CET s.r.l. Parallel Message Display

page 1

INDICE

1. INTRODUCTION........................................................................................................................................2

1.1. GENERAL DESCRIPTION OF THE DIFFERENT MODELS................................................................2

1.1.1. FMC 202.......................................................................................................................................2

1.1.2. EMC 202 ......................................................................................................................................2

1.1.3. EMC 402 ......................................................................................................................................3

1.1.4. EMF 202.......................................................................................................................................3

1.1.5. EMF 402.......................................................................................................................................3

1.1.6. AMF 401.......................................................................................................................................3

1.1.7. AMF 402.......................................................................................................................................3

1.1.8. BMF 202.......................................................................................................................................3

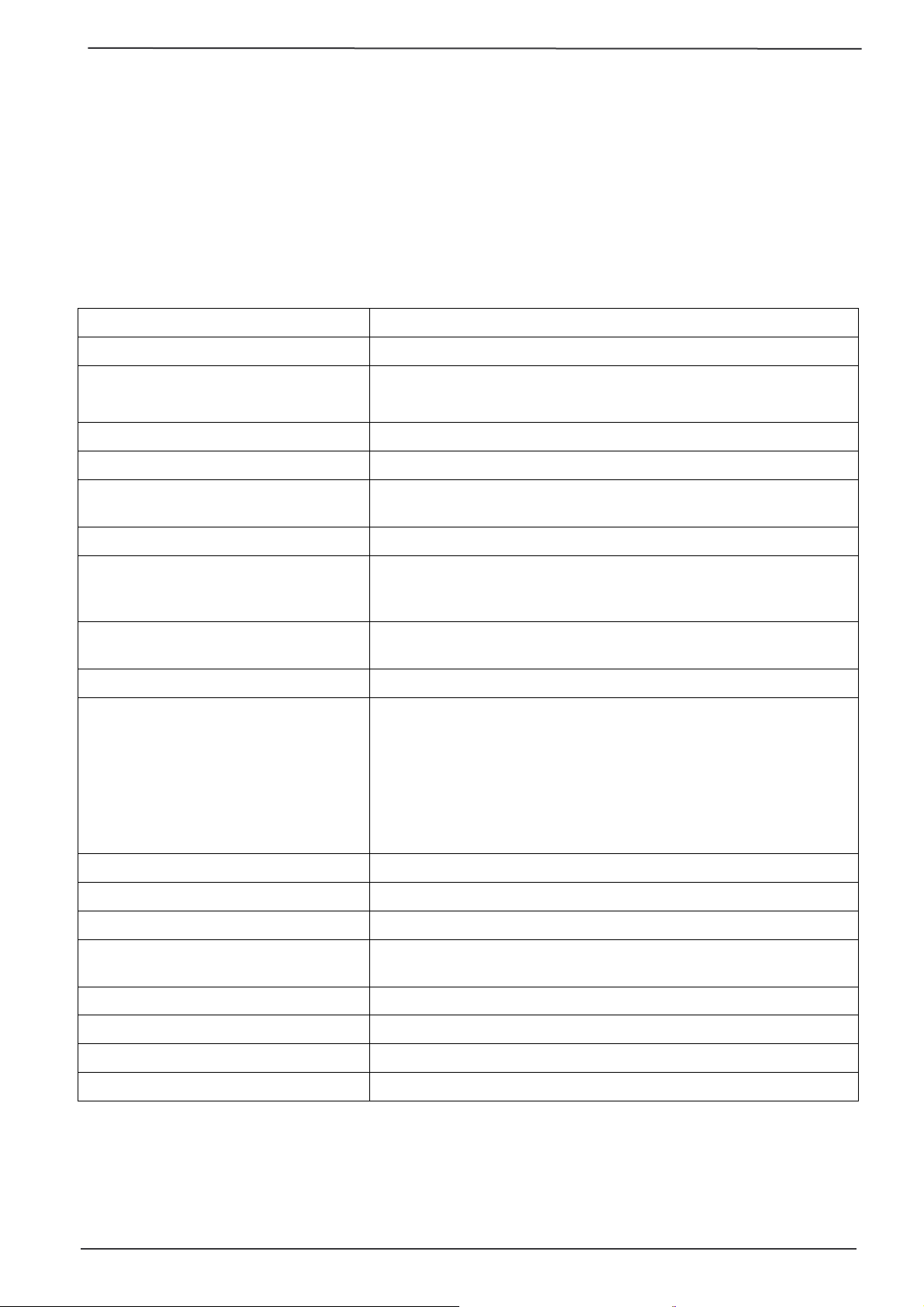

1.2. MAIN FEATURES ...............................................................................................................................3

1.3. TECHNICAL FEATURES ....................................................................................................................4

2. FUNCTIONAL DESCRIPTION....................................................................................................................5

2.1. FUNCTIONING AND USE...................................................................................................................5

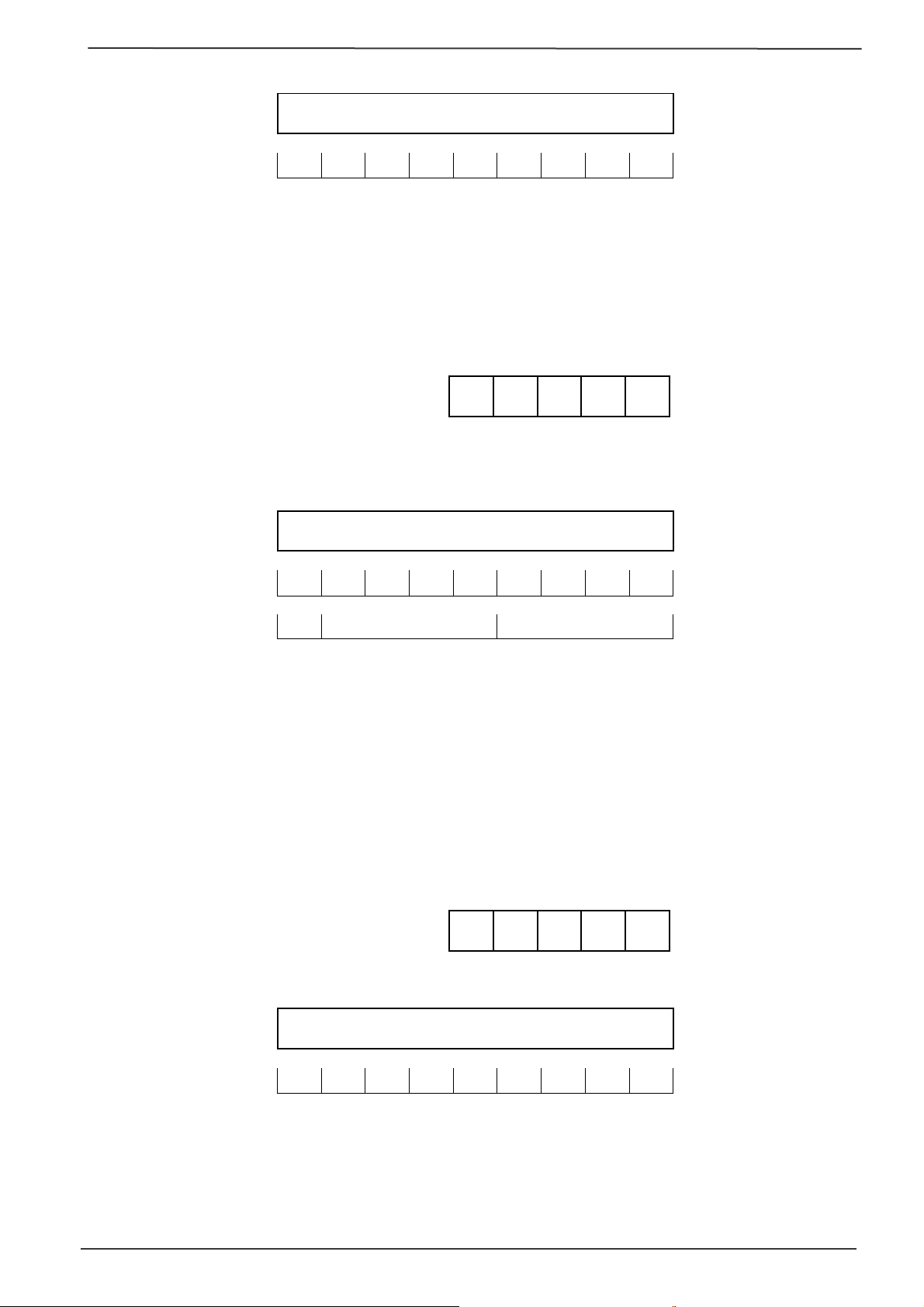

2.2. CHART OF COMMANDS ....................................................................................................................6

2.3. MESSAGE RECALL ON DISPLAY......................................................................................................6

2.3.1. Command TYPE 0: Binary message recall + Synchronism ...........................................................6

2.3.2. Command TYPE 1: BCD message recall + Synchronism..............................................................7

2.3.3. Command TYPE 6: Message recall through independent inputs ...................................................7

2.3.4. Command TYPE 8: Continuous message recall in BINARY code..................................................8

2.3.5. Command TYPE 11: Sub-message display in BINARY code ........................................................8

2.3.6. Command TYPE 13: Sub-message display in BCD code..............................................................9

2.4. ENTERING VARIABLES IN THE TEXT DISPLAYED ..........................................................................9

2.4.1. Command TYPE 3: Address in BCD code...................................................................................10

2.4.2. Command TYPE 4: Address in BINARY code.............................................................................10

2.4.3. Command TYPE 2: Variable in BCD code ..................................................................................10

2.4.4. Command TYPE 5: Variable in ASCII code ................................................................................11

2.5. SERVICE COMMANDS.....................................................................................................................11

2.5.1. Command TYPE 7: " Manual " operation and associated commands..........................................11

2.5.2. Command TYPE 10: Message Print............................................................................................12

2.5.3. Command TYPE 12: Display flashing mode................................................................................12

2.5.4. Command TYPE 14: System language selection / Message bank selection................................12

3. TECHNICAL DESCRIPTION ....................................................................................................................14

3.1. INPUTS.............................................................................................................................................14

3.1.1. Using inputs in POSITIVE logic...................................................................................................14

3.1.2. Using inputs in NEGATIVE logic.................................................................................................15

3.1.3. Input command timing ................................................................................................................15

3.2. SERIAL LINE.....................................................................................................................................16

3.2.1. Serial line commands .................................................................................................................16

4. PROGRAMMING THE DEVICES .............................................................................................................17

4.1. PROGRAMMING USING A PERSONAL COMPUTER ......................................................................17

4.2. programmed memory archives ..........................................................................................................17

4.3. PC – TO – DISPLAY UNIT CONNECTION........................................................................................17

5. ACCESSORIES........................................................................................................................................18

5.1. PRINTER ST40 .................................................................................................................................18

5.1.1. Technical features ......................................................................................................................18

5.1.2. Installation ..................................................................................................................................19

5.1.3. Printer – to – display unit connection...........................................................................................19

5.2. USING THE "WINTEXT" SOFTWARE PROGRAMME FOR MESSAGE DISPLAYS .........................19

6. TERMINAL AND MECHANICAL DIMENSIONS........................................................................................20

6.1. TERMINAL CONNECTION DIAGRAMS............................................................................................20

6.1.1. Connections and terminals for FMC202 - AMF401 - AMF402......................................................20

6.1.2. Collections and terminals for EMC202 - EMC402 - EMF202 - EMF402 - BMF202.......................20

6.2. OVERALL DIMENSIONS...................................................................................................................21

6.2.1. Overall dimensions for FMC202..................................................................................................21

6.2.2. Overall dimensions for EMC202 - EMC402 - EMF202 -EMF402.................................................21

6.2.3. Overall dimensions for AMF401 - AMF402 .................................................................................22

6.2.4. Overall dimensions for BMF202..................................................................................................22

6.2.5. Overall dimensions for printer ST40...........................................................................................23