Champion Valves SD User manual

Popular Control Unit manuals by other brands

Solaria

Solaria PowerXT-395R-PM Safety, installation, and operation manual

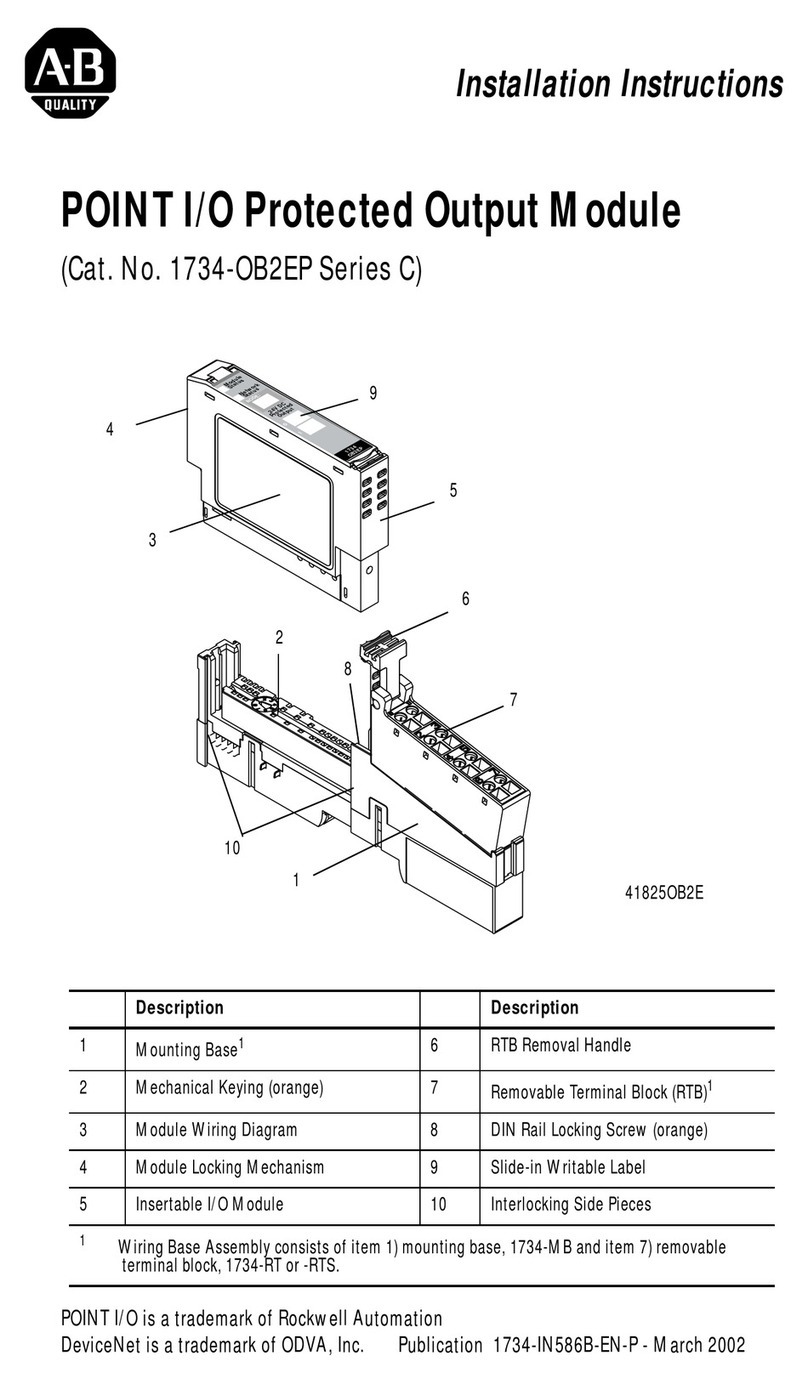

Allen-Bradley

Allen-Bradley C Series installation instructions

Pneucon

Pneucon 725 Series Installation, maintenance and operating manual

WAGO

WAGO 750-651 manual

Axiometrix Solutions

Axiometrix Solutions imc C Series Getting started

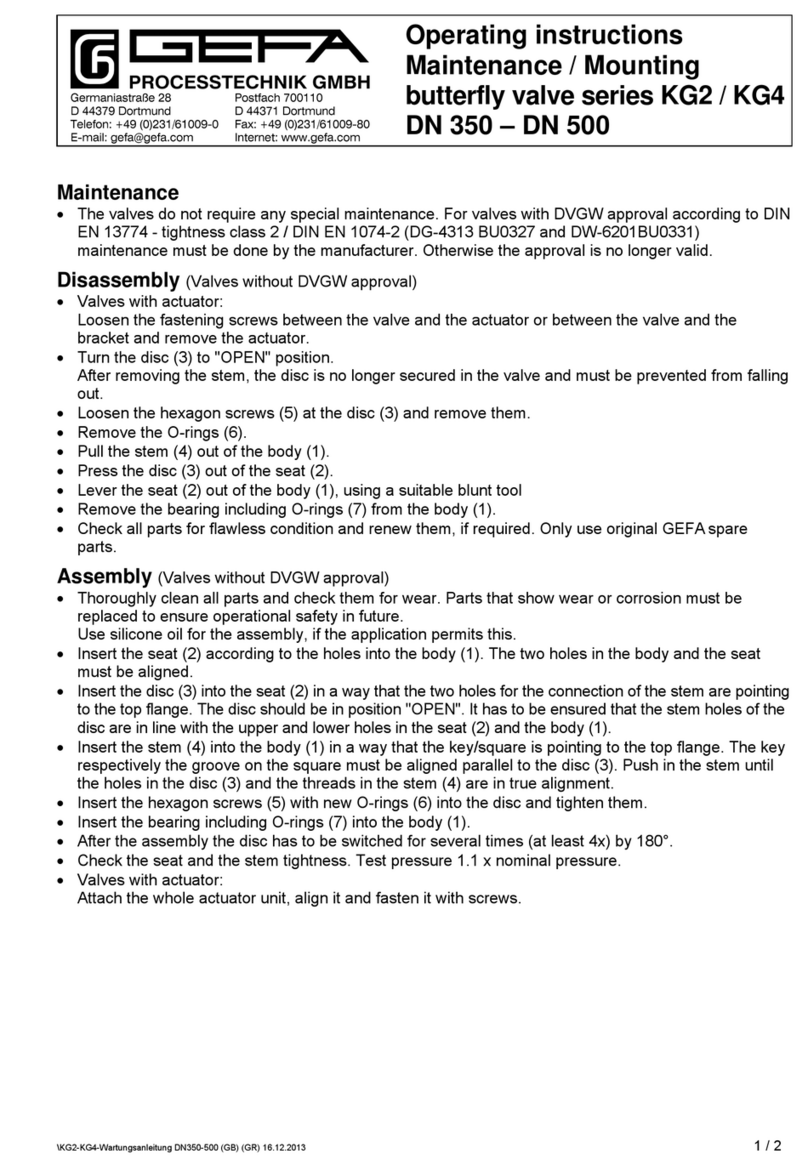

Gefa

Gefa KG2 Series operating instructions

Dedenbear

Dedenbear LIGHTNING Installation & operation manual

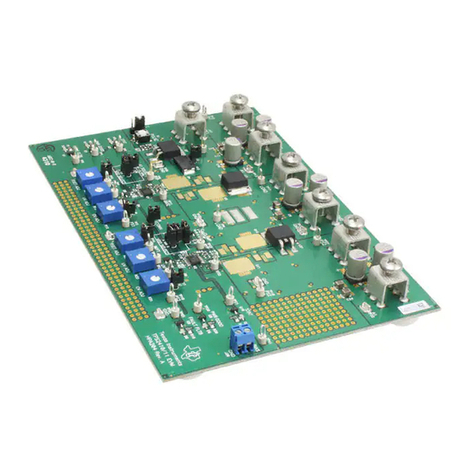

Texas Instruments

Texas Instruments TPS2410EVM user guide

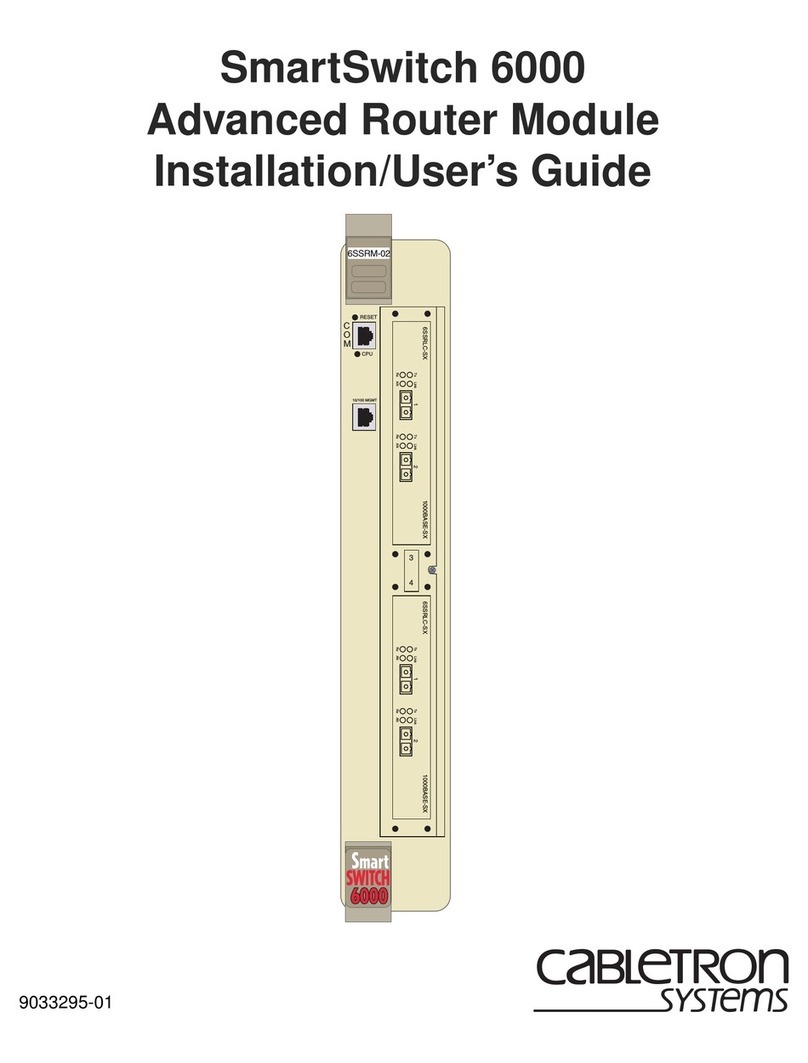

Cabletron Systems

Cabletron Systems SmartSwitch 6000 Installation & user guide

Matrix Orbital

Matrix Orbital LCD0821 user manual

Santerno

Santerno ASAC-0 instruction manual

Altechna

Altechna WATT PILOT quick start guide

Azbil

Azbil ACTIVAL VY519 J Series Specifications & instructions

Siemens

Siemens SINUMERIK 808D Commissioning manual

Siemens

Siemens CLS-1000 Instructions & maintenance

green-i

green-i GITLC user guide

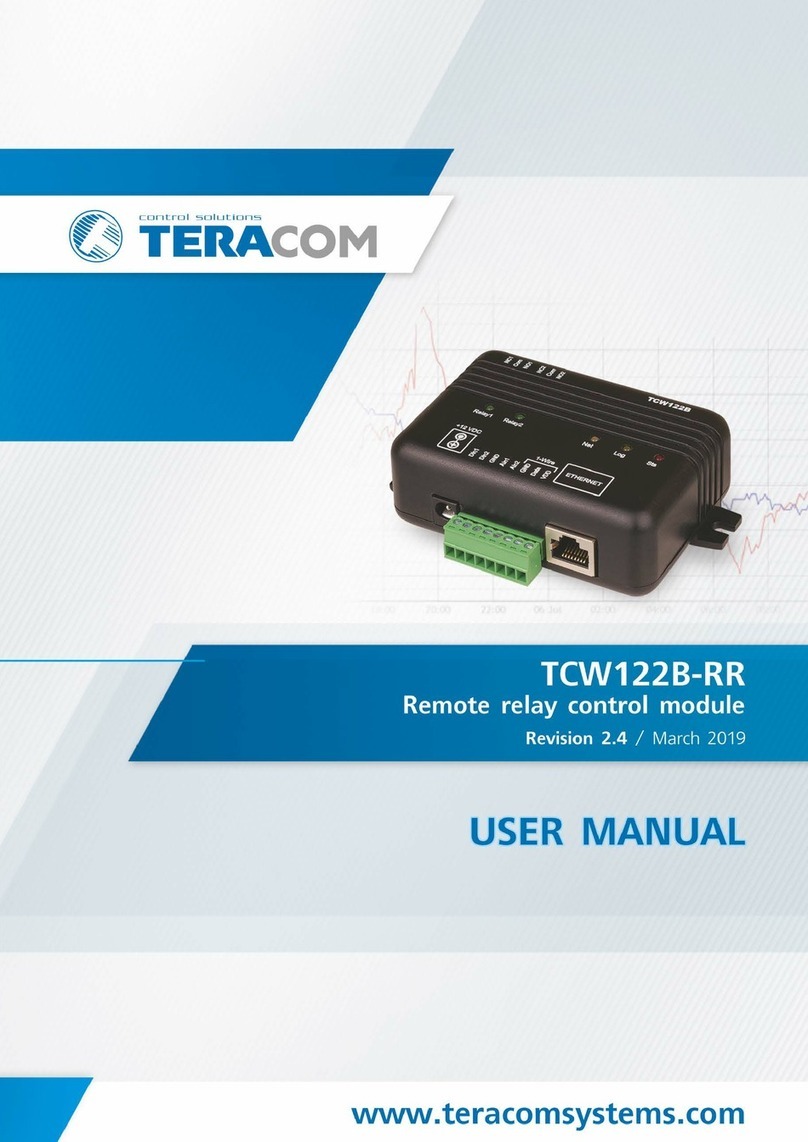

Teracom

Teracom TCW122B-RR user manual

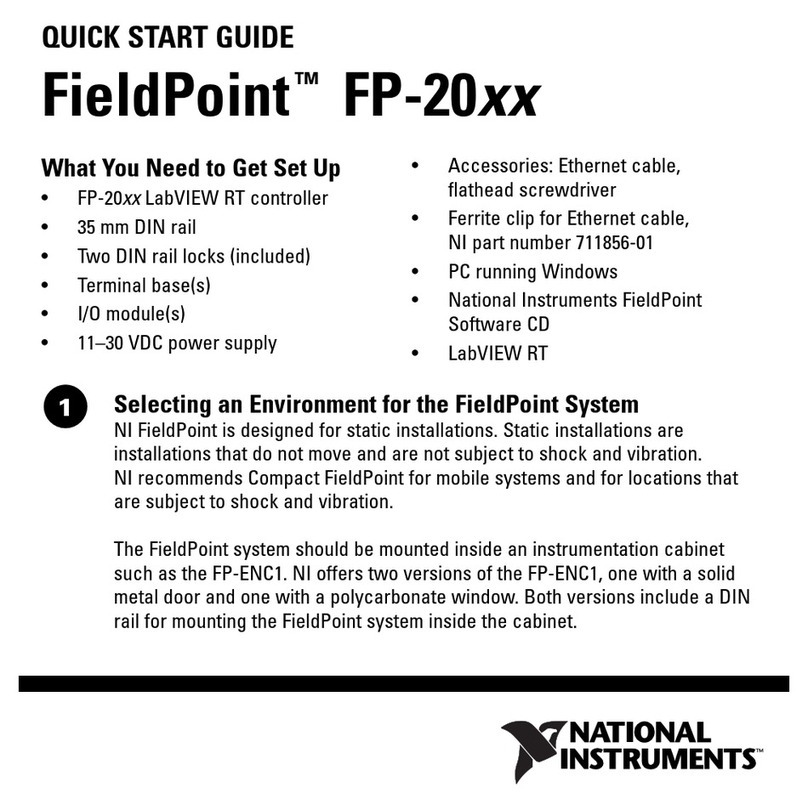

National Instruments

National Instruments FieldPoint FP-20 Series quick start guide