Dräger PAS AirPack 1 Trolley Module

Airline Compressed Breathing Air Supply System Instructions for Use

3352691 : 'D' Edition : October 2003 : Subject to Modification

1

1642

Approvals

The Drä er PAS AirPack 1 Trolley Module conforms to the requirements of EN139 and meets the

requirements of EC Council Directive PPE (89/686/EEC) and PED (97/23/EC).

PPE EC Type examiner; SGS United Kin dom Limited, Unit 202b, Worle Parkway, Weston-super-

Mare, BS22 0WA, UK. Notified Body No. 0120. CE Mark approved and issued with EC Type Examination

Certificate.

PED EC Type examiner; Lloyds Re ister, Hiramford, Middlemarch, Office Villa e, Siskin Drive, Coventry,

CV3 4FJ, En land. Notified Body No. 0038. The equipment is manufactured in accordance with the

requirements of Conformity Assessment Trolley Modules B + D of the Pressure Equipment Re ulations.

A copy of the Declaration of Conformity is available from Drä er on request.

For Your Safety

The Drä er PAS AirPack 1 Trolley Module incorporates a hi h performance pressure reducer. The reducer

is factory set and must not be tampered with, or removed from the manifold, as this invalidates the

conditions of the Drä er warranty. Correct operational condition is valid only if Drä er service and re-

seals the pressure reducer.

uUse of this equipment requires wearer trainin and observance of these Instructions for Use and the

Instructions for Use supplied with the selected associated breathin equipment.

uUse the equipment for the purpose specified in this instruction, or as confirmed in writin by Drä er.

uUse and maintenance of this equipment requires knowled e and compliance with National Re ulations,

Laws and Standards overnin the use of respiratory equipment in the country of use.

uOnly trained competent personnel should inspect and service the equipment at re ular intervals and

a record kept of such inspections and service.

uOnly trained and competent personnel should carry out the char in of the compressed air cylinders.

uDrä er recommends that a Service Contract be obtained from your Drä er Branch or A ent.

uContact Drä er for details of Service Contracts and Service Trainin Courses.

uUse only ori inal Drä er Spare Parts for service and maintenance.

uUse only ori inal Drä er Test Equipment for service and maintenance.

uNotify Drä er if there is a component fault or failure.

Liability Statement

Terms and Conditions of warranty for the Drä er PAS AirPack 1 Trolley Module can be obtained from Drä er

on request. Responsibility for reliable function of the equipment transfers to the owner or operator when

serviced or repaired by untrained personnel, (not employed or authorised by Drä er), or when used in a manner

not conformin to its intended use.

Description and Intended Use

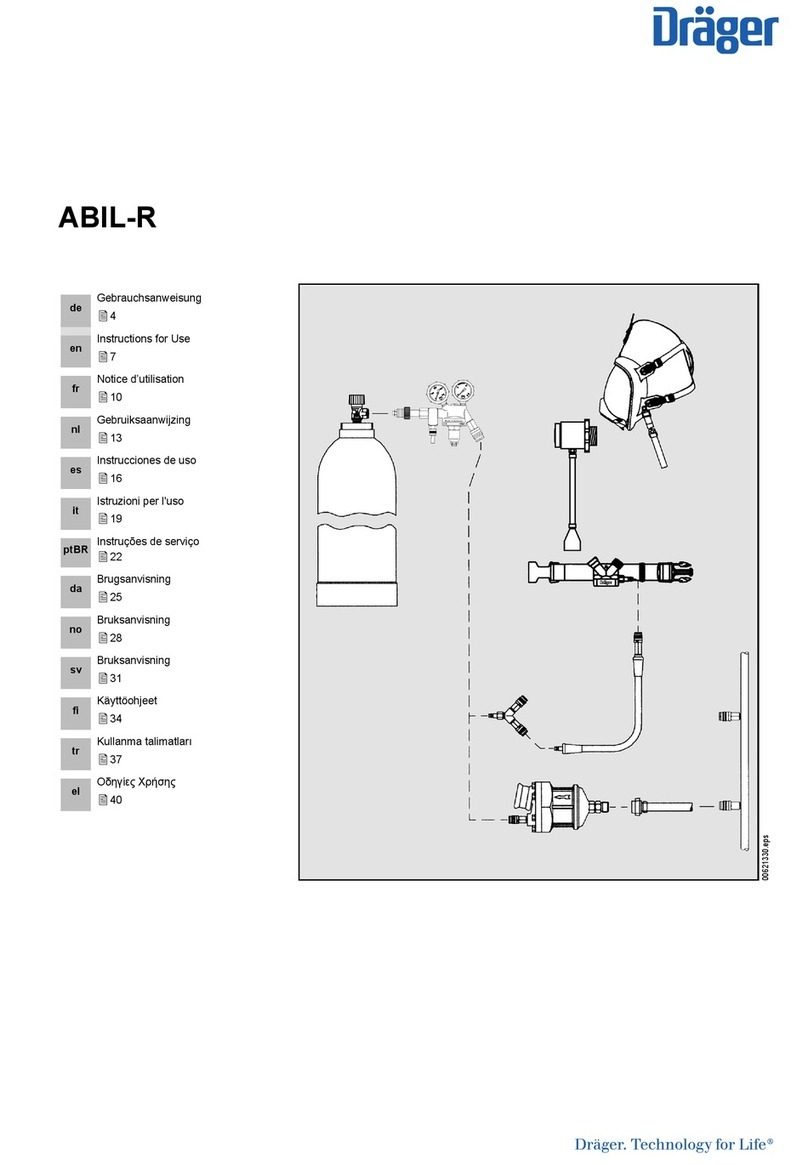

The Drä er PAS AirPack 1 Trolley Module is a

compact mobile two-wheel trolley unit with

flexible rubber airline hose and hose windin drum,

plus stora e capacity for two valved hi h-pressure

cylinder assemblies. The module provides a low-

pressure independent breathin air supply to the

wearer of approved Drä er breathin apparatus

fitted with airline manifold connections.

The equipment is compatible with a ran e of

associated breathin apparatus and

accessories and must be used only with air that

complies with the air quality requirements of

respirable breathable air at the pressure and

quantities (volumes) required. When the airline

fittin of the breathin apparatus is connected

to the module, the approved confi uration

provides the wearer with respiratory protection

when workin in a contaminated or oxy en

deficient aseous atmosphere.

The manifold assembly of the module allows for

the repeated removal and fittin of cylinders,

transferrin of air supply from one cylinder to

another. This feature provides a means of

providin an uninterrupted air supply to the

wearer.

Automatic activation of a preset mechanical hi h

pressure whistle warnin unit (HPWWU) alerts

the Controller of low cylinder pressure. Activation

of a low pressure whistle warnin unit (LPWWU)

alerts the Controller of a drop in pressure of the

low-pressure air supply.

If required, the cylinders may be bypassed by

connectin the inlet couplin of the trolley

module to an independent low-pressure air

supply, e. . from a works airline or LP

compressor (refer to Main Airline Pressures and

Flow and Air Quality requirement . A drop in

low air supply pressure is hi hli hted to the

Controller by the activation of an audible low

pressure whistle warnin unit (LPWWU).

The possible available extended workin duration,

depends on the confi uration selected (attached to

works airline or LP compressor - with filter unit to

maintain air quality), the capacity (volume) of

cylinder(s) selected, the number of fully char ed

cylinders available and the breathin rate of the

wearer(s).

Important Note: No more than two users of

approved airline breathin equipment

should be connected to the AirPack 1

Trolley Module at any time, and in any

confi uration. Refer to the Equipment

Confi uration details chart.

Details of equipment variants, associated

breathin equipment and accessories are

available from Drä er on request.

Technical Data

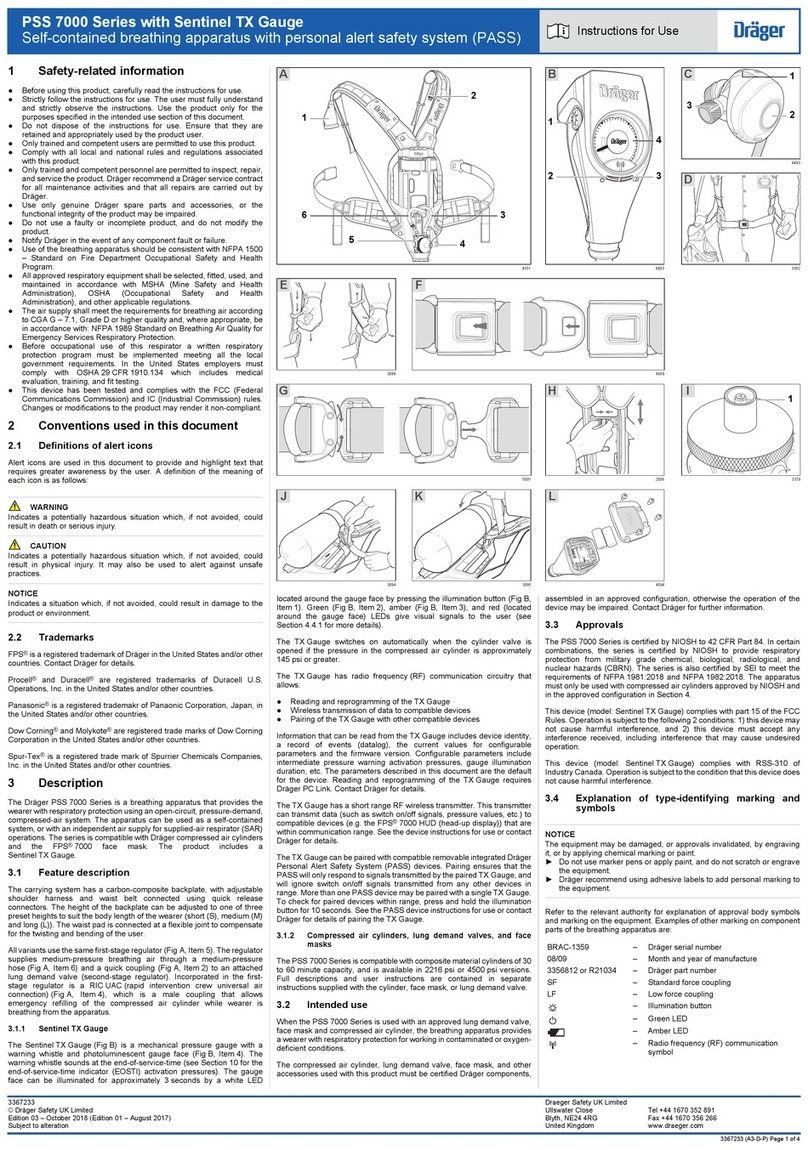

High Pressure Connections

Standard G5/8 as per EN 144-2.

200bar or 300bar.

Other hi h-pressure (HP) connections are

available to National Standards.

Operating Pressure

Low Pressure - 8bar Nominal. (6bar to 10bar)

Whistle Warning Units (WWU)

HPWWU - Preset between 60bar to 50bar

LPWWU - Preset between 3bar to 5bar

Compressed Air Cylinders

Contact Drä er for details of approved valved

compressed air cylinder assemblies available for

use with this equipment.

Important Note: Only matched pairs of cylinders

should be fitted to the Drä er AirPack 1 Trolley

Module, e. . 2 x 9 litres 200bar. Do Not mix

200bar and 300bar cylinders.

Main Airline Pressures and Flow

Safety Note: In order for the Trolley Module to

function efficiently, it is the responsibility of

the user to ensure that the followin air

pressure and flows are available from the

factory mains airline air source. Air quality

for compressed air breathin systems must

conform to the requirements of EN12021.

The selected LP independent air supply must meet

the followin parameters.

uOne User 7bar to 10bar - airflow rate of at

least 550 Litres/minute.

uTwo Users 7bar to 10bar - airflow rate of

at least 550 Litres/minute.

LP Leak Test - Indicated pressure should not

decrease more than 1bar in one minute.

Preparation for Use

Only trained and competent personnel must

perform the followin checks and preparation

procedures before release of the equipment for

operational use to a 'Controller' and potential

breathin apparatus 'Wearer'.

Visual nspection

Check the cleanliness and inte rity of,

uTrolley frame and wheels.

uCylinder support straps (2).

uWindin Drum and low pressure hose.

uPneumatics, Gau es, WWUs, Quick Release

Couplin (s) (QRC) etc.

uHP hoses and cylinder connector handwheel

assemblies (2).

Fitting the Cylinders

uPlace the AirPack 1 Trolley Module in the upri ht

position as shown in Fi . 1.

uCheck that the valve outlet port of each fully

char ed valved cylinder is clean and

undama ed. Place each cylinder throu h the

loop of each of the cylinder straps locatin the

rounded end of the cylinders into the cylinder

cradle supports at the base of the trolley frame.

uCheck that both connector handwheels are not

dama ed and that the connector O rin s are

in position and not dama ed.

uRotate the cylinders to ali n the outlet port of

each valve with the associated connector

handwheel assembly. Ensure a smooth curve

of the hi h-pressure hose. Screw each

handwheel into the appropriate cylinder valve

hand ti ht.

uTake up slack of each of the cylinder support

straps then activate the Camlock mechanism

by pullin the free end of the support strap

around the cylinder - securin each cylinder

to the frame. Fi . 1.

Leak Test and Test of WWUs

u'Close' both the hi h-pressure (HP) bleed

valves (6) of the cylinder connector

handwheel assemblies - handti ht.

u'Open' slowly, but fully, ONE of the cylinder

valves to pressurise the system. Check the

indicated pressure readin s on the HP au e

(2) and the LP au e (3).

Hi h Pressure - Indicated pressure should be

at least 80% of maximum workin pressure

indicated on the selected cylinders.

Low Pressure - Indicated pressure should be

between 6bar to 10bar.

u'Open' the HP bleed valve (6) of the connector

handwheel assembly of the opposite cylinder

(i.e. the Closed valve) there should be no

audible leak. If satisfactory 'Close' the HP

bleed valve.

u'Close' the cylinder valve. Wait for 10 to 15

seconds to allow the system to stabilise then

check the pressure readin on the HP au e

(2) and the LP au e (3).

HP Leak Test - Indicated pressure should not

decrease more than 20bar in one minute.

uFollowin satisfactory leak test, check the

activation of the HPWWU (1) and the LPWWU

(4) as follows:

Slowly vent pressure from the HP side of the

system by rippin and carefully pullin the

handle of the relief valve (7). As the pressure

decreases observe the HP au e (2) .

HPWWU - the whistle should be in to sound

between 60bar to 50bar. As soon as the whistle

sounds, release rip on the handle of the relief

valve (7) and allow the whistle to vent. When

the HPWWU stops soundin proceed

immediately to test the LPWWU.

uFollowin satisfactory HPWWU test, check the

activation of the LPWWU as follows:

A ain rip and carefully pull the handle of the

relief valve (7). As the pressure decreases

observe the LP au e (3) .

LPWWU - the whistle should be in to sound

between 5bar to 3bar.

uCheck the HP bleed valves (6) at each cylinder

valve are 'Closed' then slowly, but fully, 'Open'

the second cylinder valve to pressurise the

system. Check the indicated pressure readin s

on the HP au e (2) and the LP au e (3).

Hi h Pressure - Indicated pressure should be

at least 80% of maximum workin pressure

indicated on the selected cylinders.

Low Pressure - Indicated pressure should be

between 6bar to 10bar.

uOpen the hi h-pressure bleed valve (6) of the

connector handwheel assembly of the opposite

(first) cylinder (i.e. the closed valve.) there

should be no audible leak. If satisfactory 'Close'

the bleed valve.

u'Close' the cylinder valve and then check the

pressure readin on the HP au e (2).

Hi h Pressure Leak Test - Indicated pressure

should not decrease more than 20bar in one

minute.

uFollowin satisfactory completed tests, rip and

pull the handle of the relief valve (7) to vent

pressure from system.

uHavin passed the tests, the equipment is now

available for use.

Pre-Use Procedures

Caution: Before connectin the selected airline

breathin equipment to the tested and released

Drä er PAS AirPack 1 Trolley Module, check

that the breathin equipment has been tested

by a trained and competent person before

bein released for use. When in use the

AirPack 1 Trolley Module must be positioned

in a safe and uncontaminated area. Drä er

recommend that a Controller must be present

at all times to monitor and maintain the air

supply to the wearer of the selected breathin

equipment. Time required for the wearer of

the airline breathin equipment to safely

evacuate from the hazardous area to a safe area

must be within the air capacity of the remainin

cylinder(s) of the PAS AirPack 1 Trolley Module.

Drä er recommend that the user(s) of this final

confi uration operate and maintain a Permit

for Use procedure and also have an

established company evacuation procedure(s).

The Drä er PAS AirPack 1 Trolley Module may be

used either as a self-contained unit, i.e. usin the

attached compressed air cylinders, or by connectin

the module to an independent low-pressure air supply,

e. . from a works airline or LP compressor the

cylinders can be bypassed.

Self-contained Unit

The Controller

uWith the trolley module suitably positioned in a

safe and uncontaminated area, pull and unwind

a required len th of hose from the windin drum.

Attach any required accessories, e. . extension

hoses, 'Y' pieces, etc.

uCheck that both HP bleed valves (6) at each of

the connector handwheel assemblies are

'Closed' (clockwise).

When used as Self-contained Unit

u'Open' slowly, but fully, ONE of the cylinder

valves to pressurise the system. Check the

indicated pressure readin s on the HP au e

(2) and the LP au e (3).

Hi h Pressure - Indicated pressure should be

at least 80% of maximum workin pressure

indicated on the selected cylinders.

Low Pressure - Indicated pressure should be

between 6bar to 10bar.

When used from a works airline or

LP compressor

Safety Note: Refer to Airline Pressure and

Flow. Air quality must conform to the

requirements of EN12021. If required use the

Drä er Filter Unit.

uConnect an approved extension hose from the

selected LP independent air supply to the male

connector (5) of the trolley manifold. 'Open'

the valve of the independent air supply to

pressurise the system. Check indicated

pressure readin on the LP au e (3).

Low Pressure - Indicated pressure should be

between 6bar to 10bar.

The Controller

Important Note: Should the 'Controller' be

required to wear respiratory protection

equipment then all the followin 'Wearer'

instructions should be observed. Connect the

male couplin of the selected breathin

equipment to the female QRC (8) of the pressure

manifold. This will reduce the duration available

from the selected system. It must be observed

however that no more than two users of

approved airline breathin equipment should

be connected to the PAS AirPack 1 Trolley

Module at any time, and in any confi uration.

The Wearer

uRefer to the Instruction for Use for the selected

breathin equipment, put on the equipment and

prepare the equipment for attachment and use

with the PAS AirPack 1 Trolley Module.

uConnect the male couplin of the breathin

equipment to the female QRC of the supply

hose from the trolley module, i.e. the windin

drum.

Safety Warnin : Facial hair, beard stubble,

side-whiskers, and the wearin of spectacles

will adversely affect and interfere with

facepiece seal. Correct fit of facepiece only

ensured if facepiece seal makes close contact

with skin.

uPut on the facepiece as defined in the Instruction

for Use for the selected breathin equipment,

breathe normally and perform Function Check.

Function Check

The Controller

u'Close' the cylinder valve or the valve of the

associated air supply.

The Wearer

uBreathe normally to vent air from the system.

Durin ventin the whistle(s) will alarm at the

preset pressure. When fully vented, hold

breath. The facepiece should hold onto the face

indicatin a positive seal.

uImmediately indicate to the Controller of a

positive face seal and request to immediately

Open the valve of the associated air supply.

The Controller

uWhen Wearer indicates to the Controller of a

positive face seal the Controller should

immediately Open the associated valve to

pressurise the system.

The Wearer n Use

uInhale and hold breath. The unit must balance,

i.e. no audible leak. Continue to breathe normally.

Expired air should flow easily out of the exhalation

valve of the facepiece. Press the centre of the

rubber cover of the LDV to check for

supplementary supply airflow then release.

uContinue to breathe normally and as instructed

by the controller proceed to the workin area

takin care to support and route the airline hose

as necessary.

In Use - hen used as a Self-

contained Unit

The Controller

uRe ularly take a HP au e readin . At between

60bar to 50bar the HPWWU unit sounds

indicatin that the cylinder in use is almost

empty. To therefore maintain the air supply to

the wearer of the breathin equipment

immediately proceed as follows:

1. Slowly, but fully, 'Open' the valve of the

second fully char ed cylinder. The HP au e

(3) will indicate an increase in system pressure.

The wearer is now connected to the fully

char ed cylinder.

2. 'Close' the valve of the empty cylinder then

'Open' the bleed valve (6) of the associated

valve to vent the remainin pressure from the

HP supply hose.

3. Unscrew the connector handwheel from the

valve of the depleted cylinder. Release the

Camlock mechanism of the cylinder support

strap and remove the cylinder.

4. Select an available replacement fully char ed

cylinder and assemble to the trolley. See -

Preparation for Use Fittin Cylinders.

5. 'Close' the bleed valve (6) of the connector

handwheel assembly of the replacement

cylinder.

Note: To maintain a supply of respirable breathing

air to the wearer of the breathing equipment, this

procedure can be repeated with further available

replacement fully charged cylinders.

Safety Warnin : Should the LPWWU of the PAS

AirPack 1 Trolley Module sound, then the

controller must immediately implement the

a reed and established company evacuation

procedure(s).

The Wearer Self Contained Operation

uBreathe normally.

uWhen the task is completed, or when advised

by the Controller, proceed to the safe area

(Controller) by the safest route.

Important Note: - Refer to the evacuation

procedures as defined in the Instructions for

Use for the selected breathin equipment.

In Use - hen used from a

orks Airline or LP Compressor

Safety Note: Refer to Airline Pressure and Flow.

Air quality must conform to the requirements

of EN12021. If required use the Drä er Filter

Unit.

The Controller

uTake re ular LP au e (3) readin . The indicated

pressure should be between 6bar to 10bar.

Safety Warnin : Should the LPWWU sound,

indicatin a reduction in pressure from the

Works Airline or LP Compressor, the Controller

must immediately fully 'Open' ONE of the

cylinder valves of the PAS AirPack 1 Trolley

Module to pressurise the system. The extension

hose from the selected LP independent air

supply to the male connector (5) should be

disconnected.

uContinue to follow the instructions outlined in

the section i.e. In Use- When used as Self-

contained Unit.

The Wearer - Works Airline etc.

uBreathe normally.

uWhen the task is completed, or when advised

by the Controller, proceed to the safe area

(Controller) by the safest route.

Important Note: - If necessary refer to the

evacuation procedures as defined in the

Instructions for Use for the selected breathin

equipment.

After Use

The Wearer

uRefer to the After Use instructions in the

appropriate Instruction for Use for the selected

breathin equipment. Remove the equipment

and detach the male couplin of the breathin

equipment from the female QRC of the supply

hose of the carryin frame module.

Safety Warnin : Do Not attempt to remove the

breathin equipment until in safe area, clear of

the hazard.

The Controller

uFollowin the removal of the breathin

equipment by the wearer either:

1. disconnect the extension hose from the

selected LP independent air supply from the

male connector (5).

or

2. 'Close' the relevant cylinder valve of the

trolley module.

u Grip and pull the handle of the relief valve (7) to

vent pressure completely from system. 'Open'

the (HP) bleed valves (6) of the cylinder

connector handwheel assemblies

uCarefully and neatly rewind the airline hose

to the windin drum. Drä er recommend that

any dirt or contaminants on the hose should

be removed as it is bein rewound onto the

windin drum.

Routine Maintenance

To be performed after use of the equipment.

See also Maintenance and Test Intervals Chart.

Refer to the Instructions for Use supplied with the

selected breathin equipment, facepiece, lun

demand valve etc.

Visual nspection

Check the cleanliness and inte rity of,

uTrolley frame and wheels.

uCylinder support straps (2).

uWindin Drum and LP hose.

uPneumatics, Gau es, WWUs, Quick Release

Couplin (s) (QCR) etc.

uHP hoses and cylinder connector handwheel

assemblies (2).

uAssociated extension hoses.

Cleaning, Disinfecting, Drying

Drä er recommend that contaminated and dirty

components or assemblies, hoses etc. are

carefully cleaned and disinfected then thorou hly

dried after use, or as considered necessary by the

user.

To ensure correct operational condition of the

equipment use the cleanin and disinfectin

solutions recommended by Drä er. The use of

any other product will invalidate the Drä er

warranty and uarantee.

Safety Note: Refer to manufacturers usa e

instructions when usin cleanin and

disinfectin a ents. It is important that

attention be paid to concentration and reaction

times. Do Not use or anic solvents, such as

Acetone, Alcohol, White Spirit,

Trichloroethylene or similar.

Drä er recommends the followin :

1. Cleaning

uDrä er Safety Wash.

uSekusept

Do Not exceed a temperature of 30 de rees

Celsius.

Note: Before disinfecting, rinse off cleaning

solution in clean water.

2. Disinfecting

uIncidur

Do Not exceed a temperature of 30 de rees

Celsius.

Note: Before drying, rinse off disinfectin solution

in clean water.

uDrä er Wipex Cloths.

Details of cleanin and disinfectin a ents are

available from Drä er on request.

3. Rinsing and Drying

Remove cleanin and disinfectin solutions by

rinsin in clean water, followed by dryin .

Do Not exceed a temperature of 60 de rees

Celsius when dryin components.

Charging Cylinders

Refer to 'For Your Safety'

Safety Warnin : Air quality for compressed air

breathin systems must conform to the

requirements of EN12021.

Only char e compressed air cylinders which:

uConform to National Standards.

uFeature the ori inal manufacturers test date

and test mark.

uHave not exceeded the test date indicated

on the cylinder by the last testin station.

uDo Not used dama ed cylinders.

Rechar e to the rated pressure indicated on the

label or stamped on the neck or shoulder of

cylinder. Drä er recommend a char e rate of

27bar/minute. Rapid char in will induce an

increase in temperature resultin in an incomplete

char e - check pressure at ambient and if required

Top Up char e.

To prevent overchar in of the selected cylinder

Drä er recommend that a pressure-limitin device

is fitted to the char in compressor.

Storage - Ready for Use

uStore the Trolley Module in an upri ht position

as shown in Fi . 1. A protective dust cover is

available. Contact Drä er for details.

uStore the equipment Ready for Use in a cool

dry environment, free from dust and dirt.

Protect rubber parts - Do Not expose to direct

sunli ht.

7

56

3

241

8