicable law, pass on to the purchaser such manufacturer’s or

seller’s warranty.

CENTURY, whose policy is one of continuous improvement, reserves the right to improve its products

through changes in design or materials as it may deem desirable without being obligated to incorporate

such changes in products previously sold. This warranty is not intended to cover or include the

following items, which are set forth by way of example and not limitation:

A. Normal deterioration of trim, paint, lettering, and appearance items due to wear or exposure to

weather, road conditions, road treatments, etc.

B. Any damage or defect due to accident, misuse, abuse, improper or unauthorized repairs, failure

to provide reasonable and necessary maintenance, or uses for which the equipment was not

designed or intended.

C. Alterations or modifications that affect performance, operation or reliability.

D. Normal maintenance parts including, but not limited to, wear pads, bushings, wire rope, mud flaps,

fenderettes, light bulbs, hydraulic oil, filters, and tow sling belts.

IT IS EXPRESSLY UNDERSTOOD THAT CENTURY MAKES NO IMPLIED WARRANTY THAT

CENTURY PRODUCTS SHALL BE FIT FOR THE PURPOSE OF LIFTING OR MOVING PEOPLE

OR FOR ANY OTHER IMPROPER USE.

LIMITED WARRANTY

CENTURY®

A Division of Miller Industries Towing Equipment Inc.

8503 Hilltop Drive •P.O. Box 120

Ooltewah, Tennessee 37363

Telephone (423) 238-4171

SERIAL NUMBER

REVISED 12/1/93

CENTURY®

A Division of Miller Industries Towing Equipment Inc.

8503 Hilltop Drive •

••

•Ooltewah, Tennessee 37363 •

••

•(423) 238-4171

Mailing Address: P.O. Box 120 •

••

•Ooltewah, Tennessee 37363 •

••

•Telex: 856967 CENWKRTN UD

OWNER, USER AND OPERATORS:

CENTURY®appreciates your choice of our wrecker for your

application. Our number one priority is user safety which is best

achieved by our joint efforts. We feel that you can make a major

contribution to safety if you, as the equipment owner and operator:

1. Comply with Federal, State, and Local Regulations.

2. Read, Understand, and Follow the Instructions in this Manual.

3. Use Good, Safe Work Practices in a Common Sense Way.

4. Only have Authorized and Trained Operators running the

Wrecker.

Also contained in this manual is a Parts Section for your Wrecker.

Use of other than Factory or Factory Authorized Parts will render

the Warranty void.

i

© 1995 MILLER INDUSTRIES TOWING EQUIPMENT INC. All rights reserved.

Reproduction or use, without express permission, of editorial or pictorial content, in any

manner, is prohibited.

Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

4A.9 HOOK-UP FOR VEHICLE WITH FLAT TIRE(S) (cont’d)

(i) Raise the vehicle and place blocks on timbers beneath the

flat tire. Lower the Wheel Lift allowing the tire to rest on

the blocking.

(j) Engage parking brake and place transmission in gear (park)

of the disabled vehicle.

(k) Extend Wheel Lift further, allowing the crossbar to compress

the tire further. Re-adjust Tire Restraint as far as possible

into the flat tire. This ensures the rim of the wheel will rest on

the crossbar and tire restraint.

(l) Raise Wheel Lift and remove blocking from beneath the

tire.

(m) Install Safety Strap on flat tire. Refer to Section 4A.7,

SECURING VEHICLE TO BE TOWED.

(n) When tightening Safety Strap around a flat tire be certain it

has the tire completely collapsed. This ensures proper

installation of the strap on a flat tire. See Figure 4A.15.

IVA-11

FIGURE 4A.15

TABLE OF CONTENTS

The operator must read and understand

all instructions in this manual

before operating the wrecker.

ii

It is assumed by CENTURY that the Owner/Operator has thorough

knowledge of the accepted and lawful retrieval and towing methods as

dictated by his city, county, or state. CENTURY rejects any liability claim

that may result from the incorrect or unlawful application of its equipment.

Section I - SAFETY PRECAUTIONS I-1 thru I-15

Section II - SPECIFICATIONS II-1 thru II-5

Section III - OPERATIONAL FUNCTIONS

WRECKER III-1 thru III-5

FORMULA III IIIA-1 thru IIIA-3

Section IV - OPERATING INSTRUCTIONS

WRECKER IV-1 thru IV-8

FORMULA III WITH TILT IVA-1 thru IVA-18

STEERING WHEEL LOCK IVB-1 & IVB-2

Section V - MAINTENANCE V-1 thru V-7

MAINTENANCE RECORD V-6 & V-7

Section VI - PARTS VI-1 thru VI-38

BODY ASSEMBLY VI-2 & VI-3

FORMULA III ASSEMBLY VI-4 & VI-5

FORMULA III HYDRAULICS

STANDARD VI-6 & VI-7

WITH OPTIONAL HAND HELD REMOTE VI-8 & VI-9

OUTER CROSSBAR & LIFT ADAPTERS VI-10 & VI-11

925 WRECKER ASSEMBLY VI-12 & VI-13

Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

IVA-12

4A.10 OUTER CROSS TUBE REMOVAL

(a) Loosen "T" Handles and fully extend Outer Cross Tubes.

(b) Insert a screwdriver or 1/4" rod into Stop Rod Hole located

beside "T" Handle. See Figure 4A.16.

FIGURE 4A.16

(c) While pushing in to release Stop Rod, pull outer crosstube

off the crossbar. To reinstall outer crosstubes, simply

slide them onto the crossbar. The Stop Rod will

automatically engage when slid all the way on. Tighten "T"

Handles.

4A.11 TOW FORK ADAPTERS

(a) Remove outer crosstubes.

(b) Loosen "T" Handles on Fork Adapters and slide onto

crossbar. See Figure 4A.17.

TABLE OF CONTENTS (cont’d)

iii

Section VI - PARTS (cont’d)

925 WRECKER BOOM HYDRAULICS VI-14 & VI-15

WINCH MOTOR HYDRAULICS VI-16

HYDRAULIC CYLINDERS

WRECKER VI-17

FORMULA III VI-18 & VI-19

PUMP & FILTER HYDRAULICS VI-20 & VI-21

CONTROLS & CROSSRODS VI-22 & VI-23

HYDRAULIC WINCH ASSEMBLY VI-24 & VI-25

BOOM END SWIVEL ASSEMBLY VI-26

REAR JACK HYDRAULICS VI-27

LIGHTBAR ASSEMBLY VI-28

HEAVY DUTY TRUCK HITCH VI-29

LIGHT KIT VI-30 thru VI-32

GLAD HAND ASSEMBLY VI-33

AIR OPERATED FREE SPOOL CLUTCH VI-34 & VI-35

KING PIN ASSEMBLY VI-36

CONVENIENCE GROUP VI-37

VERNIER THROTTLE VI-38

Section VII - SCHEMATICS

ELECTRICAL VII-1 thru VII-10

HYDRAULIC VII-11 & VII-12

Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

IVA-13

4A.11 TOW FORK ADAPTERS (cont’d)

FIGURE 4A.17

NOTE

THE FORK ADAPTERS CAN BE PLACED IN ANY OF FOUR

(4) POSITIONS AND ANY LOCATION ON THE CROSSBAR.

SEE FIGURE 4A.18.

FIGURE 4A.18

NOTES Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

IVA-14

4A.12 TOW FORK & ADAPTER APPLICATIONS

(a) Align Wheel Lift with disabled vehicle.

NOTE

STEPS (b) THROUGH (d) ARE NOT NECESSARY

PERMITTING THE AXLE IS HIGH ENOUGH TO ALLOW

EXTENSION OF BOOM WITH FORKS AND ADAPTERS

INSTALLED ON CROSSBAR.

(b) Extend the Boom (without adapters or forks) until crossbar

is centered with axle of disabled vehicle.

(c) Raise vehicle until tire can be blocked up high enough to allow

forks to clear axle when installed onto the crossbar.

(d) Block up tires and lower Boom until boom can be retracted

for installation of adapters and forks.

(e) Install adapters in desired configuration on crossbar. Select

and install desired forks into adapters. Refer to Figure 4A.19.

(f) Extend Boom until Forks are beneath axle or frame as desired.

(g) Manually adjust adapters on crossbar to a point where the

forks will come in contact with the frame or axle in the desired

towing position.

(h) Tighten "T" Handles on adapters. Attach safety chains

around axle or frame, crossbar and forks as shown in

Figure 4A.19.

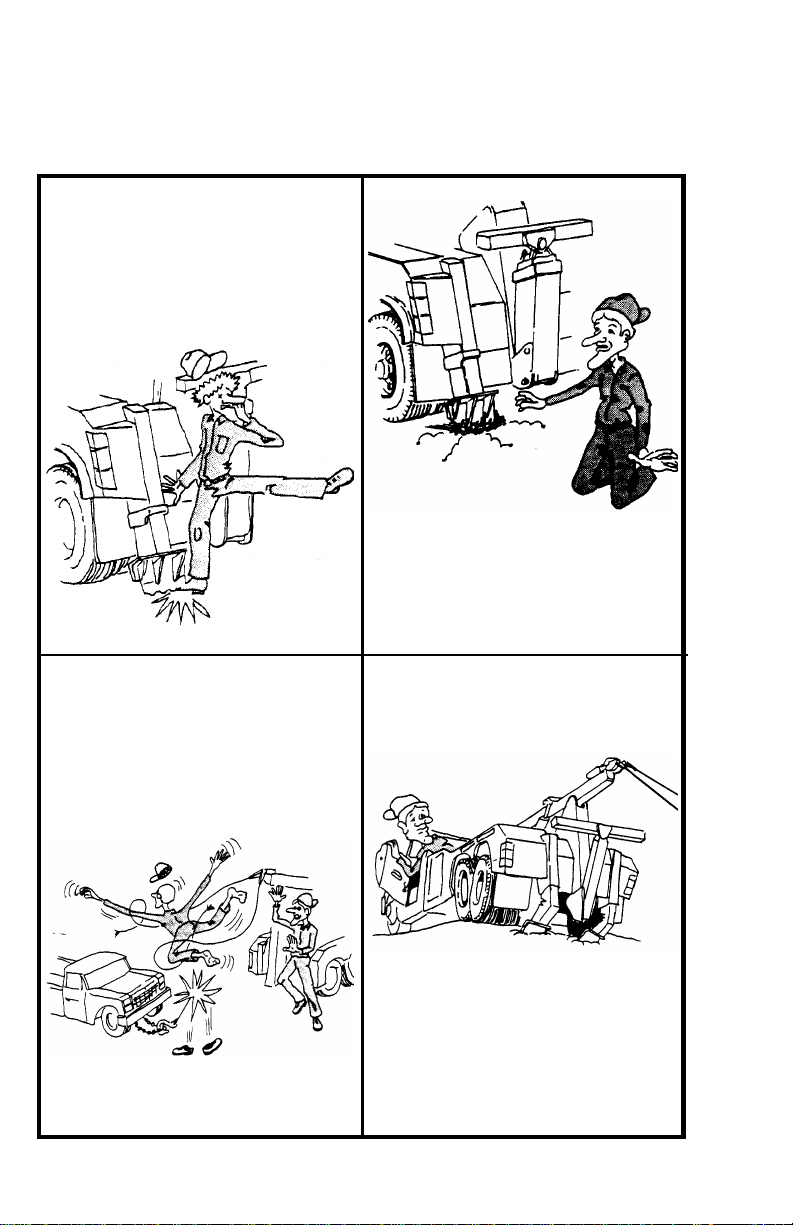

I-1

Section I - SAFETY PRECAUTIONS

Presented in the interest of safety for all wrecker operators.

NOTICE

You are obligated to operate your

wrecker safely. You can be held legally

responsible for injuries or damages

resulting from unsafe operating

practices.

The manufacturer’s recommendations

for operating this wrecker can help you

avoid unsafe practices and their bad

consequences. These

recommendations are contained in this

manual.

Century is not responsible for

the results of any unsafe practice of

wrecker operators. Furthermore, the

division is not responsible for the failure

of the wrecker or its accessories

resulting from improper maintenance.

The danger from an automobile does not cease when it is

disabled or wrecked. Recovering and towing automobiles can

be dangerous, too! The danger threatens wrecker operators

and everyone close at hand. As a wrecker operator you must

develop an awareness of the hazards involved. You must use

every safeguard within reason to prevent injuries.

For each step in operating your wrecker develop the habit of

asking yourself if it is safe to proceed. Carefully check all

rigging (especially snatch blocks) before starting a heavy lift

or pull.

We cannot warn you of all the possible dangers you will

encounter. But we will tell you of the most common hazards

we know about. Learn them well.

Section IVA - OPERATING INSTRUCTIONS

IVA-15

4A.12 TOW FORK & ADAPTER APPLICATIONS (cont’d)

FIGURE 4A.19

(i) Raise vehicle to desired height for towing.

(j) Remove any blocks previously placed under the tires.

(k) Retract Boom pulling disabled vehicle as close to the

Wheel Lift body as possible while maintaining enough

distance for sharp turns.

(l) Raise Boom to desired towing height.

(m) Pull excess Safety Chain back into Storage Caddy. Be

certain to allow enough slack for sharp turns.

USE SAFETY CHAINS

ON ALL TOWING AND

LIFTING APPLICATIONS

WHEEL LIFT (cont’d)

I-2

Section I - SAFETY PRECAUTIONS (cont’d)

1.1 Improper use of this equipment can be dangerous! Incorrect operation

can result in bodily injury to the operator and bystanders. Therefore,

a thorough understanding of the "operating principles" and "operating

instructions" as found in this manual is essential.

1.2 Study each job to be done. Apply common sense judgment to

assure safety to yourself and bystanders.

1.3 Plan ahead. Work safely. Avoid accidental damage and injury. If an

accident or fire does occur, react quickly with the tools and skills at

hand. Know how to use a first aid kit and a fire extinguisher - and

where to get assistance.

1.4 Read and understand the following instructions.

1. READ THE MOUNTING/OPERATING/MAINTENANCE MANUAL

FOR WARNINGS AND PRECAUTIONS.

2. NEVER TAKE ANYTHING FOR GRANTED. DON’T ASSUME THAT

EVERYTHING IS ALL RIGHT AT THE START OF WORK TODAY

JUST BECAUSE EVERYTHING SEEMED ALL RIGHT AT THE END

OF WORK YESTERDAY. BEFORE BEGINNING OPERATION,

THOROUGHLY INSPECT THE ENTIRE WRECKER TO BE SURE IT

IS IN GOOD OPERATING CONDITION.

3. VISUALLY INSPECT THE WRECKER FOR EVIDENCE OF

PHYSICAL DAMAGE, SUCH AS CRACKING, BENDING, OR

DEFORMATION OF PLATES OR WELDS. INSPECT CAREFULLY

FOR CRACKING OR FLAKING OF PAINT, WHICH MAY INDICATE

A DANGEROUS CRACK IN THE STRUCTURE BENEATH. DO NOT

OPERATE UNTIL REPAIRS ARE MADE.

4. LOOSE OR MISSING HARDWARE, BOLTS, NUTS, AND PINS

SHOULD BE PROPERLY TIGHTENED OR REPLACED WITH

MANUFACTURER’S SPECIFIED HARDWARE.

5. CHECK FOR FLUID LEAKS. HYDRAULIC SYSTEM MUST BE

CORRECTED BEFORE THE WRECKER IS OPERATED.

Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

IVA-16

FIGURE 4A.20

SAFETY CHAIN MUST BE SEATED IN BOTTOM OF SLOT

BEFORE ATTEMPTING TO TOW VEHICLE.

SEE FIGURE 4A.20

4A.12 TOW FORK & ADAPTER APPLICATIONS (cont’d)

4A.13 SPRING LIFT BRACKETS

(a) Align Wheel Lift with disabled vehicle.

(b) Position fork adapters in desired configuration on crossbar,

secure them in place with retaining pins and install spring lift

brackets into fork adapters. See Figure 4A.21.

I-3

Section I - SAFETY PRECAUTIONS (cont’d)

INSPECT ALL HYDRAULIC HOSES, ESPECIALLY THOSE WHICH

FLEX OR MOVE IN SERVICE, AND REPLACE IF NECESSARY.

SECURE ALL CAPS AND FILLER PLUGS FOR ALL SYSTEMS.

6. YOUR CLOTHING SHOULD BE RELATIVELY CLOSEFITTING.

7. ALWAYS WEAR PROTECTIVE ITEMS SUCH AS SAFETY

GLASSES, GLOVES, REFLECTIVE CLOTHING AND SAFETY

SHOES.

8. BEFORE OPERATING THE BOOM, REFER TO THE BOOM

CAPACITY LABELS ON THE BOOM AND INSIDE THE DOOR OF

THE CAB AND IN THE SPECIFICATIONS SECTION OF YOUR

OPERATING MANUAL. FOR CHASSIS CAPACITY, CONSULT

YOUR TRUCK DEALER. NEVER EXCEED MANUFACTURER’S

LOAD RATING. THE STIPULATIONS PERTINENT TO THESE

RATINGS SHALL ALWAYS BE CAREFULLY OBSERVED. RATINGS

SHOWN ARE BASED ON THE HYDRAULIC, MECHANICAL, OR

STRUCTURAL DESIGN OF THE WRECKER RATHER THAN

STABILITY. IT IS ALWAYS UNSAFE TO APPLY ANY LOAD WHICH

IS GREATER THAN RATED LOAD SHOWN ON THE DATA PLATE.

9. DO NOT USE THIS EQUIPMENT EXCEPT ON SOLID, LEVEL

SURFACE WITH STABILIZERS PROPERLY EXTENDED AND

TRUCK BRAKES LOCKED.

10. OPERATE ALL CONTROLS SLOWLY AND SMOOTHLY TO

AVOID DAMAGE TO WRECKER OR INJURY TO PERSONNEL.

11. DO NOT OPERATE, WALK OR STAND BENEATH BOOM OR A

SUSPENDED LOAD.

12. NEVER LIFT LOAD OVER ANYONE.

13. DO NOT USE BOOM TO LIFT PEOPLE.

14. KEEP LOAD WITHIN ONE FOOT OF THE GROUND WHENEVER

POSSIBLE.

15. FOR TRAVEL, BOOM MUST BE IN STOWED POSITION AND

P.T.O. DISENGAGED.

IVA-17

FIGURE 4A.18

(c) Extend boom until spring brackets are under front spring

hangers of vehicle to be towed. It may be necessary to tilt

the boom down in order for the spring brackets to clear the

vehicle bumper.

(d) Manually adjust spring lift bracket on crossbar to a point

where the forks will engage the springs at the front hanger

brackets. See Figure 4A.22.

FIGURE 4A.21

4A.13 SPRING LIFT BRACKETS (cont’d)

WHEEL LIFT (cont’d)

Section IVA - OPERATING INSTRUCTIONS

I-4

Section I - SAFETY PRECAUTIONS (cont’d)

ONLY AUTHORIZED AND TRAINED PERSONNEL

SHOULD BE PERMITTED TO OPERATE THIS WRECKER

UNSUPERVISED

TRAINED PERSONNEL ARE THOSE WHO HAVE WORKED

UNDER EXPERIENCED SUPERVISION AND HAVE PERFORMED

ALL WRECKER MANEUVERS, HAVE READ THE MOUNTING,

OPERATING AND MAINTENANCE MANUAL, WARNINGS AND

PRECAUTIONS, AND UNDERSTAND AND HAVE HAD

EXPLAINED TO THEM BY THEIR EMPLOYER THE HAZARDS OF

OPERATING THE WRECKER. THEY MUST BE FAMILIAR WITH

THE HAZARDS OF OPERATING AT A SITE WHERE ELECTRIC

POWER LINES, IRREGULAR GROUND CONTOUR, WATER, ICE,

MUD, OR OTHER CONDITIONS CAN INTERFERE WITH

ORDINARY CAREFUL OPERATION OF THIS WRECKER.

AN UNTRAINED OPERATOR SUBJECTS HIMSELF AND

OTHERS TO DEATH OR SERIOUS INJURY.

STAND CLEAR

WHILE OPERATING

OUTRIGGERS

USE SAFETY CHAINS

ON ALL TOWING AND

LIFTING APPLICATIONS

Section IVA - OPERATING INSTRUCTIONS

WHEEL LIFT (cont’d)

4A.13 SPRING LIFT BRACKETS (cont’d)

(e) Raise the boom until the spring lift brackets are properly

seated under the springs at the front spring brackets. See

Figure 4A.22.

(f) Insert the spring lift bracket retaining pin through the lowest

unobstructed hole of the spring lift bracket and secure with

the safety pin.

(g) Attach safety chains around the springs, brackets and

crossbar in such a manner as to prevent any movement to

front or rear.

(h) Raise the vehicle to the desired height for towing and retract

boom pulling vehicle as close as possible while maintaining

enough distance for sharp turns.

IVA-18

I-5

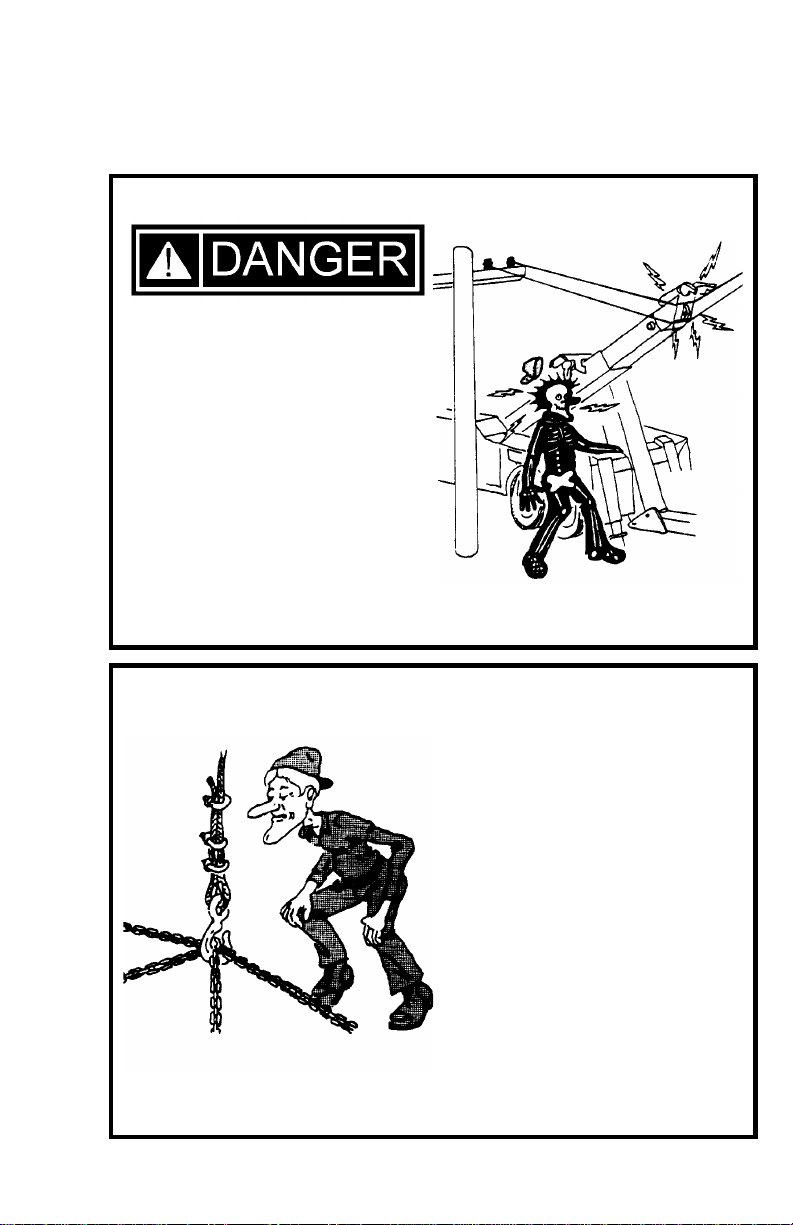

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Death or serious injury can

occur when working near

power lines.

Learn - beforehand - as

much about your working

area as possible. Be sure

that exact locations of

overhead power lines, and

other obstructions or

hazards are known.

Don’t use winch cables with

hooks attached by means of

cable clips. Use only cables with

hooks attached by means of

thimbles and machine swaged

terminals.

USE CABLE CLIPS ONLY IN

THE EVENT OF AN

EMERGENCY FIELD

TEMPORARY REPAIR.

Use at least three clips spaced

3-4 inches apart and reduce the

cable working limit by 20%.

U-bolt of the clip should never be

around the live or long end of the

cable. Replace clips as soon as

possible with swaged cable

termination.

IVB-1

FIGURE 4B.1

2. Turn steering wheel so that front wheels are directed straight

ahead.

3. Insert latch of steering wheel lock into its buckle. Make sure

it locks in place. See Figure 4B.1.

4. Place steering wheel grip on bottom of steering wheel and

secure it by tightening jam nut against sliding clamp.

5. Hook seat grip under the front edge of auto seat or to a rigid

seat frame member that is securely fastened in place. Make

sure you do not hook it to a removable seat cushion.

6. Grasp the free end of the belt and pull until belt is tight.

7. Recheck jam nut to make sure it is still tight.

CARS WITH ANTI-THEFT STEERING LOCKS

SHOULD NEVER BE TOWED ON THEIR FRONT WHEELS

WHILE LOCKED IN THE TURNED POSITION

4B.1 INSTRUCTIONS FOR INSTALLATION

1. Unlock anti-theft steering lock if vehicle is equipped with one.

STEERING WHEEL LOCK

Section IVB - OPERATING INSTRUCTIONS

I-6

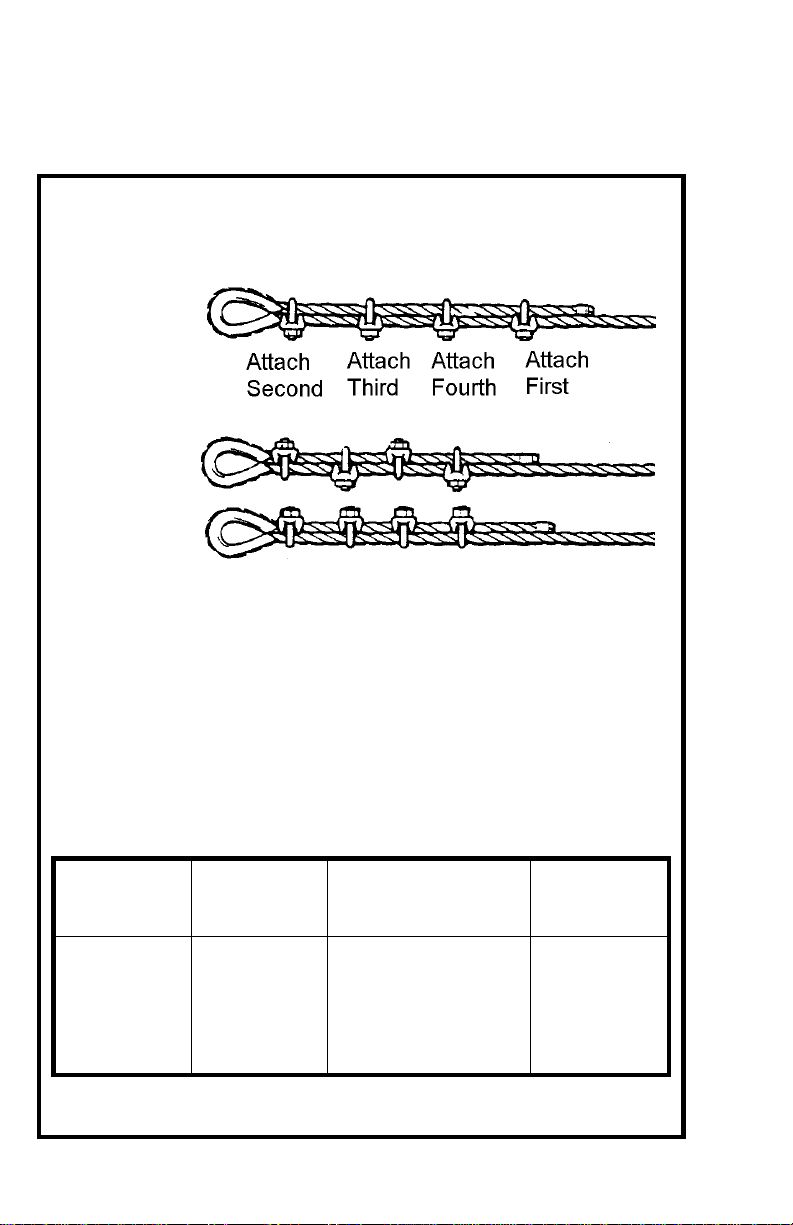

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Proper technique for using wire rope clips.

USE CABLE CLIPS ONLY IN THE EVENT OF AN EMERGENCY

FIELD TEMPORARY REPAIR.

RIGHT

WAY

WRONG

WAY

1. Turn back rope length specified in the chart. Apply first clip so

U-bolt is no less than the saddle width from the dead end. Tighten

nuts evenly and torque as specified.

2. Apply next clip as near loop as thimble will permit. Turn nuts on

firm, but do not tighten.

3. Space additional clips as indicated so distance between clips is

equal. Tighten all nuts evenly and torque as specified.

4. Apply the initial load and retighten all nuts to recommended torque

Inspect periodically and retighten as needed to the recommended

torque.

CLIP SIZE

INCHES MINIMUM

NO. OF CLIPS AMOUNT OF ROPE

TO TURN BACK

IN INCHES

TORQUE

IN FT.LBS.

3/8

7/16

1/2

9/16

5/8

3/4

2

2

3

3

3

4

6 1/2

7

11 1/2

12

12

18

45

65

65

95

95

130

This table is based on Crosby-Laughlin.

IVB-2

4B.2 INSTRUCTIONS FOR REMOVAL

1. Press button on buckle of steering wheel lock, releasing the

latch.

2. Loosen jam nut and remove grip from steering wheel.

3. Unhook seat grip from seat or seat frame.

FAILURE TO PROPERLY SECURE AND TIGHTEN

THE STEERING WHEEL LOCK

COULD RENDER IT INEFFECTIVE DURING TRAVEL,

RESULTING IN A DANGEROUS TOWING CONDITION

4B.1 INSTRUCTIONS FOR INSTALLATION (cont’d)

Section IVB - OPERATING INSTRUCTIONS

STEERING WHEEL LOCK

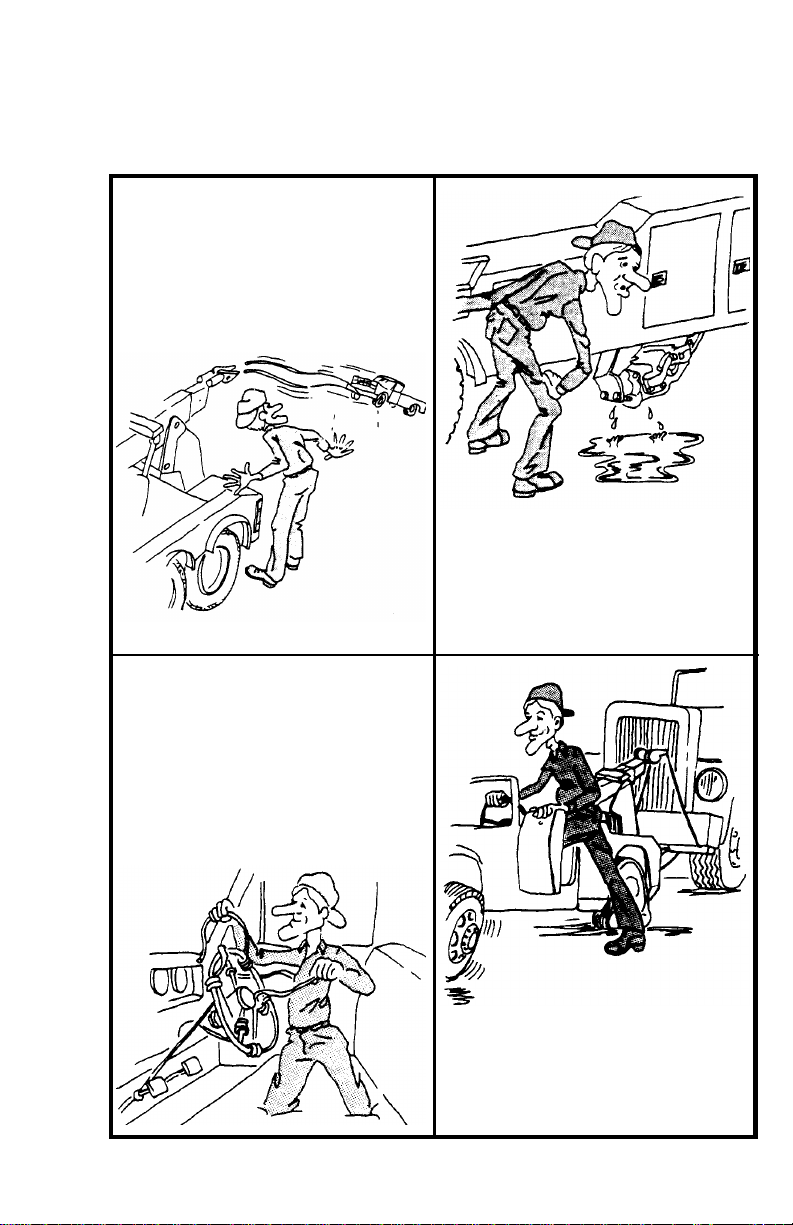

I-7

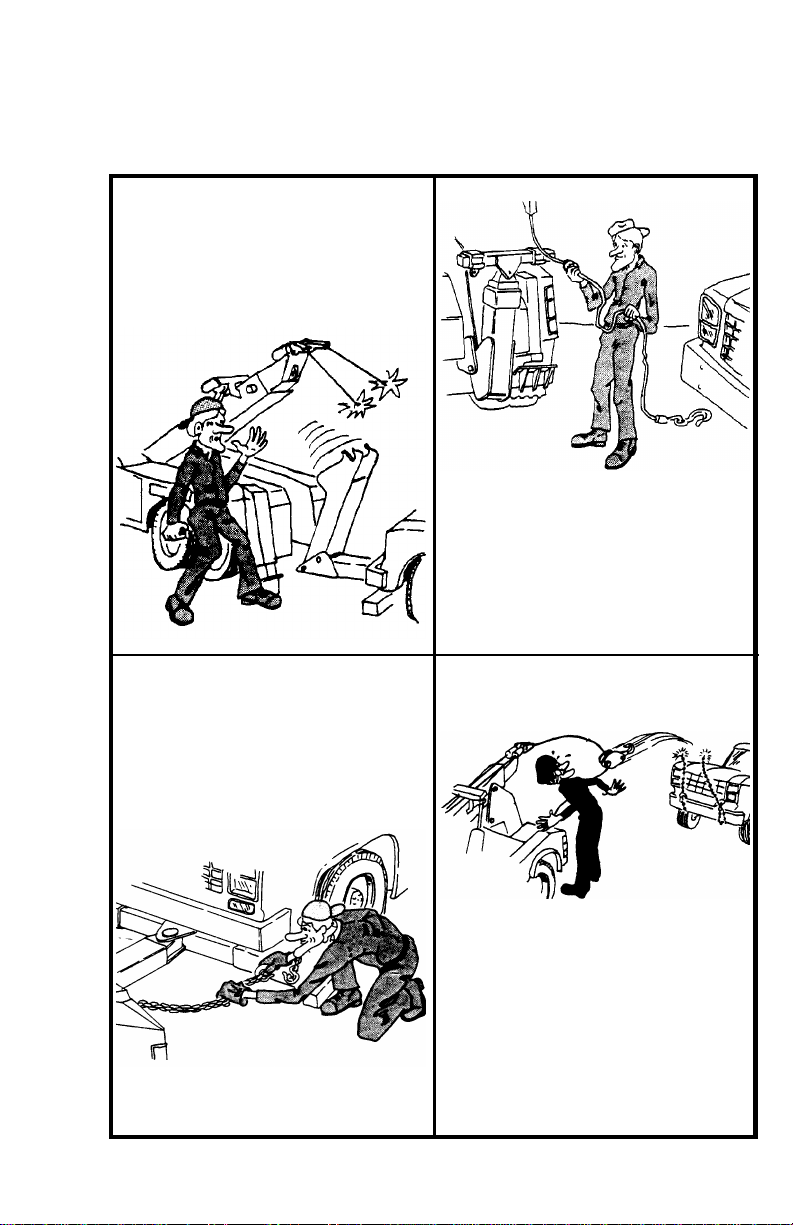

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t use a wrecker that has not

been properly maintained. Pay

special attention to wrecker

mounting bolts, cable condition,

and lubrication of moving parts.

Don’t use damaged cables on

your wrecker. Become familiar

with the various types of cable

damage and carefully inspect all

cables being used in a recovery

operation before starting to pull.

Always use two safety chains

when towing all vehicles,

regardless of distance.

After rigging cables, don’t begin

pulling without rechecking

connections. Make sure that all

cables and snatch blocks are

securely attached and cannot

accidentally pull loose.

5.1 The continued operation of your CENTURY Hydraulic Wrecker

is largely dependent upon strict adherence to a properly scheduled

preventive maintenance program. To help you in this program,

CENTURY has provided the following information regarding

lubrication, preventive maintenance and hydraulic system care.

5.2 HYDRAULIC SYSTEM

The importance of absolute cleanliness of the hydraulic system

cannot be over-stressed. The smallest amount of grit, metal flake or

other foreign material in the system can cause extensive damage to

pumps, motors and valves. CENTURY has taken every measure to

assure that each component and fitting was thoroughly cleaned

before your unit was shipped to you. Therefore, servicing of the

system should be done with extreme care.

(a) Before checking oil level in reservoir, wipe away all dirt, grease

and grime around filler cap before removing it. Make certain that

all containers, funnels and pouring spouts are absolutely clean

before filling reservoir.

(b) When replacing hoses, fittings or other components, clean

thoroughly; then assemble carefully.

(c) Failure to observe these precautions, and failure to change the

filter element at regular intervals could result in loss of your

warranty in the event of failure of certain components.

5.3 LUBRICATION & PREVENTIVE MAINTENANCE

The following general lubrication and preventive maintenance

should be performed at least once per month for moderate usage

or more often as required, for heavy usage.

(a) Inspect, repair or replace any worn, cracked, leaking, otherwise

damaged components including, but not limited to, the following:

1. Hydraulic Oil Filter

2. Oil Reservoir

3. Controls

4. Cables and Fittings

5. Hydraulic Hoses and Fittings

6. Lights and Wiring

7. Winches

8. Cylinders

9. Pivot Bearing Surfaces and Pins

(See Lubrication Charts, page V-4 & V-5.)

V-1

Section V - MAINTENANCE

I-8

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t expect your wrecker to tow

loads equal to the wrecker rating.

Wrecker ratings apply to loads

imposed during recovery with the

wrecker properly stabilized.

Don’t pull a load with your winch

without making absolutely sure

that the winch drum clutch is

FULLY engaged.

Don’t attempt to recover heavy

loads without first estimating the

amount of pull that will be

required. Rig to keep the

estimated amount of pull well

within equipment ratings.

Don’t exceed ratings of booms,

cables, snatch blocks, or winches.

Stay within nameplate ratings.

Note that boom ratings decrease

significantly as boom is extended.

Section V - MAINTENANCE (cont’d)

5.3 LUBRICATION & PREVENTIVE MAINTENANCE (cont’d)

(b) Check hydraulic oil level in reservoir and fill to proper level.

Refer to 5.4, SUMMARY OF REQUIRED LUBRICANTS for

recommended oils to use.

(c) Replace hydraulic oil filters after first week of operation, then

every three (3) months thereafter.

(d) Inspect all bolts for tightness and re-tighten as necessary.

Vibration and stress may loosen even properly torqued bolts.

(e) Lubricate all grease fittings on the Wrecker and Wheel Lift weekly

including:

1. Bellcranks and Control Handle Shafts

2. Winch

3. Cables

3.Cylinder Pivot Bearings

4.Cross Bar Pivot

5. Boom and Wheel Lift Slide Pads

6.Boom End Swivels

(f) All bearing surfaces not equipped with grease fittings should

be oiled using SAE 30 oil in a pump can.

(g) Check oil level of winches and fill to proper level, level plug

on end plates, with SAE 140 general purpose gear oil.

(h) Lubricate grease fitting on winch freespool clutch control.

(i) Lubricate winch cables using an oily rag while respooling onto

drum. Other special cable lubricants are available which have

better penetrating qualities. Consult your local oil company for

a list of these.

V-2

I-9

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t get under a raised vehicle or

load unless it has adequate safety

blocks in place.

Don’t exceed WORKING LIMIT

ratings of cable. Use breaking

strength ratings only for selecting

replacement cable.

Don’t tie down the front end of

your wrecker for recovery work or

heavy lifts. You are apt to damage

the truck frame if you do.

Don’t disengage the winch drum

clutch while the winch cable is

loaded.

Section V - MAINTENANCE (cont’d)

V-3

5.5 CARE OF HYDRAULICS IN COLD CLIMATES

Regions subject to continuous sub-zero or arctic climates require

special hydraulic fluids. Contact CENTURY or your local supplier for

information regarding specific temperature requirements.

NOTE

THERE IS NO PRACTICAL WAY TO DETERMINE

THE LIFE EXPECTANCY OF HYDRAULIC HOSES

AND OTHER RUBBER COMPONENTS.

WHILE APPEARING TO BE IN EXCELLENT CONDITION, THESE

COMPONENTS MAY BE ADVERSELY AFFECTED BY

USAGE, WEATHER OR THE PASSING OF TIME.

THEREFORE, IT IS RECOMMENDED THAT ALL

RUBBER COMPONENTS, ESPECIALLY HOSES, BE REPLACED

EVERY FIVE (5) YEARS REGARDLESS OF APPEARANCE.

5.4 SUMMARY OF REQUIRED LUBRICANTS

(a) Hydraulic Oil

Examples:

1. Texaco Rando HD 46

2. Shell Tellus Oil 46

3. Mobil Nuto H46

or EQUAL

(b) Winch Worm Gear Oil - SAE 140 general purpose gear oil.

Examples:

1. Humble - Pen-O-Led EP #5

2. Phillips - Phillips Worm Gear Oil 140

3. Shell - Macona #978

4. Sinclair - Pennant EP #6

5. Standard - Stanogear #5

6. Texaco - Maropa #5

(c) Grease - Synthetic Fortified such as Drydene SFG.

(d) Oil for miscellaneous bearing surfaces - SAE 30.

(e) Cable Oil - SAE 30 or special cable lubricant.

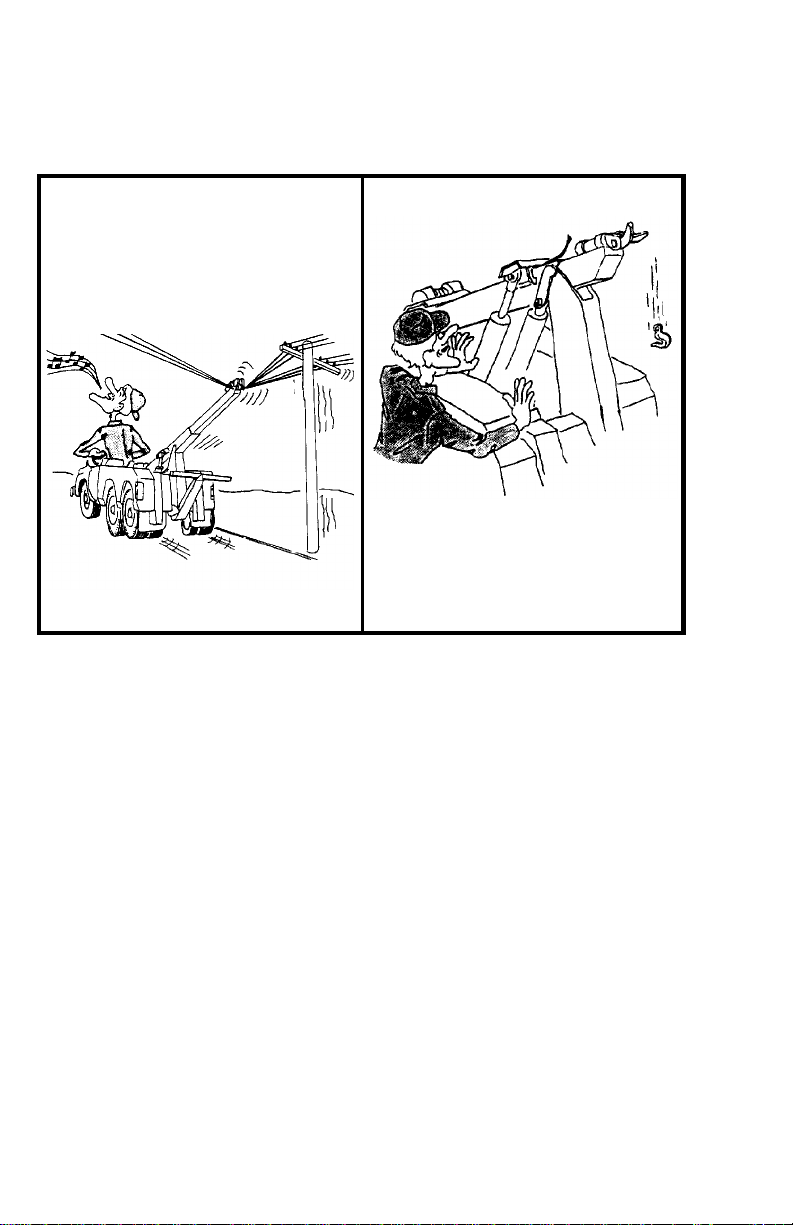

I-10

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t lower out board legs or rear

jack spades unless the area under

them is clear. Pay particular

attention to keeping this area clear.

Don’t use rear spades on paved

surfaces unless you are willing to

accept responsibility for possible

damage to such surfaces.

Don’t permit bystanders in the

area while performing recovery

work.

Don’t move your wrecker while

either outboard legs or rear

spades are extended.

Section V - MAINTENANCE (cont’d)

V-4

NOTE

THE ABOVE SERVICE REQUIREMENTS

SHOULD BE SERVICED MONTHLY.

SERVICE MORE OFTEN IF THE EQUIPMENT

IS USED FREQUENTLY.

5.6 LUBRICATION - WRECKER

1. Control Handle Shafts - synthetic fortified grease

2. Cable - oily rag or approved cable lubricant

3. Winches - SAE 140 gear oil to proper level

4. Cylinder Pivot Bearings - synthetic fortified grease

5. Winch Freespool - synthetic fortified grease

6. Hydraulic Reservoir - approved hydraulic fluid to proper level

7. Hydraulic Filters - replace after first week then every three

(3) months

8. Boom End Swivels - synthetic fortified grease

9. Sheaves - synthetic fortified grease

10. Extended/Lift Cylinders - synthetic fortified grease

11. Boom Slide Pads - synthetic fortified grease

12. Door Hinges - synthetic fortified grease

LUBRICATION CHART (Wrecker)

I-11

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t completely unwind all cable

from a winch while loaded. Keep

AT LEAST five wraps on the drum.

Don’t operate your wreckers

engine faster than recommended.

Excessive speeds can damage

PTO shafts, hydraulic pumps, and

winches.

Don’t rely on anti-theft steering

locks to secure the steering

wheel. Use a special steering

wheel clamping device. Rope is

commonly used to secure steering

wheels, but that is not as reliable

as devices designed for this

purpose.

Don’t tow a vehicle that reduces

the weight on the front wheels of

your wrecker more than 40

percent.

Section V - MAINTENANCE (cont’d)

V-5

NOTE

THE ABOVE SERVICE REQUIREMENTS

SHOULD BE SERVICED MONTHLY.

SERVICE MORE OFTEN IF THE EQUIPMENT

IS USED FREQUENTLY.

5.7 LUBRICATION - WHEEL LIFT

1. Lift Cylinder Pivot Bearings - synthetic fortified grease

2. Upper Arm Assembly - synthetic fortified grease

3. Tilt Cylinder - synthetic fortified grease

4. Wheel Lift Outer Boom - synthetic fortified grease

5. Wheel Lift Inner Boom - synthetic fortified grease

6. Wheel Lift Pivot Pin - synthetic fortified grease

7. Tire Restraint Plunger - synthetic fortified grease

LUBRICATION CHART (Wheel Lift)

I-12

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t use towing forks that are not

of proper size for pick-up

requirements.

After you have hooked up a

vehicle for towing, don’t start the

tow until you have double checked

the hook-up, installed safety

chains, and released the parking

brakes of the towed vehicle.

Don’t travel with the wrecker PTO

engaged. Engage it only while

operating the wrecker controls.

Don’t tow a vehicle on its drive

wheels unless steps have been

taken to protect its transmission

and differential. Follow

recommendations of the vehicle

manufacturer. As an alternative,

use a towing dolly.

Section V - MAINTENANCE (cont’d)

MAINTENANCE RECORD

DATE MECHANIC WEEKLY * MONTHLY QUARTERLY SERVICE PERFORMED

* IMPORTANT: HYDRAULIC HOSES AND CABLES SHOULD BE INSPECTED

WEEKLY FOR SIGNS OF ABRASION.

V-6

I-13

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

Don’t tow a vehicle on its front

wheels if they are damaged.

Don’t tow a vehicle on its front

wheels unless the steering wheel

is secured with the front wheels

straight ahead.

Don’t tow a vehicle at night

without proper signal lights on the

towed vehicle and the wrecker.

Don’t drive wrecker with boom

elevated.

Section V - MAINTENANCE (cont’d)

MAINTENANCE RECORD

DATE MECHANIC WEEKLY * MONTHLY QUARTERLY SERVICE PERFORMED

* IMPORTANT: HYDRAULIC HOSES AND CABLES SHOULD BE INSPECTED

WEEKLY FOR SIGNS OF ABRASION.

V-7

I-14

Section I - SAFETY PRECAUTIONS (cont’d)

SAFETY TIPS

SAFE TOWING

Don’t move wrecker or extend

boom where overhead power lines

may be encountered.

Don’t continue to wind in winch

cable after the hook is against the

boom end.

There are two key factors in safe towing:

1. Have enough front axle weight for safe steering.

2. Avoid excess rear axle weight.

The issue here is safety. Unsafe steering may cause a serious accident.

It is recommended that a safe steering formula that maintains at least 40

percent of the UNLADEN (unloaded) front axle weight, for towing, be

used.

That formula is expressed as follows: ML =.6 FAW x WB/OH

where:

ML = maximum lifted load for safe steering.

FAW = unladen (unloaded) weight at front axle.

WB = wheel base or distance between the center of the

front axle to the center of the rear axle(s).

OH = overhang or distance from the center of the rear

axle(s) to the lift point of the towing device.

NOTES

This manual suits for next models

1

Table of contents