8

Operation and Maintenance

Model Number 060-0198-6 Trailer Sprayer

Operation

Operating power is obtained from a 12 volt

Battery. Be sure to connect the red to the

positive (+) source and attach the black to

the negative (-) source.

IMPORTANT: Before spraying chemicals, ll the

tank full of plain water to gain familiarization

with the sprayer and to prevent the waste of

expensive chemicals.

Maintenance Instructions

This sprayer has been carefully designed

and built and should provide many years

of reliable service if properly cared for.

• Keeping the sprayer clean and dry will

prolong the unit’s life.

• Grease Wheels at regular intervals, at least

once every six months, more frequently if

used regularly.

• Should rust develop, sand lightly then paint

area with enamel paint.

• Check tire pressure at regular intervals

Proper inflation will prolong the life of tires

(see side of tire for inflation amount).

Cleaning and Storage

Most spray materials are highly corrosive.

The most important aspect of long dependable

service from your sprayer is a thorough cleaning

immediately following each use. In addition,

the residue of one type of chemical could

cause an undesirable eect when a dierent

chemical is used for a dierent purpose.

The most eective cleaning method is to

pump several rinses of clean water through

the tank, pump, hoses, boom, spray gun, etc.

A neutralizing agent such as a solution of

Nutra-Sol, a detergent or household ammonia

as recommended by the chemical manufacturer

can assist in removal of a persistent chemical.

When the system is thoroughly cleaned, drain

the tank, suction line, pump, hoses, etc.

1. Wash and flush out sprayer after comple-

tion of each phase of your program. Flush out

sprayer when changing chemicals if there is a

possibility of the chemicals being incompatible.

Use of a detergent is advisable if the chemical

manufacture does not make specific cleaning

recommendations. Flush system completely,

including nozzles. Never use metal objects to

open clogged nozzles.

2. Clean sprayer thoroughly before storing at

the end of the spraying season. Permanent type

antifreeze added to the nal rinse will leave a

rust inhibiting film on parts of the sprayer.

STOP

Parts and Support

Please do not return this product to the

store prior to contacting Certified

TM.

At Certified

TM our goal is to deliver quality, value

and outstanding service. If for any reason our

product does not meet your expectations, please

contact us and we will take care of any problem

you may have with this unit.

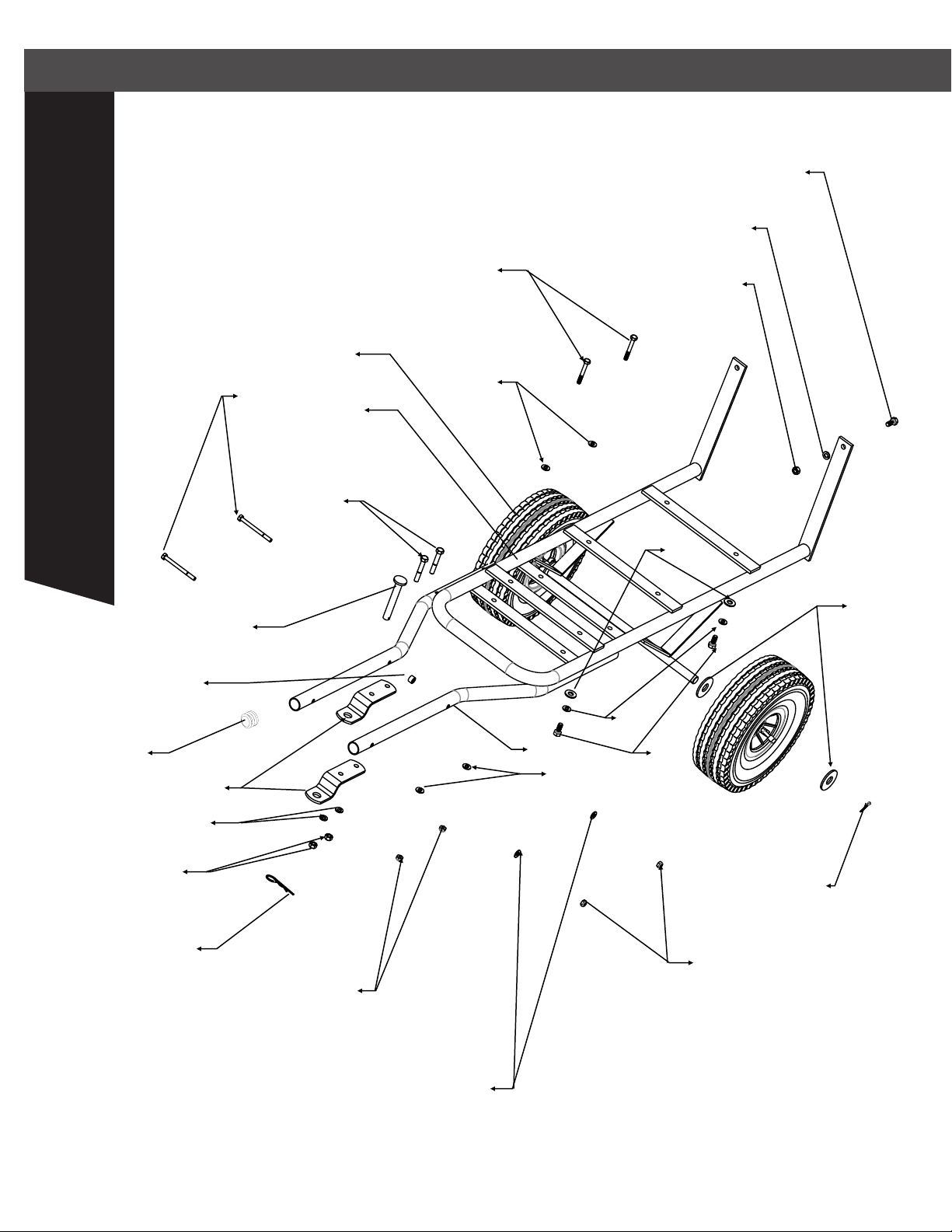

When ordering replacement parts please have

the model number, part description, part

number, inspector number and date on carton

available so that we can best serve you.

1 (844) 428-7277

MADE IN U.S.A

TRILEAF DISTRIBUTION

TRIFEUIL TORONTO,

CANADA M4S 2B8