Cetetherm Midi Compact TA

Installation, service and operating instruction

1

Contents

1General ..................................................................................................................................3

1.1 Comfort......................................................................................................................................................3

1.2 Installation .................................................................................................................................................3

1.3 Long-term security.....................................................................................................................................3

1.4 CE-marking................................................................................................................................................3

1.5 Information about the document................................................................................................................3

1.6 General warnings ......................................................................................................................................4

2Operating instructions..........................................................................................................5

2.1 Operation...................................................................................................................................................5

2.2 Safety equipment/inspection .....................................................................................................................5

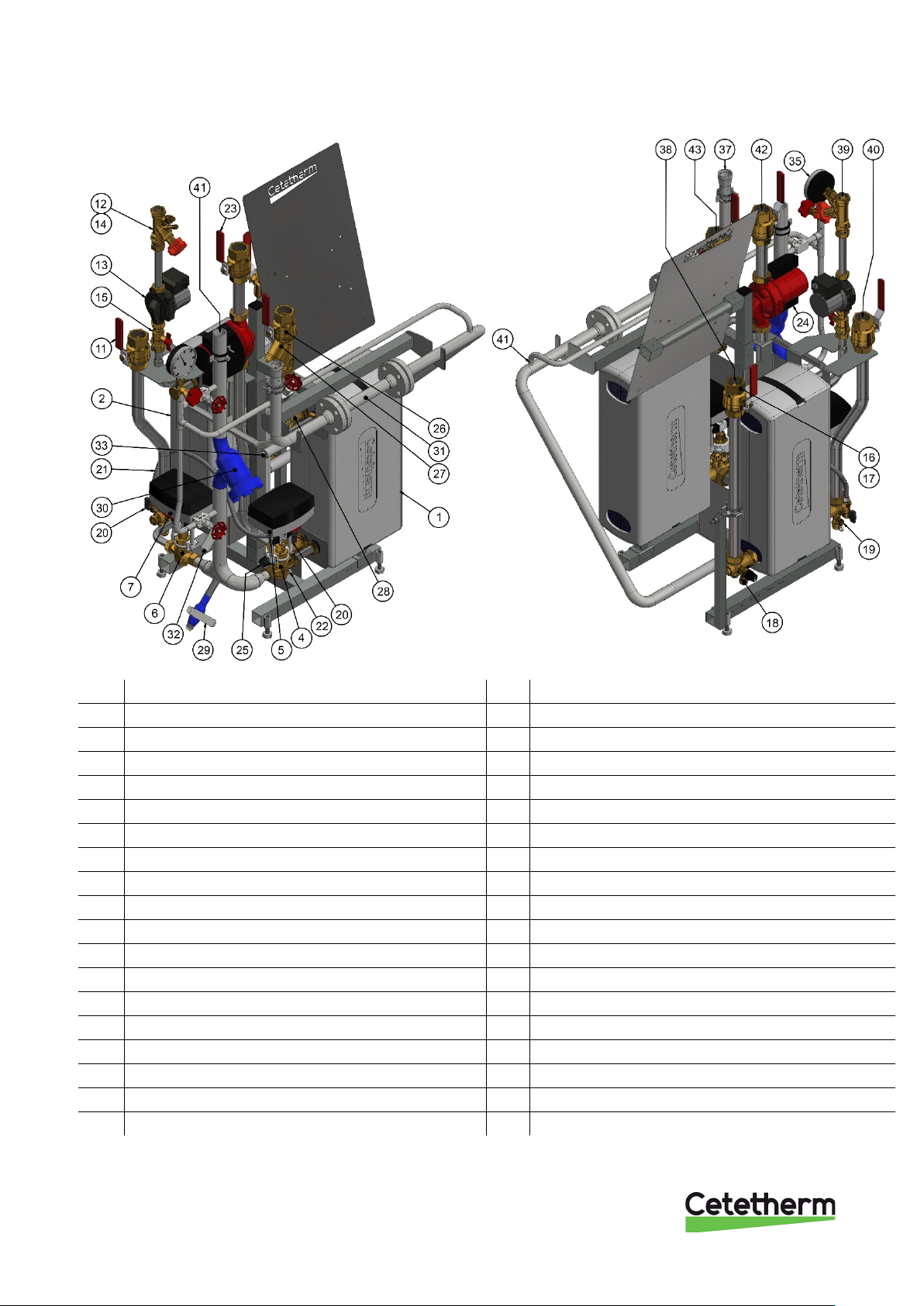

3Product overview ..................................................................................................................6

3.1 Midi Compact TA .......................................................................................................................................6

3.2 Product overview Midi Compact TA with vertical metering .......................................................................7

3.3 Product overview Midi Compact TA with horizontal metering ...................................................................8

4Installation.............................................................................................................................9

4.1 Unpacking..................................................................................................................................................9

4.2 Preparation ................................................................................................................................................9

4.3 Mounting....................................................................................................................................................9

4.4 Adjustments and settings for start up ..................................................................................................... 10

4.5 Dismantlement........................................................................................................................................ 10

4.6 Measure sketch Midi Compact ............................................................................................................... 11

4.7 Measure sketch Midi Compact with vertical metering ............................................................................ 12

4.8 Measure sketch Midi Compact with horizontal metering........................................................................ 13

5Schematic diagram, main components.............................................................................14

5.1 Midi Compact.......................................................................................................................................... 14

5.2 Midi Compact with vertical metering....................................................................................................... 15

5.3 Midi Compact with horizontal metering .................................................................................................. 16

6Pump settings and pump capacity ....................................................................................17

6.1 General................................................................................................................................................... 17

6.2 DHWC pump Grundfos UPSO 15-55, capacity...................................................................................... 17

6.3 Heating circuit pump Grundfos Magna3 25–100, settings and capacity................................................ 18

6.3.1 Heating circuit pump Grundfos Magna3 25-100, capacity ................................................................ 18

6.3.2 Grundfos Eye operating indications .................................................................................................. 18

7Service instructions............................................................................................................19

7.1 Service instructions, tap water ............................................................................................................... 19

7.1.1 Tap water temperature too low ......................................................................................................... 19

7.1.2 Tap water temperature too high ........................................................................................................ 19

7.1.3 Hot water temperature unstable........................................................................................................ 19

7.1.4 Noise in the DHWC system............................................................................................................... 20

7.2 Service instructions, heating system ...................................................................................................... 20

7.2.1 Heating system temperature too high or too low .............................................................................. 20

7.2.2 No heating ......................................................................................................................................... 20

7.2.3 Noise in the radiator system.............................................................................................................. 20

7.2.4 Heating temperature unstable........................................................................................................... 21

7.2.5 Heating system often needs topping up............................................................................................ 21

8Service actions for the installer .........................................................................................22

8.1 Check the function of the hot water valve and actuator ......................................................................... 22

8.2 Check the function of the heating actuator and valve ............................................................................ 23

8.3 Check DHWC pump ............................................................................................................................... 24

8.4 Check the volume take-up and pressure equalizing of the expansion vessel ....................................... 24

9Maintenance and repairs ....................................................................................................25

9.1 Cleaning the district heating strainer ...................................................................................................... 25

9.2 Clean the heating circuit strainer............................................................................................................ 26

9.3 Change the complete DHWC pump or pump components.................................................................... 26

9.4 Change the complete heating pump or pump components ................................................................... 27