it to have a permanent air vent. This vent must be either

direct to outside air or to an adjacent room or internal space

which must itself have a permanent air vent of at least the

samesizedirect to outside air.

The minimum effective area of the permanent air vent(s)

related to the maximum rated input of the boiler and shou

be 202 cm2(30.5 in2).

3. Installation requirements

3.1 General

The installation of the boiler must be in accordancewith the

Gas Safety installation and use Regulations, relevant

Building Regulations, the Byelaws of the Local Water

Undertacking, the Safety Document 635, the Electricity at

work Regulations BS 767I. It should also be in accordance

with thecfollowing British Standard Codes of Practice - BS

689l.BS7953.BS7074: I :2.BS5449: l.BSS440: I :2.

3.2 Location

The position chosen for the boiler must permit the provision

of a satisfactory flue termination and also provide adequate

spacefor servicing and air circulation around the boiler.

The boiler must not be installed in a room or internal space

containing a bath or a shower. Ena bedroom area, a bed-sit-

ting room, or a private garage.

Where installation will be in an unusual position, special

procedures may be necessary, and BS 6798, gives detailed

guidance on this aspect.

A cupboard or compartment used to enclose the boiler must

be designed and constructed specifically for this purpose. An

existing cupboard or compartment may be used provided

that it is modified for the purpose.

Details of essential features of cupboard/compartment

design, including airing cupboard installations are given in

BS 6798.

3.3 Gas supply

The gas installation should be in accordance with BS 689 1.

The meter to be used must be of adequate capacity to meet

the total gas load. i.e. boiler plus other gas appliances.

Ensure that the pipework from the meter to the boiler is of

adequate size. Do not use pipes of a smaller size than the

boiler gasconnection.

The complete installation must be tested for soundness as

described in the above standard.

3.4 Flueing

Detailed recommendations for flueing are given in BS 5440 :

Part 1.

The following notes are for general guidance only :-

3.4.1 The boiler should be sited such that the maximum pos-

sible length of the flue system can be contained within the

building and that the route of the flue rises continuously to

the terminal and is asdirect aspracticable.

The first 600 mm (2 ft) of flue pipe should rise vertically from

the draught diverter connection before the use of any bends

or elbows.

Horizontal or shallow angle runs, right angled bends and

mitred elbows should beavoided.

Where an existing brick chimney is to be used it should be

swept thoroughly before connection of the new boiler, and

the chimney should be lined. The boiler can be used with

fanned or fan diluted flues.

An approved British Gas terminal must be fitted and the

terminal sited at not lessthan 600 mm (2 ft) above the roof

edge,and, where possible, above the ridge line. The flue must

not be terminated at or adjacent to a wall face (except for fan

diluted flues).

3.5 Air supply

Detailed recommendations for air supply are given in BS

5440: 2.

The following notes are intended to give general guidance.

3.5.1 Room or internal spaceair supply

Where the boiler is to be installed in a room or internal space,

the boiler requires the room or internal space containing

3.5.2 Cupboard or compartment air supply

Where the boiler is to be installed in a cupboard or compart-

ment permanent air vents are required (for combustion, flue

dilution and cooling purposes) in the cupboard or compart-

ment at high and low level. These air vents must either

communicate with a room or internal space or be direct to

outside air.

The minimum effective areas of the permanent air vents

required in the cupboard or compartment are specified below

and are related to the maximum rated heat input of the

boiler.

POSITION AIR VENT AREAS

AIR OVFENTS

Air from room Air direct from

or internal space

outside

High

Level 468cm’ (72.5in’) 234cm’ (36 in’)

Low

Level 936cm? (14.5in’) 468cm’ (72.5ir

Note : Both air vents must communicate with the sameroom

or internal space or must both be on the same wall to outsi-

de air.

Where cupboard or compartment air vents communicate

with a room or internal space, the room or internal space

must itself have a permanent air vent(s) as specified above

(3.5. I).

3.5.3 Effect of an extract fan

If there is any type of extract fan fitted in the premises, there

is a possibility that if adequate air inlet area from outside is

not provided, spillage of the products from the boiler flue

could occur, when the extract fan is in operation. Where such

installations occur, a spillage test asdetailed in BS 5440 : I :

must be carried out and ventilation requirement to BS

5440 : 2.

3.6 Water circulation systems

Open or sealed type central heating systems should be in

accordance with the relevant recommendations given in BS

5376 : 2, BS 5449 : 1(for small bore or microbore systeme‘

Hot water systems should be in accordance with the relev.

recommendations given in BS 5449 and BS 5546.

3.7 Electrical supply

This appliance must be earthed. All wiring must conform to

the BS 7671. The Flexiflame 140 requires a 240 V, single

phase,50 Hz supply. The boiler should be connected to the

mains via a fused double pole switch or via a 13 amp.

socketoutlet in conjunction with a fused plug. The fuse rating

should be 3 amp.

The point of connection to the mains should be readily acces-

sible and adjacent to the boiler.

The supply chord must be 0.75 mm2 three core heat resisting

cable.

4. Installation of boiler

4.1 General

The wall on which the boiler is sited must be capable of

adequately supporting the weight of the boiler and any ancil-

lary equipment and should be non-combustible.

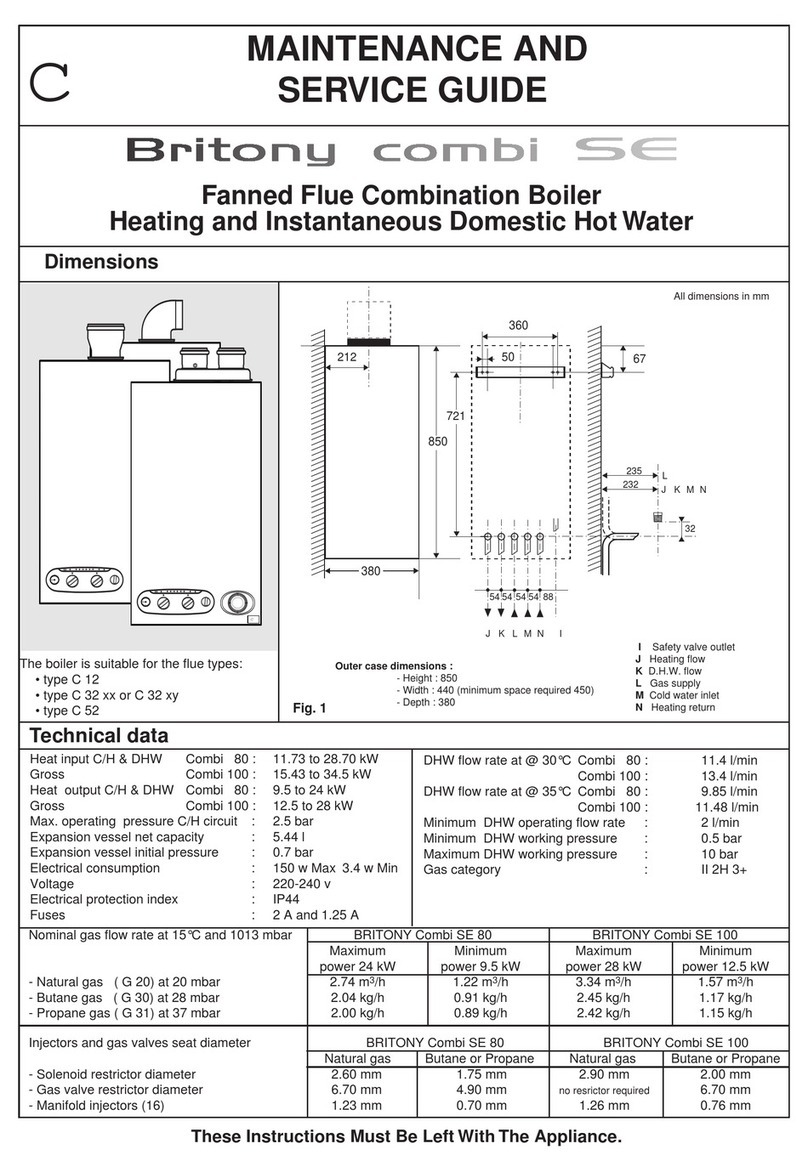

A vertical flat area is required for the boiler asfollows :

Wide 900 mm 36 ins

High 1185mm 47 ins.

Above dimensions include the necessary clearances around

the boiler for caseremoval and for air movement.

3