Edition 1 – December 2019 SAFETY FIRST i

MSA G1 Classic Breathing Apparatus

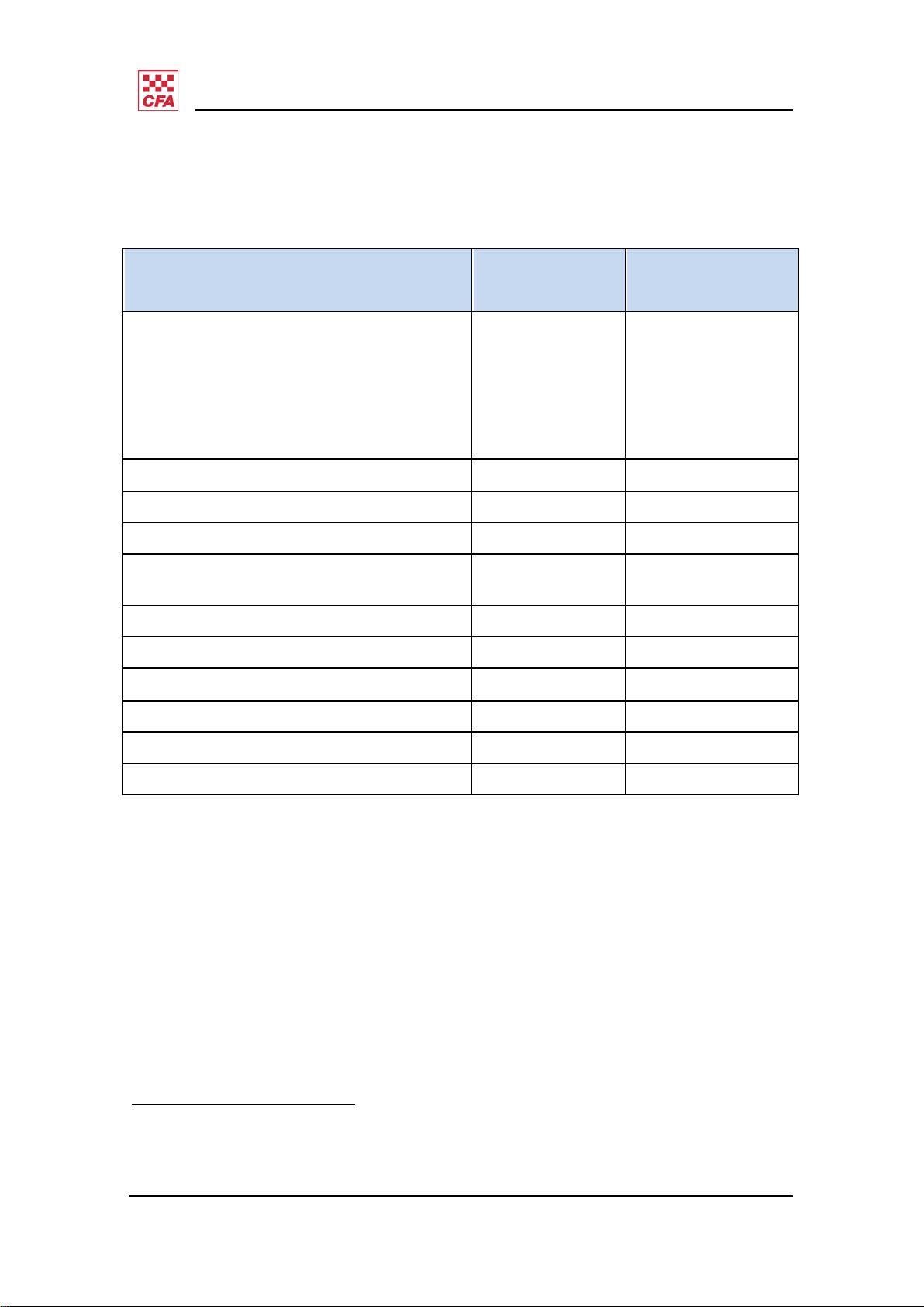

Contents

Foreword........................................................................................................................1

Introduction................................................................................................................... 2

Awareness of MSA G1 Electronic BA................................................................................2

Related Resources ..........................................................................................................5

Icons in this Manual .........................................................................................................5

Chapter 1 Specifications and General Precautionary Safety Measures.......7

Terminology ....................................................................................................................7

General Description and Specifications of the G1 C ...........................................................8

Precautionary Safety Measures ......................................................................................10

Chapter 2 Cylinder and Components...................................................................13

Cylinder ........................................................................................................................13

MSA G1 Classic BA.......................................................................................................19

Components..................................................................................................................20

Chapter 3 Operation..................................................................................................39

Functional Pre-Operational Check ..................................................................................39

Visual Inspection ...........................................................................................................39

Changing the Cylinder....................................................................................................43

Functional Test..............................................................................................................48

Chapter 4 Donning and Doffing.............................................................................53

Flash Hood....................................................................................................................53

Don the BA Set..............................................................................................................58

Distress Signal Unit........................................................................................................68

Post Incident Wash-Down ..............................................................................................70

Doff the BA set..............................................................................................................71

Doff the Flash Hood.......................................................................................................77

Emergency Shared Air Procedure (Buddy Breathing).......................................................79

Chapter 5 After-use Care and Maintenance........................................................85

Authorised Service.........................................................................................................85

Cleaning the BA After Use..............................................................................................85

After Doffing..................................................................................................................88