Bin TrailerT. G. Schmeiser Co., Inc.

Ph. (559) 268-8128

Fax (559) 268-3279

www.tgschmeiser.com

3

ASSEMBLY AND OPERATION.............................16

Attaching to Pulling Vehicle................................16

Initial Setup Checklist.........................................16

Implement Break-In............................................16

Operation Instructions........................................16

Detaching from Pulling Vehicle............................17

Features and Options.......................................17

Transition Ramps.....................................17

Platforms and Fenders............................17

MAINTENANCE.......................................................18

Lubrication Points...............................................18

Pull Frame Hinges...................................18

Wheel Hub Bearings.................................18

Service Items......................................................18

Tires...........................................................18

Rollers.......................................................18

Maintenance Schedule.......................................19

STORAGE................................................................20

Storage Preparation...........................................20

Placing in storage...............................................20

Removing From Storage..................................20

Disposal of Equipment at End of Useful Life...20

PARTS SECTION.....................................................21

Ordering Parts....................................................21

Parts Drawings...............................................21

2-Bin Narrow with Transition Ramps..........21

Narrow models with Adjustable Stops........22

Standard models with Adjustable Stops.....23

Standard models with Platforms and

Fenders......................................................24

Tire and Wheel Hub Ass’y (Standard)........25

Tire and Wheel Hub Ass’y (Narrow)............26

LIMITED WARRANTY STATEMENT.....................27

CONTENTS

INTRODUCTION........................................................4

Engineered for Long Life...................................4

Serial Number Information....................................4

Replacement Parts................................................4

Warranty Information............................................4

Serial Number Location.........................................4

Factory Contact Information..................................4

Dealer Contact Information....................................4

SPECIFICATIONS......................................................5

FEATURES.................................................................5

OPTIONS....................................................................5

SAFETY......................................................................6

Safety Alert Symbols............................................6

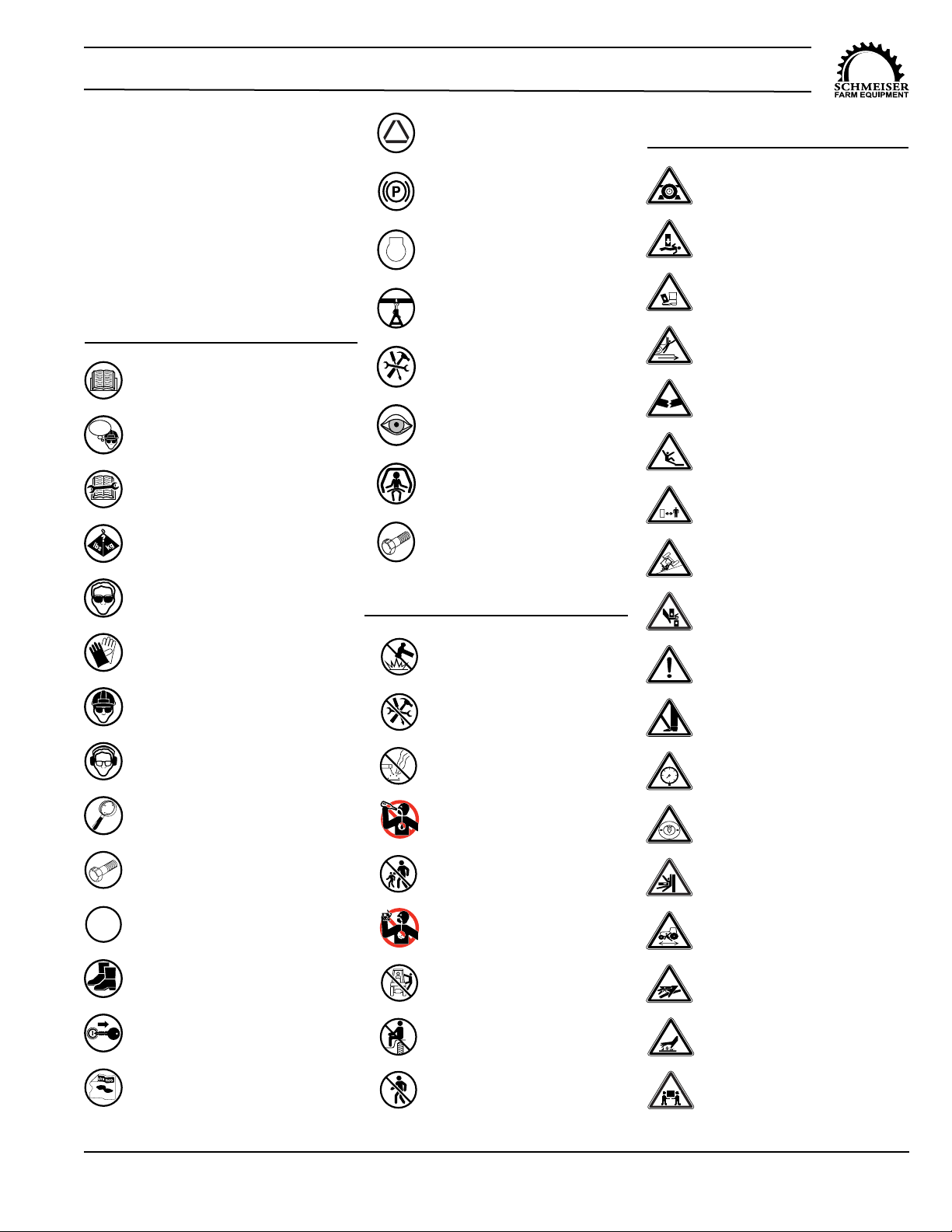

Safety Icons Nomenclature..................................7

Personal Protection/Important Information..7

Prohibited Actions........................................7

Hazard Avoidance.......................................7

General Safety......................................................8

Assembly Safety...................................................8

Towing Safety.......................................................9

Safety Chain................................................9

Operation Safety.................................................10

Tractor Requirements................................10

Tractor Safety Devices..............................11

ROPS and Seat Belt..................................11

Attaching to Tractor............................................11

Prior to Connecting Unit ............................11

Connecting to the Tractor..........................11

Maintenance Safety............................................12

Tire Safety.................................................12

Bolt Torque Requirements.........................12

Tire and Lug Torque Specifications...........13

Welding Repairs........................................13

Storage Safety...................................................13

SAFETY SIGNS AND DECALS............................14

Safety Sign and Decals Placement...............14

Safety Signs and Decals...................................15